Detection method for inner bore and external diameter of disc type clutch disc hub

A technology for clutch discs and disc hubs, which is applied in the field of auto parts manufacturing, can solve the problems of slow detection speed, prone to missed detection, low detection efficiency, etc., and achieve the effect of improving detection speed, detection efficiency and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

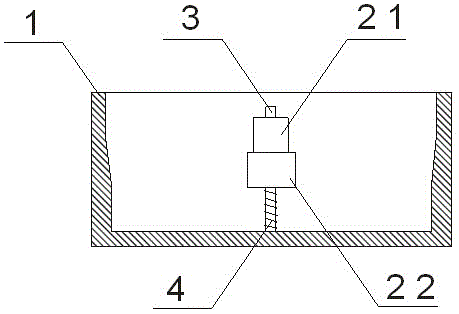

[0014] Example: see figure 1 , a method for detecting the inner hole and outer diameter of a disc clutch hub, using a disc hub detection tool for detection, the disc hub detection tool includes a detection cylinder 1, the detection cylinder 1 is an open upper end and a lower end respectively Cylindrical structure. A detection pin is vertically provided in the detection cylinder 1 , and the detection pin includes aperture detection through gauges 21 and aperture detection stop gauges 22 distributed up and down, the axis of which coincides with the axis of the detection cylinder 1 . The inner diameter of the upper part of the inner wall of the detection cylinder 1 is larger than that of the lower part, and the inner diameter gradually decreases from the upper part to the lower part of the inner wall, so that the upper part of the side wall of the detection cylinder 1 forms a through gauge for outer diameter detection, and the lower part forms a stop gauge for outer diameter dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com