Vertical chemical fiber adhesive mixing stirrer

A mixer and chemical fiber technology, applied in the direction of mixers, mixers with rotating agitation devices, chemical instruments and methods, etc., can solve the problems that affect the stability of product quality, the glue is easy to appear in viscose, and there are blind spots in viscose mixing. , to achieve stable and reliable product quality and stable and reliable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

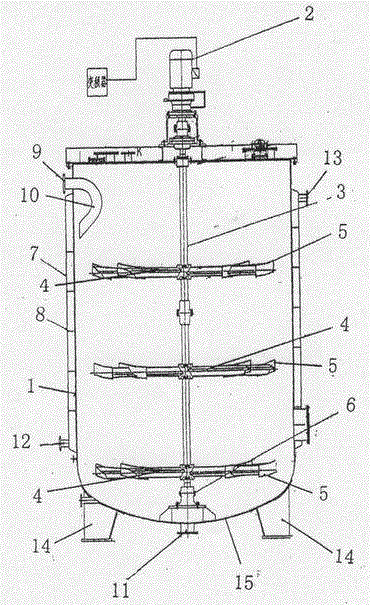

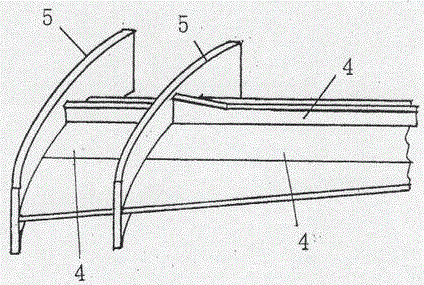

[0013] figure 1 , 2 Shown: The mixer used for chemical fiber viscose mixing is installed above a vertical cylindrical tank 1 with a motor 2 with variable frequency speed regulation. The drive shaft of the motor 2 is the same as the stirring shaft 3 in the tank 1. Shaft connection, upper, middle and lower three agitators 4 are distributed on the agitation shaft 3, and the two ends of the three agitators 4 have two curved arc structure agitating blades 5 arranged at intervals, and the oblique blades of the middle agitator 4 The inclination direction of the plate is opposite to that of the inclined blades of the upper and lower agitators 4, and the bottom end of the agitating shaft 3 is provided with an adjustable spherical bearing seat 6 which is fixed on the oval bottom cover 15 of the tank body 1, and the outer periphery of the tank body 1 is wrapped with a jacket 7, which A spiral spacer belt 8 is arranged in the gap between 7 and the tank body 1. There is a feed port 9 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com