Method for avoiding excessive vibration of undercarriage in overhead state

A landing gear and state technology, applied to ground equipment, aircraft parts, transportation and packaging, etc., can solve the problems of excessive structural vibration, structural weight increase, excessive vibration, etc., and achieve the effect of simple model and high calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

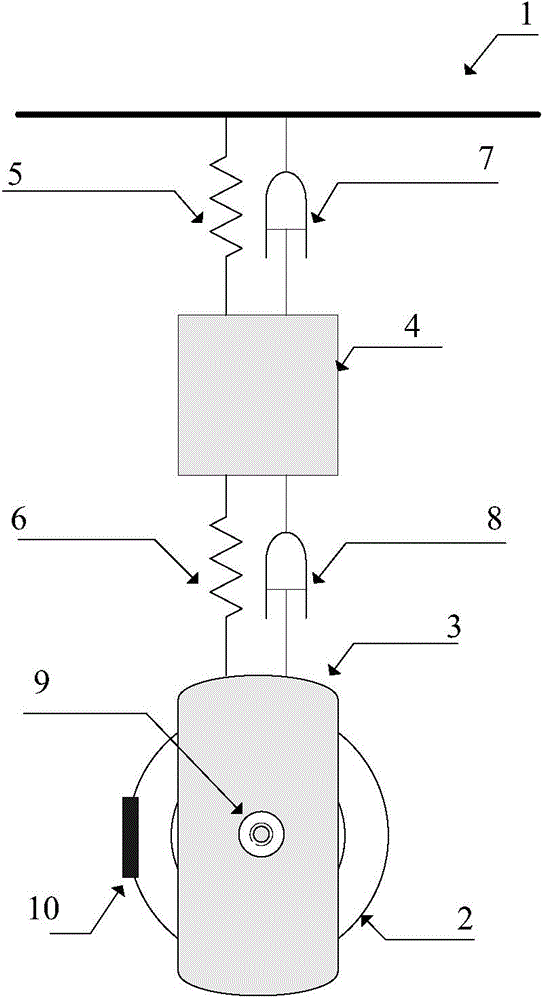

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing, please refer to Figure 1 to Figure 2 .

[0020] Such as figure 1 Shown is a schematic diagram of a two-degree-of-freedom vibration model, including a rigid boundary 1, a runner 2, a runner frame 3, a mass 4, a spring 5, dampers 6 and 7, a rotating shaft 9, and a runner eccentric mass 10.

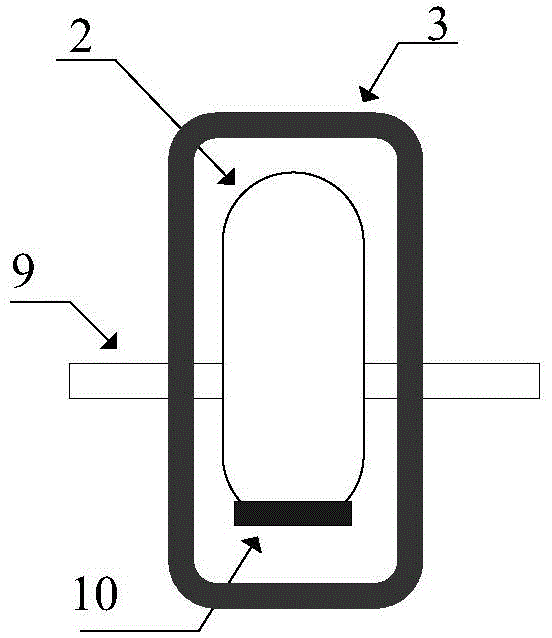

[0021] Such as figure 2 As shown, it is a schematic diagram of a wheel rotation model, including a runner 2 , a runner frame 3 , a rotating shaft 9 , and a wheel eccentric mass 10 .

[0022] A method of avoiding excessive vibration in the lift-off state of the landing gear, comprising:

[0023] 1. The runner frame 3, the runner 2, the rotating shaft 9 and the runner eccentric mass 10 together constitute the mass M 2 ;

[0024] 2. Adjust the wheel eccentric mass M 3 to change the magnitude of the rotational excitation;

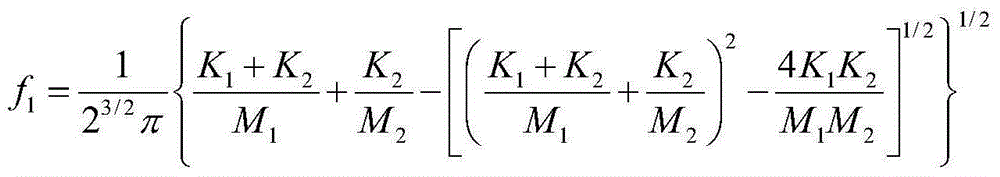

[0025] 3. Adjust mass block M 1 , M 2 , spring sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com