An environmentally friendly dismantling and inspection line for waste and recycled items

A kind of article and waste technology, which is applied in the field of environmental protection dismantling and inspection line, can solve the problems of unfavorable waste recycling, uneven recycling speed of tooling boards, and affecting recycling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

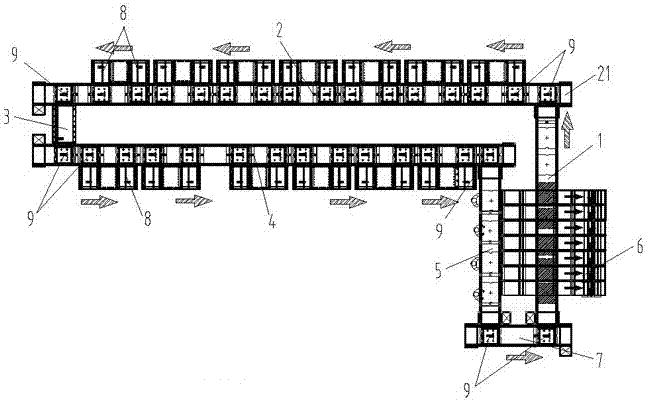

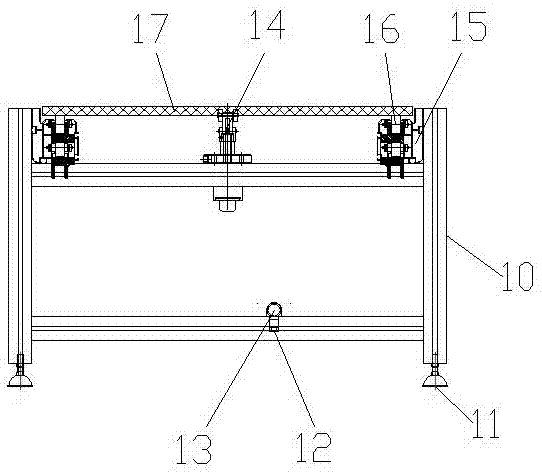

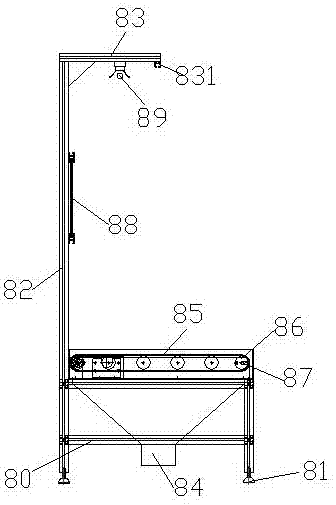

[0020] In this example, refer to figure 1 and Figure 5 As shown, an environmentally friendly dismantling and inspection line for waste and old recycled articles of the present invention includes a tooling board feeding transmission line 1, a first dismantling and inspection transmission line 2 for dismantling the tooling board 17 in the first process, and a first dismantling and inspection transmission line for transition The dismantling transition line 3 for conveying the dismantling tooling board 17, the second dismantling transmission line 4 for dismantling the tooling board 17 in the second process, the sorting transmission line 5 for sorting waste items, and the The sorting transmission line 6 and the tooling plate recovery transition line 7 for separately transporting the sorted waste and old articles, one end of the tooling plate material transfer line 1 is connected to the tooling plate recovery transition line 7, and the tooling plate material transfer line 1 The ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com