A mass-producible degassing process for electrolytic chromium sheets

A technology of electrolytic chromium and process, which is applied in the field of high-temperature smelting of nonferrous metals, can solve problems such as degassing of chromium sheets, and achieve the effects of high production efficiency, convenient furnace, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific examples, but the present invention is not limited thereto.

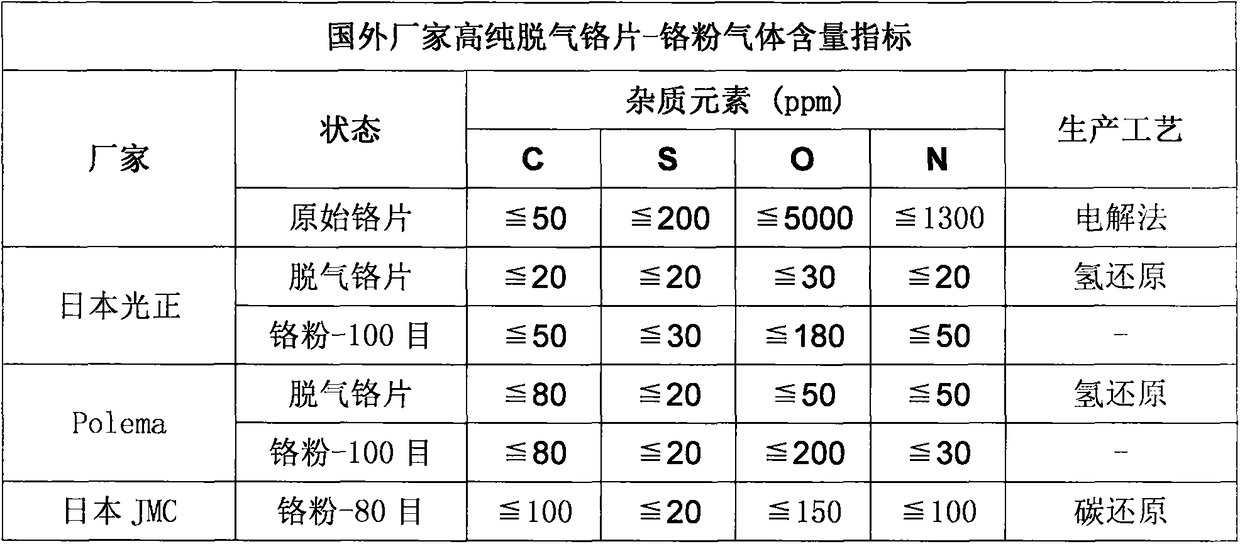

[0026] The original electrolytic chromium sheet is used, the oxygen content is 0.53% (wt.%), and the bulk density is 1.4g / cm3;

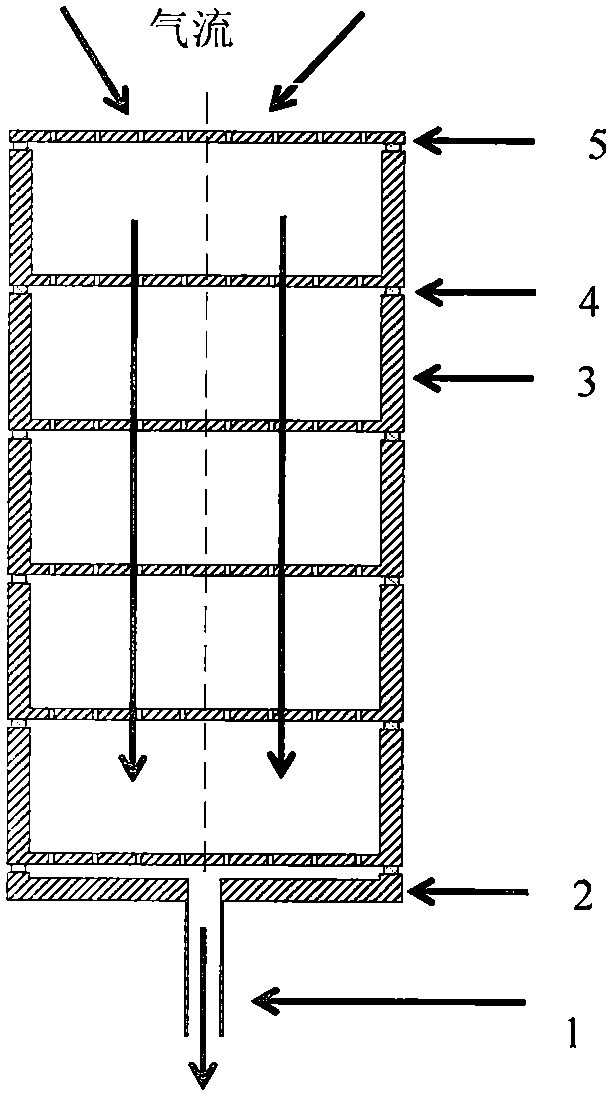

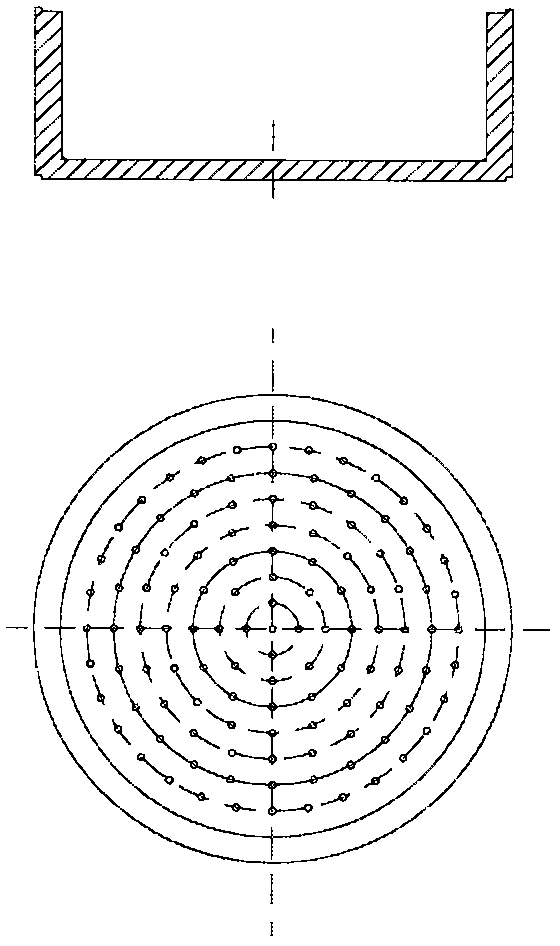

[0027] Tungsten crucible is used for charging, the size of the crucible is 430mm in outer diameter, 400mm in inner diameter, the height of a single crucible is 88mm, and the bottom thickness is 8mm; 117 through holes with a diameter of 5mm are opened at the bottom, and they are evenly distributed. A total of 8 layers of material are charged, each layer is sealed with a 0.5mm molybdenum sheet, and the total weight of the material is 115kg;

[0028] The temperature difference in the uniform temperature zone of the furnace is ±10 degrees Celsius, the heating temperature is 1450 degrees Celsius, the heating time is 15hrs, and the holding time is 15hrs. The hydrogen flow rate is 15L / min~30L / min; the hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com