Copper-aluminum composite material for soft package battery connecting piece and production process thereof

A technology of copper-aluminum composite materials and soft-pack batteries, which is applied to battery pack parts, electronic equipment, electrical components, etc., can solve the problems of non-continuous large-area compounding, unstable quality, and high production costs, and achieve social and economic benefits. Obvious benefits, simple series-parallel connection, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

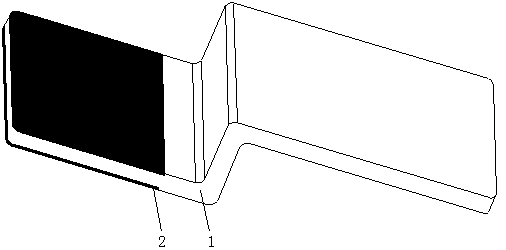

[0020] like figure 1 Shown, a kind of production technology of copper-aluminum bimetal composite strip, concrete steps are as follows: Copper plate 2 is soaked 5 minutes with the sulfuric acid of concentration 15%, rinses with clear water, cleans with acetone, blows dry, brushes with metal surface cleaning machine To remove the oxide film on the copper surface, clean the aluminum plate 1 with acetone to clean the oil on the aluminum surface, rinse with water, soak with 20% NaOH alkali solution at 60°C for 5 minutes, rinse with water, and rinse with 20% HCl solution at 60°C Neutralize for 5 minutes to form a bright NaCl film on the surface of the aluminum plate 1, wash it with clean water, and fix the prepared core material and the front end of the cladding plate together under an argon protective atmosphere, then send them to a heating furnace for heating , the primary rolling temperature is 350°C, the reduction rate is 65%, the secondary rolling is cold rolling after intermed...

Embodiment 2

[0024] like figure 1 Shown, a kind of production technology of copper-aluminum bimetal composite strip, concrete steps are as follows: Copper plate 2 is soaked 5 minutes with the sulfuric acid of concentration 15%, rinses with clear water, cleans with acetone, blows dry, brushes with metal surface cleaning machine To remove the oxide film on the copper surface, clean the aluminum plate 1 with acetone to clean the oil on the aluminum surface, rinse with water, soak with 20% NaOH alkali solution at 60°C for 5 minutes, rinse with water, and rinse with 20% HCl solution at 60°C Neutralize for 5 minutes to form a bright NaCl film on the aluminum surface, wash it with water, and fix the prepared core material and the front end of the cladding plate together under an argon protective atmosphere, then send them to a heating furnace for heating. The first rolling temperature is 300°C, the reduction rate is 50%, the second rolling adopts cold rolling after intermediate annealing, the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com