No-pump high-pressure pulsed water jet generation device

A high-voltage pulse generator technology, applied in the field of water jets, can solve the problems of high energy utilization, high cost of high-pressure pumps, and low maintenance costs, and achieve the effects of convenient use, low cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

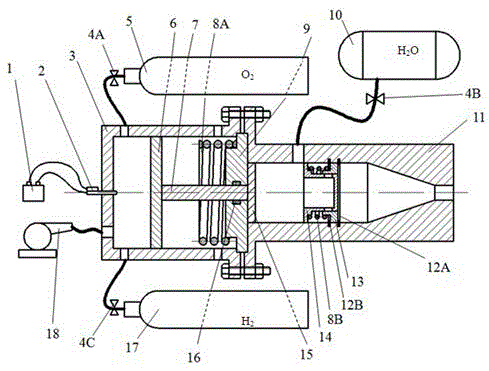

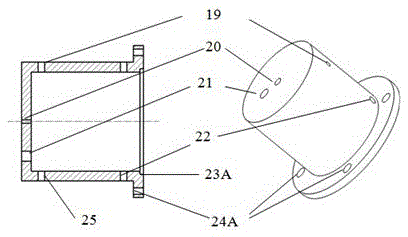

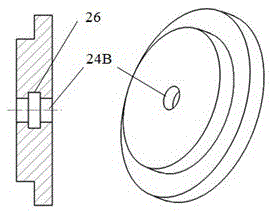

[0026] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-6 As shown, the pumpless high-pressure pulse water jet generating device is composed of a power supply 1, a spark plug 2, a valve 4, an oxygen tank 5, a hydrogen tank 17, a water tank 10, a centrifugal blower 18 and a pulse jet generating component; the pulse jet generating component It mainly includes a power cavity 3, a primary piston 6, a connecting rod 7, a spring 8, a base 9, a sealing ring 16, a secondary piston 15, a jet cavity 11, a valve core 14, and a sealing ring 13; the power cavity 3 and the jet cavity 11 are hollow cylinders, and one end of the power cavity 3 is open and one end is closed, and one end of the jet cavity is opened and the other end is provided with a straight cone jet outlet; The through holes 24A and 24D on the edge are connected with bolts, and the base 9 placed in the positioning grooves 23A and 23B is clamped and fixed, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com