Tough column-type porcelain insulator for high-voltage line

A high-voltage line and porcelain insulator technology, applied in the field of porcelain insulators, can solve the problems of poor bending moment resistance, low mechanical strength, and low tensile strength of the connecting body, so as to improve the tensile and torsional strength of the connection and improve the connection strength and impact toughness, the effect of preventing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

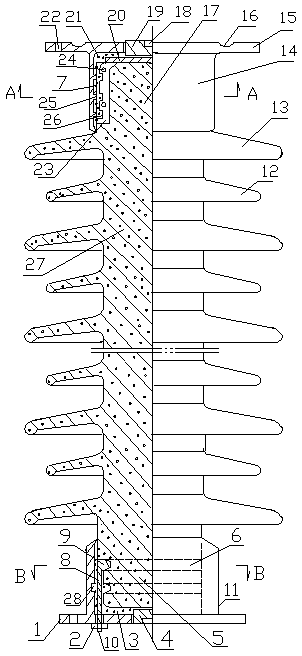

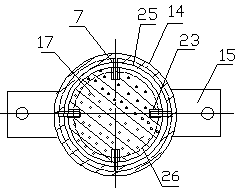

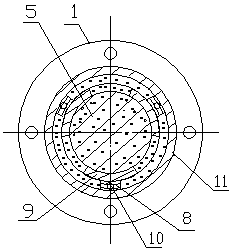

[0025] Example 1, in figure 1 , figure 2 and image 3 Among them, the tough pillar porcelain insulator for high-voltage lines is L160B1180 (1100) type, with a structural height of 1180mm and a weight of 26Kg (compared with the original model, the weight is similar), which includes an insulator body, an upper steel cap 14 and The lower steel cap 11 has a support plate 15 on the top surface of the upper steel cap. The support plate has a wire groove 16 and a connecting hole 22. The insulator body is made of 30wt% calcined bauxite, 20wt% kaolin, and 15wt% quartz powder. , 15wt% Luxi Niantang porcelain clay, 5wt% Yichun Gaoan porcelain clay and 15wt% feldspar, the insulator body has a bone cylinder 27 and an upper core 17 and a lower core 5 integrally connected to both ends of the bone cylinder , a large shed 13 and a small shed 12 are arranged at intervals on the bone cylinder, a glaze layer with a thickness of 0.2-0.3 mm is provided on the surface of the bone cylinder and the...

Embodiment 1

[0037] The technical indicators of a strong and tough column type porcelain insulator for high-voltage lines described in Example 1 are as follows:

[0038] Tensile failure load is 175KN, bending failure load is 15.3KN, creepage distance: main 3315mm

[0039] Impulse withstand voltage (standard lightning peak value) 560KV, power frequency voltage withstand voltage (effective value) 288KV

[0040] Hot and cold abrupt change / K: 165, artificial pollution withstand voltage 40.90KV

[0041] Tensile strength: 208MPa, impact toughness (AKV±20℃, 8.2J / cm 2 ).

Embodiment 2

[0042] Example 2, in figure 1 , figure 2 and image 3 Among them, the tough pillar porcelain insulator for high-voltage lines is L160B1170 (1300) type, with a structural height of 1100mm and a weight of 24Kg (compared with the original model, the weight is similar), which includes the insulator body, the upper steel cap 14 and The lower steel cap 11 has a support plate 15 on the top surface of the upper steel cap. The support plate has a wire groove 16 and a connecting hole 22. The insulator body is made of 40wt% calcined bauxite, 10wt% kaolin, and 20wt% quartz powder. , 10wt% Luxi Niantang porcelain clay, 8wt% Yichun Gaoan porcelain clay and 12wt% feldspar, the insulator body has a bone cylinder 27 and an upper core head 17 and a lower core integrally connected to both ends of the bone cylinder Head 5, a large shed 13 and a small shed 12 are arranged at intervals on the bone cylinder, and a glaze layer with a thickness of 0.2-0.3 mm is provided on the surface of the bone c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com