Metal pickling corrosion inhibiting solution and preparation method and use thereof

A metal acid and corrosion inhibitor technology, applied in the field of metal pickling corrosion and protection, to achieve the effect of high corrosion inhibition rate, low production cost and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

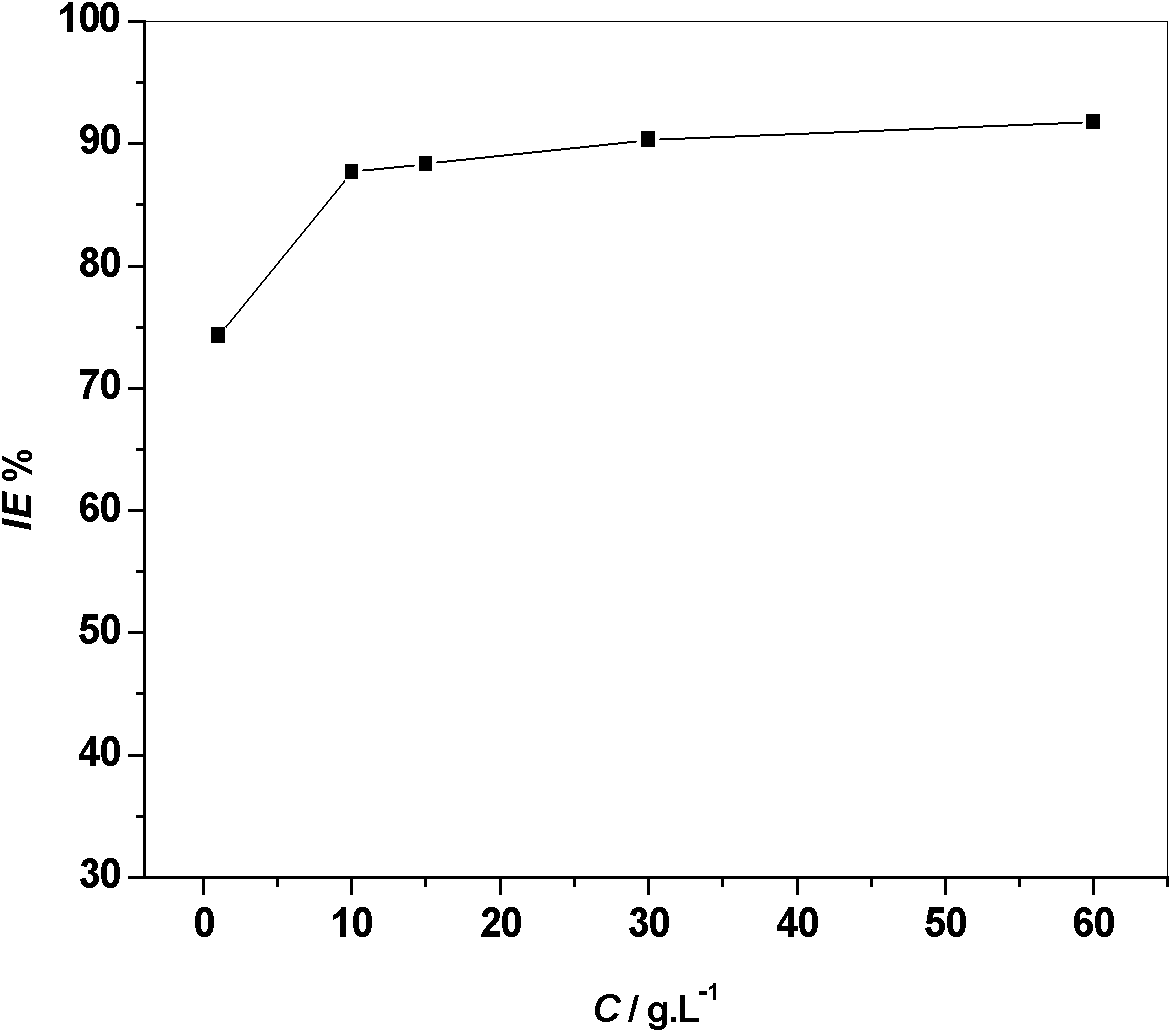

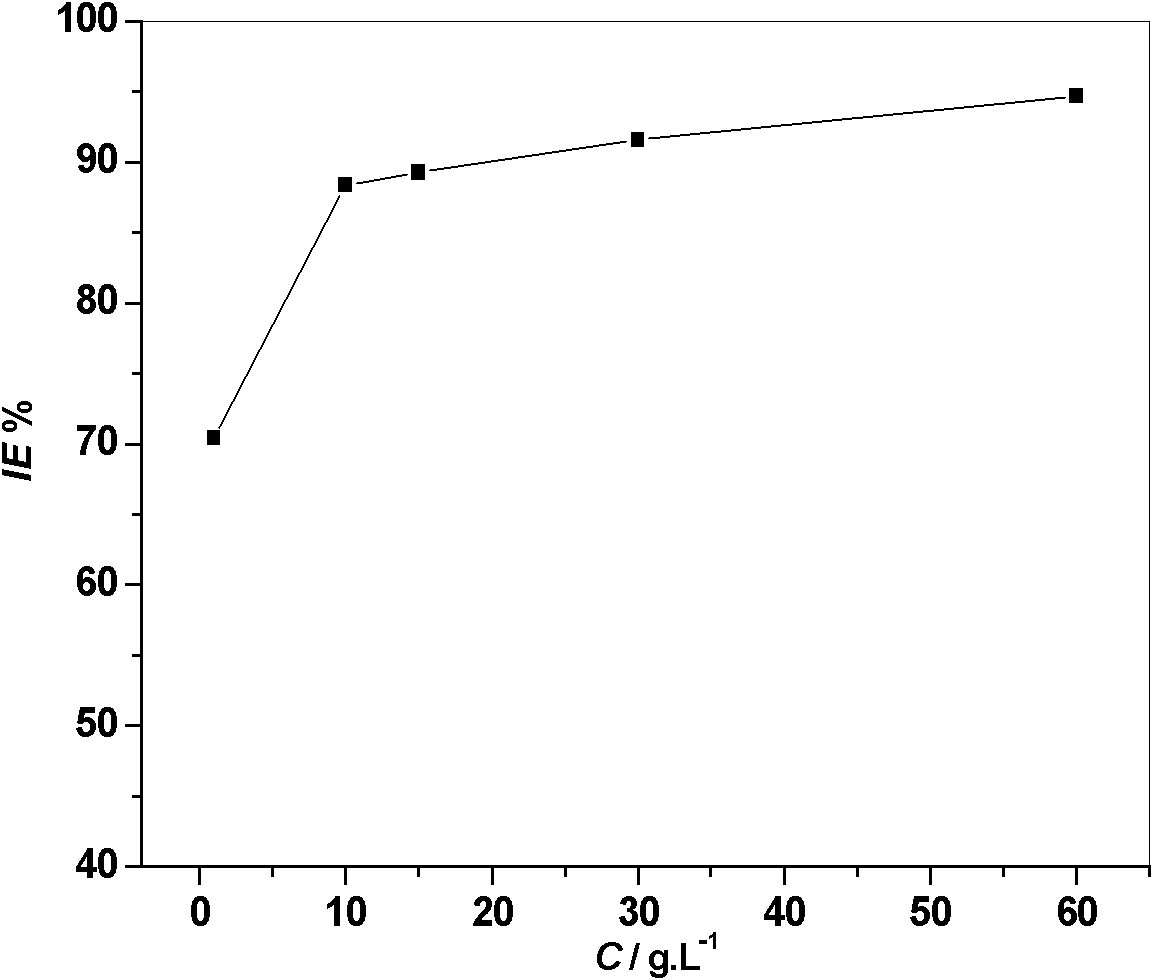

[0031] Example 1 Preparation of metal pickling corrosion inhibitor of the present invention

[0032] Weigh 30g of wet distiller’s grains, put it into a 1.5L large beaker, accurately measure 1L of 5% (mass concentration, the same below) of H 2 SO 4 Pour the solution into a beaker with wet vinasse, seal the beaker with plastic wrap after stirring, let stand at room temperature for 72 hours, stir again, and then filter to filter out insoluble impurities. The resulting solution is the metal pickling corrosion inhibitor .

Embodiment 2

[0033] Example 2 Preparation of metal pickling corrosion inhibitor of the present invention

[0034] Weigh 20g of wet distiller’s lees, put it into a 1.5L large beaker, accurately measure 1L of 5% HCl solution and pour it into the beaker with wet distiller’s lees, seal the beaker with plastic wrap after stirring, and place it at a constant temperature at room temperature Stir in a magnetic stirrer for 36 hours, then stand for 30 minutes, and finally filter to filter out insoluble impurities. The resulting solution is the metal pickling corrosion inhibitor.

Embodiment 3

[0035] Example 3 Preparation of metal pickling corrosion inhibitor of the present invention

[0036] Weigh 10g of dried distiller’s grains, put it into a large 1.5L beaker, and accurately measure 1L of 5% H 2 SO 4 Pour the solution into a beaker with dried vinasse, seal the beaker with plastic wrap, place it in an ultrasonic cleaner at room temperature, and extract the maximum ultrasonic power for 72 hours (ultrasonic power: instrument model: ASS5150B, power: 180W, ultrasonic frequency : 40 KHz), then stand for 20 minutes, and finally filter to filter out insoluble impurities. The resulting solution is the metal pickling corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com