A light-weight and high-strength column-type porcelain insulator

A porcelain insulator and insulator technology, applied in the field of light-weight and high-strength cylindrical porcelain insulators, can solve the problems of low resistance to mechanical damage, low tensile strength, reduced reliability and safety, etc., and achieve no insulation aging and anti-fouling. Ability, high mechanical shock resistance, the effect of ensuring quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

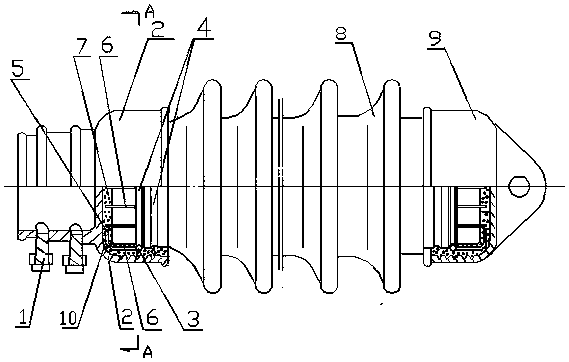

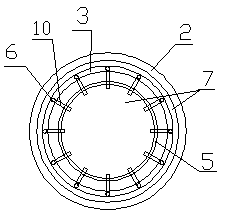

[0024] Example 1, in figure 1 and figure 2 Among them, the light-weight high-strength post-type porcelain insulator is L160B1180 (1400) type, with a structural height of 1180mm and a weight of 28Kg (compared with the original same model, the weight is reduced by 4Kg), which includes the insulator body 8, the upper steel cap 2 and the lower steel cap 9, the upper steel cap and the lower steel cap are glued and connected with the two ends of the insulator body respectively with an adhesive layer 7, the adhesive layer is made of steel sand and glued cement, and magnetic Sand is mixed with cement or high-strength adhesive, and a reinforcing frame made of stainless steel wire (the diameter of the stainless steel wire is generally 1-2 mm) is arranged in the adhesive layer, and the reinforcing frame includes straight pull rods 6 and embedded The annular body 3 in the radial groove 4 on the end surface of the insulator body, the straight pull rods (twelve) are arranged at intervals ...

Embodiment 2

[0036] Example 2, in figure 1 and figure 2 Among them, the light-weight high-strength post-type porcelain insulator is L160B1400 type, with a structural height of 1400mm and a weight of 38Kg (compared with the original model, the weight has dropped by about 5Kg), which includes an insulator body 8, an upper steel cap 2 and The lower steel cap 9, the upper steel cap and the lower steel cap are connected with the two ends of the insulator body respectively with an adhesive layer 7. The adhesive layer is made of steel sand and adhesive cement, and magnetic sand and adhesive cement can also be used. Mixed with cement or high-strength adhesive, the adhesive layer is provided with a reinforcement frame made of stainless steel wire (the diameter of the stainless steel wire is generally 1-2 mm), and the reinforcement frame includes a straight pull rod 6 and an insulator The ring body 3 in the radial groove 4 on the surface of the end of the insulator, the straight rods (twelve) are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com