Patents

Literature

35results about How to "Stable and reliable quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

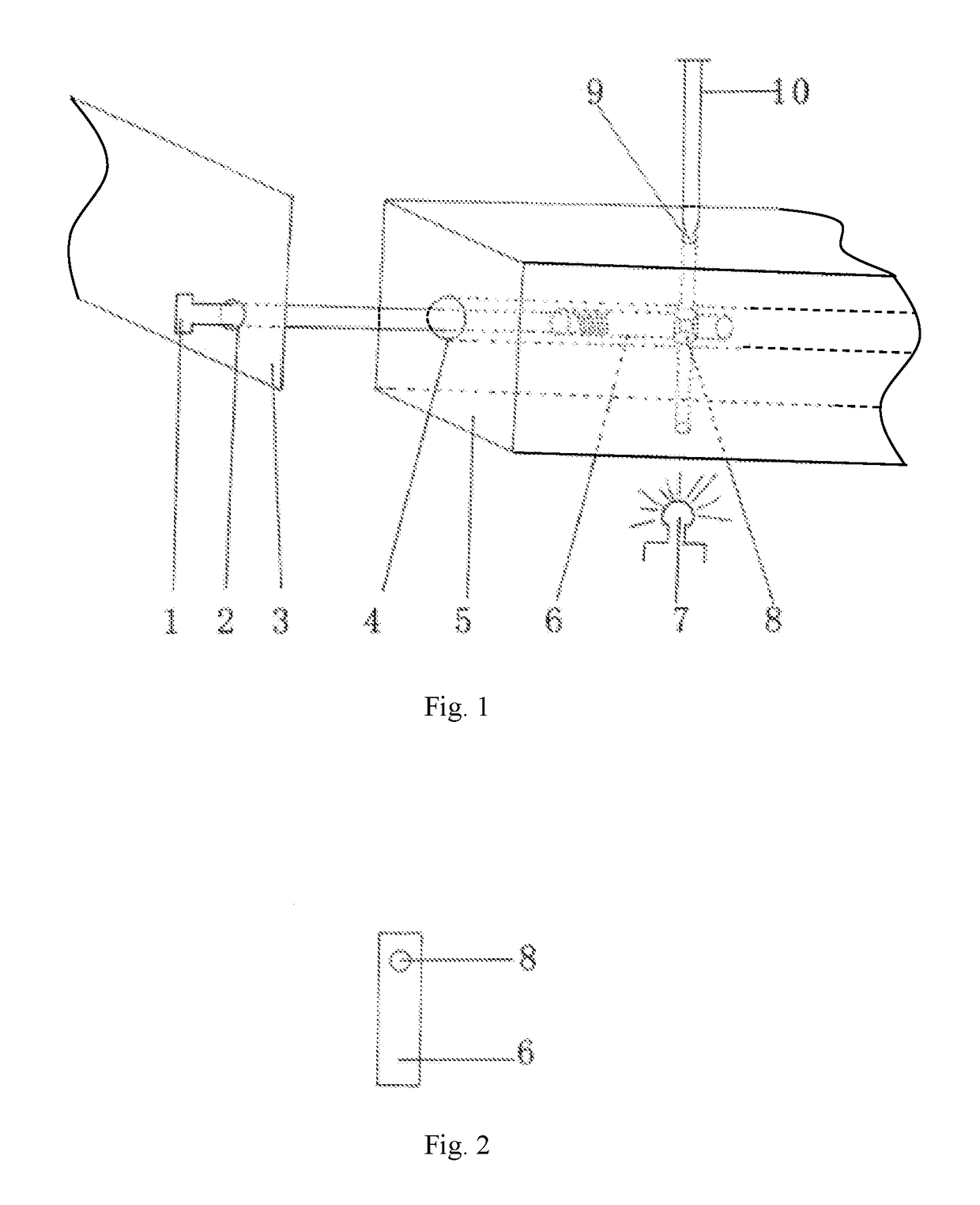

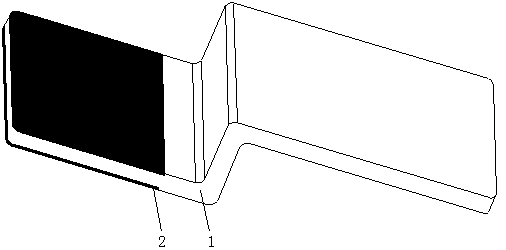

Electronic cigarette

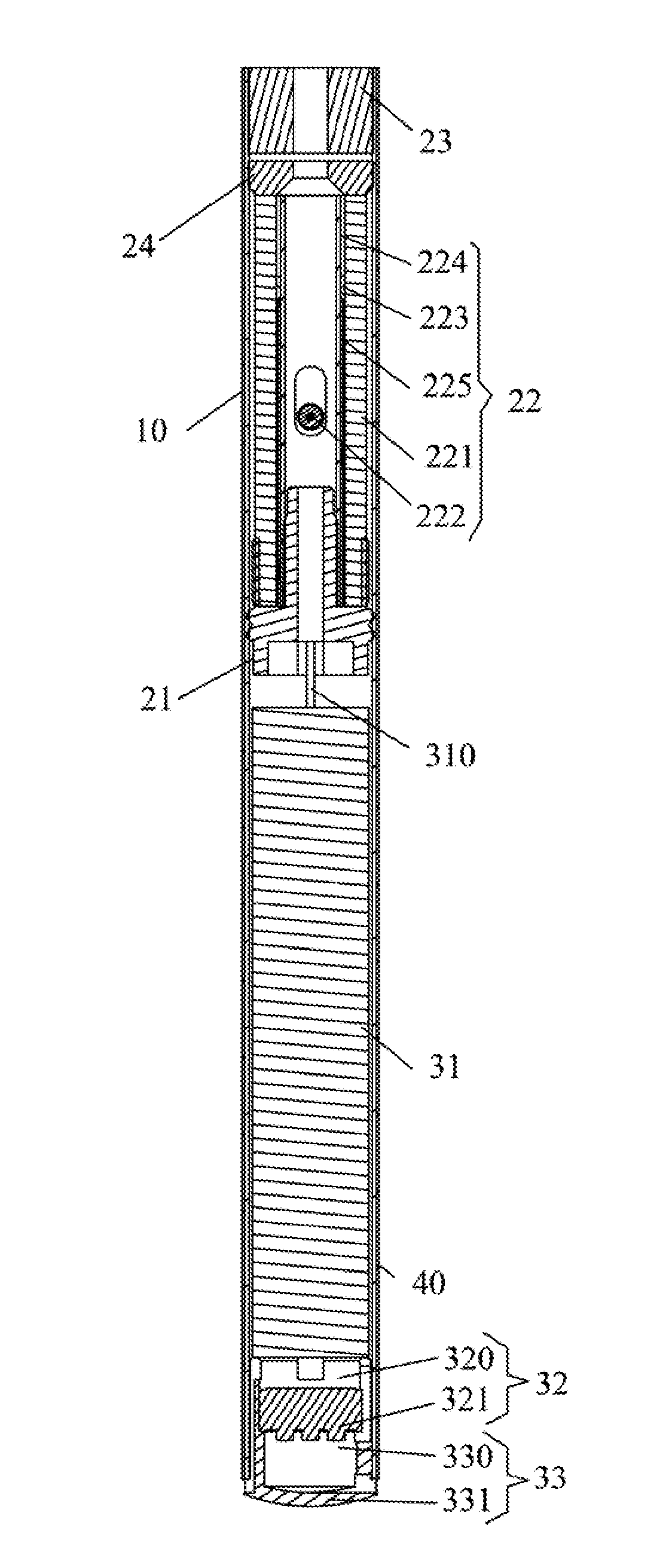

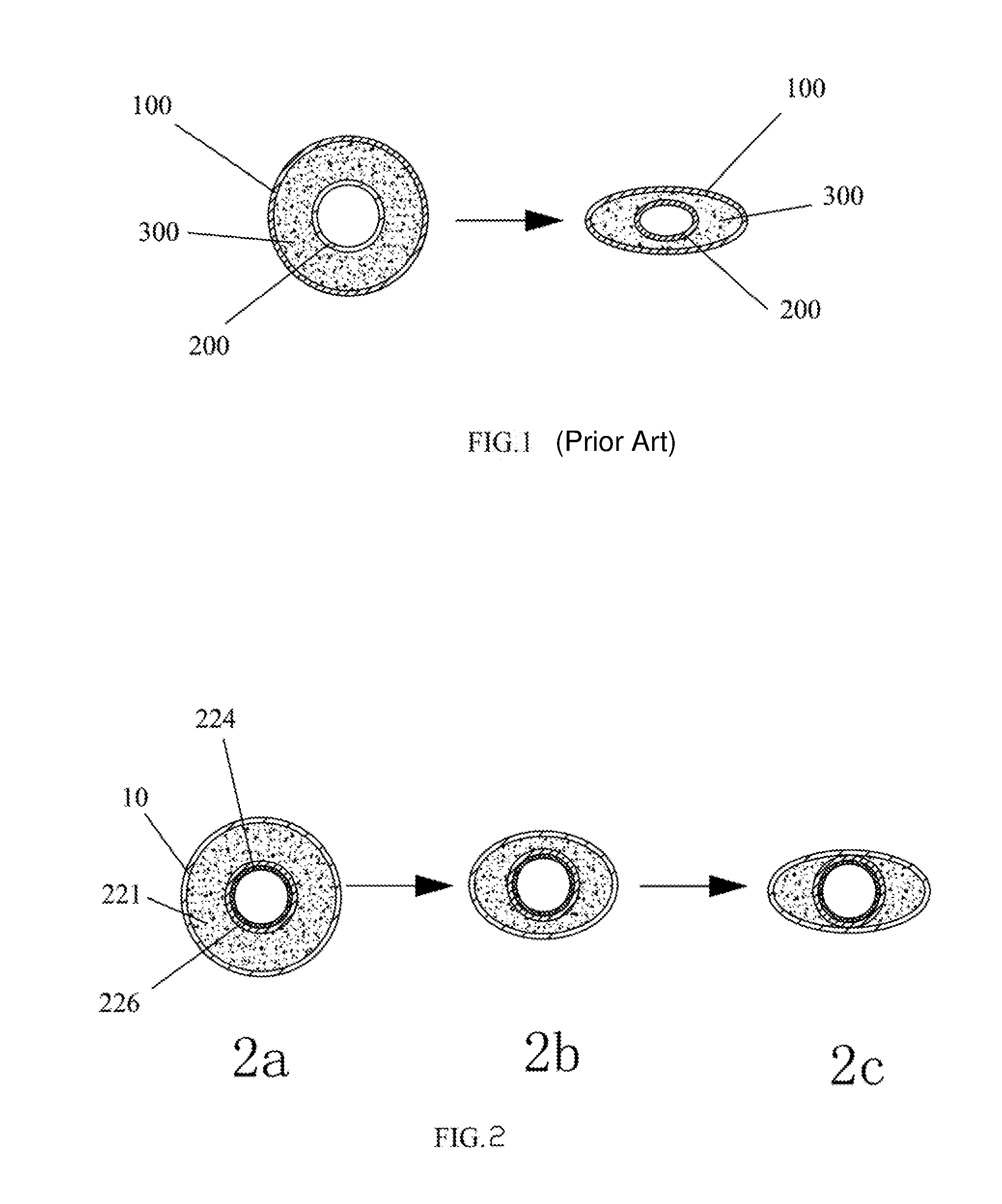

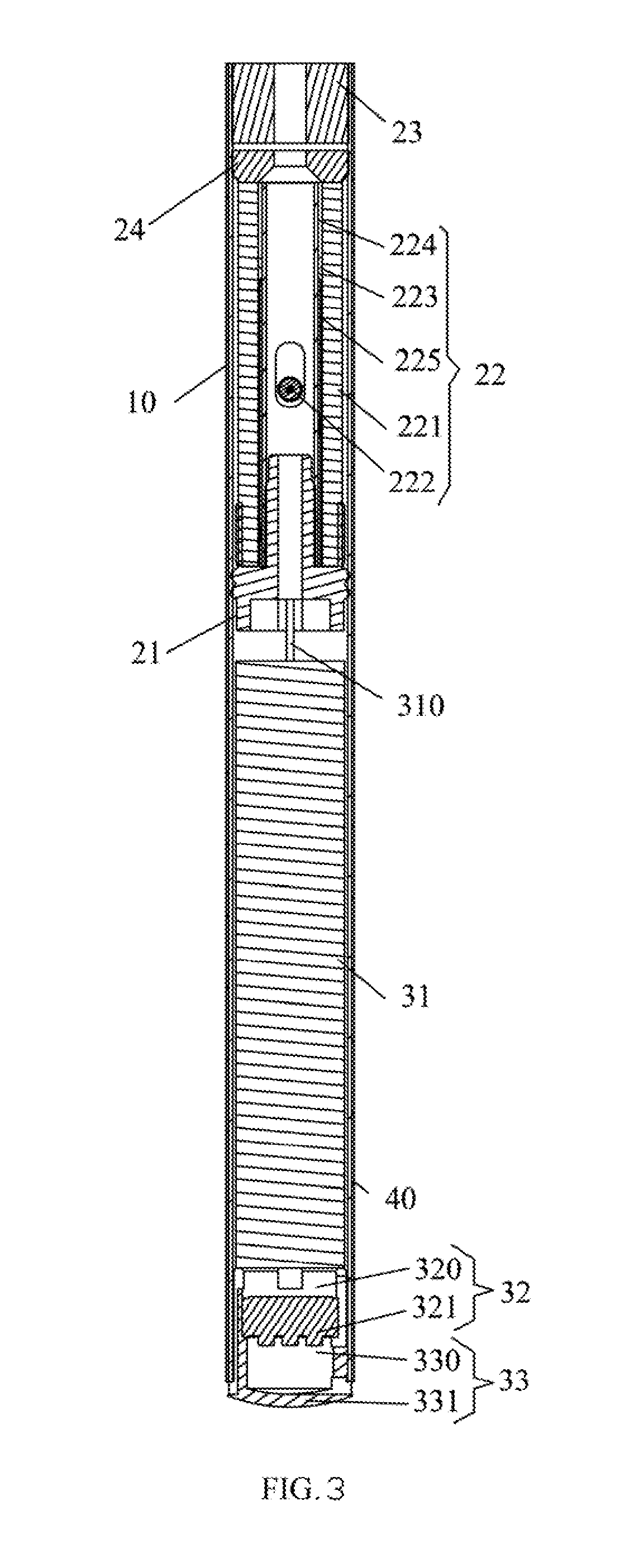

InactiveUS20160128388A1Add support functionSolve the lack of spaceTobacco devicesHand ironElectronic cigaretteSmoke

Disclosed is an electronic cigarette, comprising a tube sleeve and an atomizer assembly which is provided in the tube sleeve and is used for producing smoke, wherein the atomizer assembly comprises an oil storage space which is mainly composed of a liquid storage part; the atomizer assembly is provided with a support mechanism which prevents the oil storage space from deforming excessively when the oil storage space is pressed. By means of the support mechanism, the electronic cigarette can achieve the technical effects of no overflow of cigarette oil after the electronic cigarette is pressed, a robust structure and stable and reliable quality.

Owner:KIMREE HI TECH

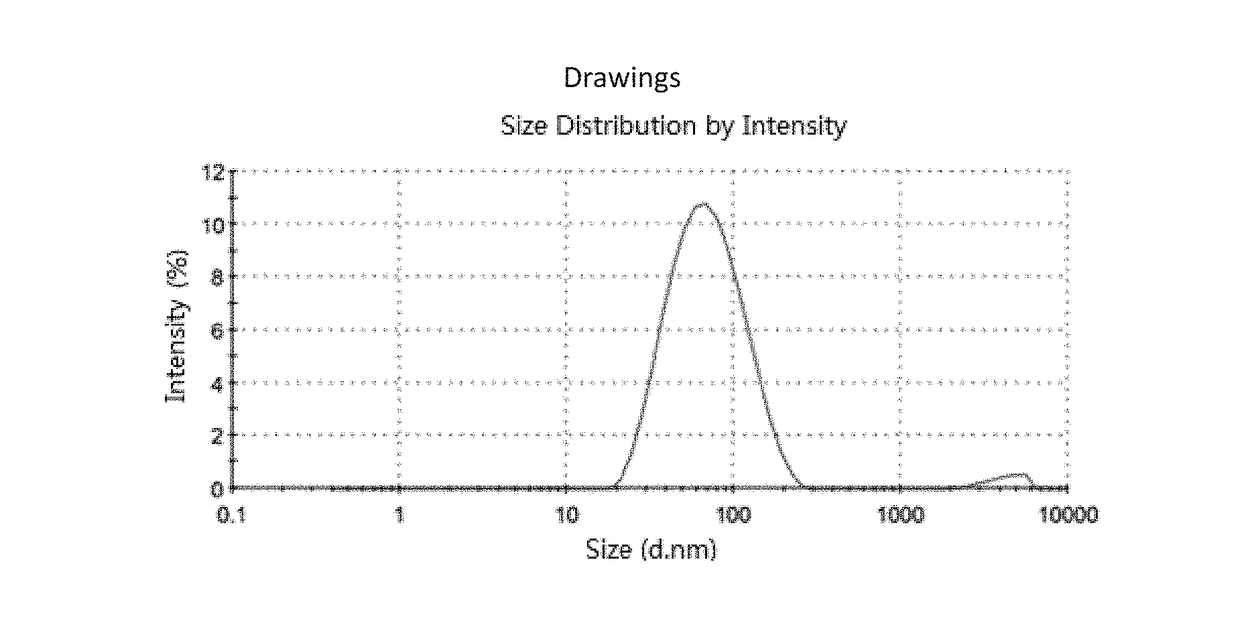

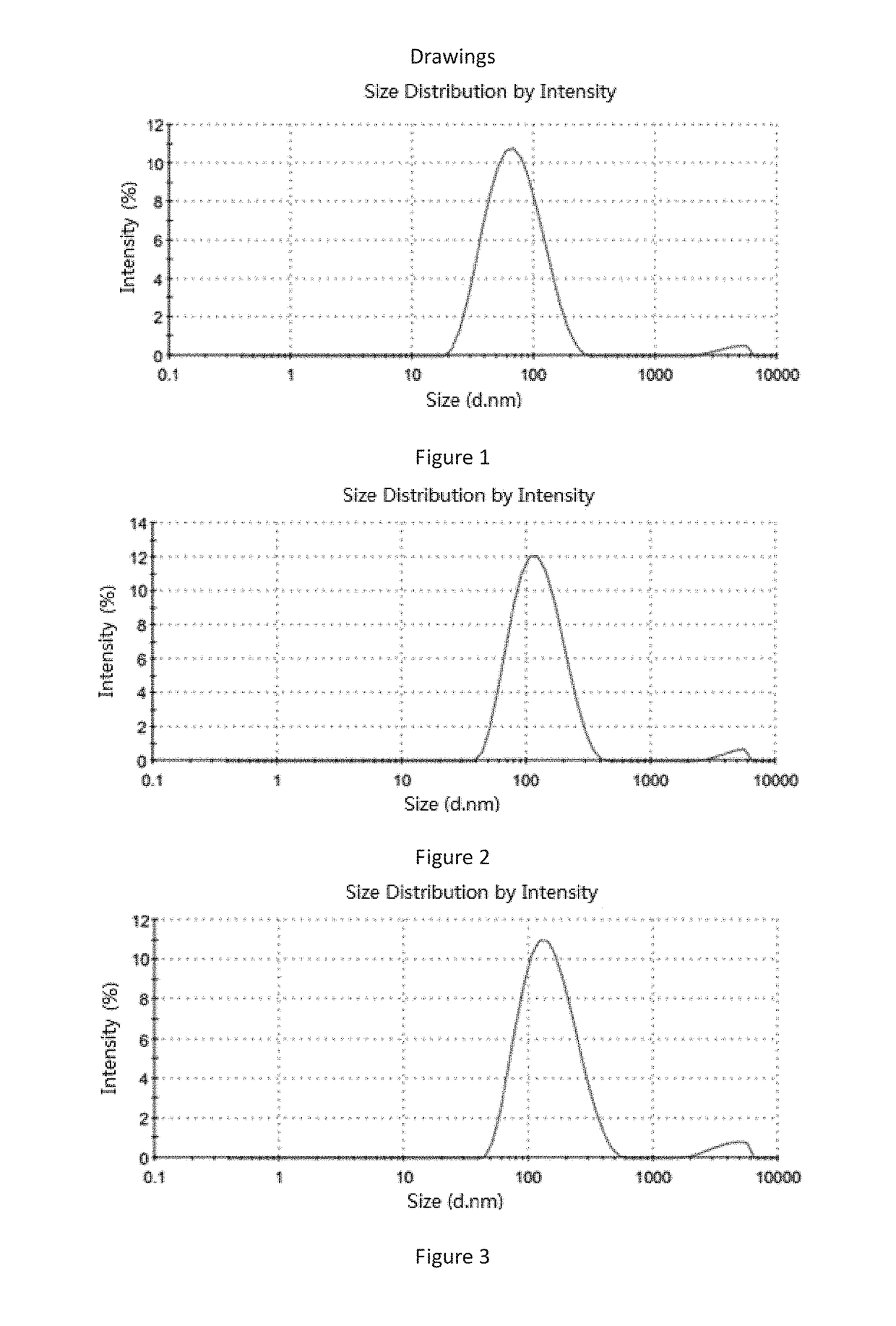

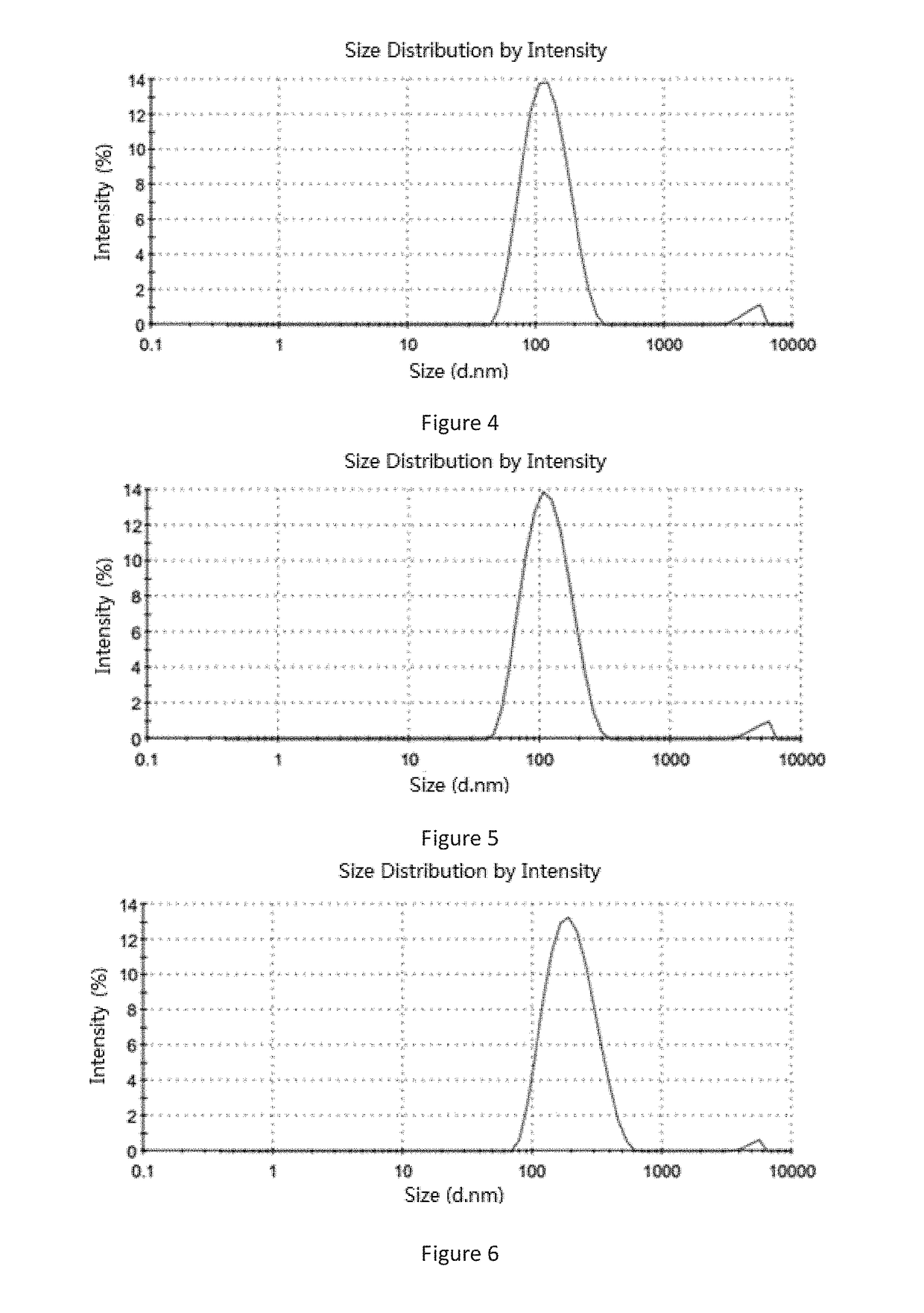

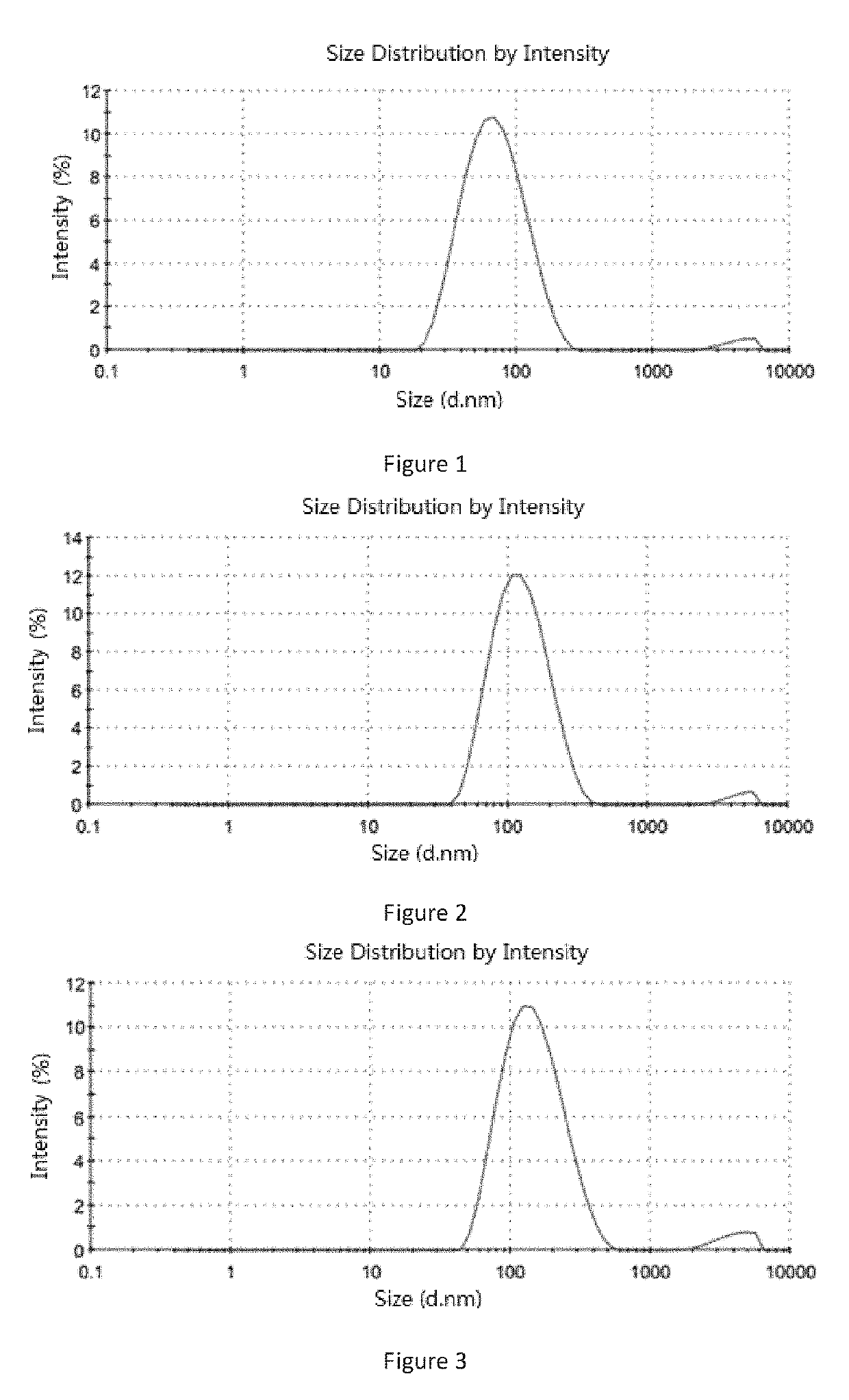

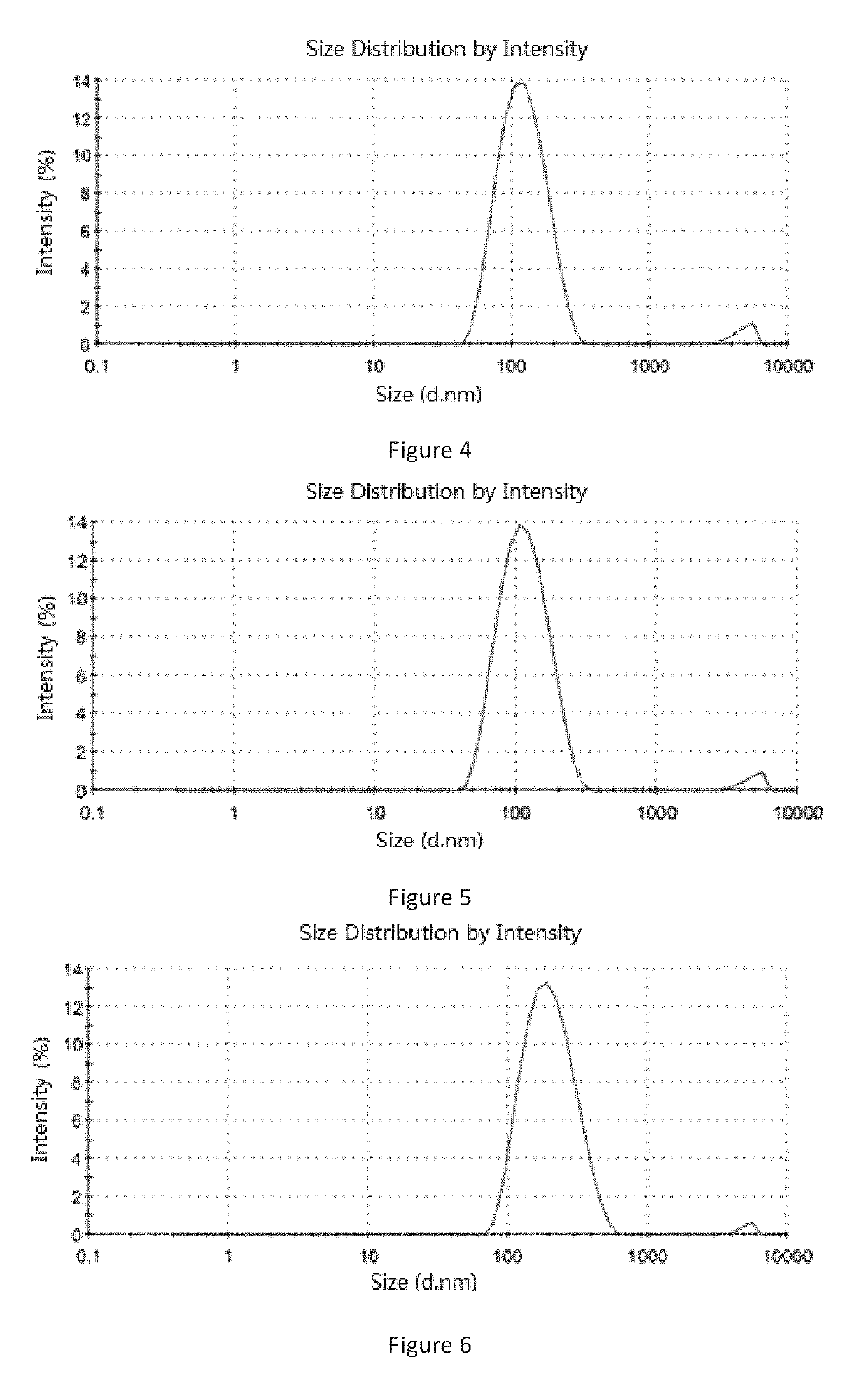

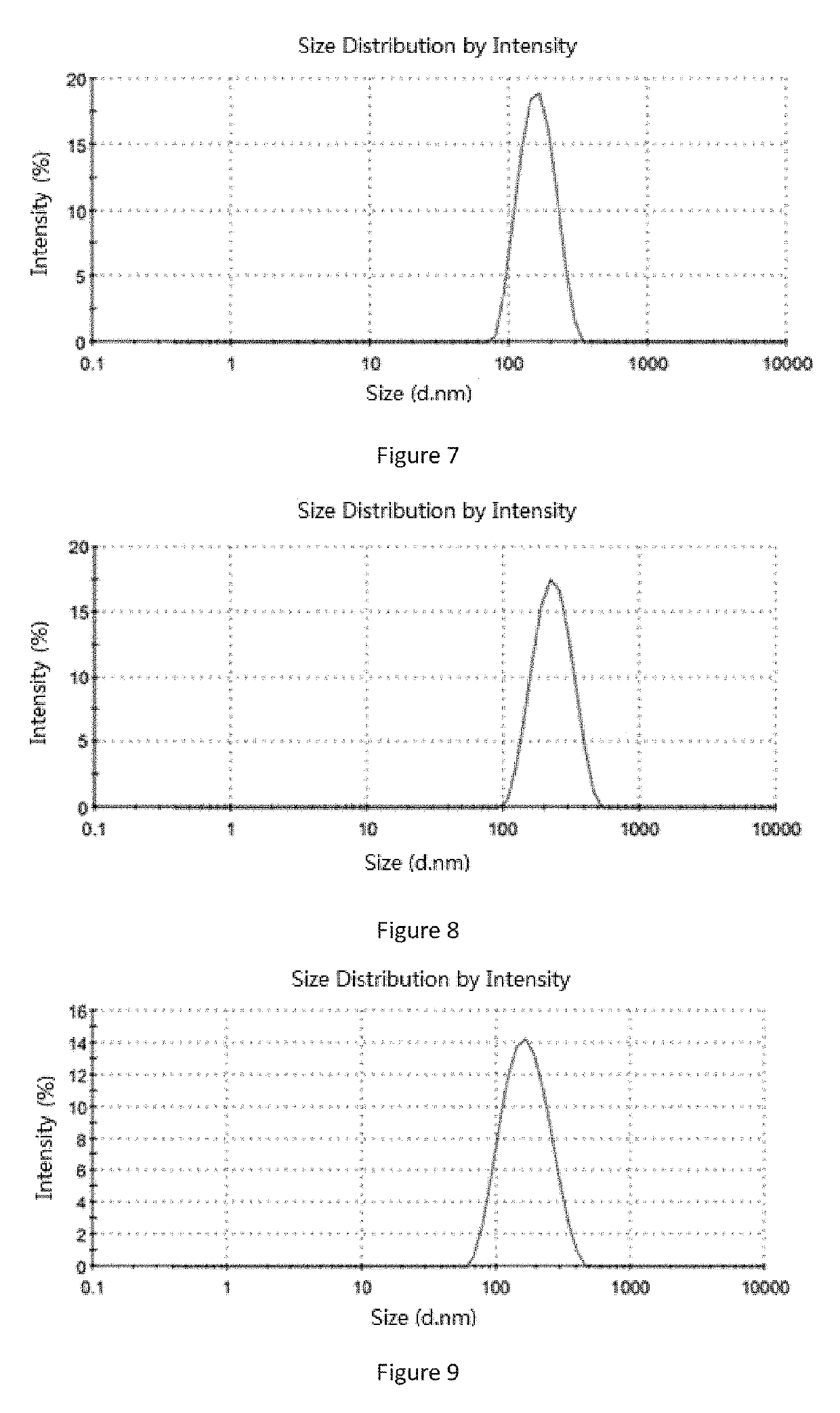

Liposomes with ginsenoside as membrane material and preparations and use thereof

ActiveUS20170172920A1High encapsulation efficiencyReduced stabilityAntibacterial agentsCosmetic preparationsLipid formationHeat sensitive

Among others, the present invention provides a blank liposome, preparation methods thereof, and a loaded liposome including the blank liposome and an active substance. The liposomes have a membrane comprising lipids and a ginsenoside of Formula I, and may further comprise a surfactant, a heat-sensitive excipient, a pH sensitive material, or an ion additive.

Owner:XIAMEN GINPOSOME PHARM CO LTD

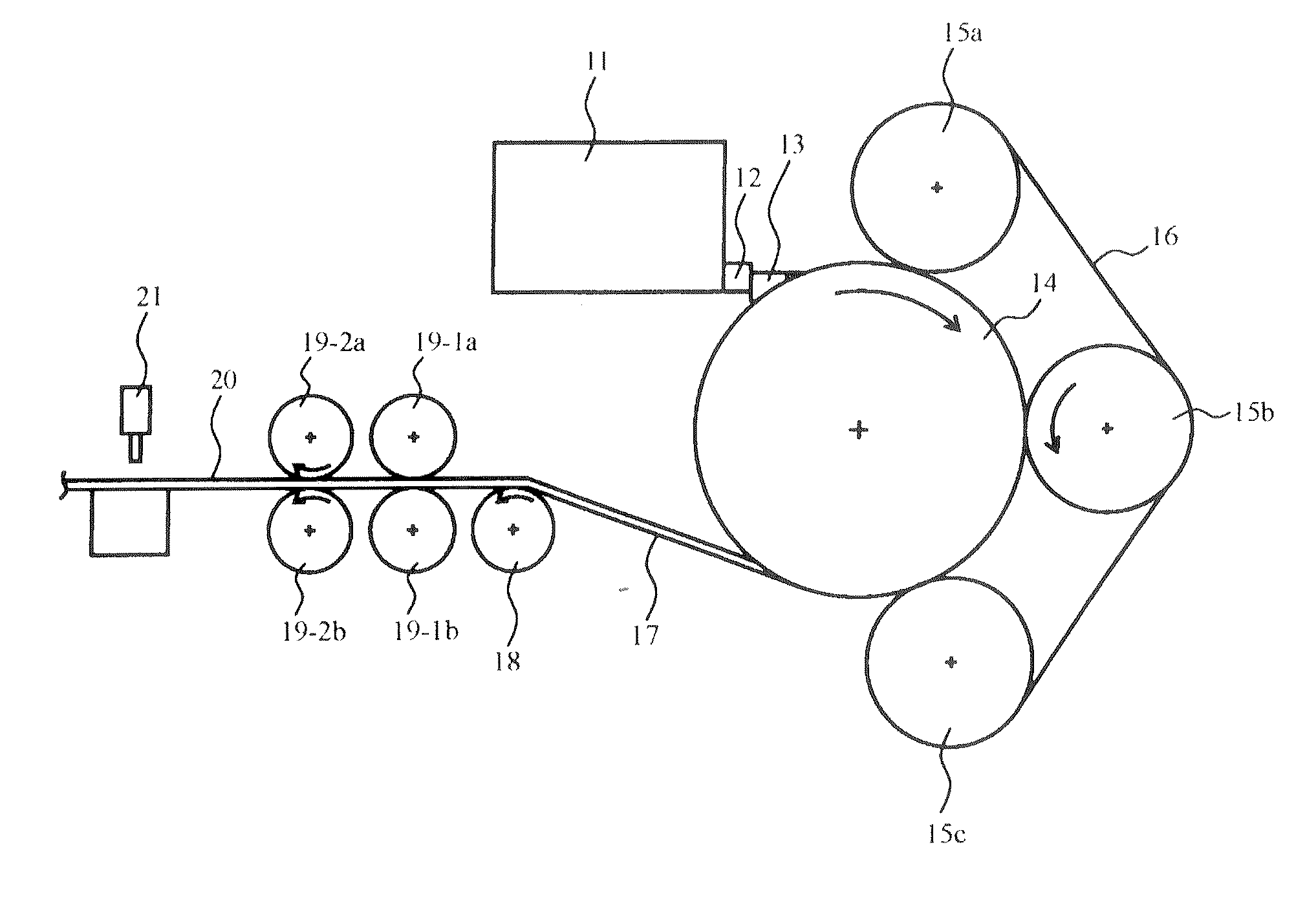

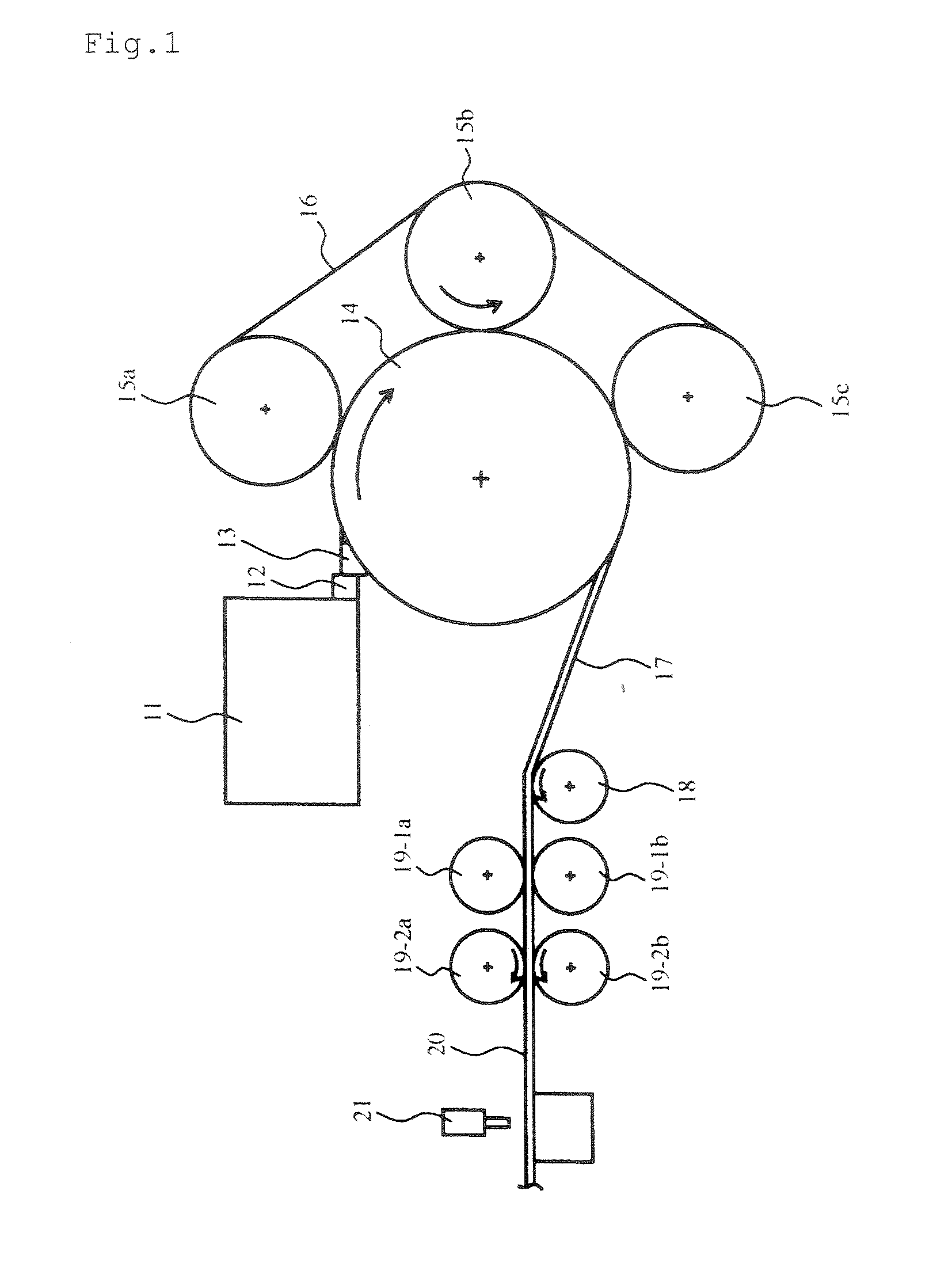

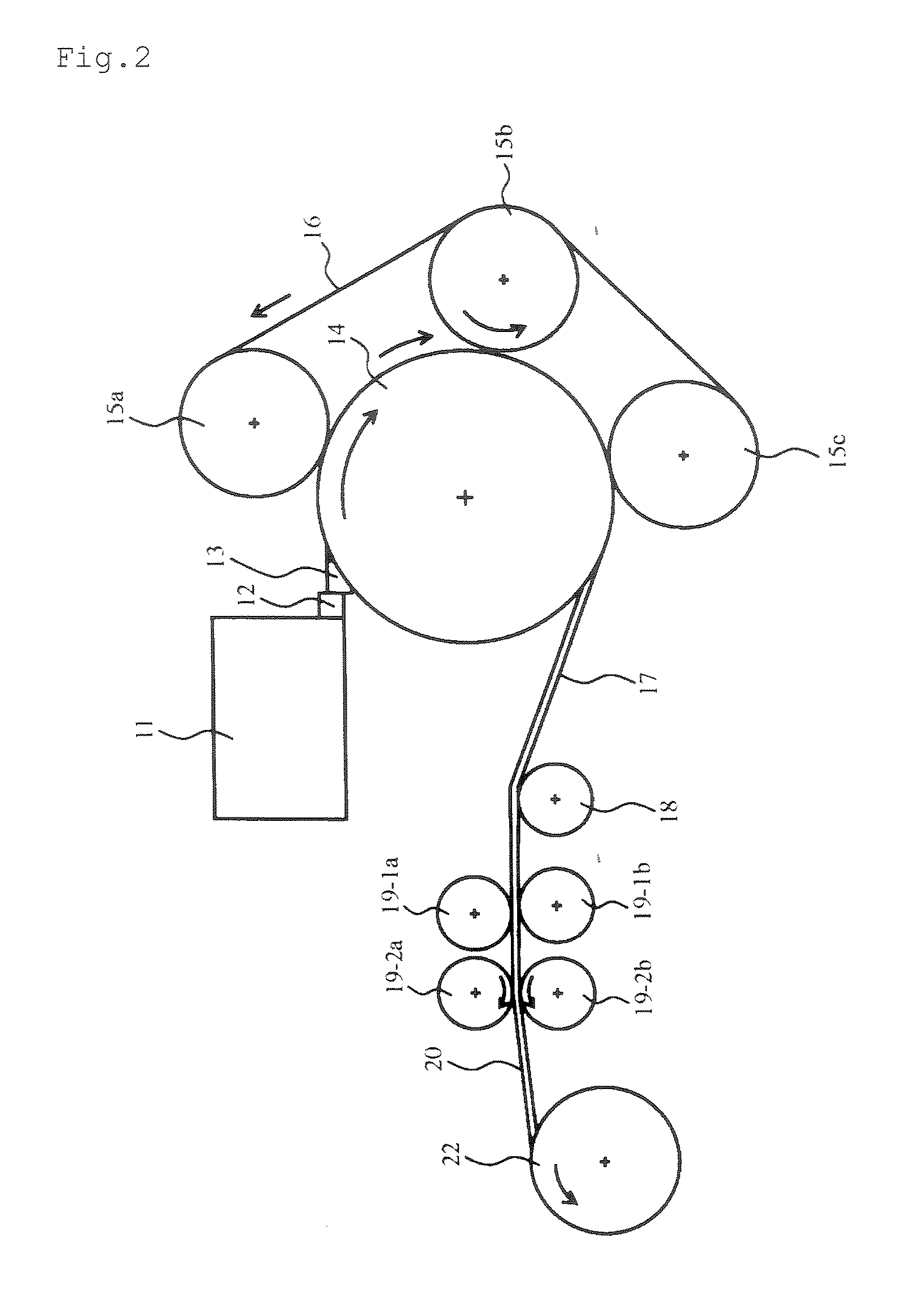

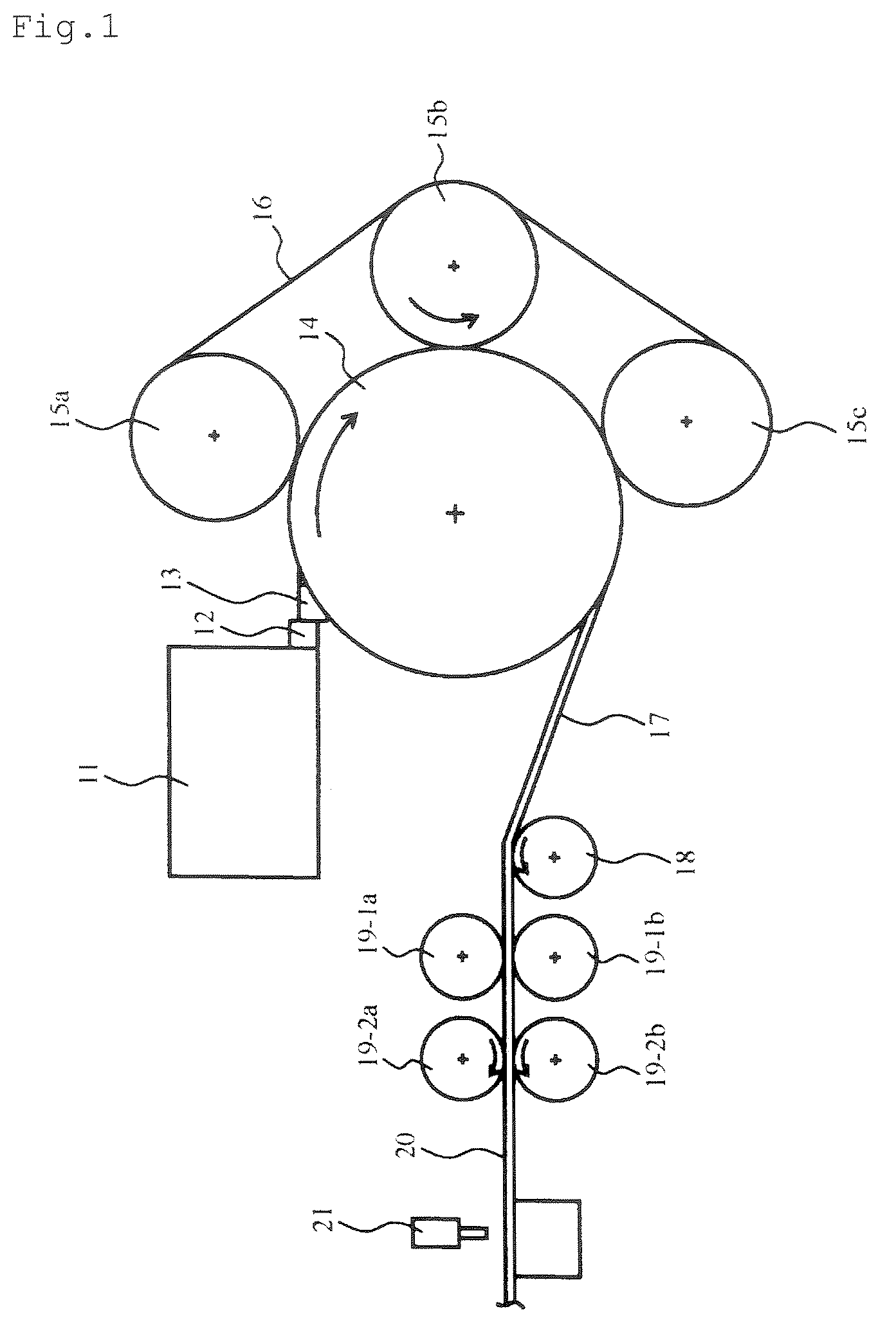

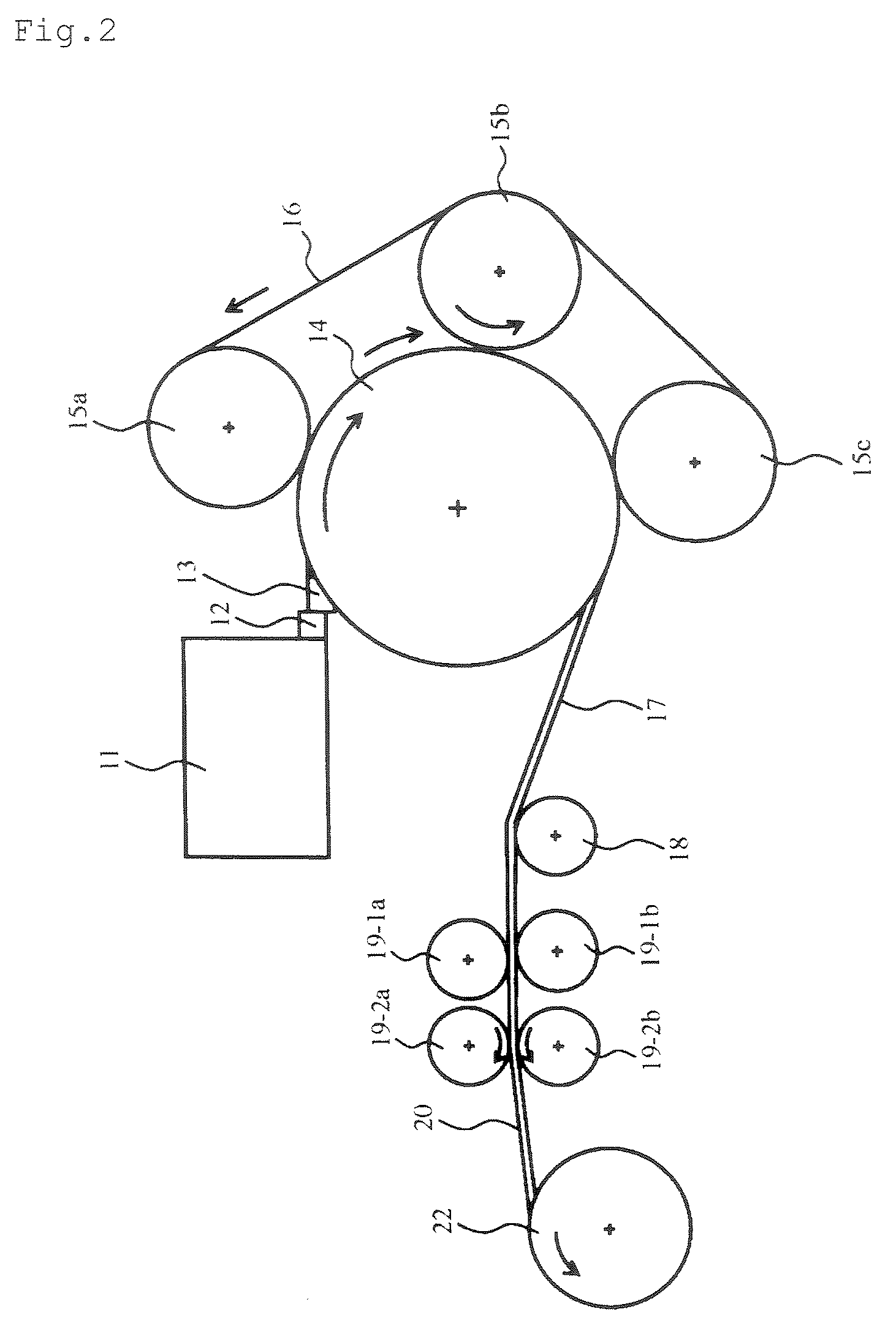

Method for producing manganese dry cell negative electrode zinc material

InactiveUS20080029189A1Quality improvementStable and reliable qualityPrimary cell electrodesProduction rateChemical factor

Presented is methods to make high quality anode zinc pellets without adding lead by continuous or non-continuous casting and rolling method in high productivity. Disclosed is full details of material and process engineering as regards alloy compound, process machinery or equipment, and test and evaluation method addressing metallographic aspect in addition to chemical factors.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

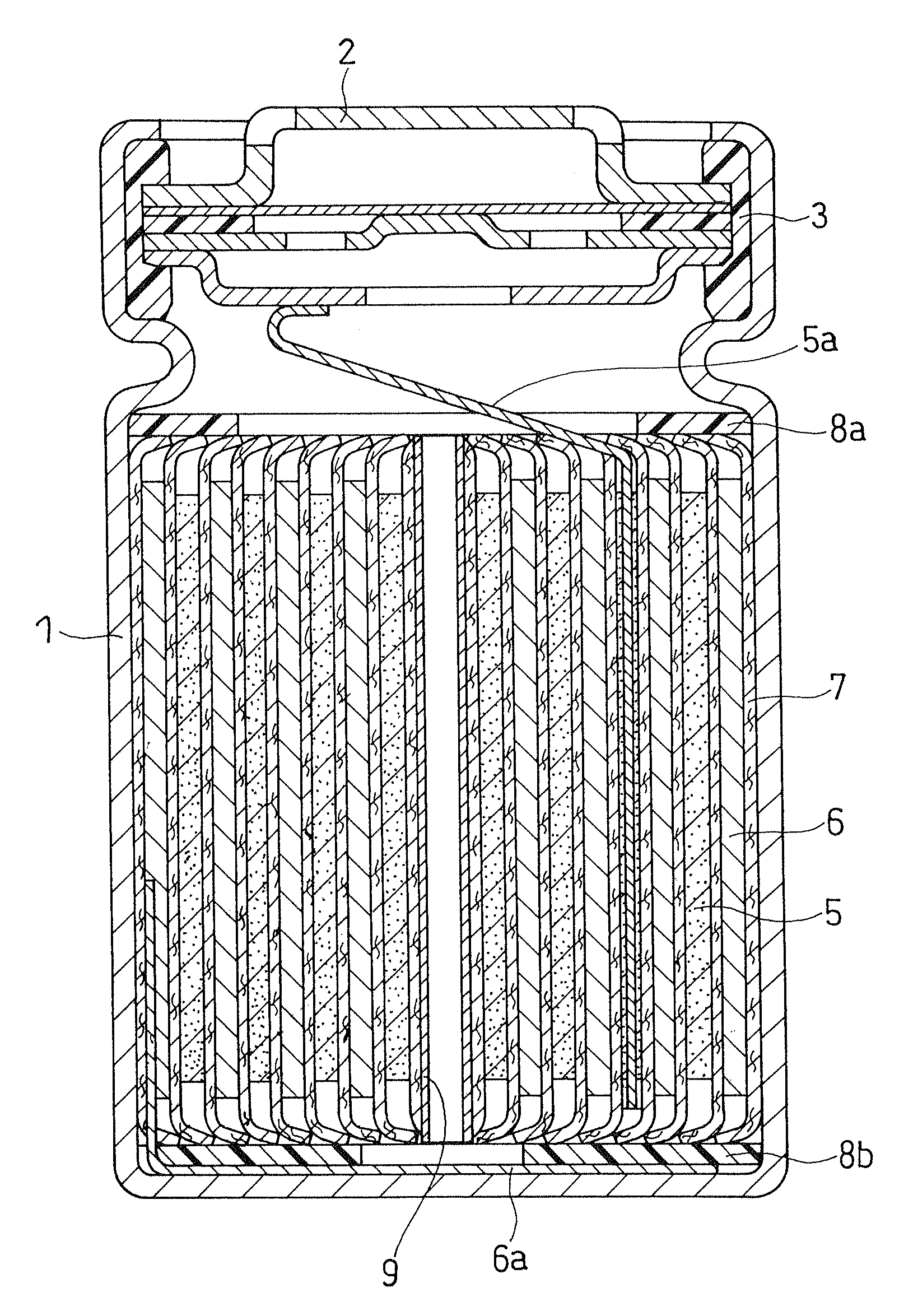

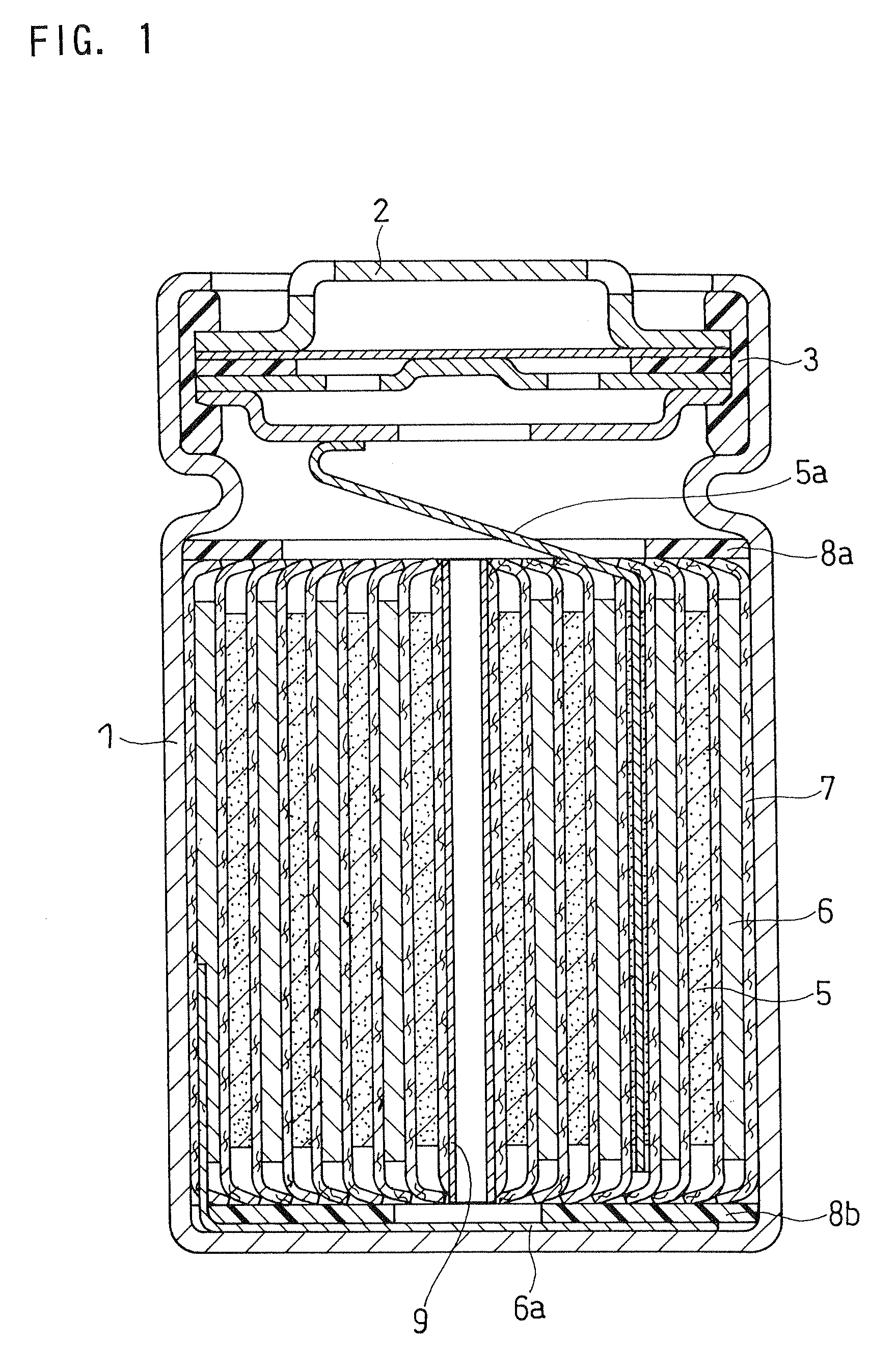

Non-aqueous electrolyte secondary battery

InactiveUS20080008932A1Improve heat resistanceEfficient preparationLi-accumulatorsCell component detailsAntistatic agentPhysical chemistry

In a non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, and a separator, the separator is immersed in a non-aqueous electrolyte, and the separator contains an aromatic resin and an antistatic agent. The precision upon rolling out a reel-like rolled product of the separator is thus improved, and winding misalignment in separators decreases. Also, minute short circuit occurrence decreases drastically. As a result, a reliable quality, high capacity non-aqueous electrolyte secondary battery can be efficiently and advantageously manufactured.

Owner:PANASONIC CORP

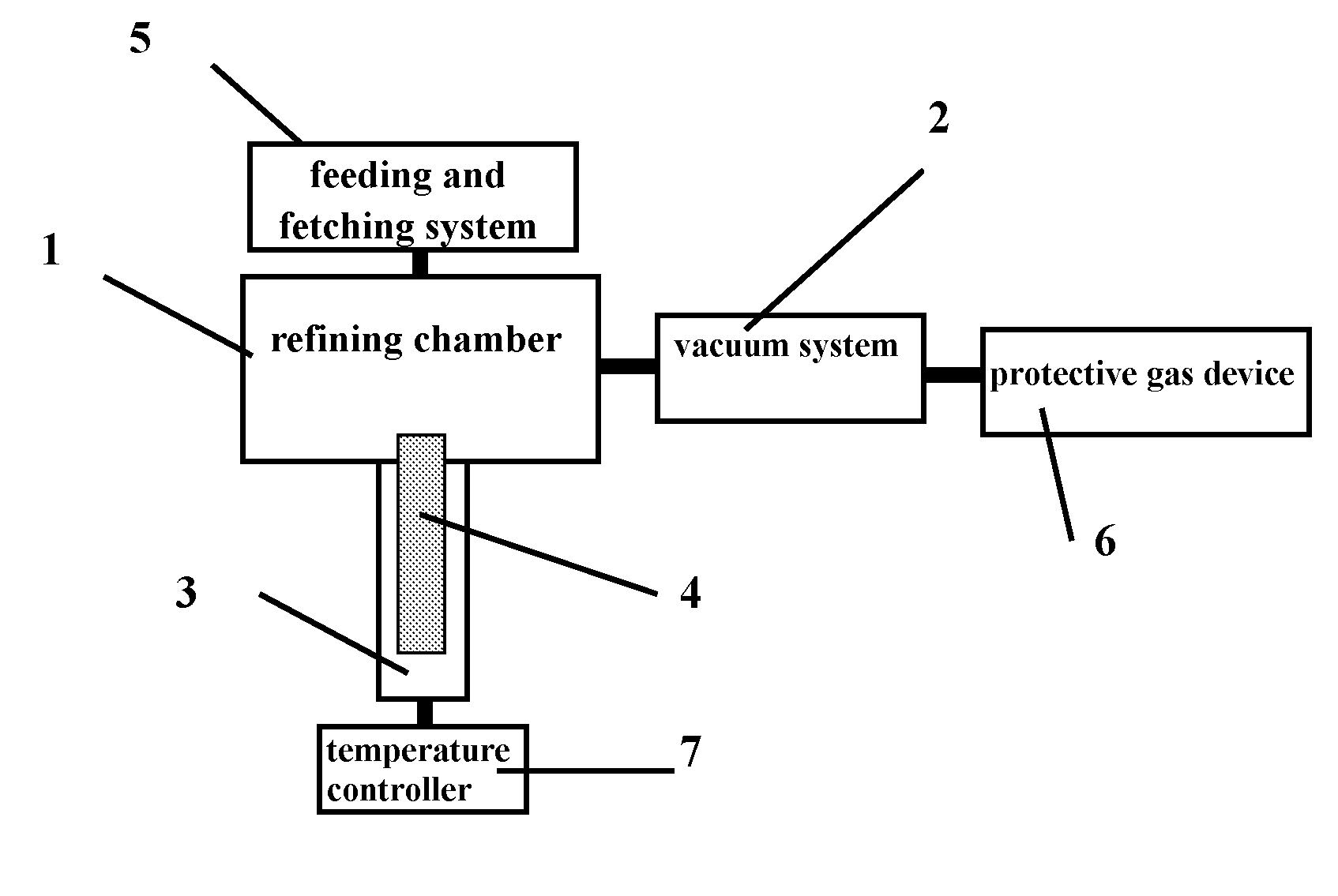

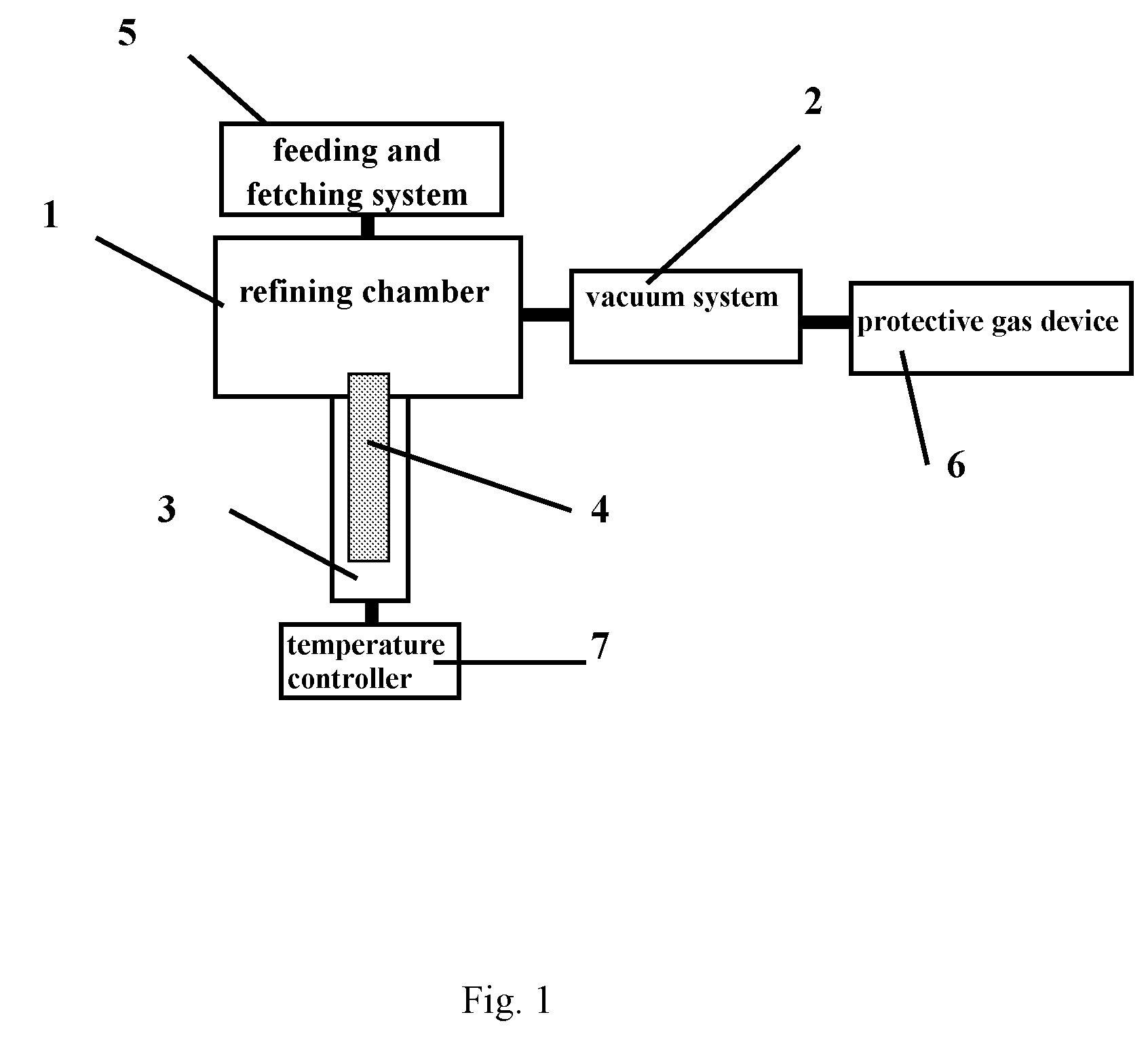

High vacuum in-situ refining method for high-purity materials and an apparatus thereof

InactiveUS7753987B2Good effectEnvironmentally friendlyCalcium/strontium/barium compoundsBlast furnace detailsCrucibleUltra high purity

Owner:SHENGZHOU GUOSHENG NEW ENERGY TECH

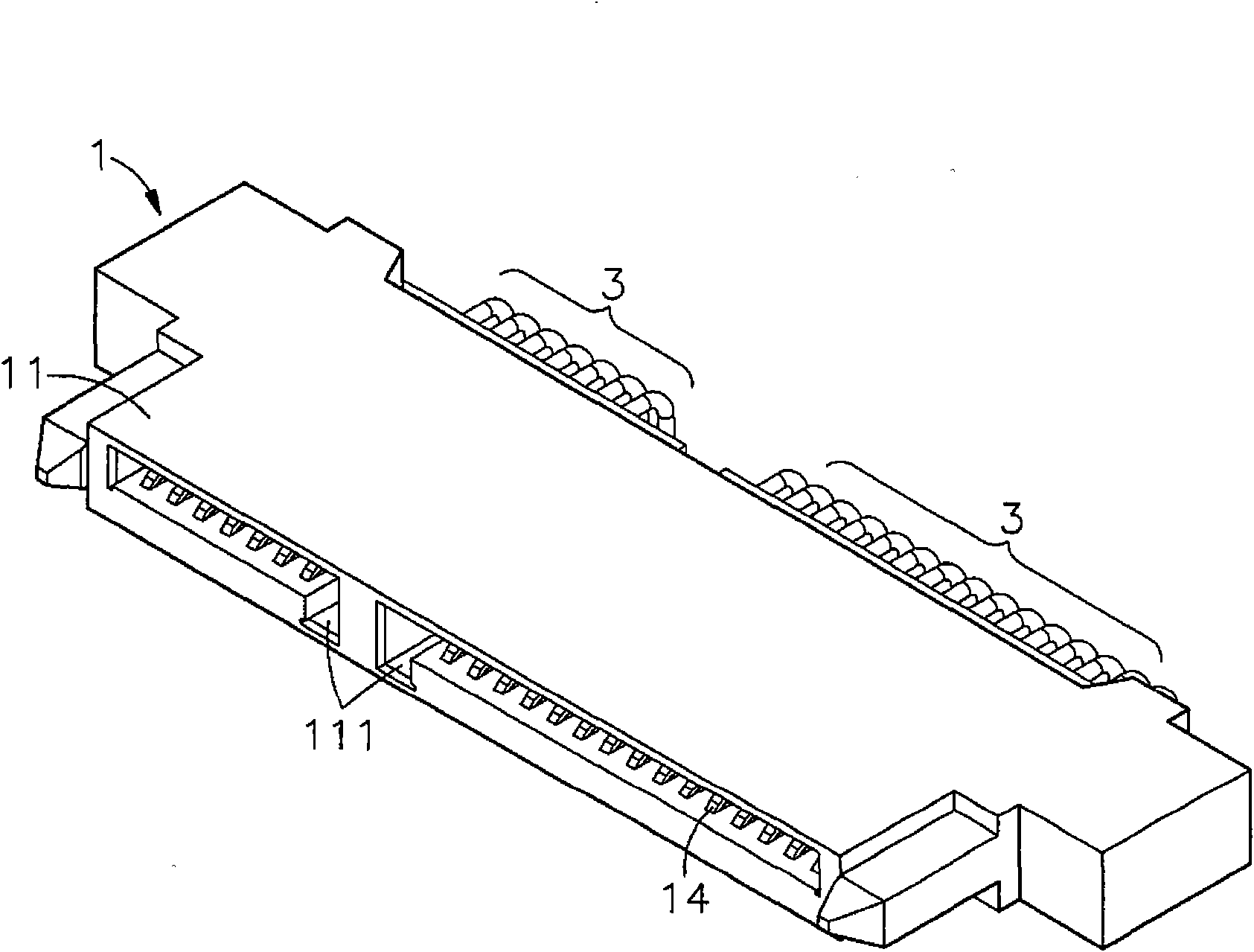

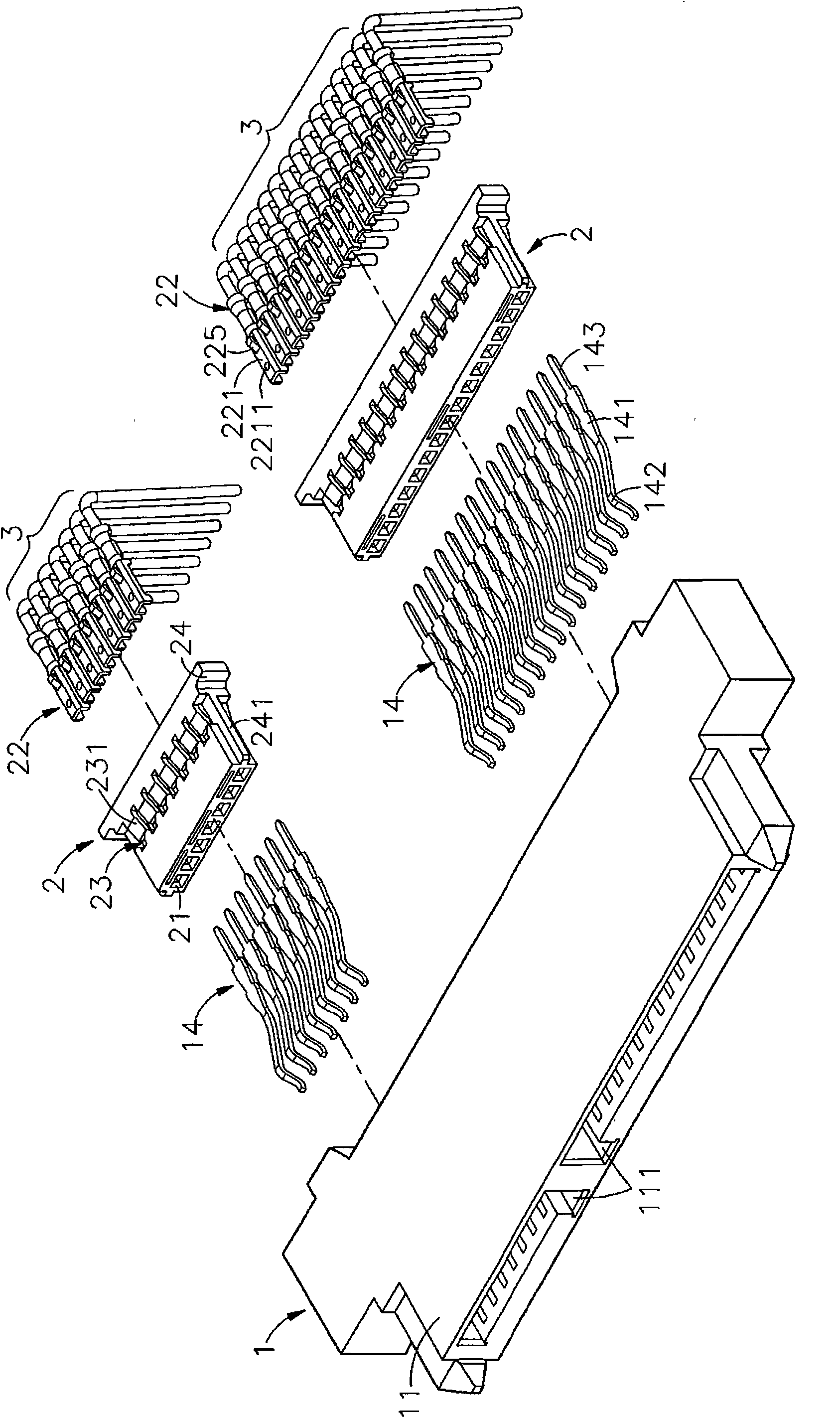

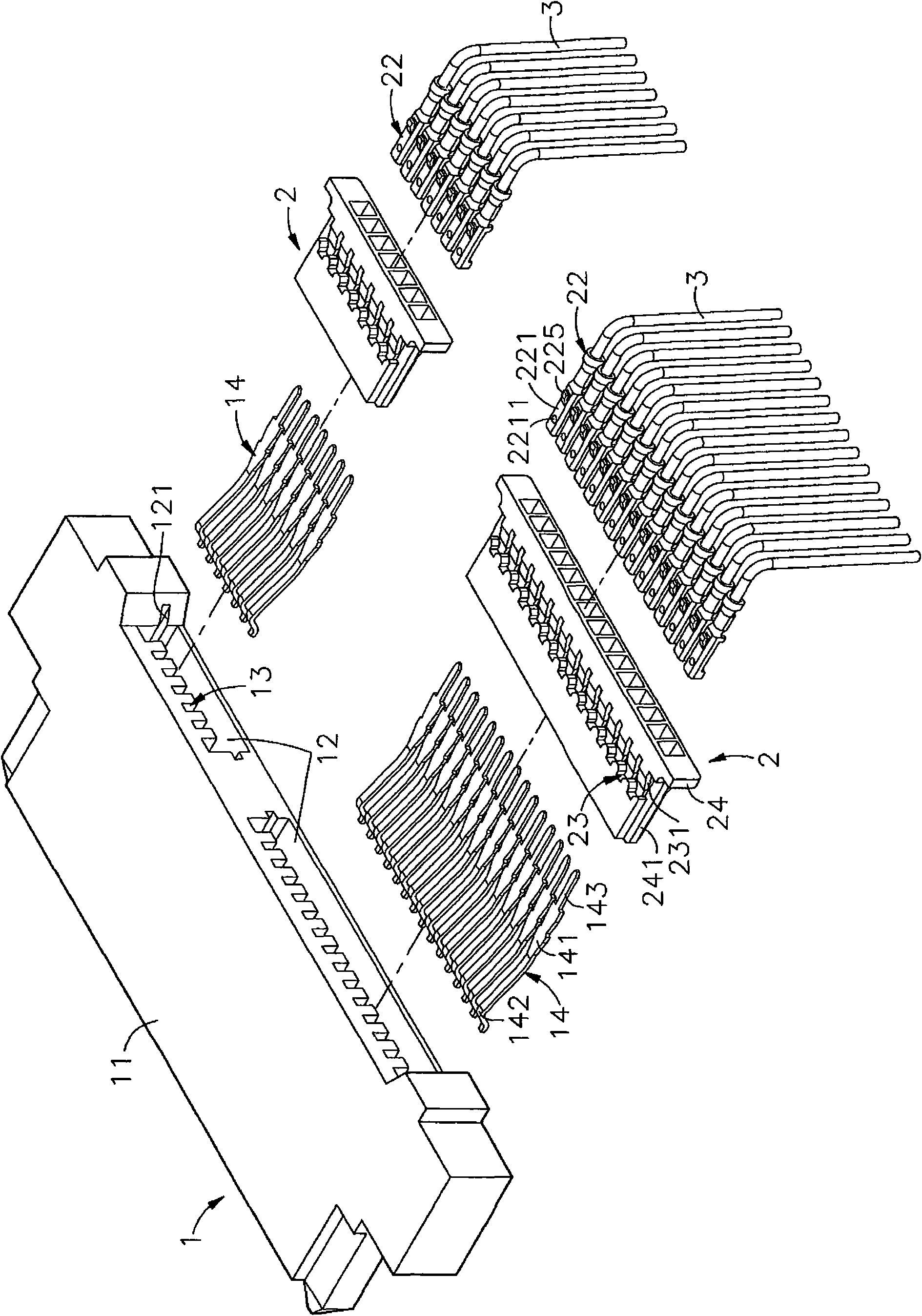

Electric connector

InactiveCN101931152AEasy to assembleEasy alignmentCouplings bases/casesElectricityElectrical connection

The invention relates to an electric connector which comprises a seat body, an adapter and a cable, wherein one side of the seat body is provided with a butting part, the other side of the seat body far away from the butting part is formed with a plugging slot, conductive terminal sets are arranged in a plurality of penetrating channels communicated between the plugging slot and the butting part, the adapter is assembled in the plugging slot to ensure that stopping part and rails at two sides of the adapter are respectively abutted against the outer side of the plugging slot or after a rail slot corresponding to the plugging slot is embedded and clamped, an adapting terminal set penetrated inside the adapter is correspondingly electrically connected with the conductive terminal sets, and then the cable is combined at the rear end of the adapting terminal set to form an electrical connection state. By adopting the structural design of the adapter, the invention ensures that the conductive terminal set and the cable can be conveniently assembled and aligned without a welding mode, avoids the inconvenience and the difficulty caused by complex welding operations, and can effectively shorten the time and the cost consumed during the integral production.

Owner:ACES ELECTRONICS CO LTD +1

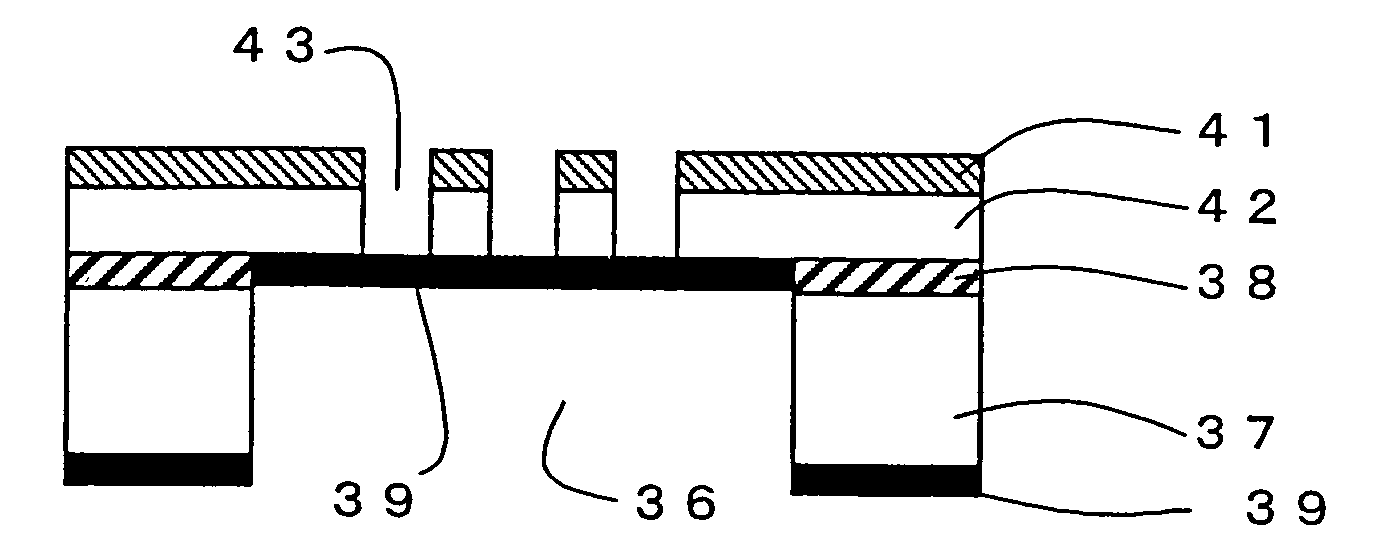

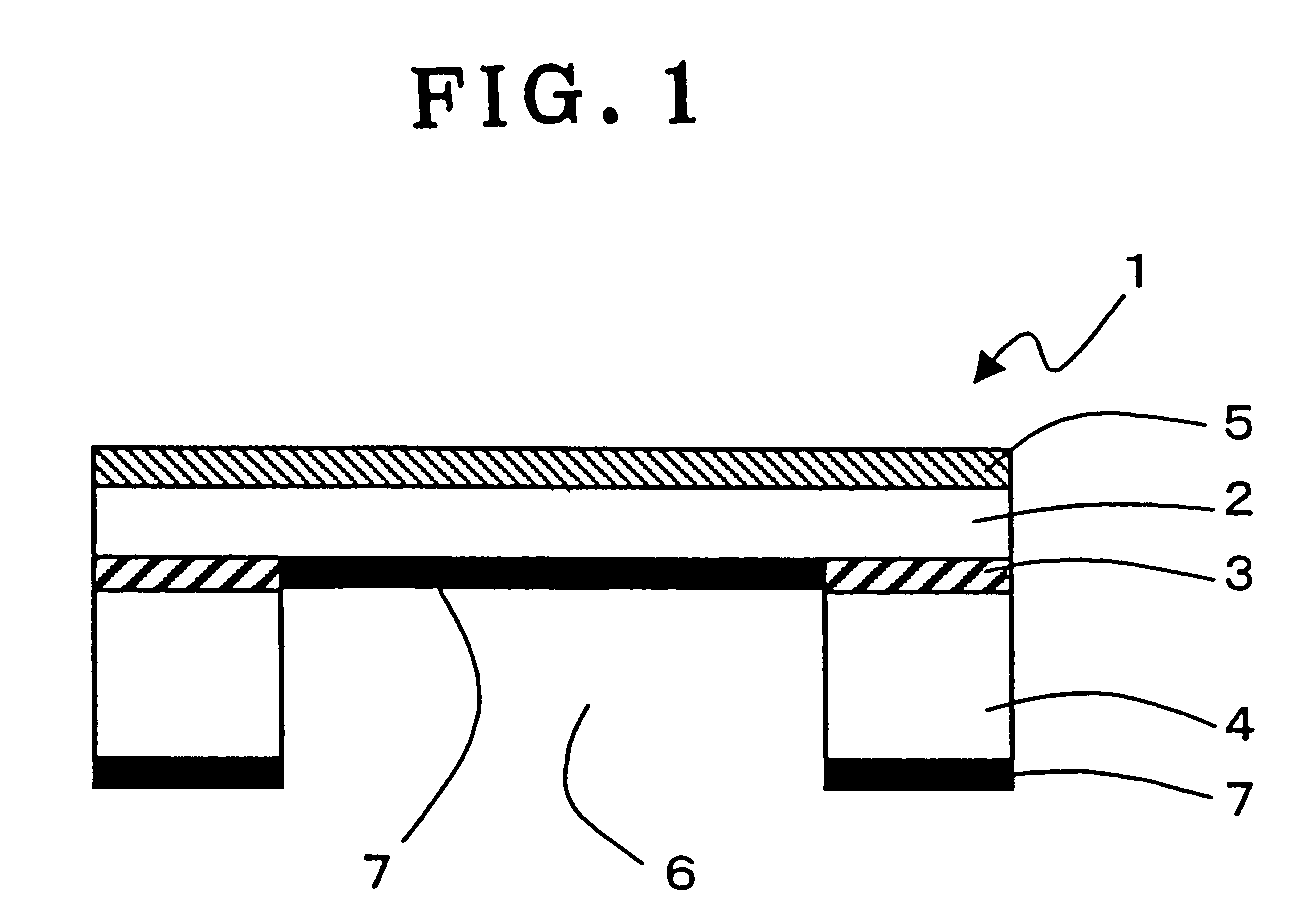

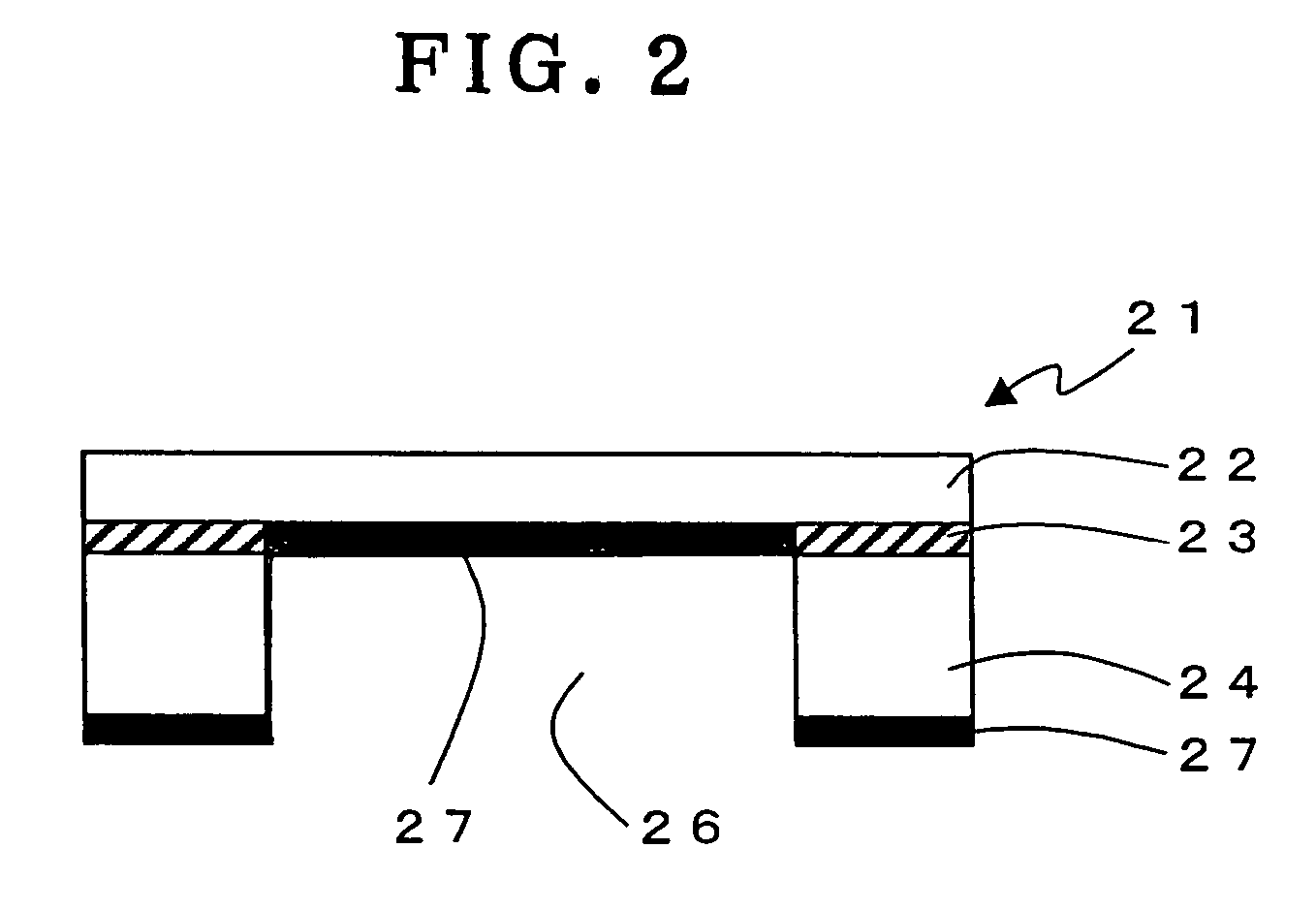

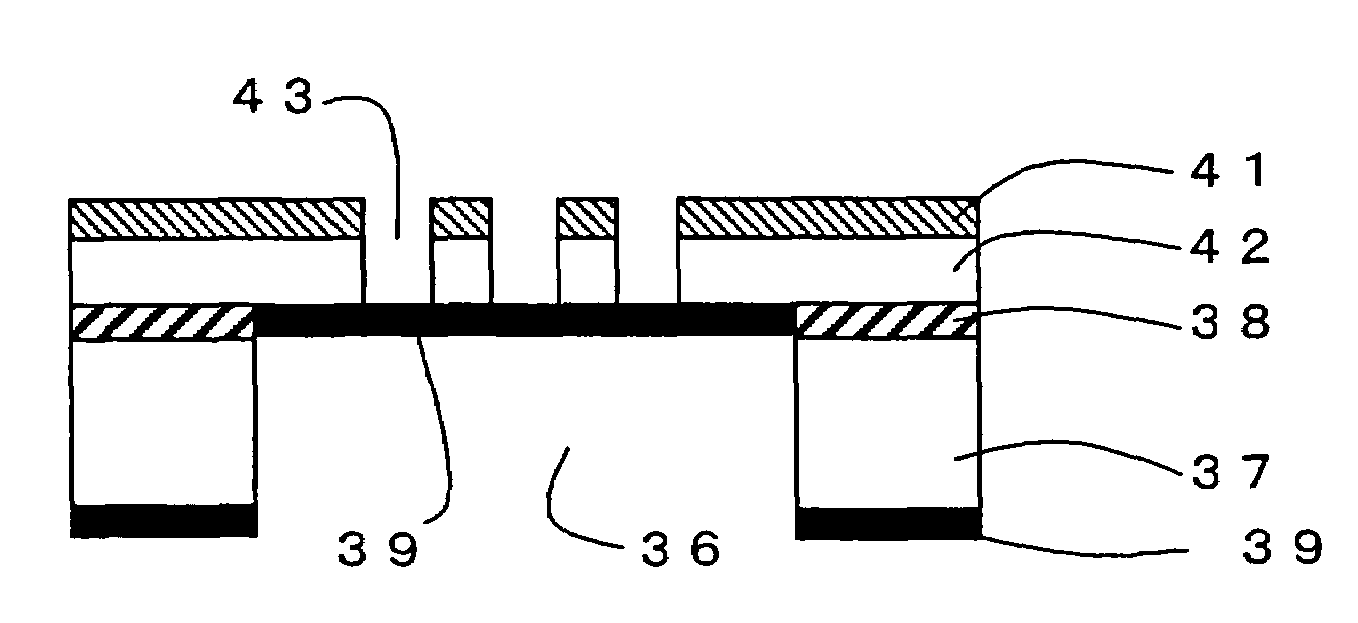

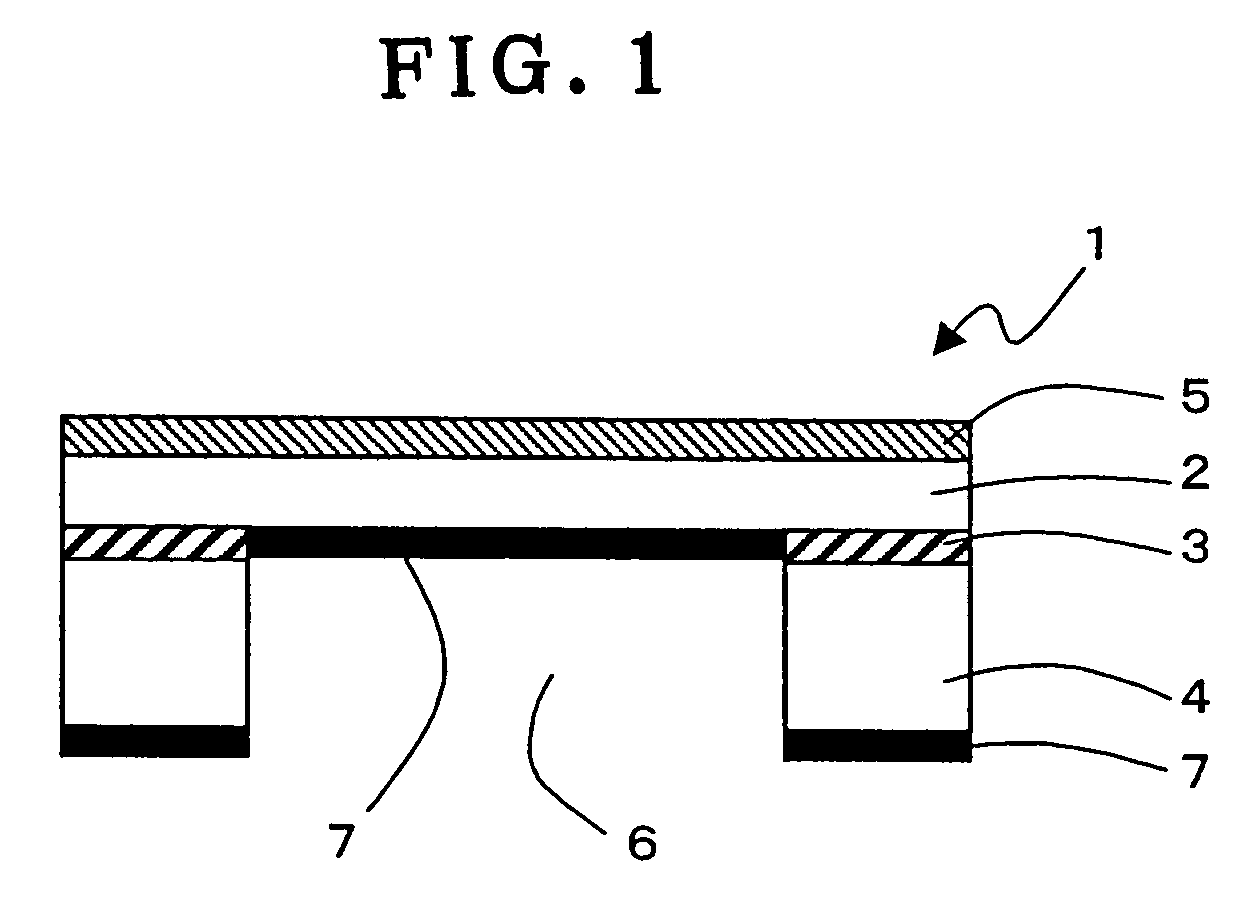

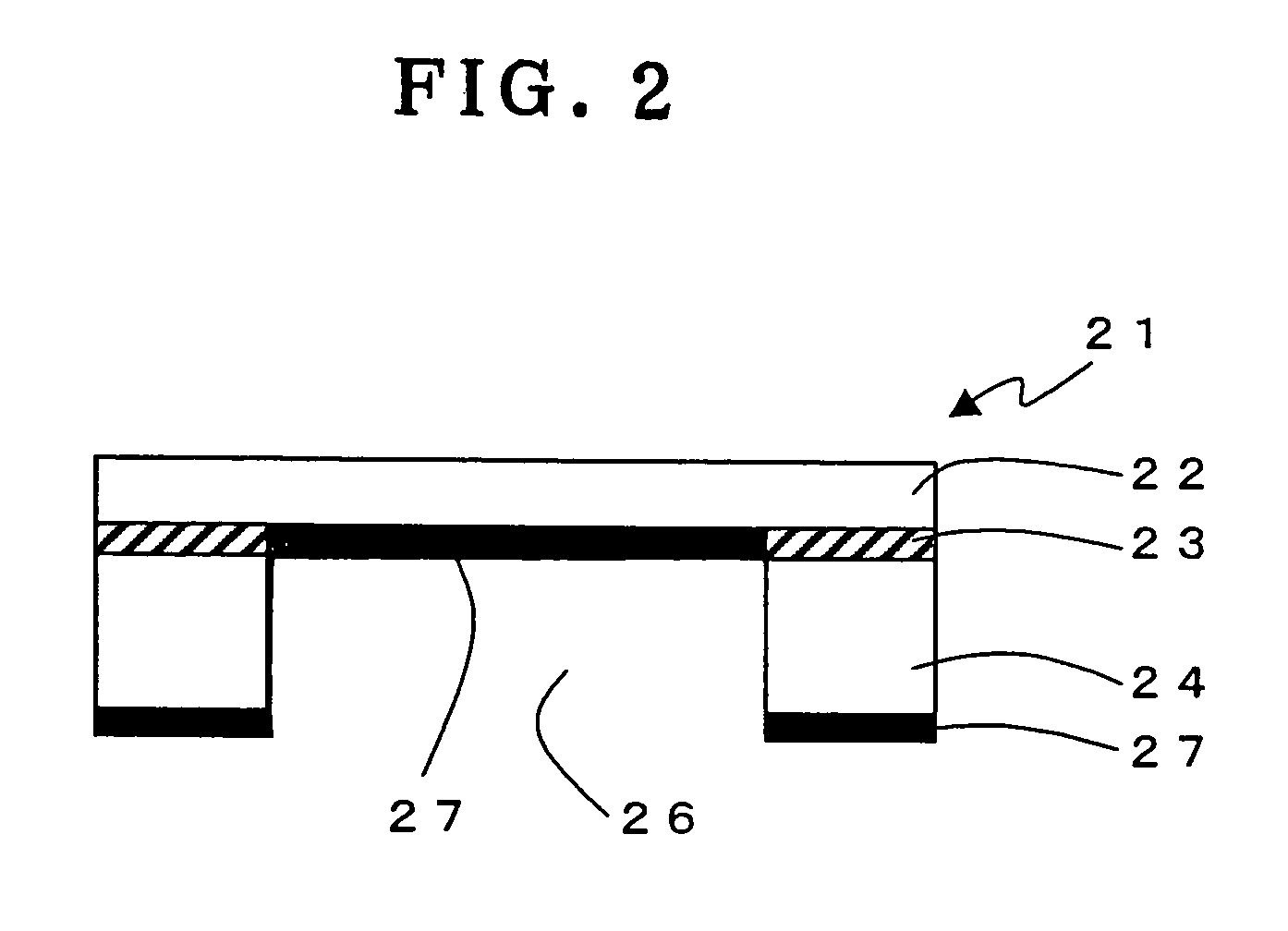

Mask blank for charged particle beam exposure, method of forming mask blank and mask for charged particle beam exposure

InactiveUS7479233B2Stable and reliable qualityReduce internal stressElectric discharge tubesDecorative surface effectsSilicon membraneSilicon oxide

The present invention provides a mask blank used for the charged particle beam exposure made by employing an SOI substrate having a silicon membrane higher reliability in quality, without the problem of deformation due to the compression stress of a silicon oxide film as an intermediate layer of the SOI substrate, and provides a method for forming a mask blank and a mask used for the charged particle beam exposure. The mask blank used for the charged particle beam exposure made by employing an SOI substrate having a front-side silicon membrane and a back-side silicon layer with a silicon oxide layer interposed therebetween is characterized in that the back-side silicon layer and the silicon oxide film of said SOI substrate are partially removed to form an opening to be an exposed region and an etching stop layer having lower stress is formed in the opening.

Owner:DAI NIPPON PRINTING CO LTD

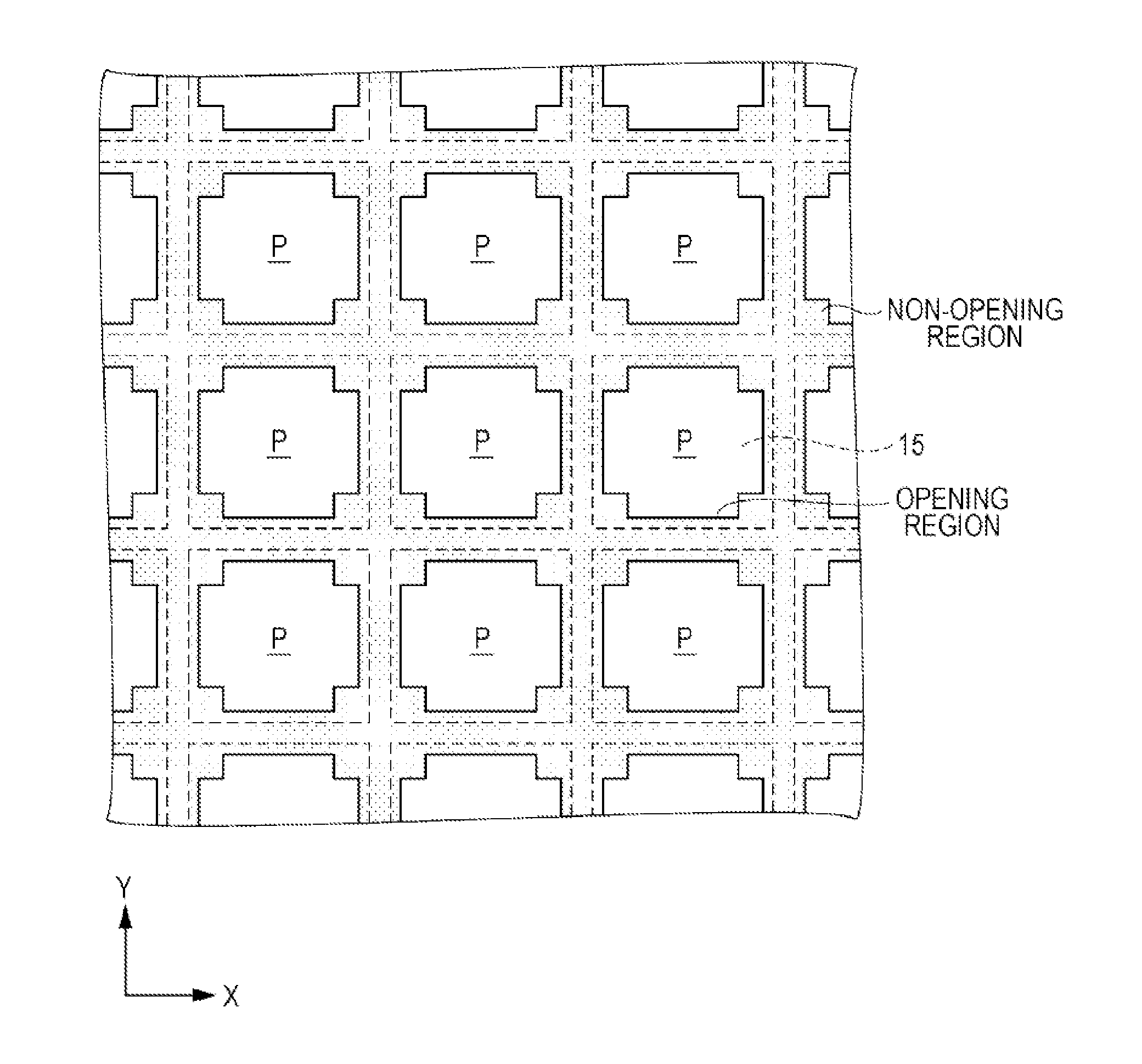

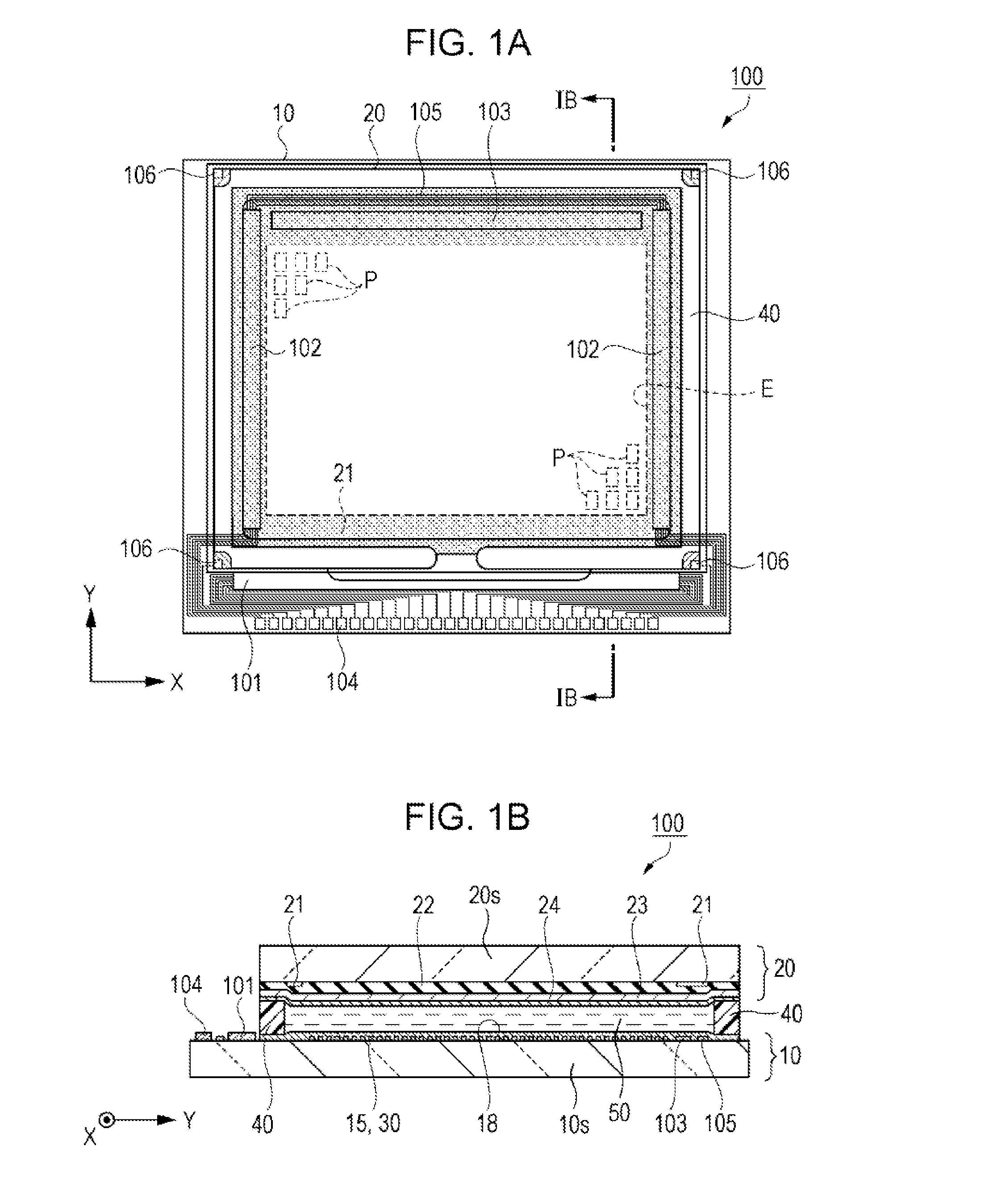

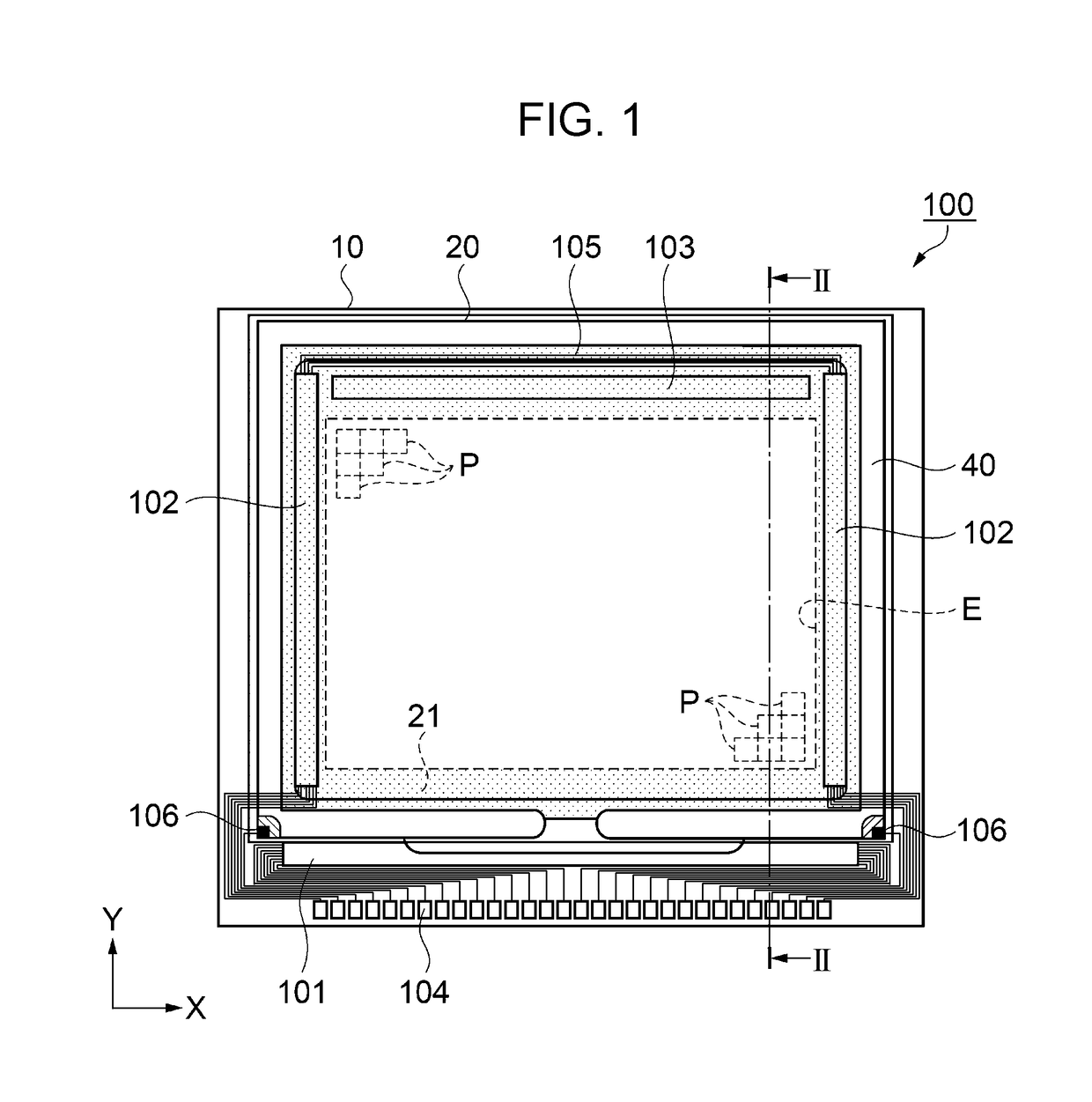

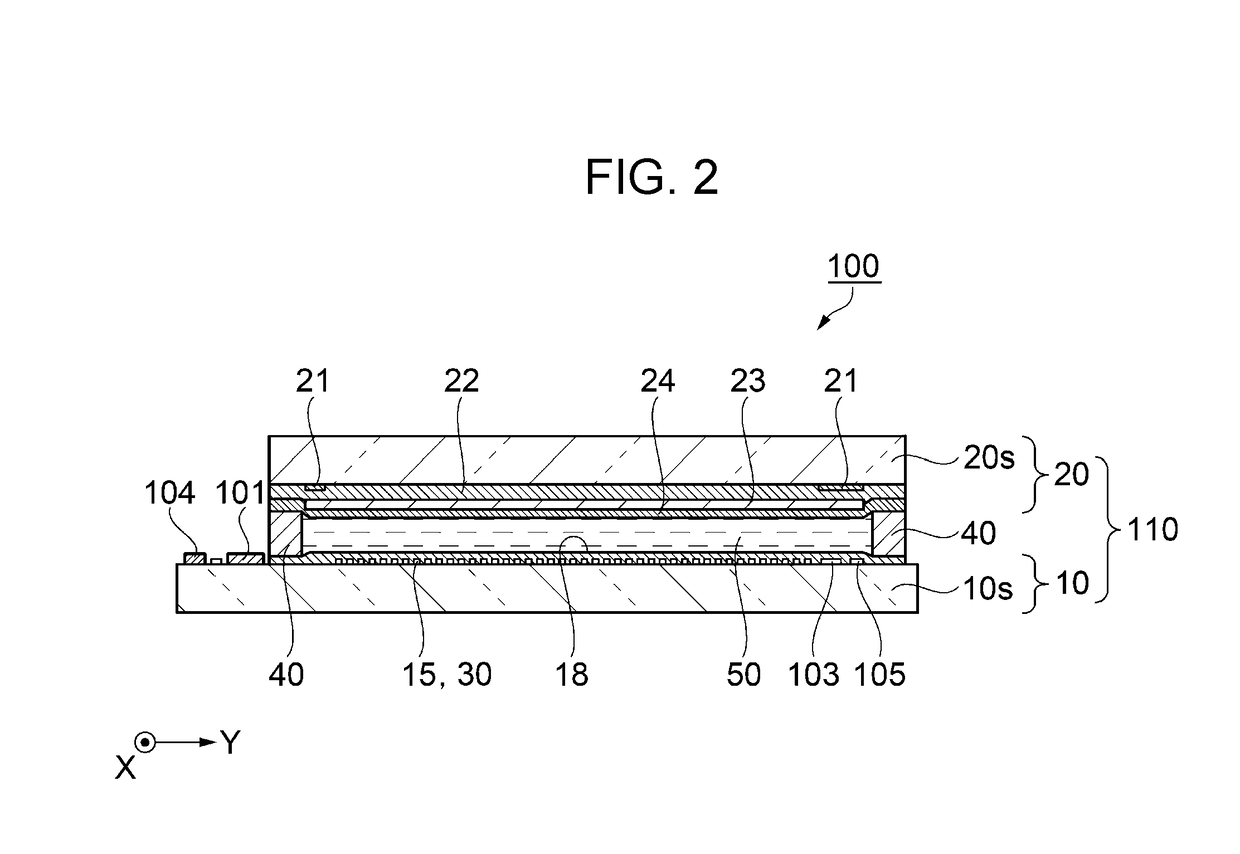

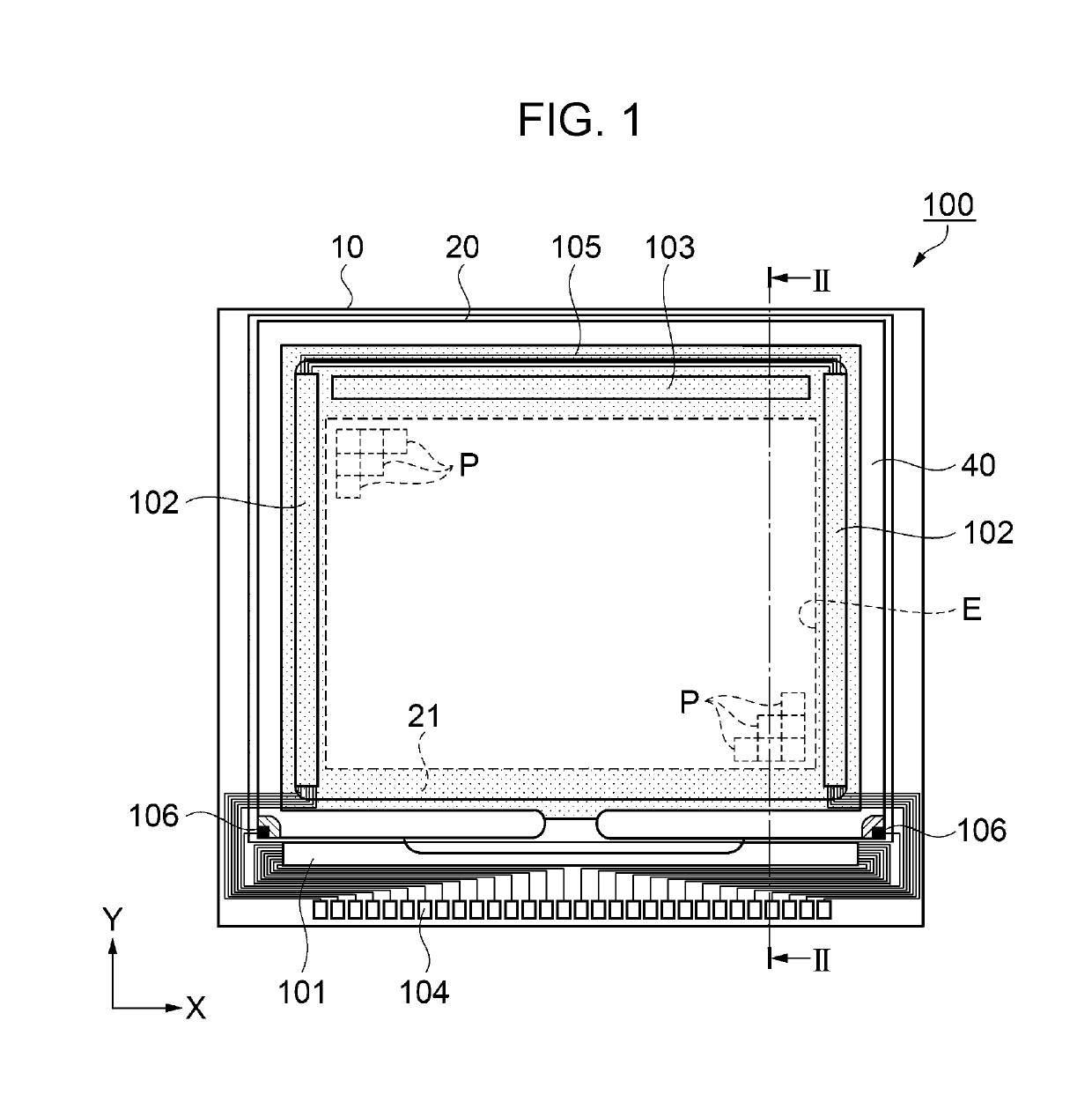

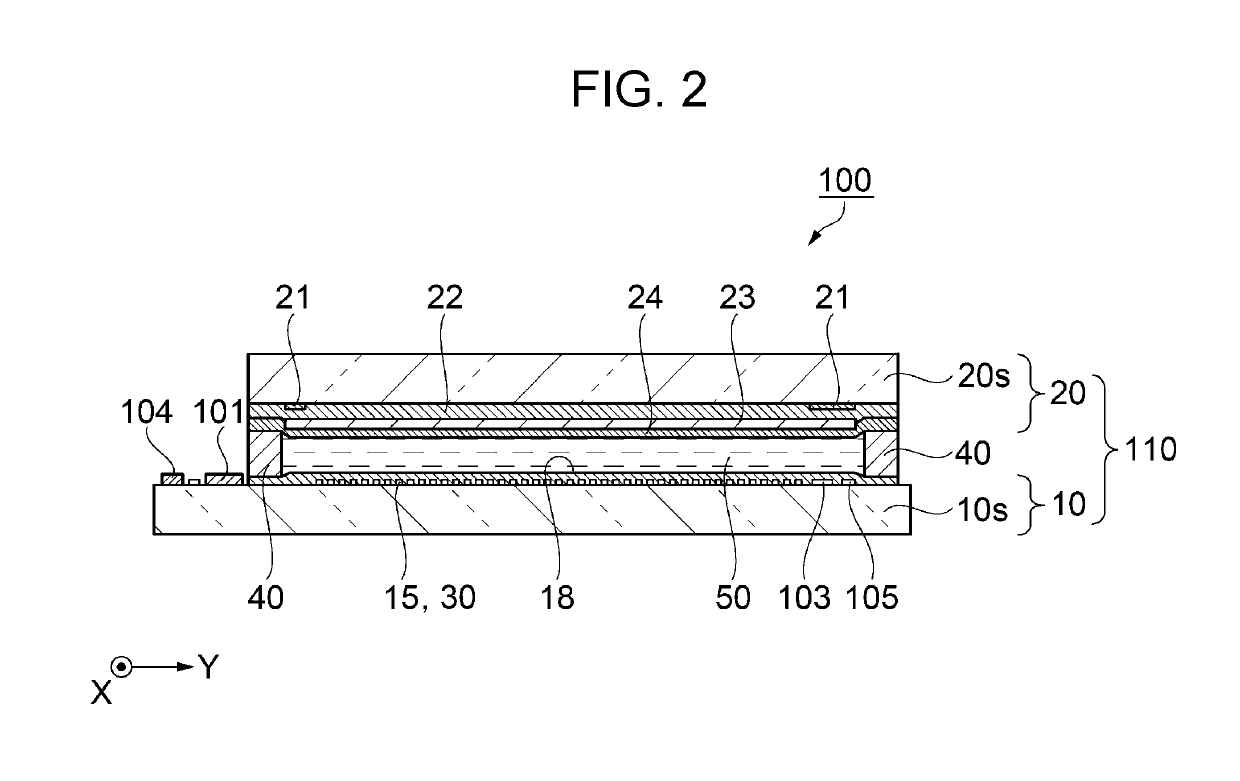

Liquid crystal device and electronic apparatus

InactiveUS20130300993A1Improve display qualityImprove reliabilityNon-linear opticsEngineeringElectron

There is provided a liquid crystal device including a first substrate, a second substrate, a liquid crystal layer that is interposed between and supported by the first substrate and the second substrate, a protrusion portion that is provided on the first substrate and protrudes toward the liquid crystal layer, and a plurality of pixel electrodes that are arranged in the vicinity of the protrusion portion. In the liquid crystal device, a spacing between ends of the plurality of pixel electrodes and an end of the protrusion portion is greater than a height of the protrusion portion.

Owner:SEIKO EPSON CORP

Foamed Plastic Material For Making Automobile Interior Parts And Manufacturing Method Thereof

Disclosed is a foamed plastic material, particularly a foamed plastic material for making automobile interior parts, and a manufacturing method of the foamed plastic material. The foamed plastic material can be used in mass production by means of known injection molding processes and an automobile interior part manufactured with such a material shows a noble quality and a soft tactile impression similar to a manual surfacing material.

Owner:SANYUAN ADVANCE TECH INC DESIGN CO LTD

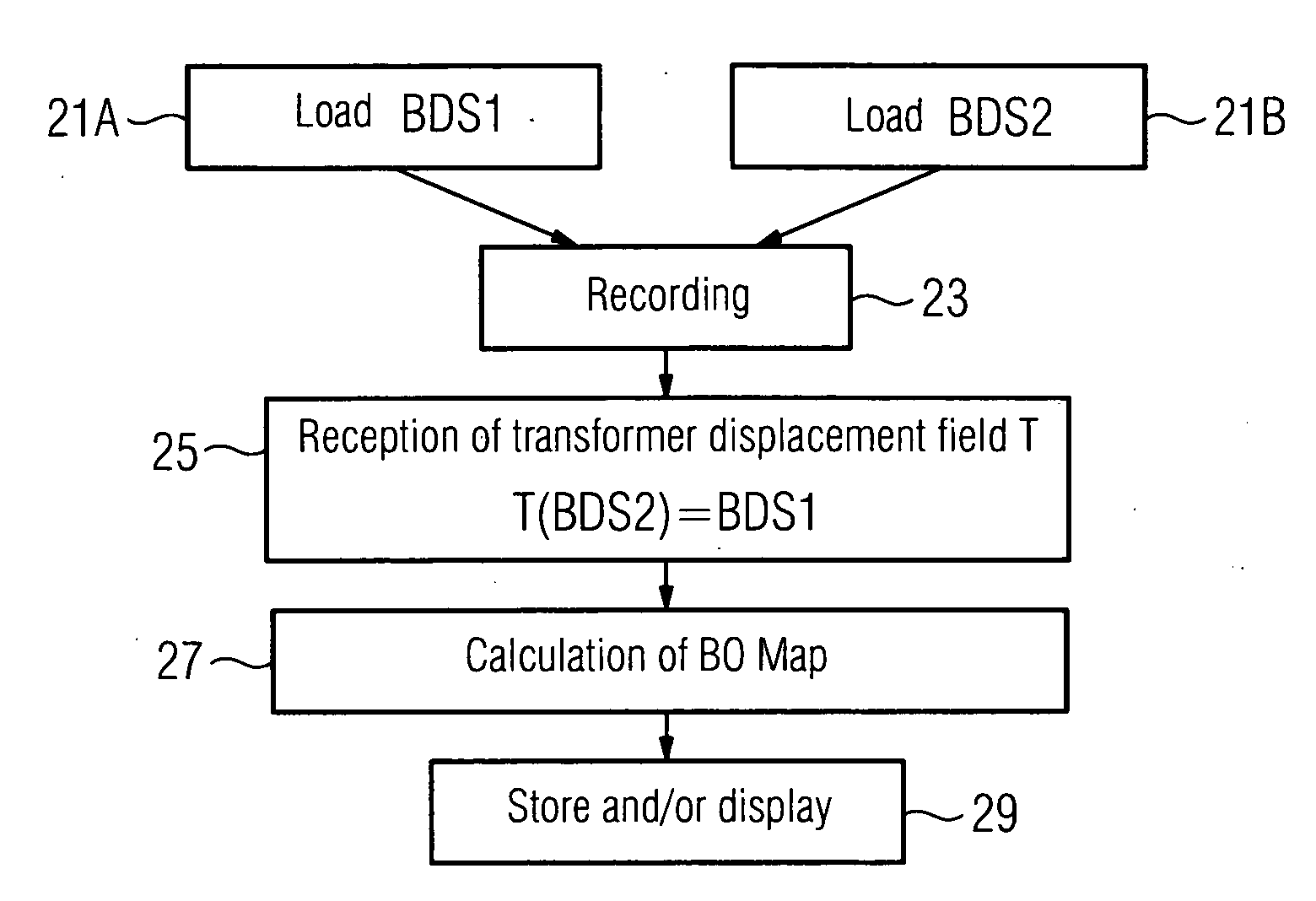

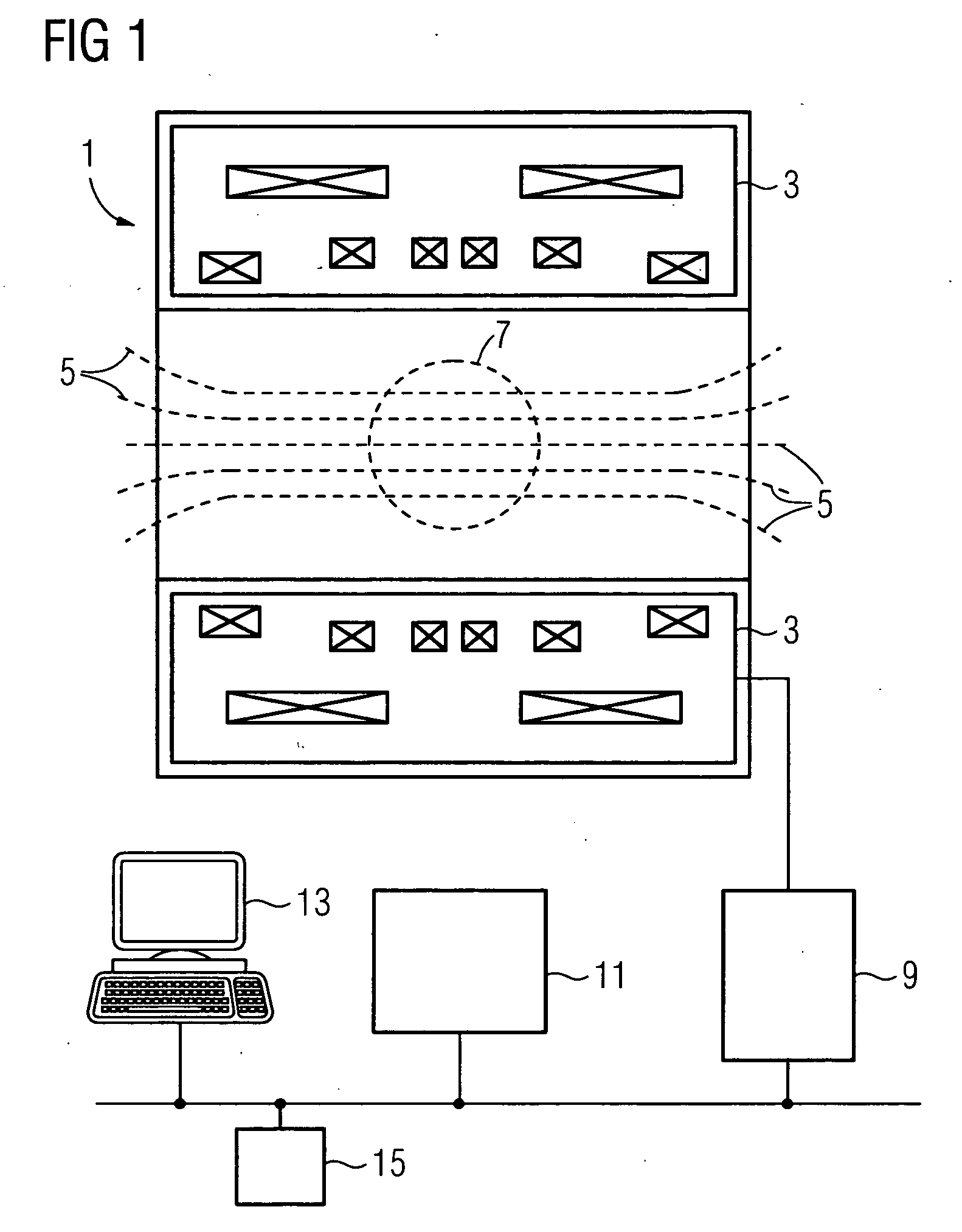

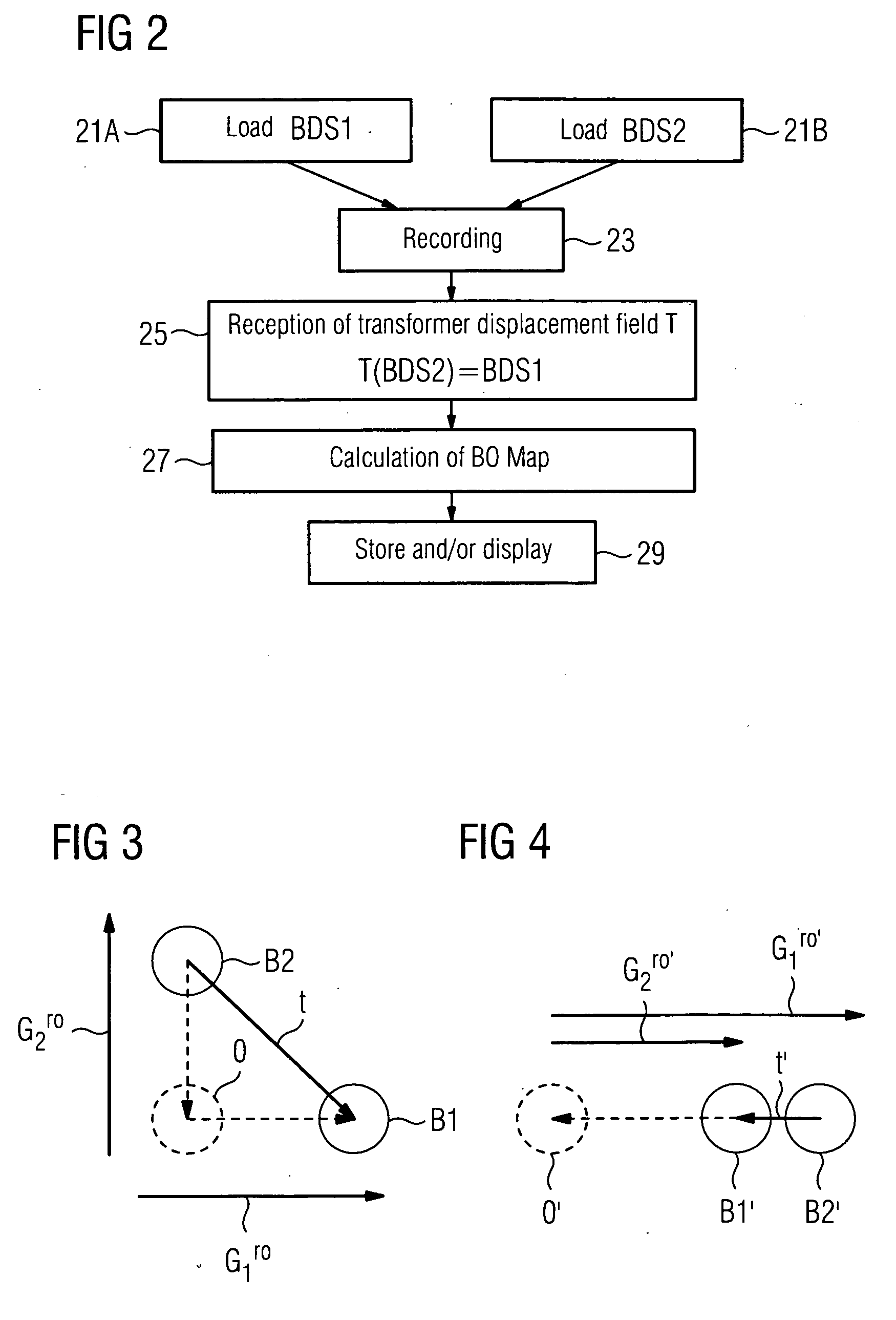

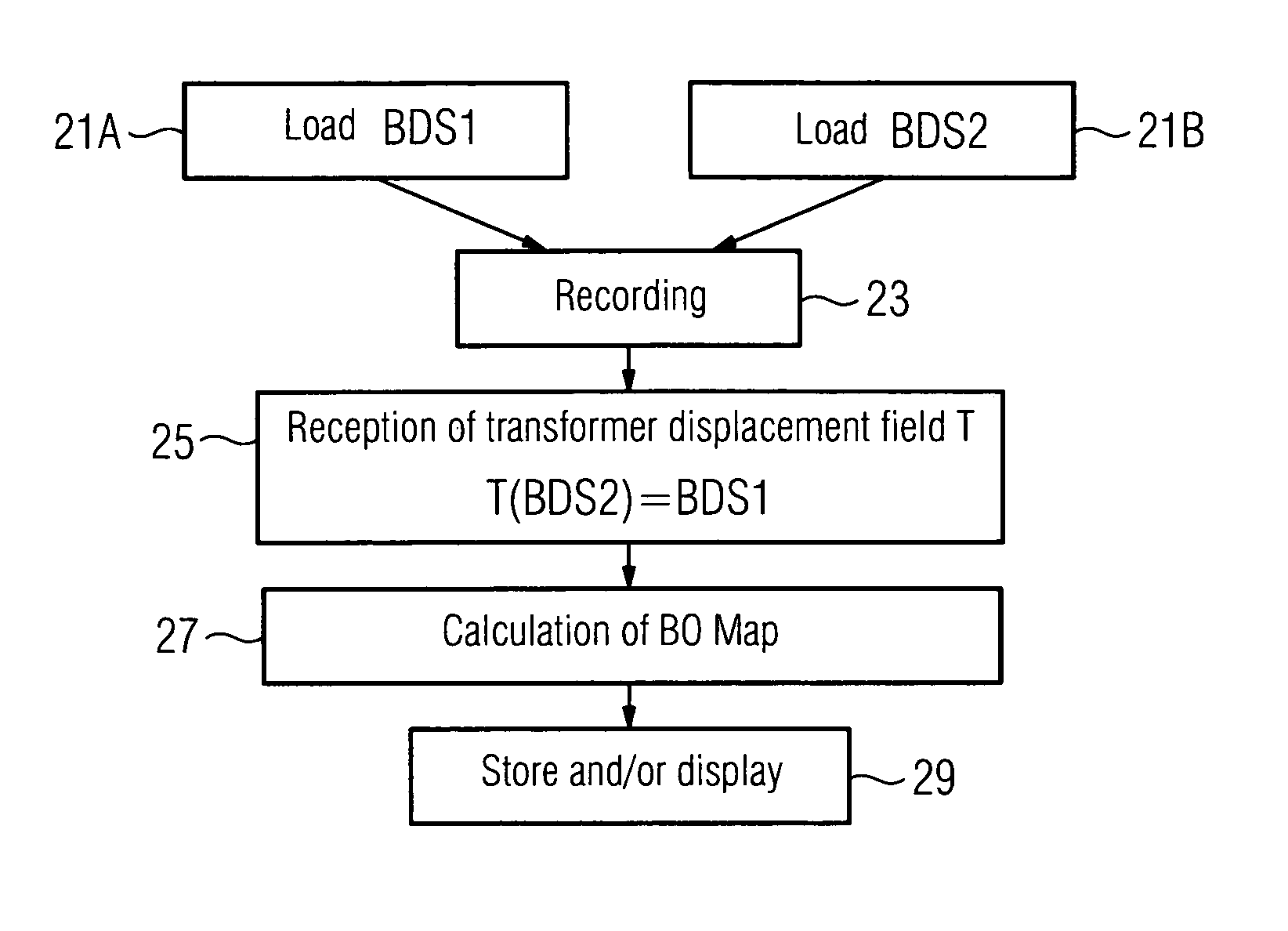

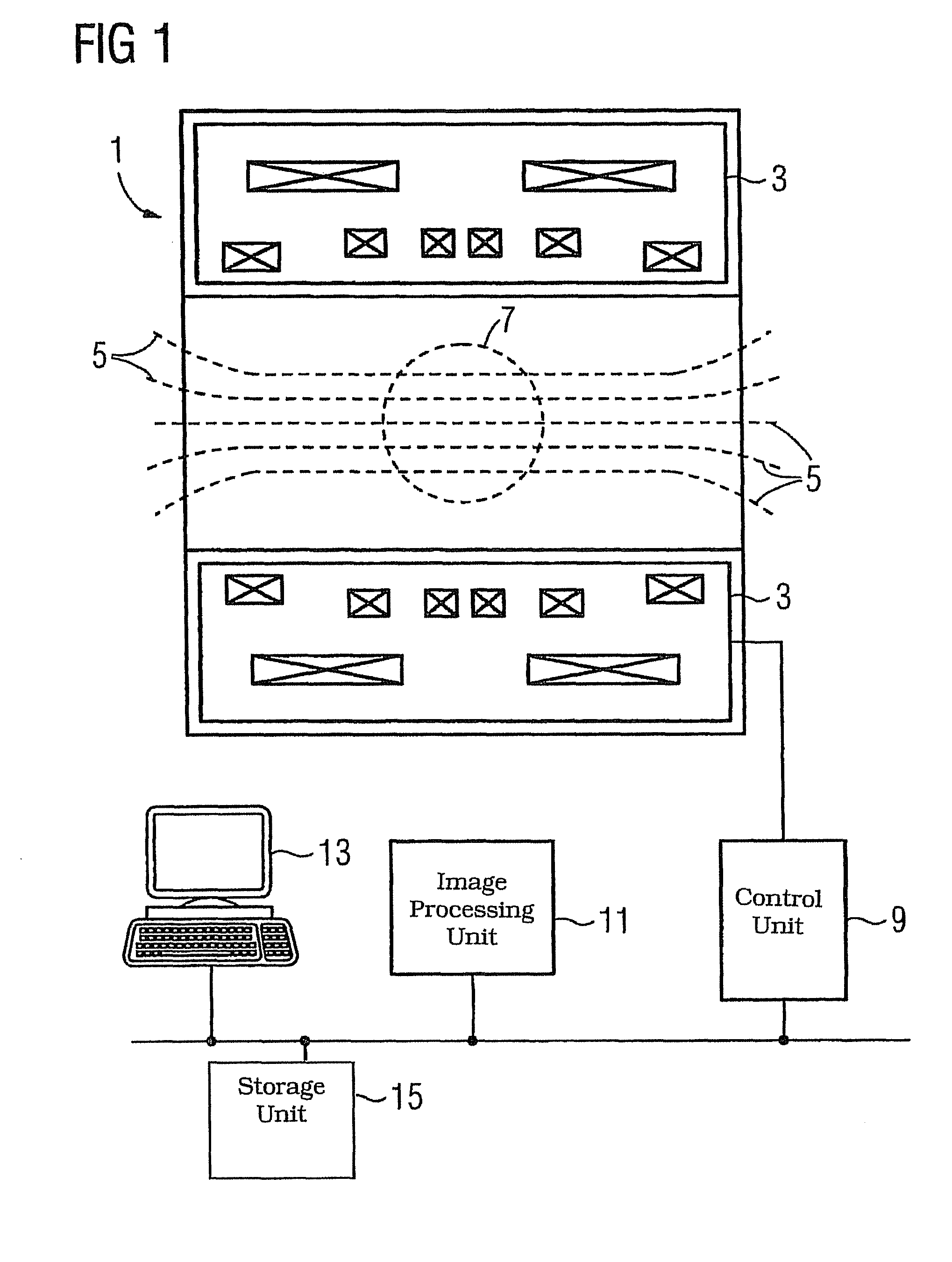

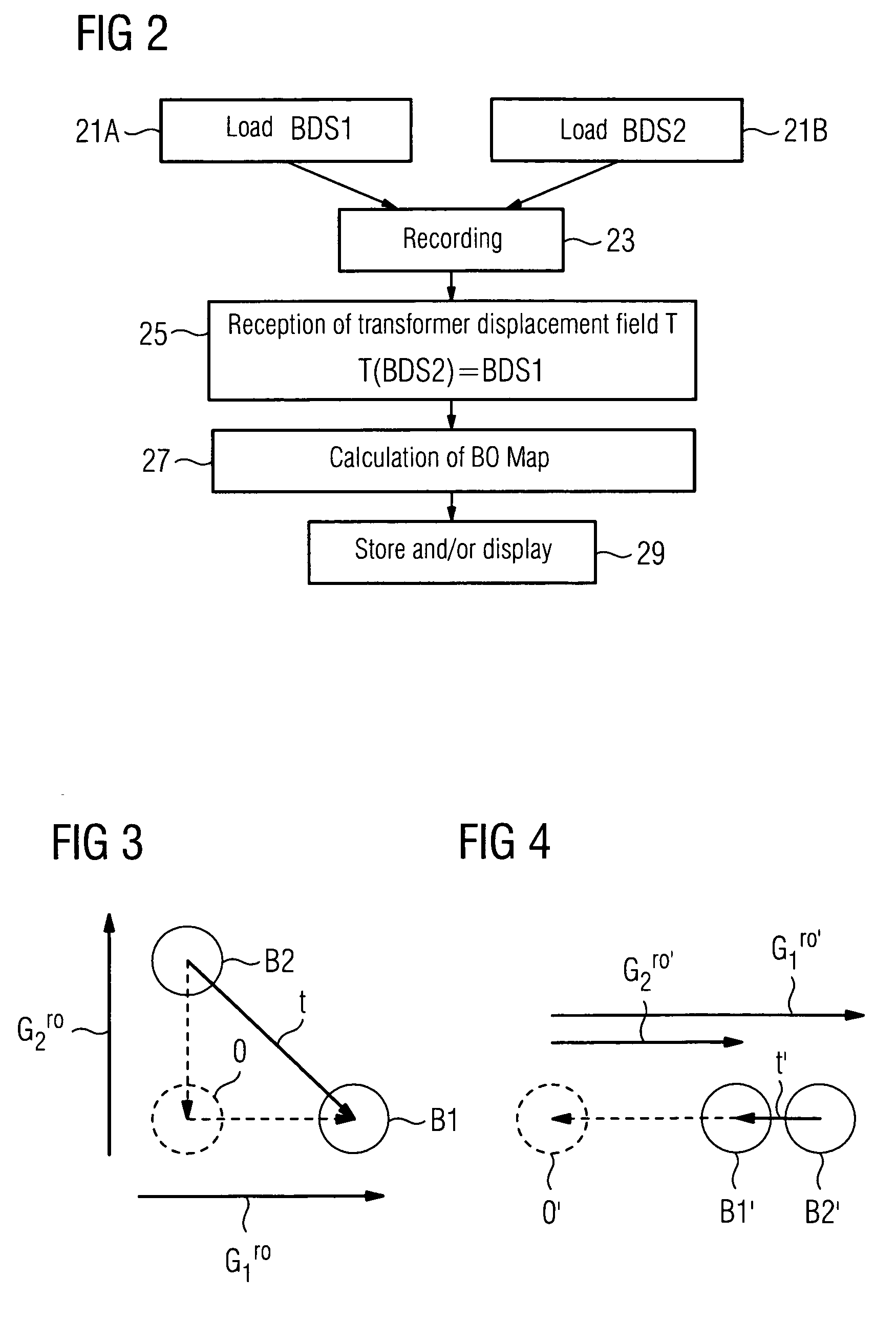

Method for determining local deviations of a main magnetic field of a magnetic resonance device

InactiveUS20090021258A1Determine deviationStable and reliable qualityCharacter and pattern recognitionMeasurements using NMR imaging systemsResonanceImaging data

The invention relates to a method for the determination of local deviations of a main magnetic field of a magnetic resonance device from a setpoint value, comprising: loading of a first image data record of an examination region recorded by means of the magnetic resonance device with a first frequency encoding gradient; loading of a second image data record of the same examination region recorded by means of the magnetic resonance device with a second frequency encoding gradient, with the first and the second frequency encoding gradient being different; reception of a transformation displacement field as the end result of a recording of the first and the second image data record; calculation of local deviations of the main magnetic field from a setpoint value on the basis of the calculated transformation displacement field; and display or storage of the calculated local deviations of the main magnetic field.

Owner:SIEMENS HEALTHCARE GMBH

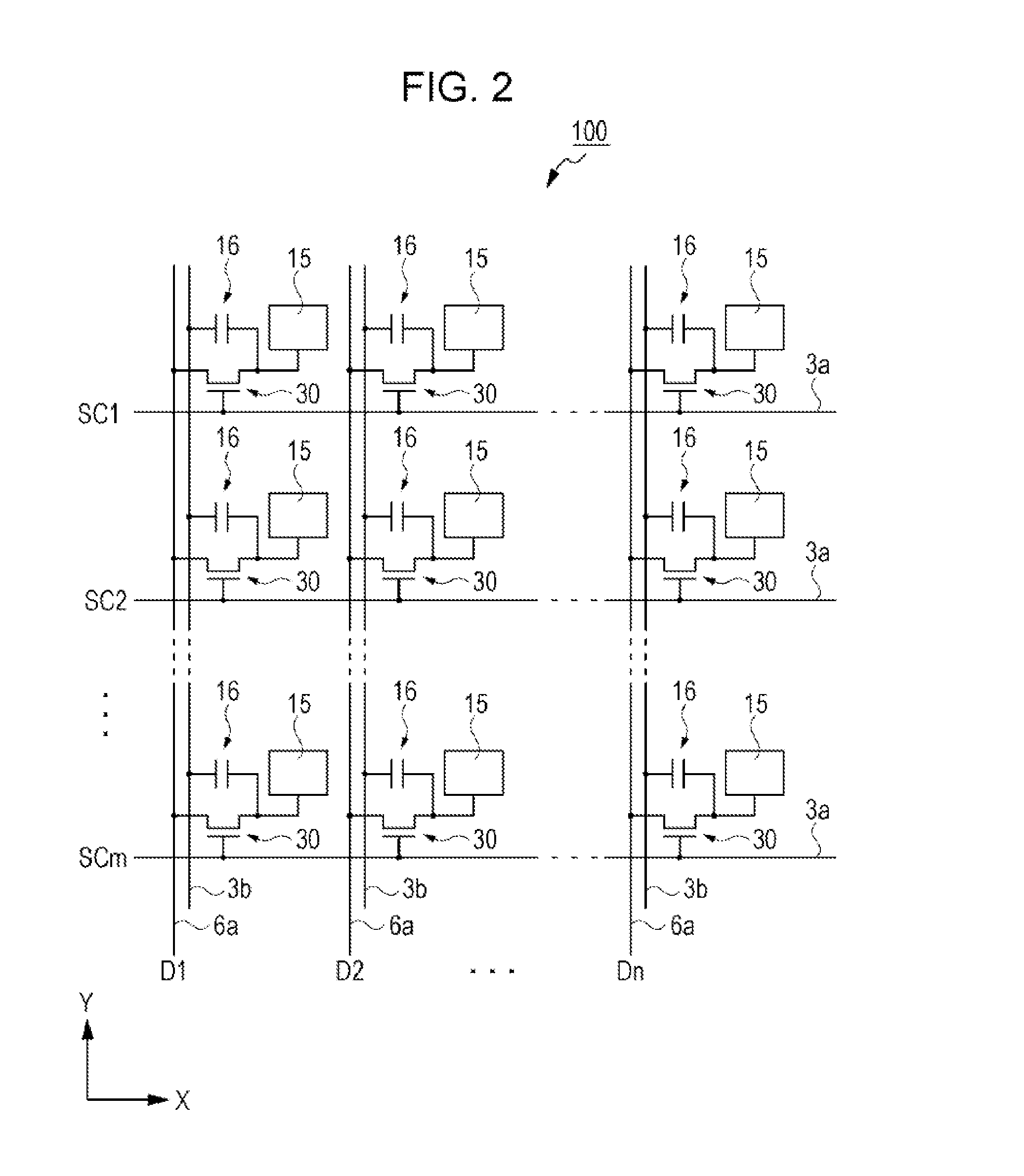

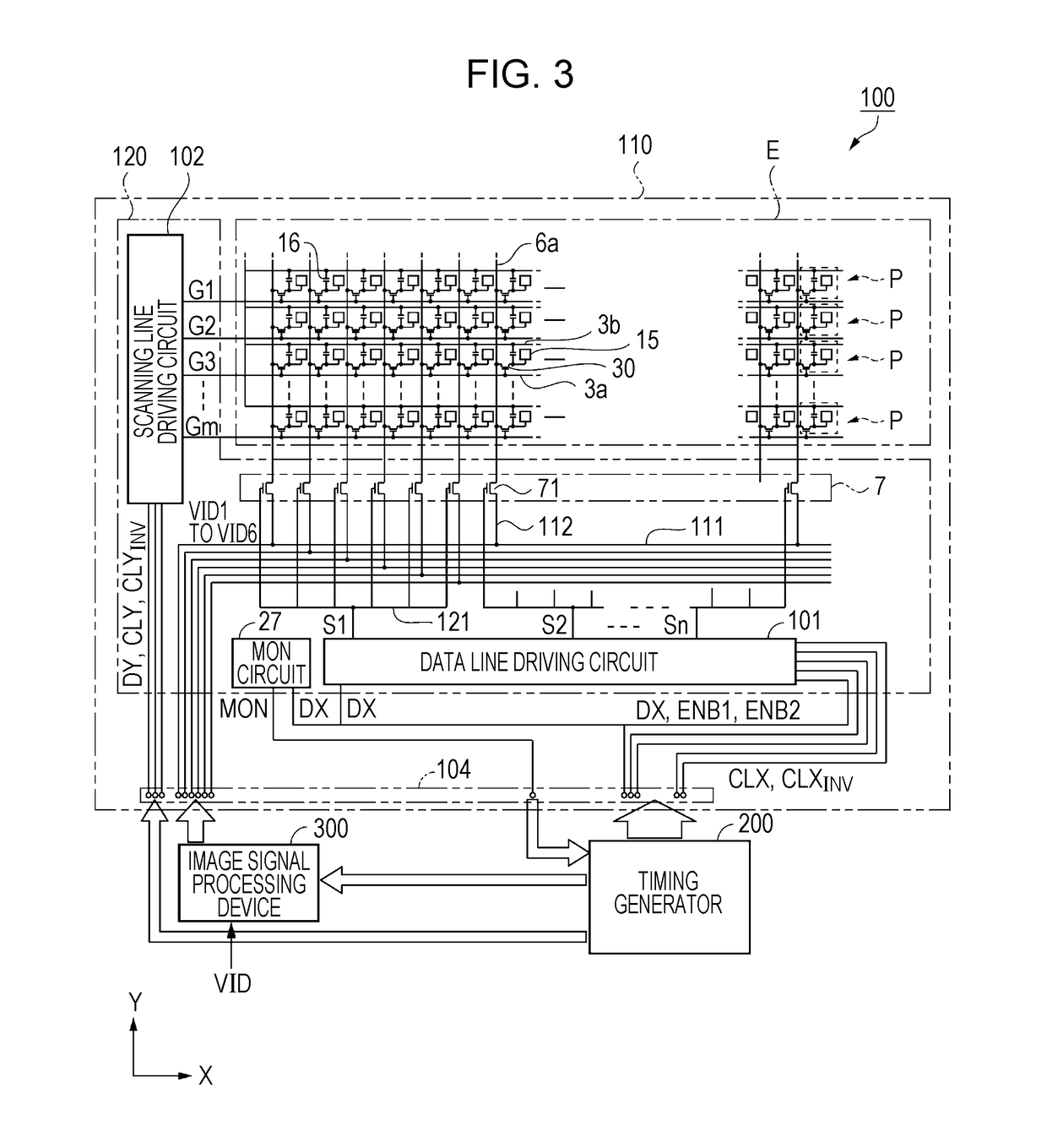

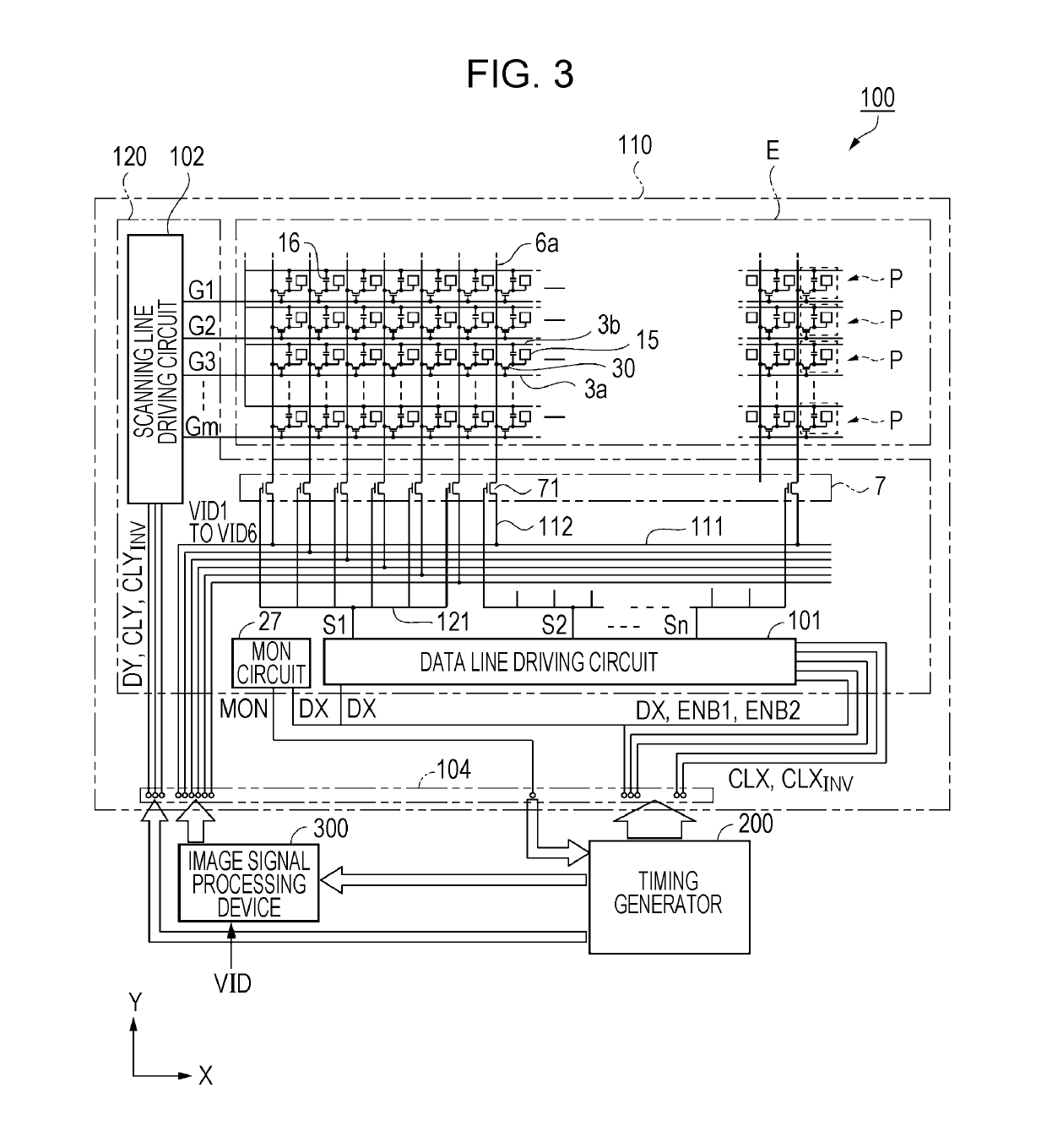

Electro-optical device and electronic apparatus

ActiveUS20180373106A1Good dispersionStable driving stateStatic indicating devicesSolid-state devicesElectronSample and hold

A liquid crystal device as the electro-optical device includes a data line connected to a switching element provided for each pixel; a sample and hold circuit having a sampling transistor, a gate of which is supplied with a selection signal, a source of which is supplied with an image signal, and a drain of which is connected to the data line; and a monitor circuit having a monitoring transistor, a gate of which is supplied with an input signal, and a delay signal indicating the delay amount of the selection signal is sent out from a drain of the monitoring transistor, in which the sampling transistor includes a plurality of transistors connected in parallel to each other, and the monitoring transistor includes one transistor.

Owner:SEIKO EPSON CORP

Production process of high-quality trimethyl orthoacetate

InactiveCN106699522AEfficient removalAvoid Yield ProblemsOrganic compound preparationOximes preparationSolventIon-exchange resin

The invention discloses a production process of high-quality trimethyl orthoacetate. The production process comprises the following steps: performing salification reaction on acetonitrile, methanol and chlorine hydride in the presence of a solvent unsym-trimethyl benzene, so as to obtain ethyleneimine methyl ether hydrochloride; then adding the ethyleneimine methyl ether hydrochloride into a methanol solution; dropwise adding an aminomethanol solution to regulate a pH value, performing alcoholysis reaction to obtain a trimethyl orthoacetate crude product; filtering out solid ammonium chloride, and recycling the solid ammonium chloride; adsorbing filtrate by use of strong-basicity macroporous ion-exchange resin so as to remove chloridion; and finally performing continuous rectification, thereby obtaining a trimethyl orthoacetate product with content greater than 999.5% and yield greater than 85%. The production process is simple in process, the product is stable and reliable, and the used unsym-trimethyl benzene solvent is low in toxicity and safe to use.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

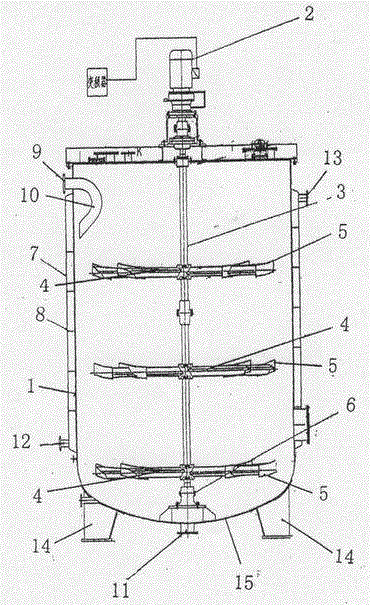

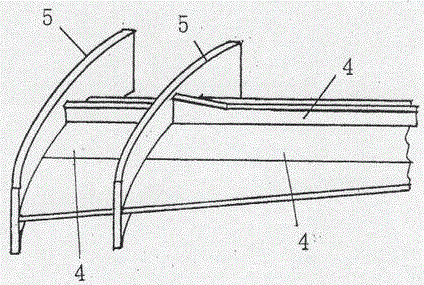

Vertical chemical fiber adhesive mixing stirrer

InactiveCN105478034ASolve the many defects that existStable and reliable qualityRotary stirring mixersFiberBlade plate

The present invention provides a vertical chemical fiber adhesive mixing stirrer, wherein a motor capable of being subjected to speed regulation by frequency variation is arranged above a vertical cylindrical tank, the transmission shaft of the motor is coaxially connected to the stirring shaft rod inside the tank, an upper stirrer, a middle stirrer and a lower stirrer are distributed on the stirring shaft rod, both ends of the three stirrers are respectively provided with two stirring bladders arranged at intervals and having a curve arc structure, the inclination directions of the inclined blade plate of the middle stirrer and the inclined blade plate of the lower stirrer are opposite, the bottom end of the stirring shaft rod is provided with an adjustable spherical bearing pedestal fixed on the elliptical sealing bottom of the tank, a jacket is wrapped on the outer periphery of the tank, the gaps between the jacket and the tank are provided with spiral separation belts, the upper side of the tank is provided with a material inlet, the bottom portion is provided with a material outlet, the lower side of the jacket is provided with a water inlet, and the upper side is provided with a water outlet. According to the present invention, with the structure, the adhesive mixing is uniform, the cooling is rapid, the process is stable during the production process, the yield is high, and the quality is good.

Owner:HUBEI GOLDEN RING

Mask blank for charged particle beam exposure, method of forming mask blank and mask for charged particle beam exposure

InactiveUS7588815B2Stable and reliable qualityReduce internal stressElectric discharge tubesDecorative surface effectsSilicon membraneSoi substrate

The present invention provides a mask blank used for the charged particle beam exposure made by employing an SOI substrate having a silicon membrane higher reliability in quality, without the problem of deformation due to the compression stress of a silicon oxide film as an intermediate layer of the SOI substrate, and provides a method for forming a mask blank and a mask used for the charged particle beam exposure. The mask blank used for the charged particle beam exposure made by employing an SOI substrate having a front-side silicon membrane and a back-side silicon layer with a silicon oxide layer interposed therebetween is characterized in that the back-side silicon layer and the silicon oxide film of said SOI substrate are partially removed to form an opening to be an exposed region and an etching stop layer having lower stress is formed in the opening.

Owner:DAI NIPPON PRINTING CO LTD

Connection structure for woodware part

ActiveUS9976585B2Uniform hardnessIncrease profitRod connectionsStaplesEngineeringMechanical engineering

The present invention provides a connection structure for a woodware part. Firstly, an implanting hole (4) is drilled at an appropriate location on the contact surface of a second woodware part (5), a through embedding hole (9) is drilled on the side surface of the second woodware part (5), the central lines of the implanting hole and the embedding hole are perpendicular to and intersect with each other, a wooden nut (6) is placed into the implanting hole (4), the central line of a nail penetration hole (8) on the wooden nut (6) and the central line of the embedding hole (9) are overlapped, and a round nail (10) is embedded along the embedding hole and the nail penetration hole; a through bolt hole (2) is drilled at a corresponding location on the contact surface of a first woodware part (3), and finally, the connection of the first and second woodware parts is realized by screwing a bolt (1) into the wooden nut through the bolt hole; the problems that firmness and rapidness of the connection structure are not unified and that the woodware part cannot be recycled between old and new woodware of the same model are solved; and the connection structure has the advantages of improving utilization ratio of wood, saving energy and protecting the environment, and manufacturers can realize carbon trading.

Owner:TIAN SHENGJUN

Method for determining local deviations of a main magnetic field of a magnetic resonance device

InactiveUS7812603B2Determine deviationStable and reliable qualityMagnetic measurementsCharacter and pattern recognitionResonanceImaging data

The invention relates to a method for the determination of local deviations of a main magnetic field of a magnetic resonance device from a setpoint value, comprising: loading of a first image data record of an examination region recorded by means of the magnetic resonance device with a first frequency encoding gradient; loading of a second image data record of the same examination region recorded by means of the magnetic resonance device with a second frequency encoding gradient, with the first and the second frequency encoding gradient being different; reception of a transformation displacement field as the end result of a recording of the first and the second image data record; calculation of local deviations of the main magnetic field from a setpoint value on the basis of the calculated transformation displacement field; and display or storage of the calculated local deviations of the main magnetic field.

Owner:SIEMENS HEALTHCARE GMBH

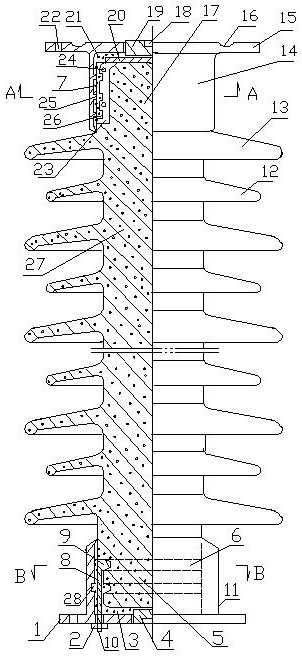

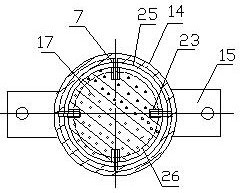

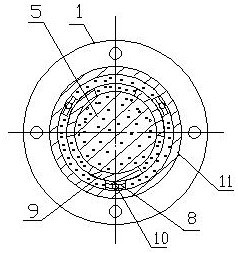

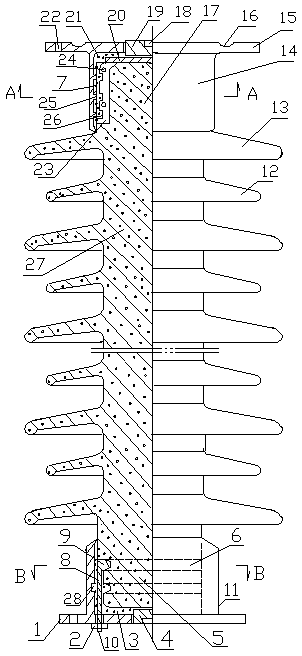

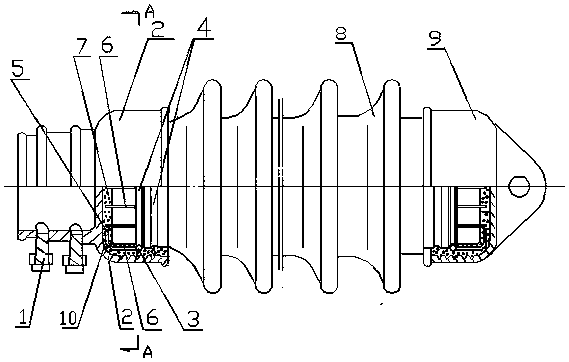

A Strong and Tough Porcelain Porcelain Insulator for High-Voltage Lines

ActiveCN111341507BHigh tensile strengthReduce manufacturing costSupporting insulatorsClaywaresMechanical impactStructural engineering

The invention discloses a strong pillar porcelain insulator for high-voltage lines, which comprises an insulator body, an upper steel cap and a lower steel cap. The insulator body has a bone cylinder, an upper core head and an The lower core head and the bone cylinder are provided with large and small umbrella skirts at intervals, the upper core head is provided with annular grooves and insertion grooves, the inner surface of the upper steel cap is provided with annular bosses at intervals, and the upper steel cap and Connectors are arranged between the upper core heads, annular grooves are arranged at intervals along the axial direction of the lower core head, annular grooves are arranged at intervals on the inner surface of the lower steel cap, and the lower steel cap and the lower core head There are clamping parts between them. The present invention has high mechanical strength, excellent electrical performance, stable and reliable quality, high mechanical impact resistance, strong pollution resistance, small maintenance workload, and low cost, which can fully meet the requirements of 110‑330KV Technical requirements for pillar porcelain insulators for high voltage transmission lines.

Owner:江西省萍乡市玻瓷高压绝缘子有限公司

Method for producing manganese dry cell negative electrode zinc material

A method for manufacturing non lead added anode zinc material for manganese dry batteries comprising compounding a zinc alloy by melting zinc, 0.1 mass % or more and 0.7 mass % or less of bismuth and other impurity elements inevitably contained in zinc in a melting furnace; casting the compounded molten zinc alloy to a molded material in the form of a band or in the form of a bar; rolling the molded material in band form to form a zinc alloy sheet; and punching the rolled zinc alloy sheet in a designated thickness into a designated shape.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

New sealing method of acid-proof flame-proof battery casing

InactiveCN101096127AHigh strengthCorrosion resistance is not lowCell component detailsHeat sealerHeating time

The invention relates to a new sealing method for anti-acid flameproof battery shell. Battery upper cover and groove made of ABS plastic and AS plastic are sealed in thermal melting. At first, electric heating formwork corresponding to battery structure is manufactured and installed on the thermal sealing machine. Then half-finished battery with sealing shell is set on the thermal sealing machine and electric heating plate inserts between the battery upper cover and the battery groove. The sealing position is heated. Heating temperature is controlled in 270deg.C-280deg.C and heating time is in 6-13 seconds. Finally the electric heating plate is drawn out. The battery upper cover and the battery groove are pressed to the proper position so as to accomplish sealing. The invention is used for sealing of battery shell and makes two different plastic melted thermally and bonded. The invention is provided with high producing efficiency and good sealing quality. The invention is favor of circumstance protection.

Owner:JIANGSU SHUANGDENG GROUP

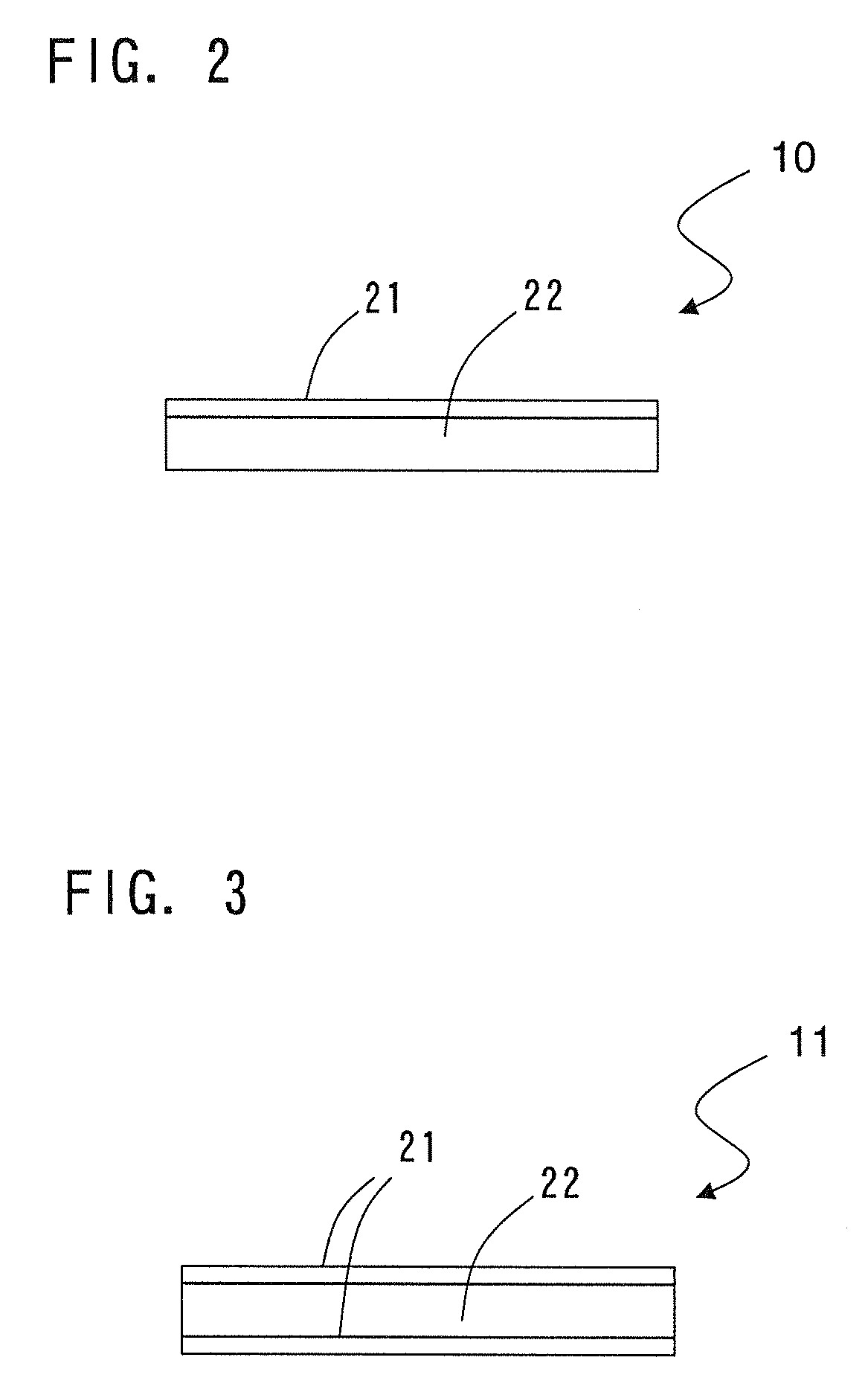

Copper-aluminum composite material for soft package battery connecting piece and production process thereof

InactiveCN110233230AHigh bonding strengthSolve the pack connection problemElectrical equipmentVehicle componentsComposite strengthArgon atmosphere

The invention relates to a copper-aluminum composite material for a soft package battery connecting piece and a production process thereof. The process comprises the following steps of: pretreating the surfaces of copper and aluminum to remove an oxide film on the surface of the metal, performing hot rolling twice under argon atmosphere protection to achieve the thickness of a finished product, and finally, performing heat treatment annealing to increase the bonding strength of a copper-aluminum composite plate, wherein the aluminum plate in the copper-aluminum composite material comprises thefollowing components percentage by weight: 0-0.2% of Fe, 0-0.1% of Si, 0-0.02% of Zn, 0-0.02% of Ga, and the balance being Al, the thickness of the aluminum plate is 3-13mm, the copper plate is red copper with the purity of 99.993 percent, and the thickness of the copper plate is 0.4-2.0mm. The copper-aluminum composite material and the production process thereof effectively solve the problem ofpack connection of the lithium battery pack, and achieve safe, reliable, light and simple series-parallel connection of the lithium battery pack, and the product has the characteristics of high composite strength, no contact resistance between copper and aluminum, and a reliable quality stability point; and moreover, the copper-aluminum composite material for the soft package battery connecting piece and the production process thereof have the advantages of safety, reliability, high composite strength and no contact resistance between copper and aluminum.

Owner:ZHENGZHOU FORCE COPPER

Electro-optical device and electronic apparatus with sampling and monitoring transistors

ActiveUS10495935B2Good dispersionStable driving stateTransistorStatic indicating devicesImage signalElectric equipment

An electro-optical device (e.g., a liquid crystal device) includes a data line connected to a switching element provided for each pixel, a sampling transistor that has a gate supplied with a selection signal, a source supplied with an image signal, and a drain connected to the data line, and a monitoring transistor. A gate of the monitoring transistor is supplied with an input signal. A delay signal indicating a delay amount of the selection signal is sent out from a drain of the monitoring transistor. The sampling transistor includes a plurality of transistors connected in parallel to each other along the data line. The monitoring transistor includes one transistor along the data line.

Owner:SEIKO EPSON CORP

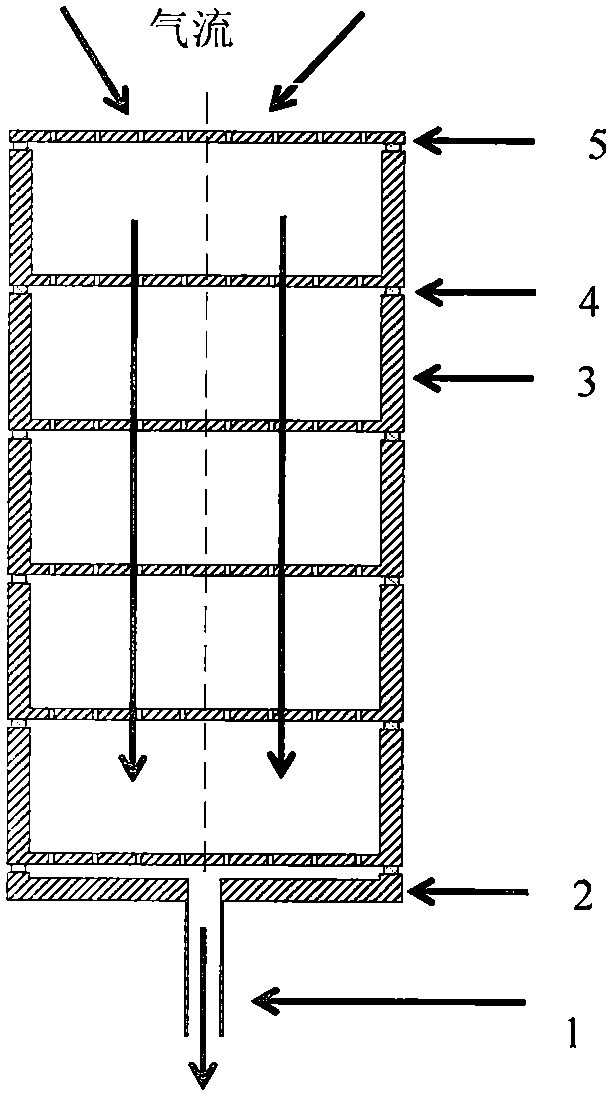

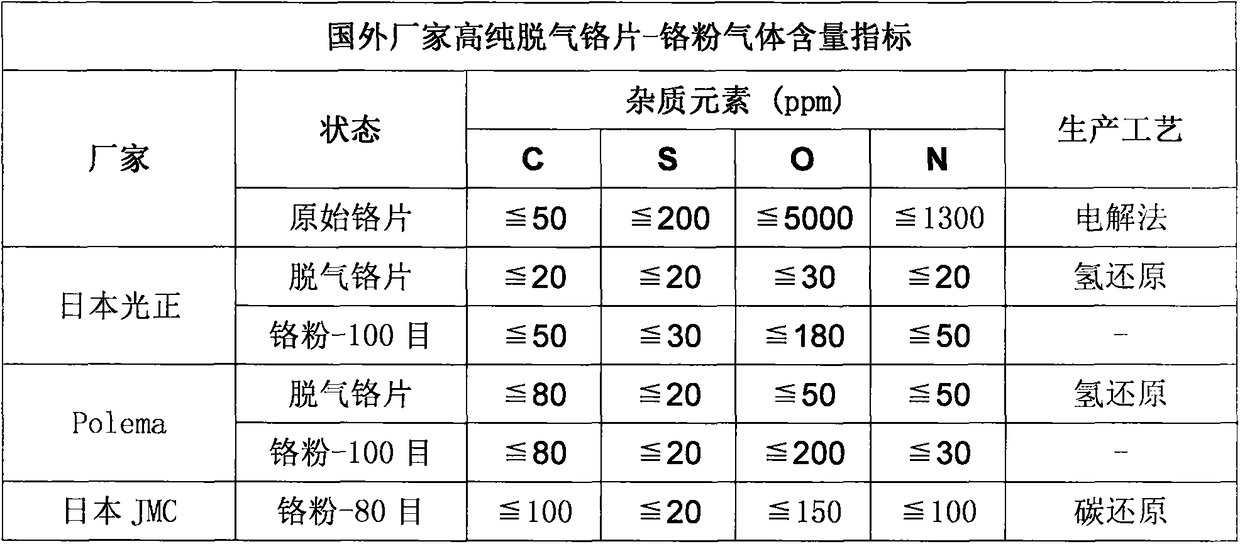

A mass-producible degassing process for electrolytic chromium sheets

The invention belongs to the field of high-temperature smelting of nonferrous metal and provides a novel hydrogen reduction degassing method of an electrolytic chrome sheet. Water is generated through an oxygen reaction of hydrogen and the chrome sheet at the high temperature, and the deoxidizing effect is achieved. The technique comprises the specific steps that a communicating pipe (1) and a base (2) are connected through threads in a welded mode, after it is detected that no gas is leaked, and the base (2) is put in the middle of a furnace bottom cover; then the communicating pipe (1) is connected to the position of a hydrogen outlet in the furnace bottom, and the effect that pipelines are well connected without gas leakage is guaranteed; then a hard sealing ring (4) is put on the base (1), the effect that positions of the periphery of the hard sealing ring (4) are even is guaranteed, and then a crucible (3) is put on the hard sealing ring (4); 3-8 crucibles are installed according to the steps, and finally, an end cover (5) is put on the crucible on the uppermost layer; and vacuumizing is conducted till the pressure is 10 Pa or lower at the room temperature after charging, hydrogen with the purity being 99.9% or higher is introduced, the hydrogen pressure is kept to be positive pressure, that is, -0.1-1.5 Mpa, then heating is slowly conducted till the temperature reaches 1400-1500 DEG C, heat preservation is conducted for 5-20 hrs, then cooling is conducted till the temperature is 50 DEG C or lower under the condition that hydrogen continues to be introduced, and discharging is conducted. Therefore, the technique which can achieve mass product and is used for producing the high-purity low-oxygen electrolytic chrome sheet through hydrogen reduction is achieved.

Owner:北京兴荣源科技有限公司

Liposomes with ginsenoside as membrane material and preparations and use thereof

ActiveUS10639276B2Low efficiencyHigh efficiency and safety and stabilityAntibacterial agentsOrganic active ingredientsMedicineActive agent

Among others, the present invention provides a blank liposome, preparation methods thereof, and a loaded liposome including the blank liposome and an active substance. The liposomes have a membrane comprising lipids and a ginsenoside of Formula I, and may further comprise a surfactant, a heat-sensitive excipient, a pH sensitive material, or an ion additive.

Owner:XIAMEN GINPOSOME PHARM CO LTD

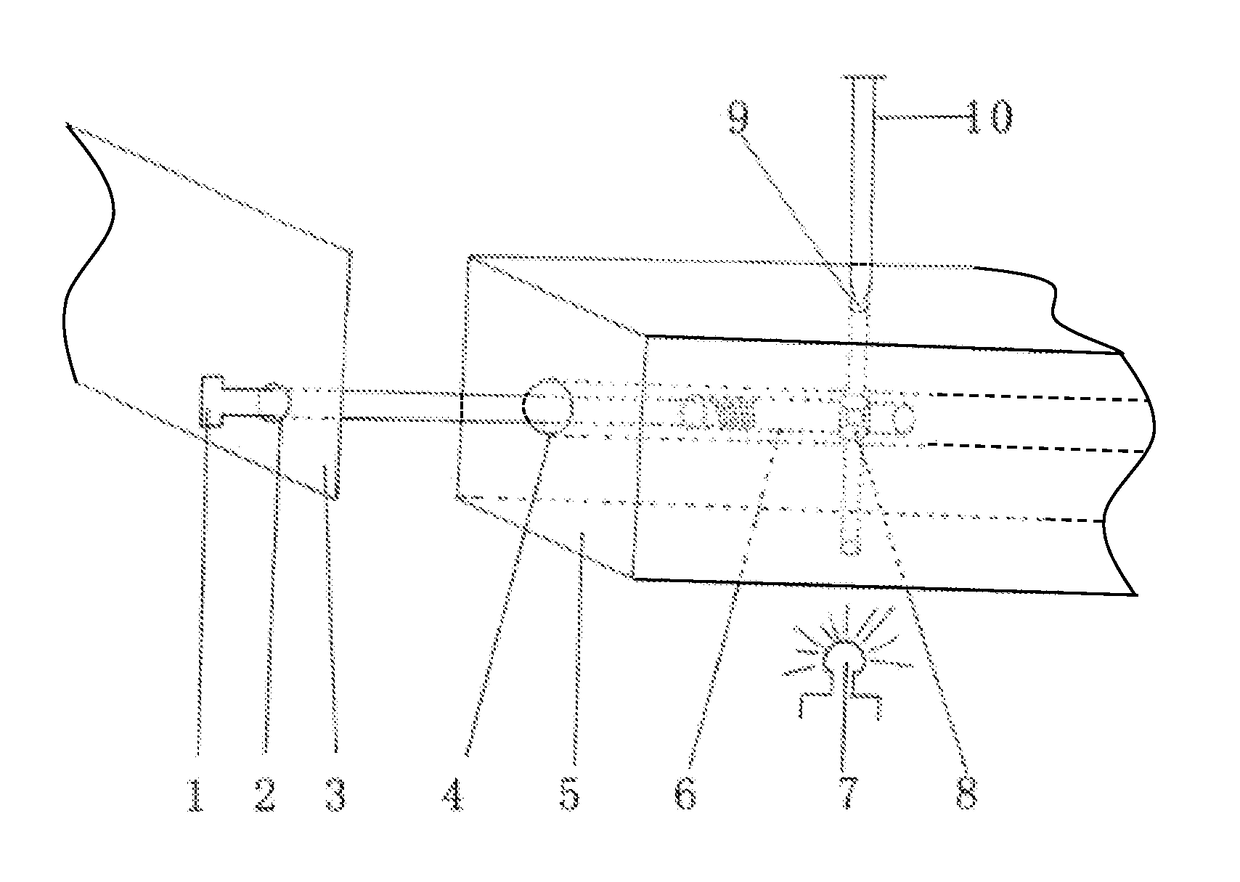

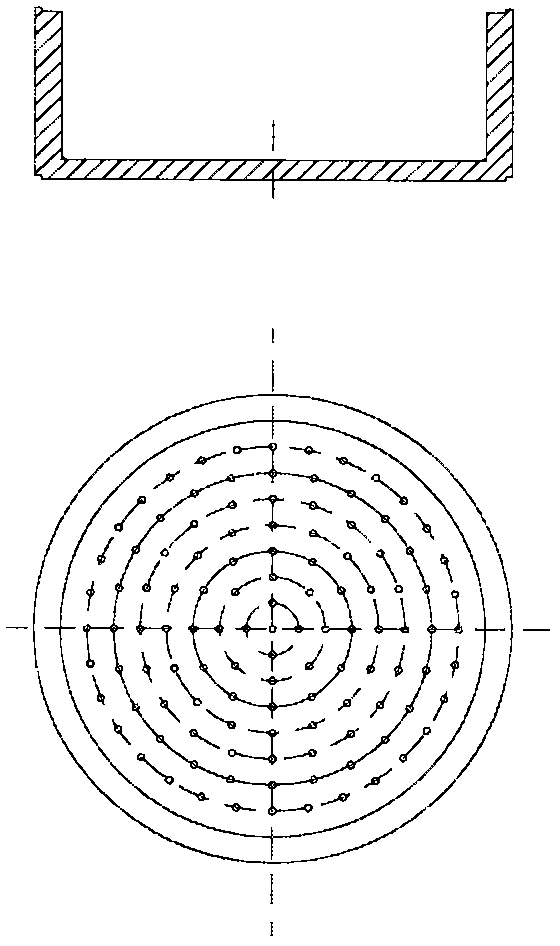

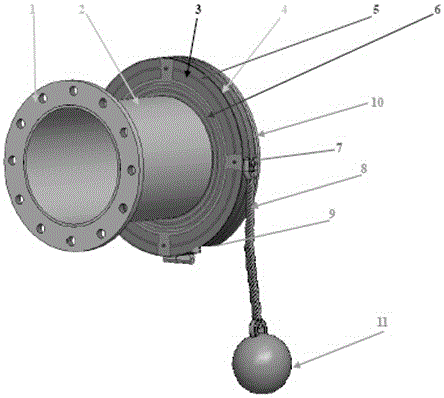

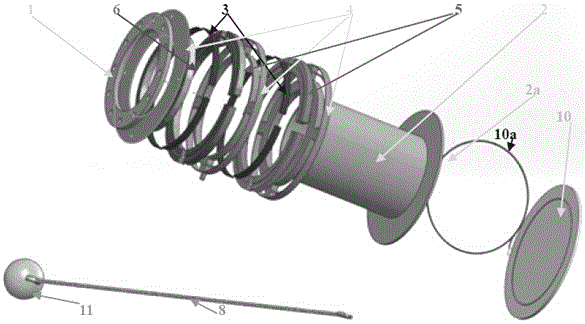

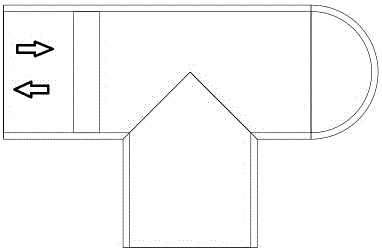

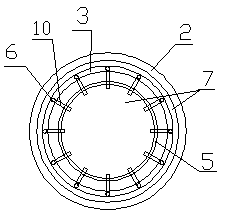

Passive permanent magnetic valve for emergent tide storage for water intake in nuclear industry

ActiveCN105697855AAchieve passive switching actionEasy to makeOperating means/releasing devices for valvesValve housingsSpecial designMagnetic valve

The invention relates to a passive permanent magnetic valve for emergent tide storage for water intake in the nuclear industry. The passive permanent magnetic valve comprises a flange plate (1), a valve guide pipe (2), permanent magnets (3), air gaps (4), magnet yokes (5), a bearing (6), a rotary handle (7), a floating ball rope (8), a positioning pin (9), a magnetic valve deck (10), a sealing ring (10a), a floating ball (11), a magnetic valve deck cover (12) and a valve shell. According to the permanent magnetic valve disclosed by the invention, magnetic path and structure design and verification are performed with a finite element method according to working conditions and practical application requirements. A magnetic path is formed by the permanent magnets, the magnet yokes and magnetic resistance components to control the operation of the valve. No power or manual operation is needed, and the valve is opened and closed according to requirements under special design. The passive permanent magnetic valve is simple in structure, low in manufacture cost, outward-leakage-free, good in sealing performance, high in reliability and good in corrosion-resistance, and has a passive property. The passive permanent magnetic valve is especially applicable to passive automatic water intake in a nuclear power plant and gas and liquid fluid transportation under various emergency conditions.

Owner:SHENYANG HUADA R & D CENT OF POLYMER MATERIALS CO LTD

Tough column-type porcelain insulator for high-voltage line

ActiveCN111341507AHigh tensile strengthIncreased torsional strengthSupporting insulatorsClaywaresMechanical impactEngineering

The invention discloses a tough column-type porcelain insulator for a high-voltage line. The insulator comprises an insulator body, an upper steel cap and a lower steel cap. The insulator body is provided with a bone column body, and an upper core head and a lower core head which are integrally connected with the two ends of the bone column body. Large umbrella skirts and small umbrella skirts arearranged on the bone column body at intervals. An annular groove and a plug-in slot are formed in the upper core head. Annular bosses are arranged on the surface of the inner side of the upper steelcap at intervals. A plug connector is arranged between the upper steel cap and the upper core head. Annular clamping slots are formed in the lower core head at intervals in the axial direction of thelower core head. Annular trenches are formed in the surface of the inner side of the lower steel cap at intervals. A clamping piece is arranged between the lower steel cap and the lower core head. Thetough column-type porcelain insulator has the advantages of high mechanical strength, excellent electrical performance, good quality stability and reliability, high mechanical impact resistance, highpollution resistance, small maintenance workload and low cost, and can completely meet the technical requirements on a column-type porcelain insulator for a 110-330KV high-voltage power transmissionline.

Owner:江西省萍乡市玻瓷高压绝缘子有限公司

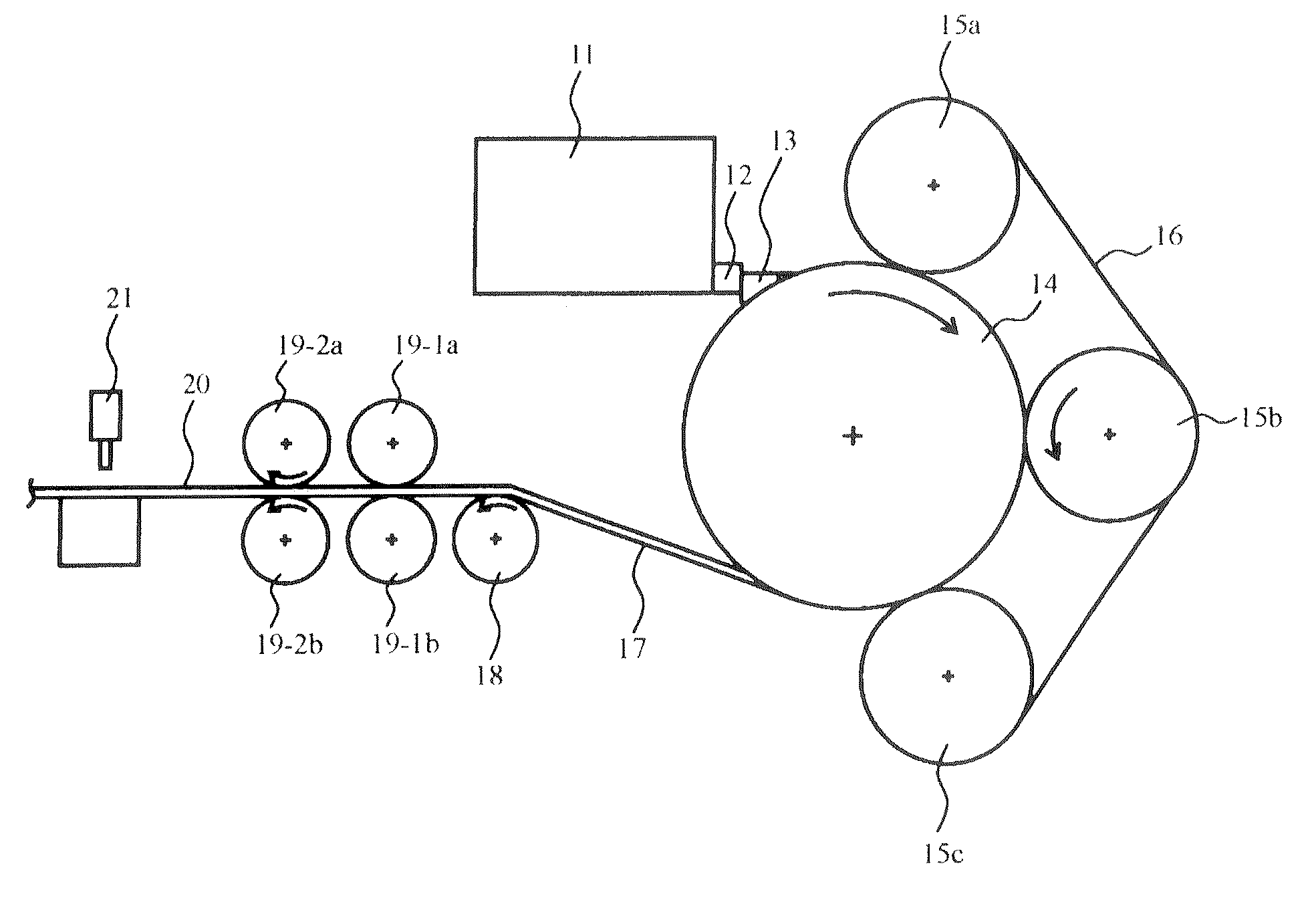

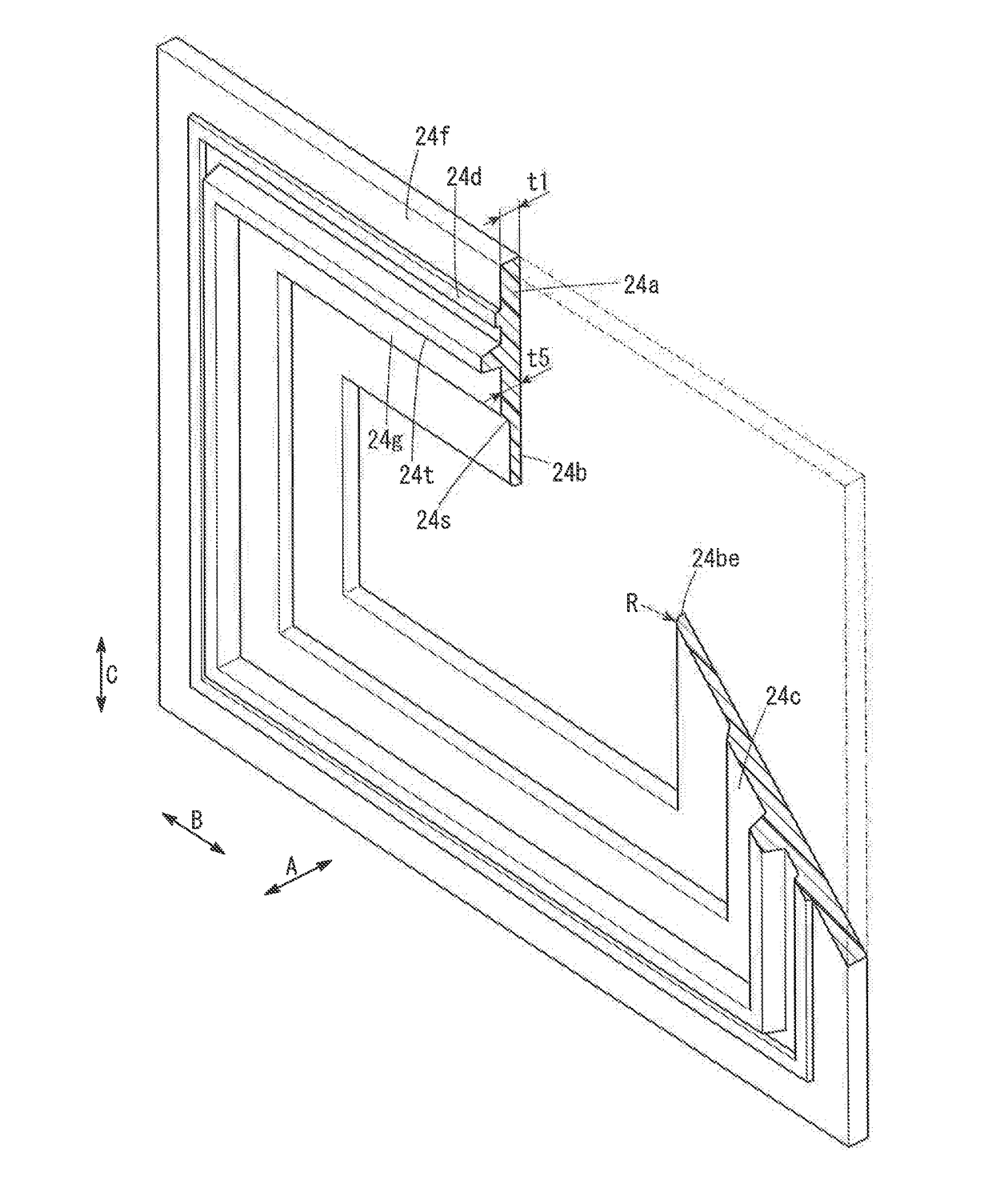

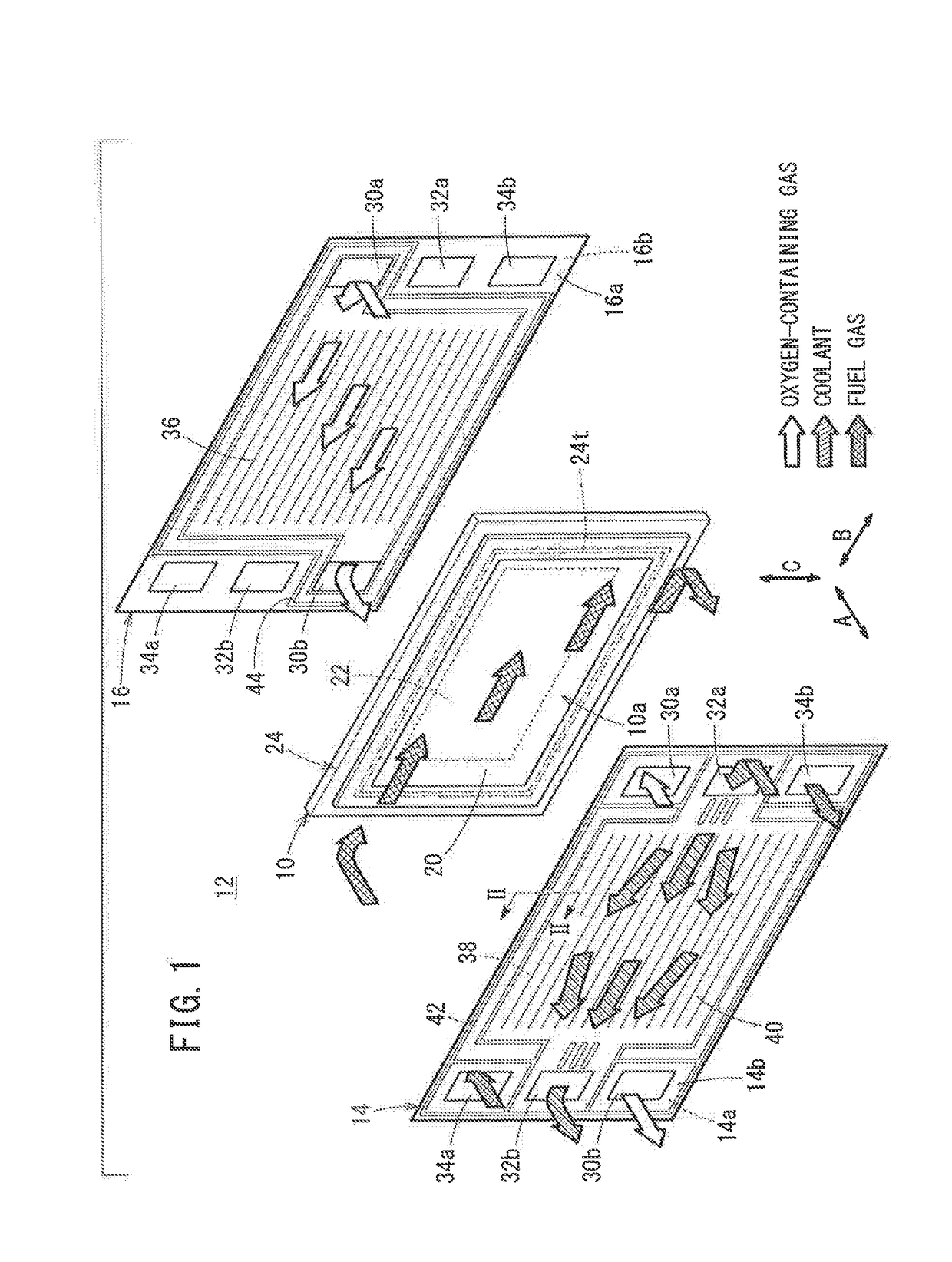

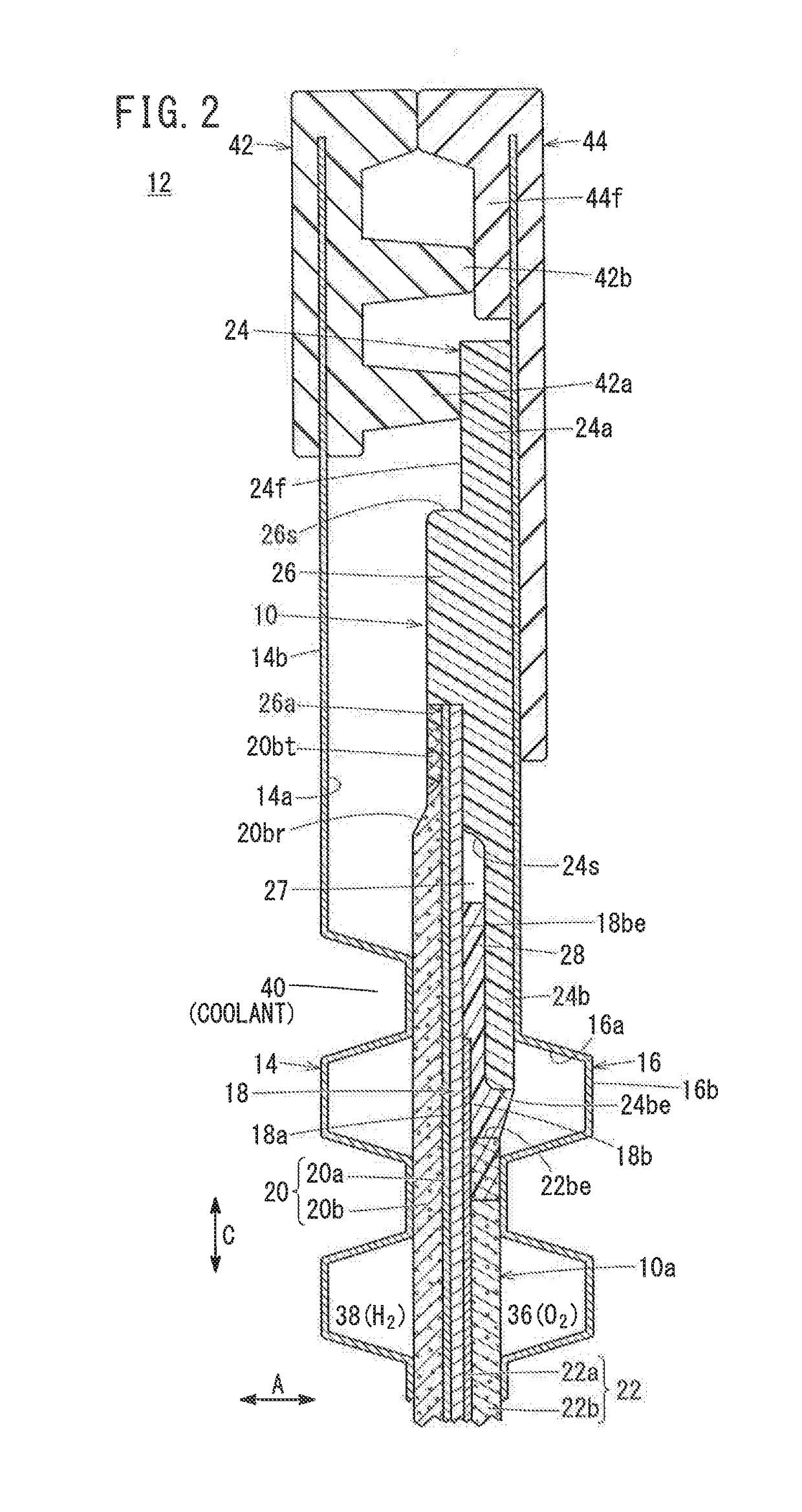

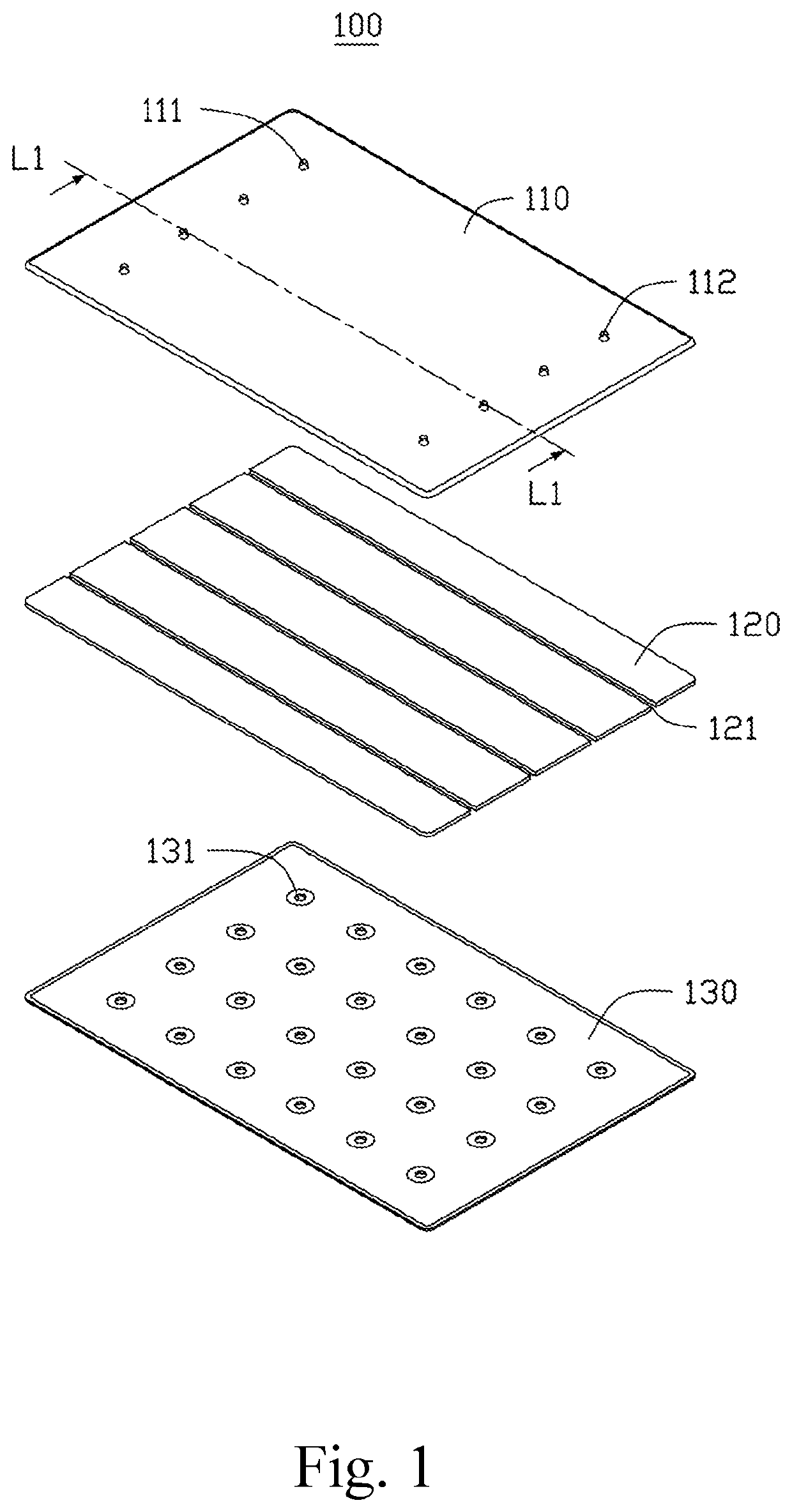

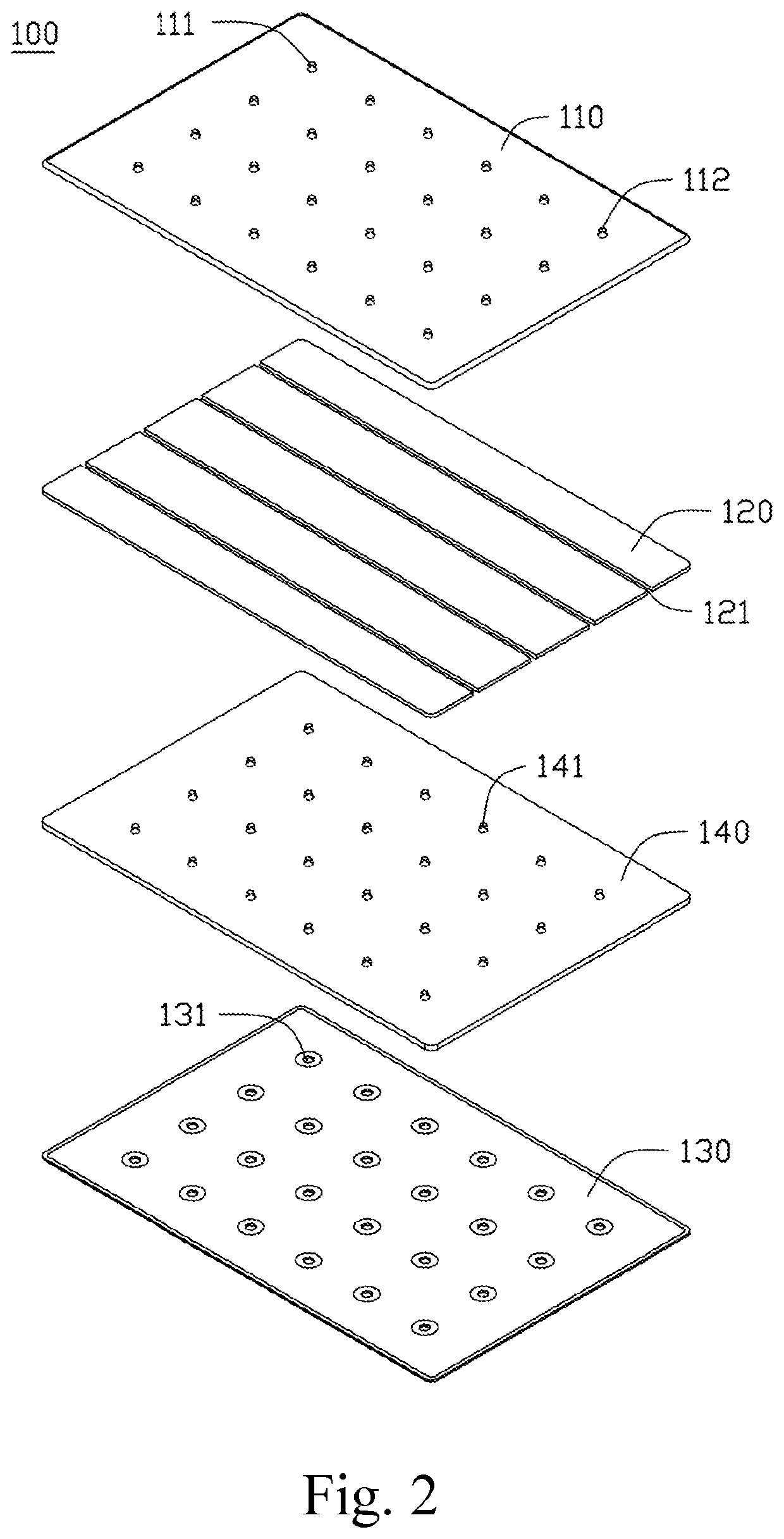

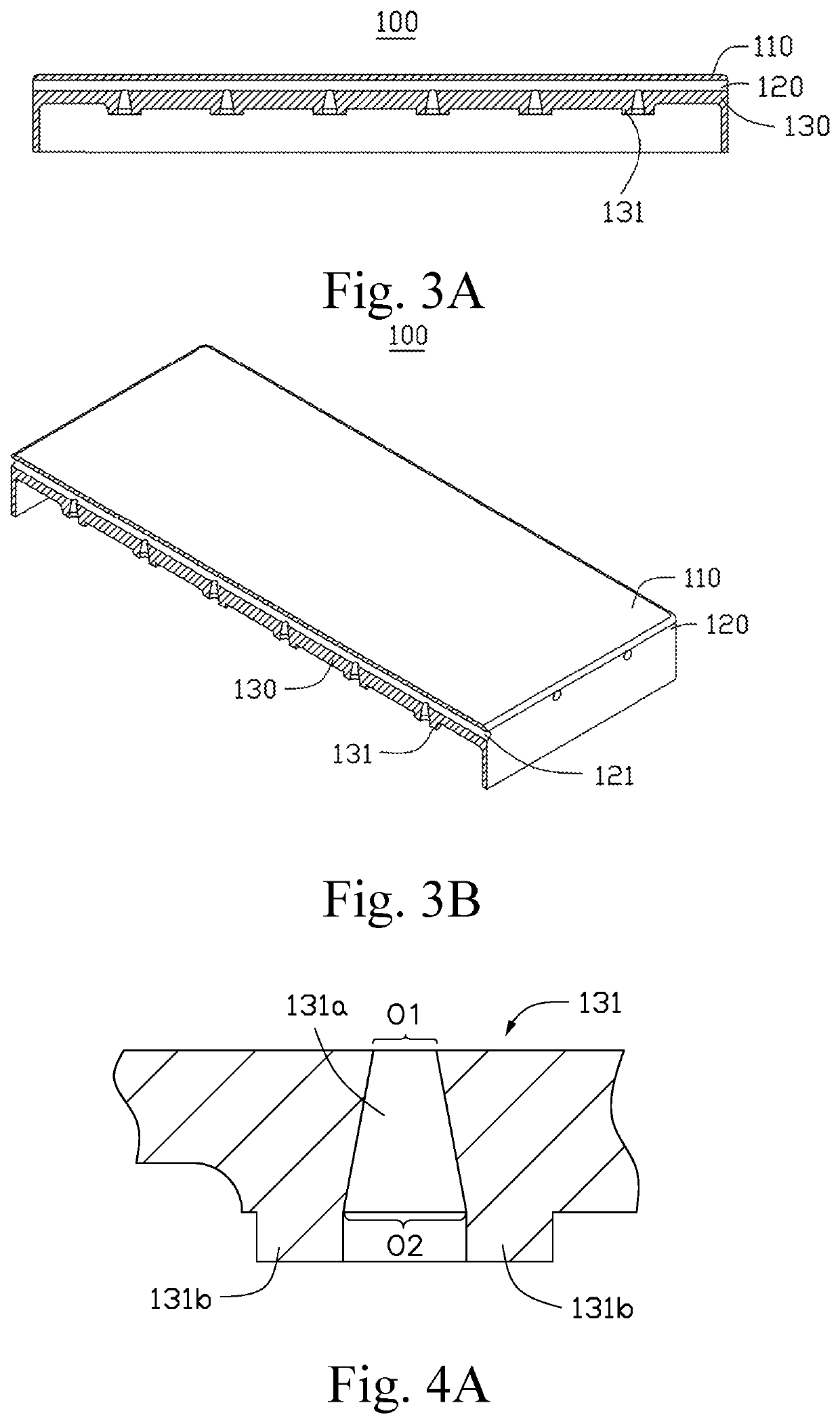

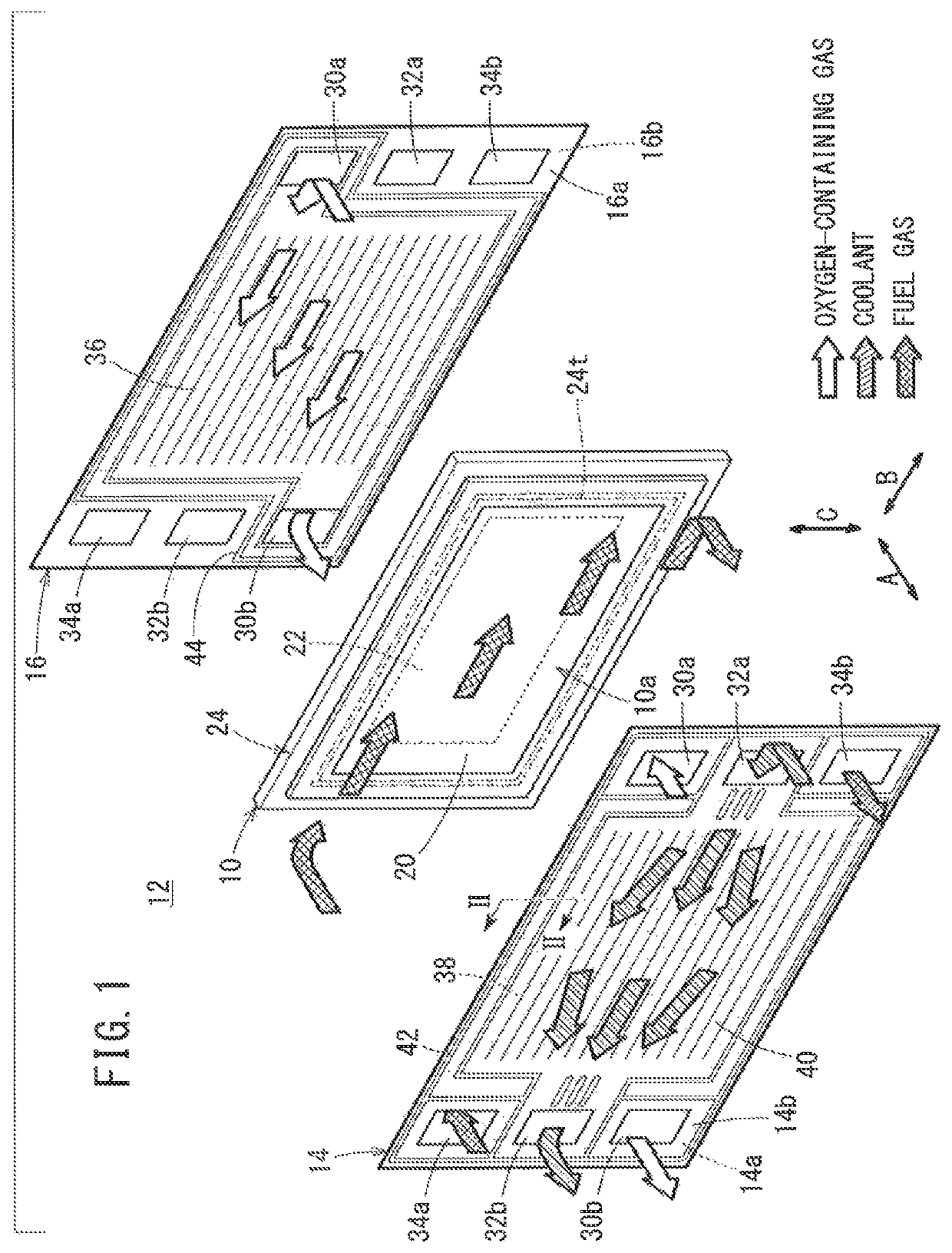

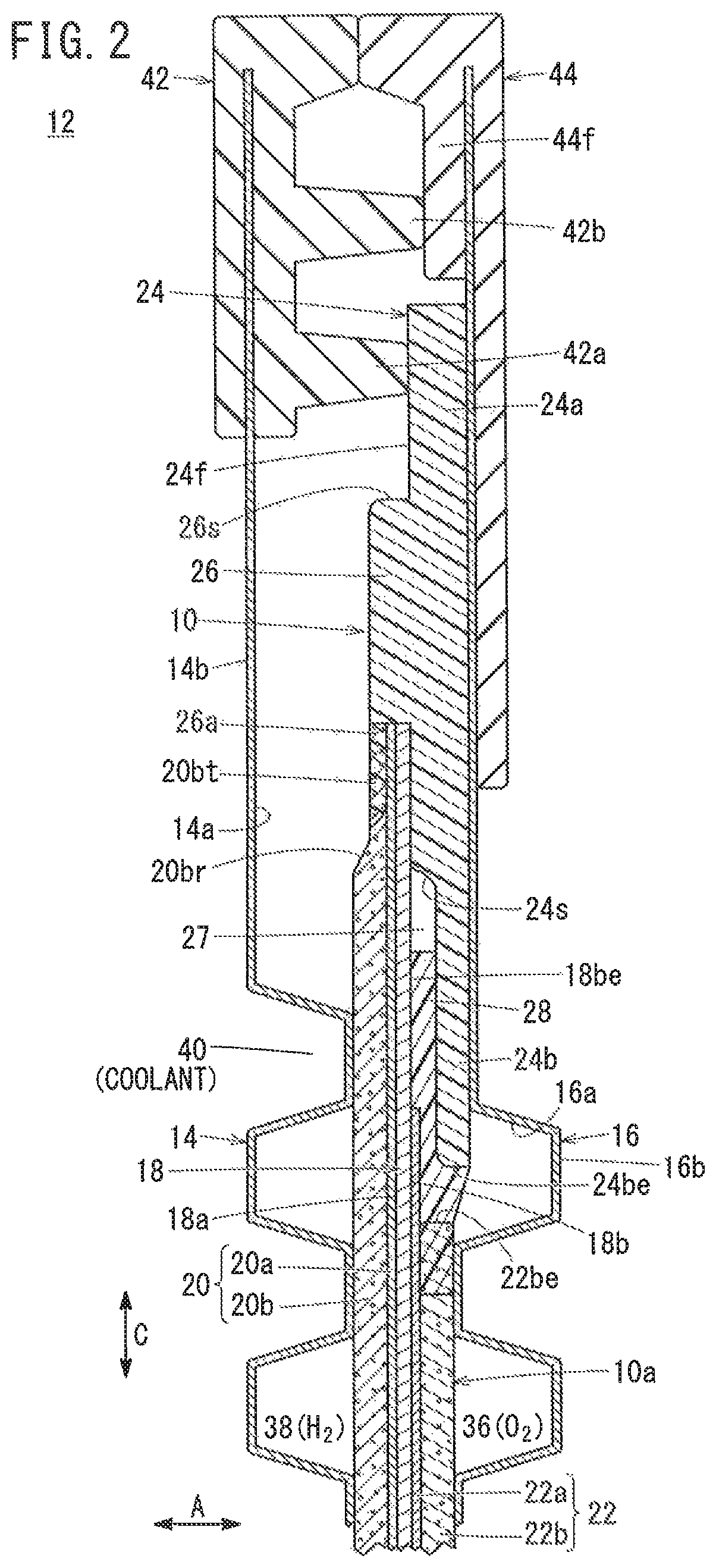

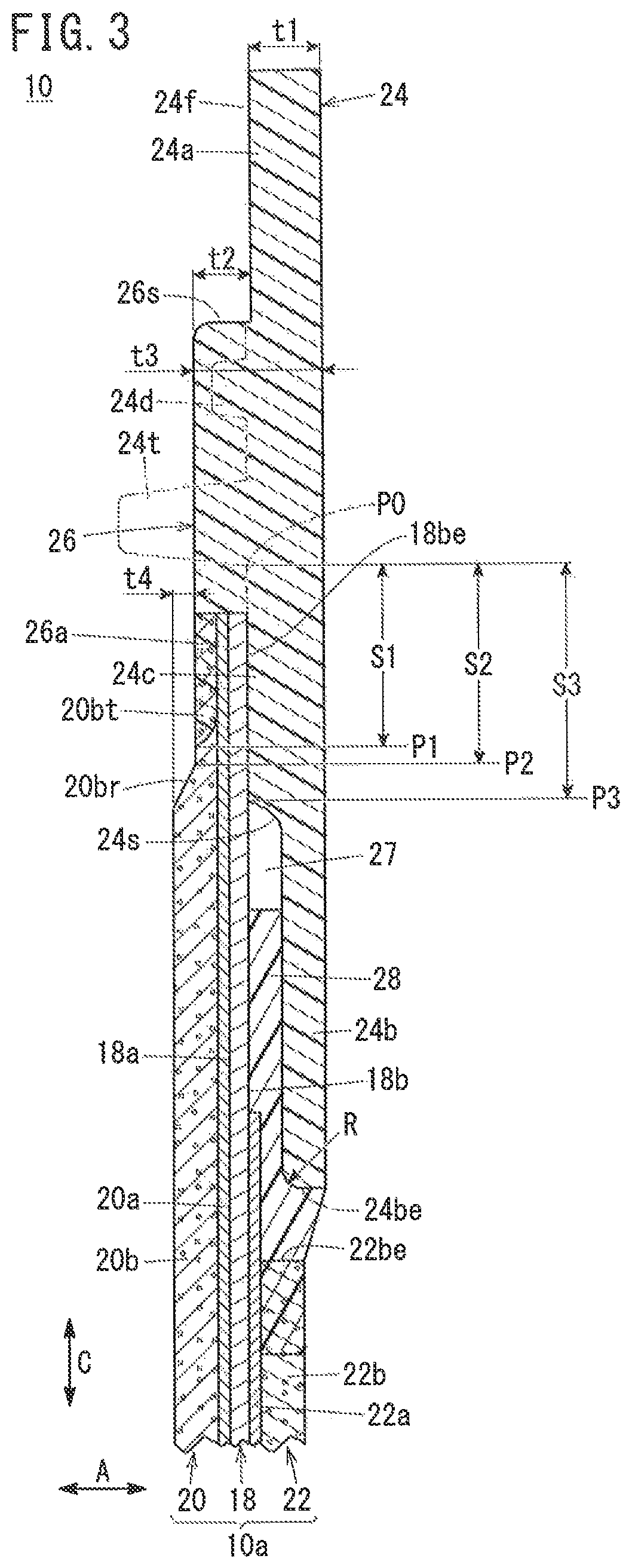

Resin frame equipped membrane electrode assembly for fuel cell and method of producing the same

ActiveUS20170117560A1Avoid deformationAvoid it happening againFinal product manufactureMotive system fuel cellsFuel cellsEngineering

A resin frame equipped membrane electrode assembly includes an MEA having different sizes of components, and a resin frame member. A resin melt portion is provided for the resin frame member. The inside of a first gas diffusion layer is impregnated with resin as a part of the resin melt portion. A thin portion is provided at an outermost peripheral portion of the resin frame member through a step at an outermost peripheral portion of the resin melt portion, and the thin portion is thinner in a thickness direction than the resin melt portion.

Owner:HONDA MOTOR CO LTD

Connection structure for woodware part

ActiveUS20160348704A1Uniform hardnessIncrease profitRod connectionsStaplesMechanical engineeringNail penetration

The present invention provides a connection structure for a woodware part. Firstly, an implanting hole (4) is drilled at an appropriate location on the contact surface of a second woodware part (5), a through embedding hole (9) is drilled on the side surface of the second woodware part (5), the central lines of the implanting hole and the embedding hole are perpendicular to and intersect with each other, a wooden nut (6) is placed into the implanting hole (4), the central line of a nail penetration hole (8) on the wooden nut (6) and the central line of the embedding hole (9) are overlapped, and a round nail (10) is embedded along the embedding hole and the nail penetration hole; a through bolt hole (2) is drilled at a corresponding location on the contact surface of a first woodware part (3), and finally, the connection of the first and second woodware parts is realized by screwing a bolt (1) into the wooden nut through the bolt hole; the problems that firmness and rapidness of the connection structure are not unified and that the woodware part cannot be recycled between old and new woodware of the same model are solved; and the connection structure has the advantages of improving utilization ratio of wood, saving energy and protecting the environment, and manufacturers can realize carbon trading.

Owner:TIAN SHENGJUN

A light-weight and high-strength column-type porcelain insulator

ActiveCN107910139BSufficient supplyFully oxidizedSupporting insulatorsClaywaresMechanical impactElectrical performance

The invention discloses a light and high-strength column-type porcelain insulator. The light and high-strength column-type porcelain insulator comprises an insulator body, an upper steel cap and a lower steel cap, wherein the upper steel cap and the lower steel cap are respectively glued and connected with two ends of the insulator body by an adhesive layer, a reinforcement rack is arranged in theadhesive layer, and the insulator body mainly comprises 20-40wt% of calcined aluminum bauxite, 20-40wt% of Shaanxi clay, 8-25wt% of Pingxiang south village porcelain clay, 2-5wt% of Fujian porcelainclay, 10-20wt% of feldspar, 1-3wt% of peat soil and 1-3wt% of multi-component accelerant formed from JS-silicon-aluminum. The light and high-strength column-type porcelain insulator is prepared by uniformly mixing and ball-milling the main raw materials, adding the peat soil and the multi-component accelerant for ball-milling and mixing, and performing vacuum pugging, profile blank formation, glazing, sanding and high-temperature baking. The light and high-strength column-type porcelain insulator is high in mechanical strength, excellent in electrical performance, high in mechanical impact-resistant capability and high in pollution-resistant capability, and the requirement of the porcelain insulator for an electrical contact network can be completely met.

Owner:江西利峰电瓷制造有限公司

Cell culture device and electromagnetic stimulation cell culturing system having the same

InactiveUS20200308525A1Stable and reliable qualityImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiophysicsBiomedical engineering

A cell culture device comprises a top layer, a diffusion layer, and a suspension layer. The diffusion layer comprises at least one diffusion channel. The suspension layer comprises multiple suspension units. The multiple suspension units are connected to the diffusion channel. A fluid is conducted through the diffusion channel and flow into the suspension units for drop suspended. Cells are cultivated in the fluid suspended in the suspension unit. The cell culture device can be used in an electromagnetic cell culturing system. The electromagnetic cell culturing system is a combination of hanging drop method, microfluidic technology and electromagnetic stimulation. The electromagnetic cell culturing system can improve the growth of cells and also is capable of continuously providing culture medium into the cell culture device. The cell culture device can be used to cultivate large quantity of cells with high productivity and stable quality.

Owner:NAT INST OF HEALTH REPRESENTED BY THE SEC OF THE DEPT OF HEALTH & HUMAN SERVICES NAT INST OF HEALTH

Resin frame equipped membrane electrode assembly for fuel cell and method of producing the same

ActiveUS10665873B2Simple structureStable and reliable qualityFinal product manufactureMotive system fuel cellsFuel cellsPhysical chemistry

A resin frame equipped membrane electrode assembly includes an MEA having different sizes of components, and a resin frame member. A resin melt portion is provided for the resin frame member. The inside of a first gas diffusion layer is impregnated with resin as a part of the resin melt portion. A thin portion is provided at an outermost peripheral portion of the resin frame member through a step at an outermost peripheral portion of the resin melt portion, and the thin portion is thinner in a thickness direction than the resin melt portion.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com