Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve the degree of intelligent operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

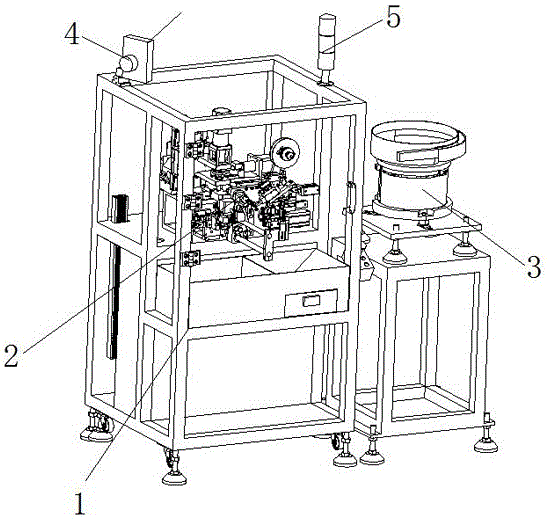

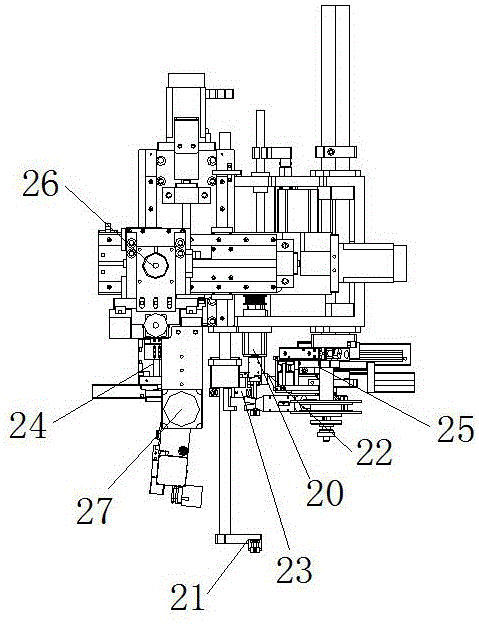

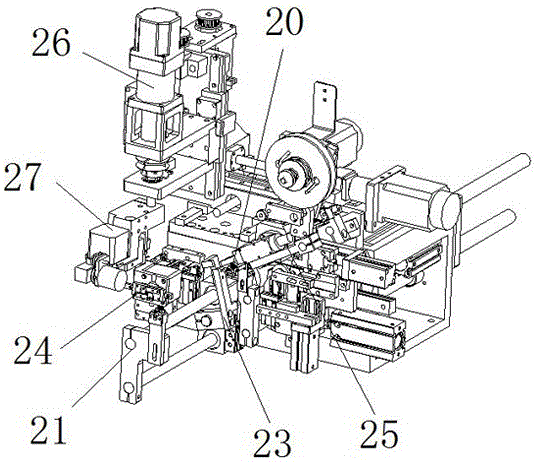

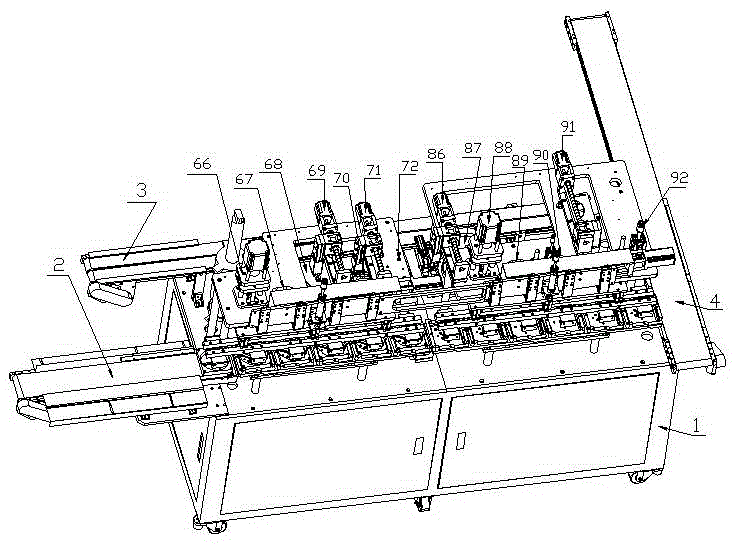

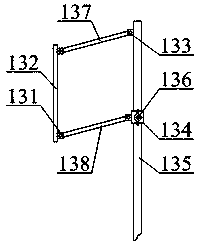

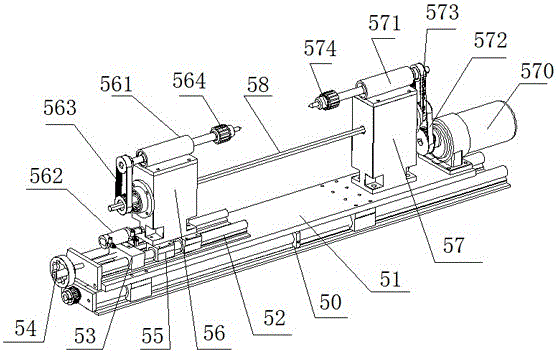

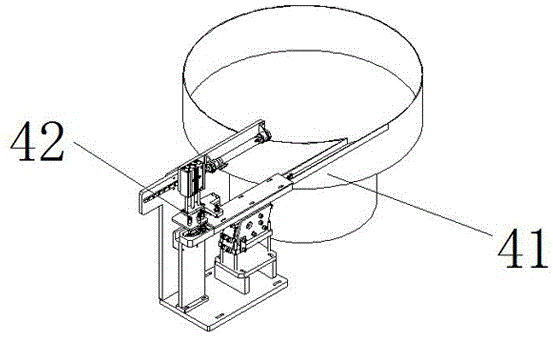

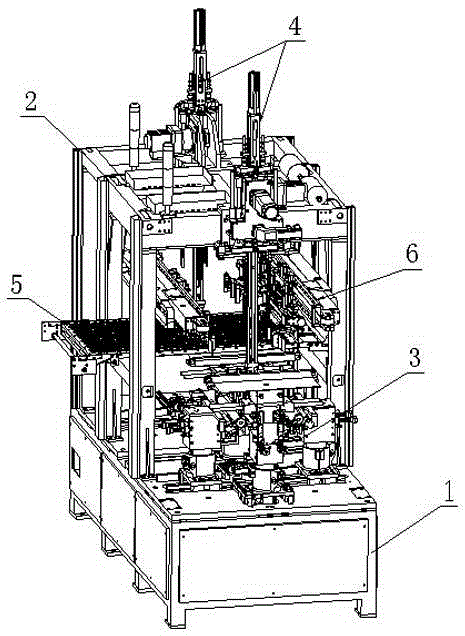

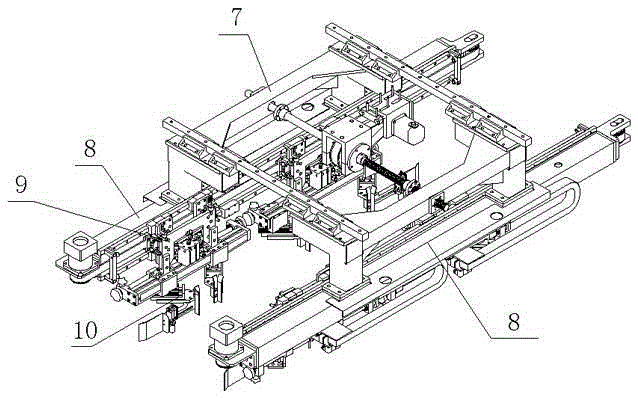

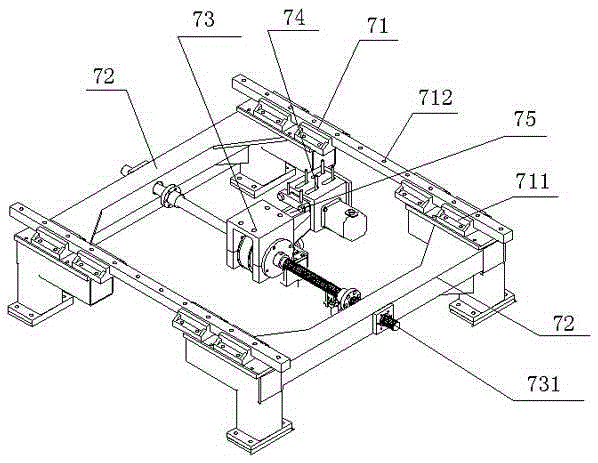

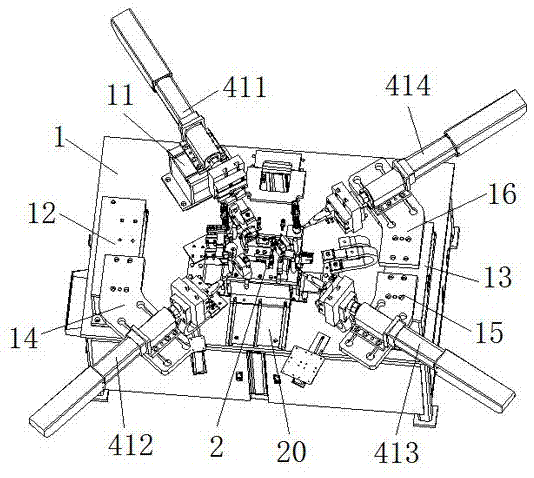

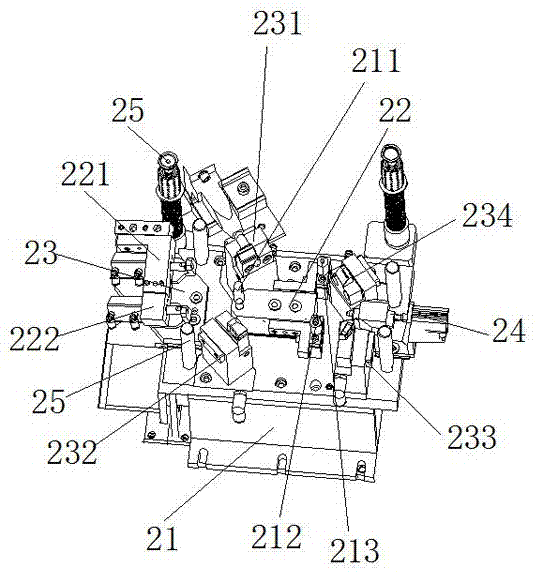

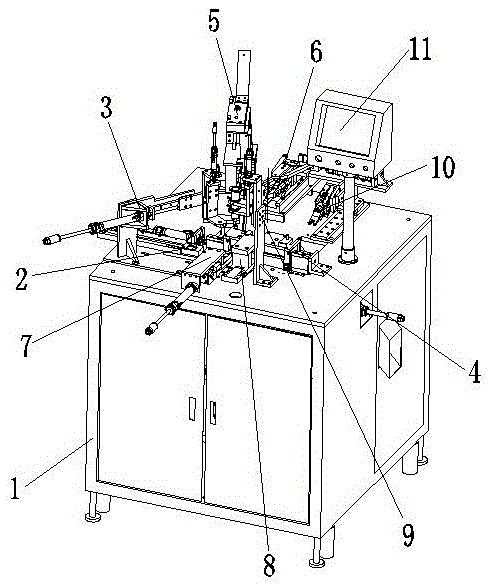

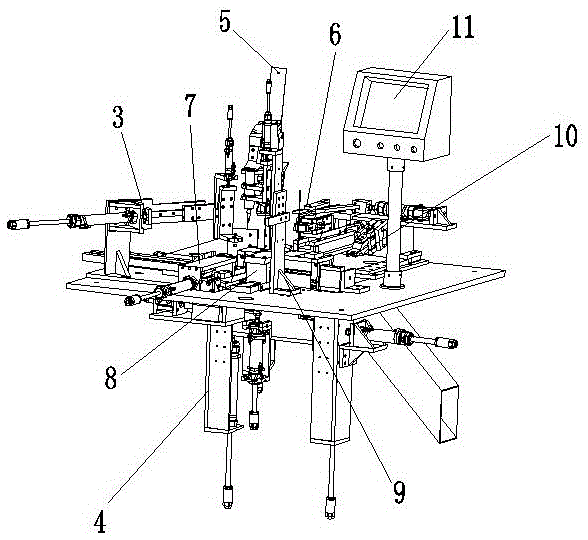

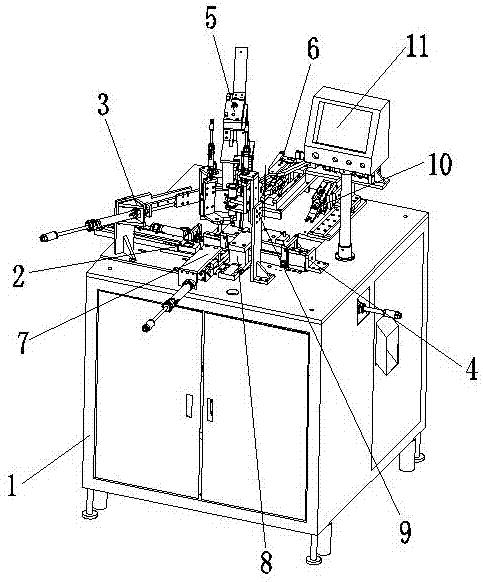

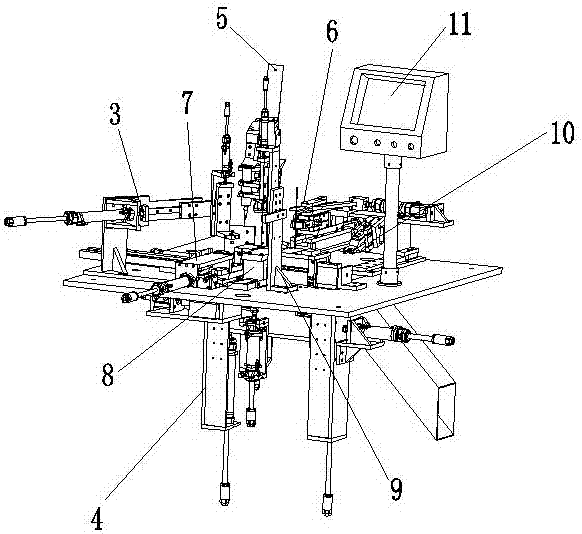

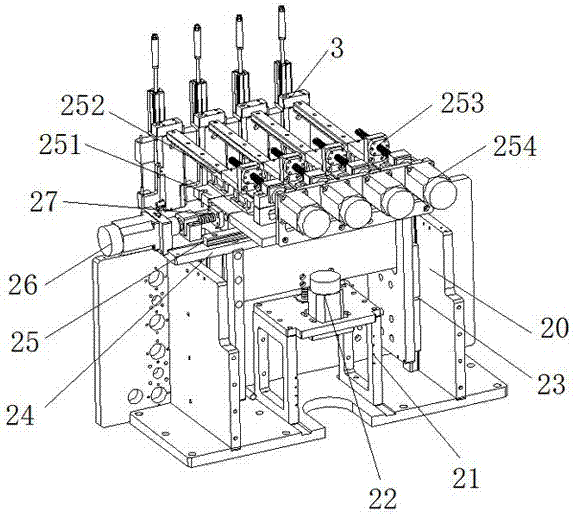

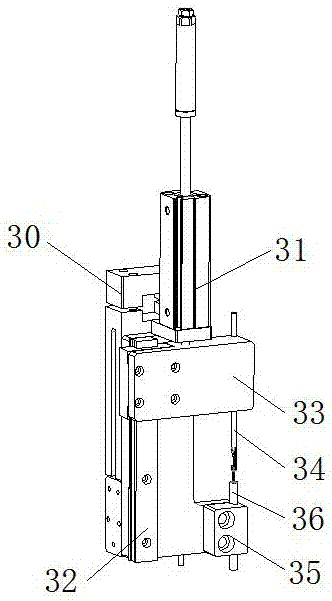

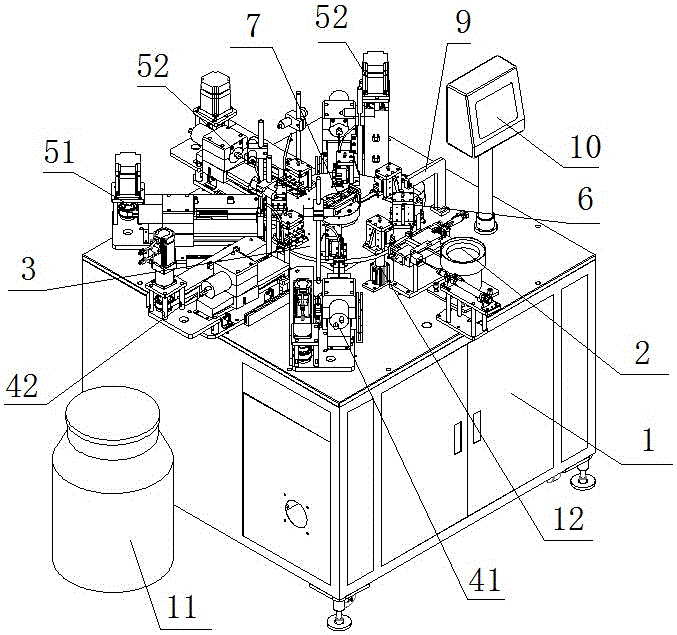

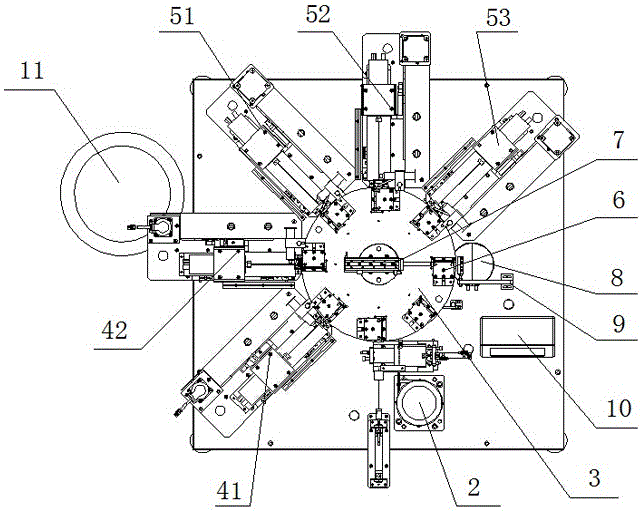

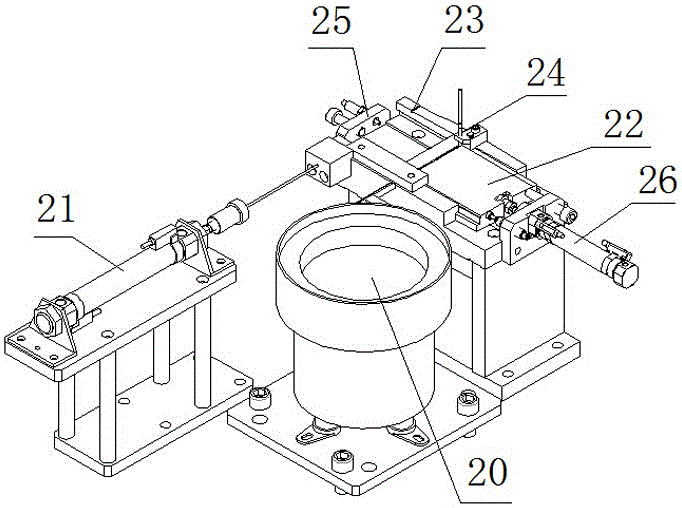

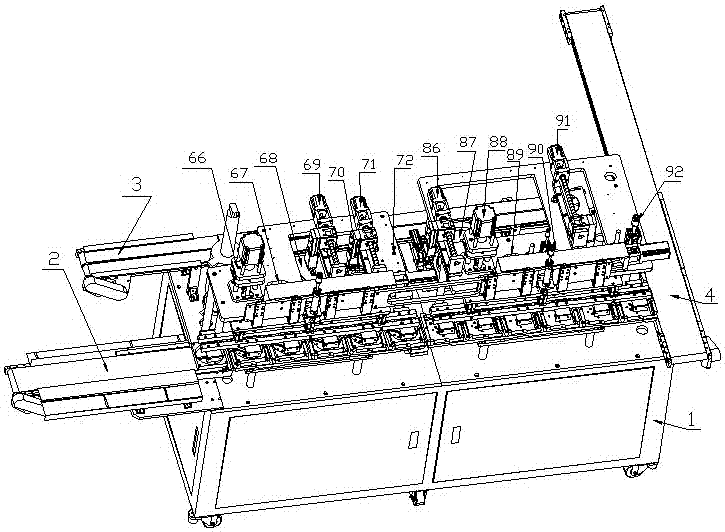

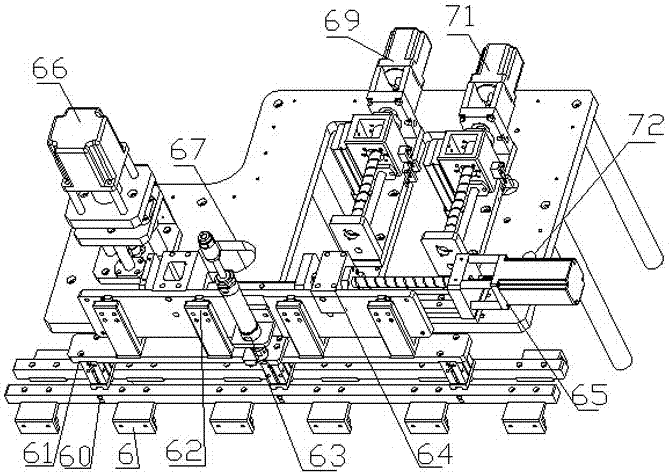

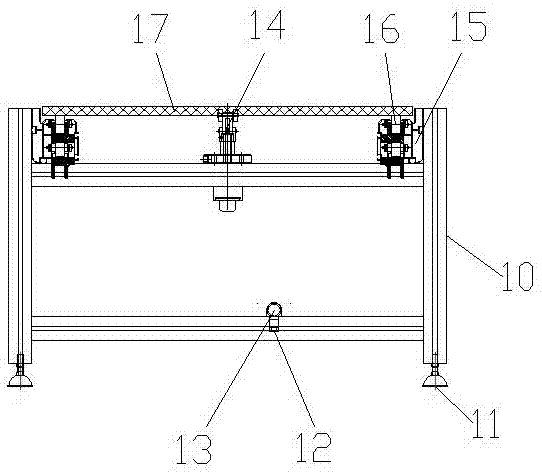

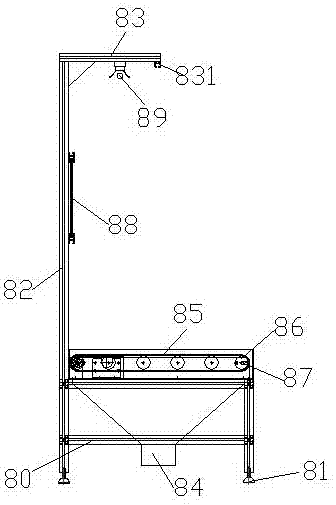

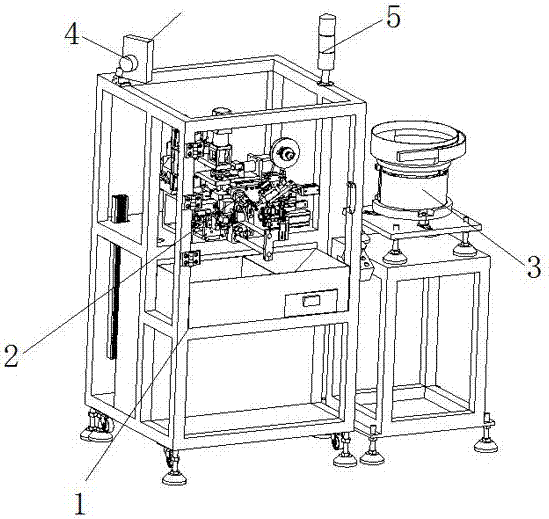

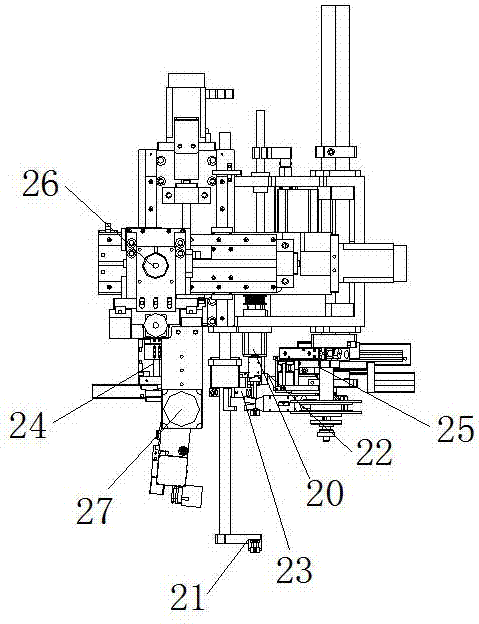

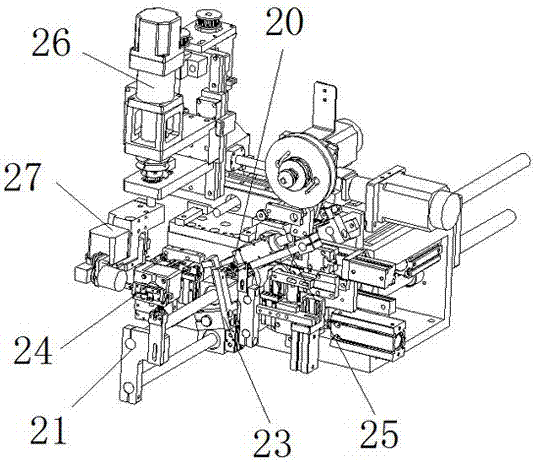

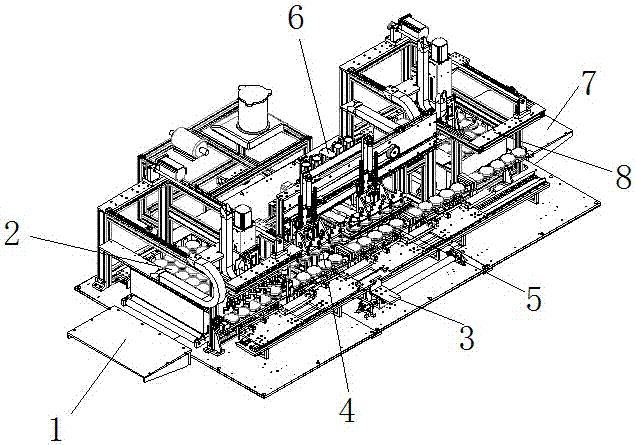

Robot with functions of automatic inserting of insulating sleeve, wire winding and glue coating

ActiveCN105761930AFully automatedImprove the degree of intelligent operationCoils manufactureEngineeringHooking

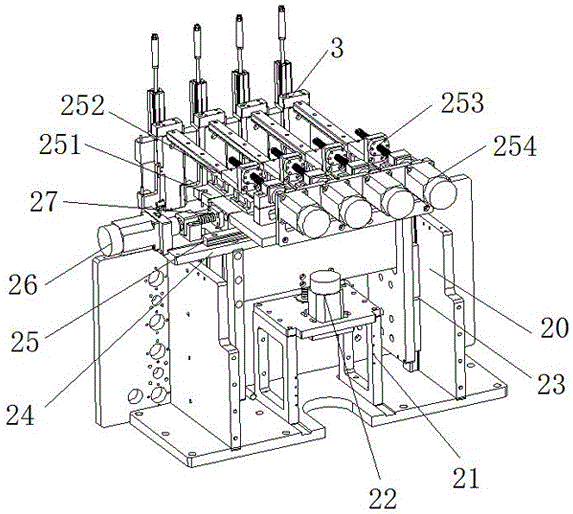

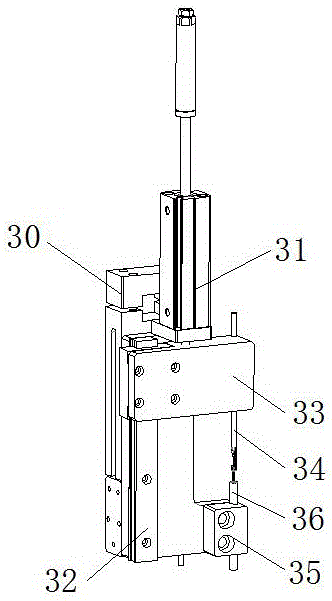

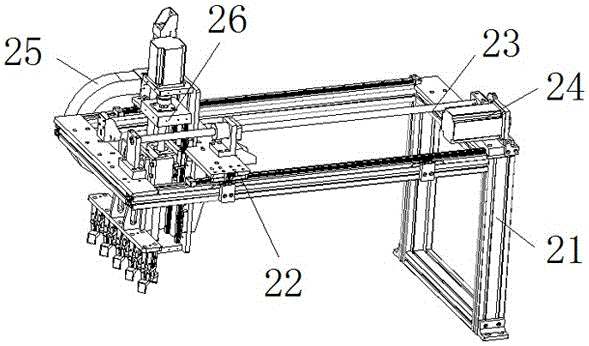

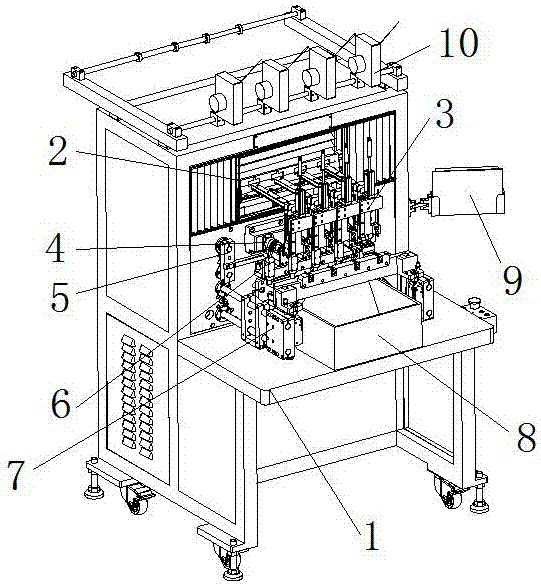

The invention relates to a robot with functions of automatic inserting of an insulating sleeve, wire winding and glue coating. The robot comprises a machine frame, an automatic framework feeding mechanism, a framework wire winding and glue coating mechanism, a tension force mechanism and a mechanical state alarm lamp, wherein the automatic framework feeding mechanism is mounted on the right side of the machine frame and used for transporting frameworks, the framework wire winding and glue coating mechanism is mounted in the machine frame and used for performing pipe casing, wire displacement and glue coating on the frameworks, and the pulling force mechanism and the mechanical state alarm lamp are mounted on the machine frame. According to the robot disclosed by the invention, the automatic framework feeding mechanism and the framework wire winding and glue coating mechanism are arranged, the automatic framework feeding mechanism is used for fully and automatically conveying the framework, and the framework wire winding and glue coating mechanism is provided with a wire winding main shaft mechanism, framework feeding mechanisms, a right-angle wire pressing mechanism, a pipe conveying mechanism, a wire displacement positioning mechanism, a wire conveying and pipe penetrating mechanism, a glue coating mechanism and a finished product discharging mechanism, full automation completion of a series of operations of feeding the frameworks, conveying casing pipes, threading the casing pipes, thread hooking on the frameworks, wire displacement of the frameworks, coating glue of the frameworks, discharging finished products and full automation wire displacement and positioning are realized, the intelligent operation degree is high, the efficiency is high, the effects are good, and the cost is low.

Owner:苏州创易技研股份有限公司

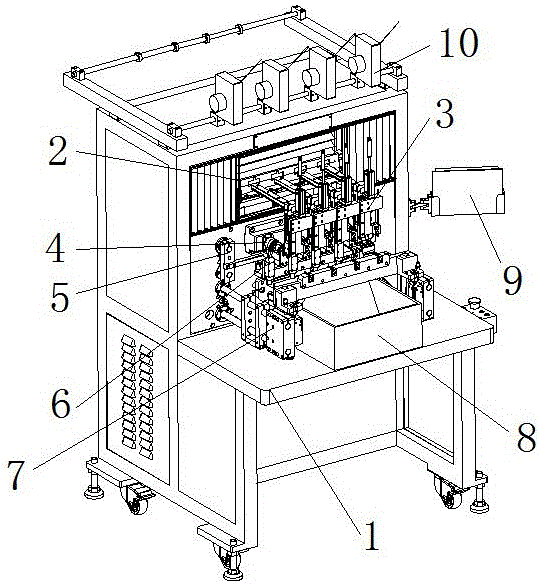

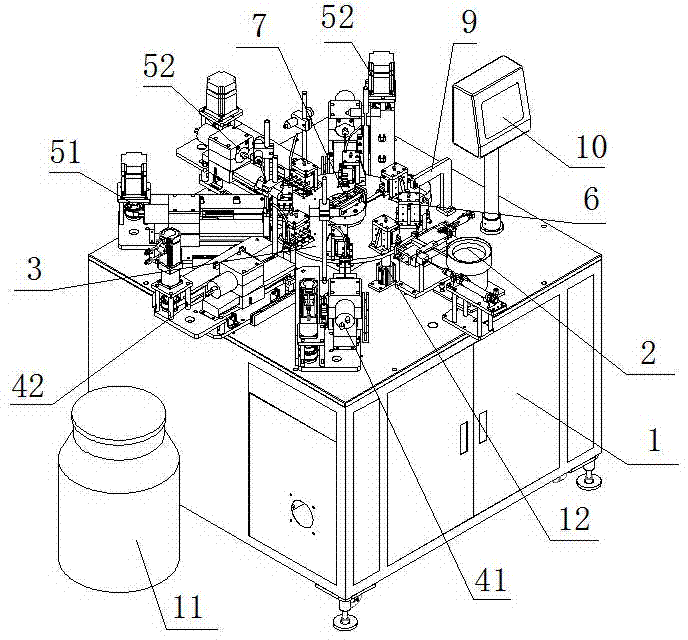

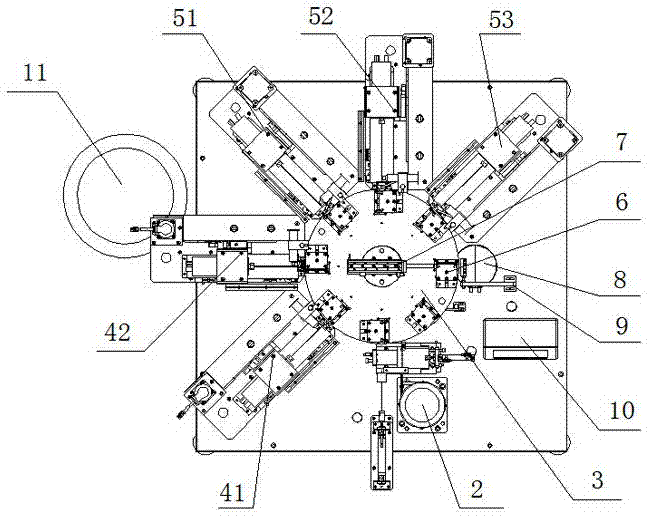

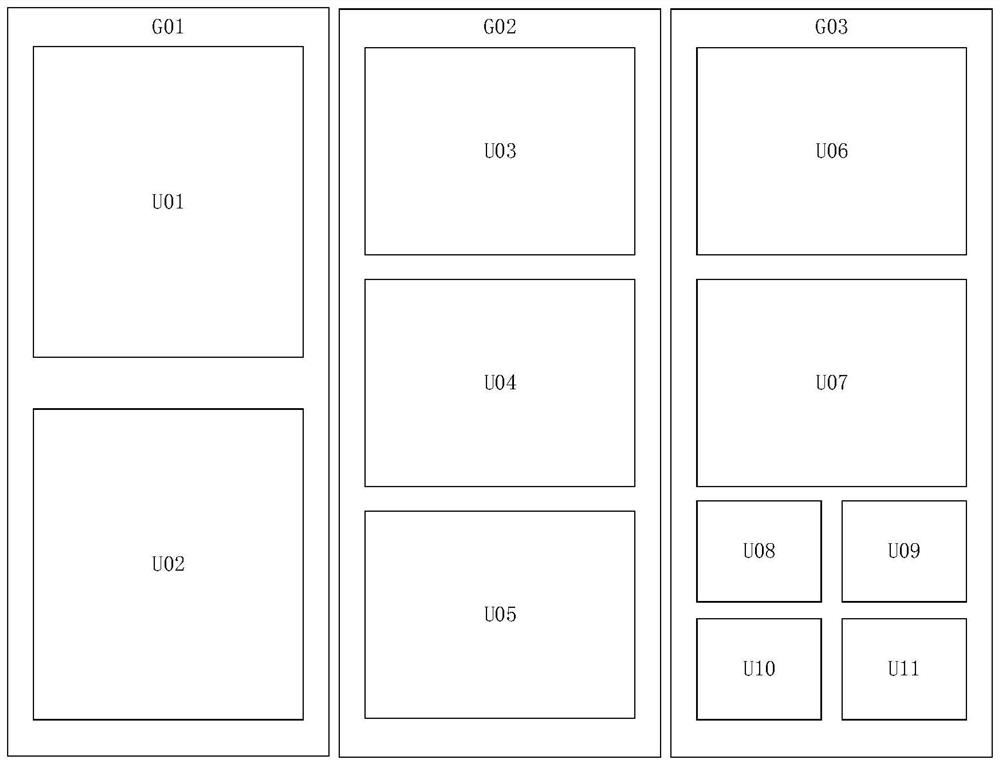

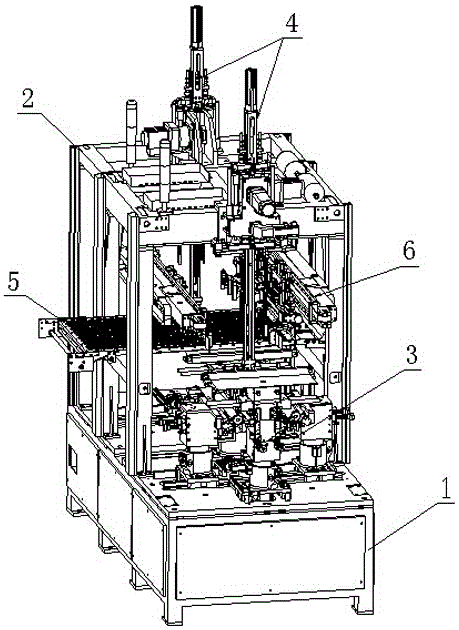

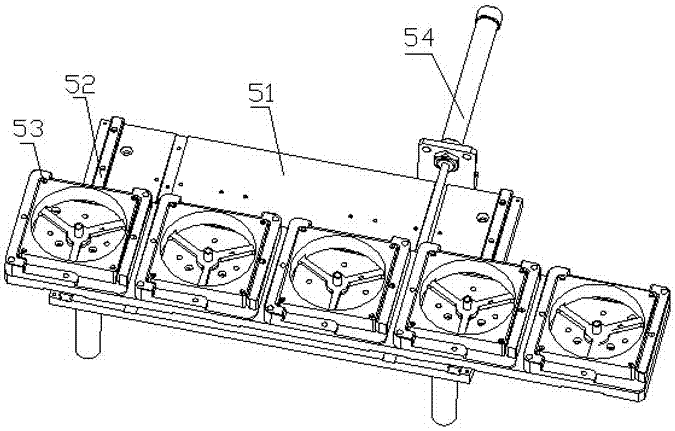

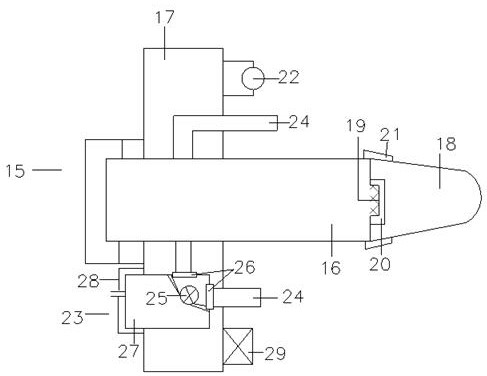

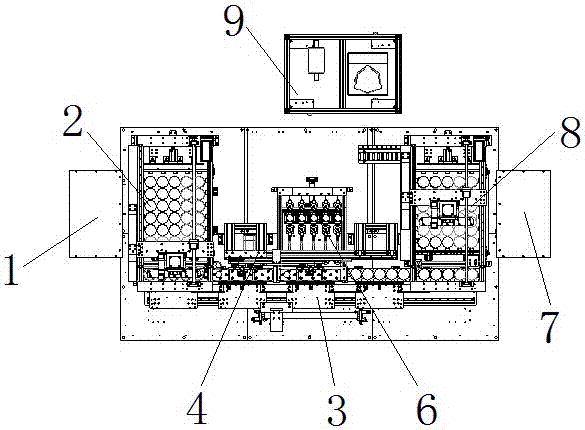

Closed intelligent micro-adjustable entire column full automatic wire winding machine

ActiveCN105810430ANot easy to disconnectPrevent disconnectionCoils manufactureWinding machineEngineering

The invention discloses a closed smart micro-adjustment entire column full automatic wire winding machine. The wire winding machine comprises a machine table, a wire arrangement transmission mechanism, independent wire arrangement mechanisms, a wire winding mechanism, a finished product discharging mechanism, a wire clamping mechanism, a skeleton feeding mechanism, a finished product unloading box, an operation system touch screen and tension mechanisms. According to the wire winding machine, wire skeletons are automatically fed through the skeleton feeding mechanism; wire clamping and wire hooking are carried out by the wire clamping mechanism; full automatic wire winding is realized by matching the wire winding mechanism with the independent wire arrangement mechanisms; the independent wire arrangement mechanisms can arrange the wires independently; the independent wire arrangement mechanisms feed back wire arrangement speeds intelligently through wire arrangement intelligent sensors; the wire arrangement angles of the wire arrangement guide pins are adjusted, thus adapting to the instant wire winding speeds; the independent wire arrangement mechanisms hook the wire from the start ends of the skeletons; breakage conditions in wire hooking and welding processes are avoided; winding without disordered wires is carried on the entire column of the precise coils full automatically; winding, wire hooking and wire arrangement are carried out from the top ends to the bottom ends full automatically when the pin bottoms of start winding ends are winded; the intelligent operation degree is high; and the cost is low.

Owner:苏州创易技研股份有限公司

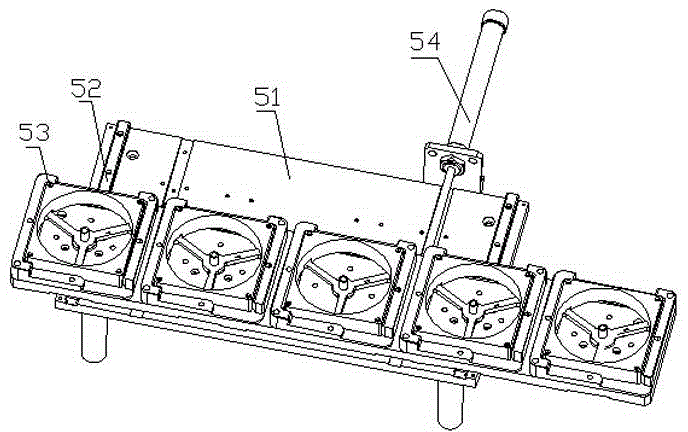

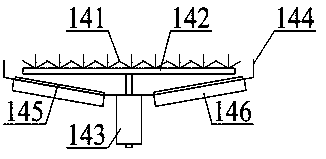

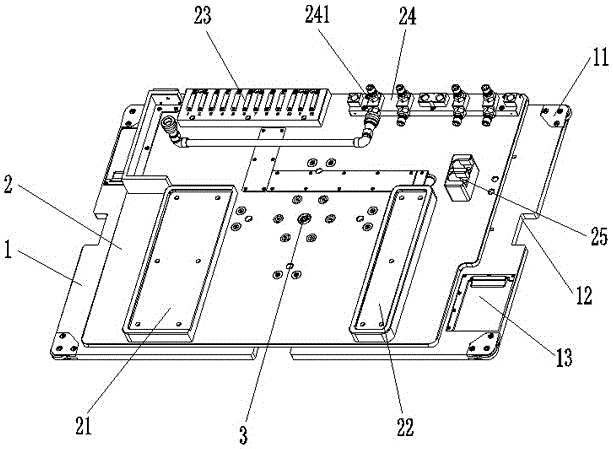

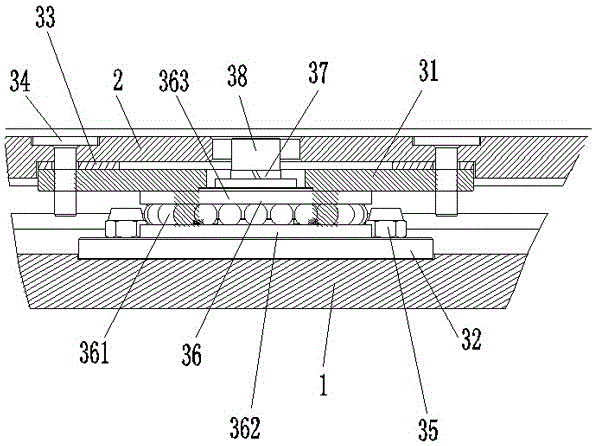

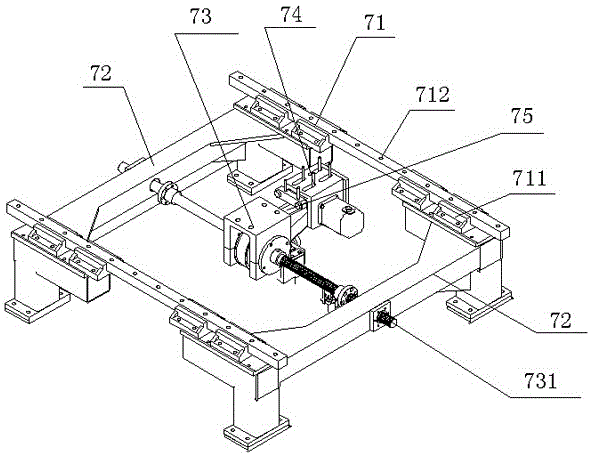

Intelligent tooling plate for assembling air conditioner

ActiveCN105479415AAvoid Composition CostsLow costAssembly machinesWork benchesElectricityEngineering

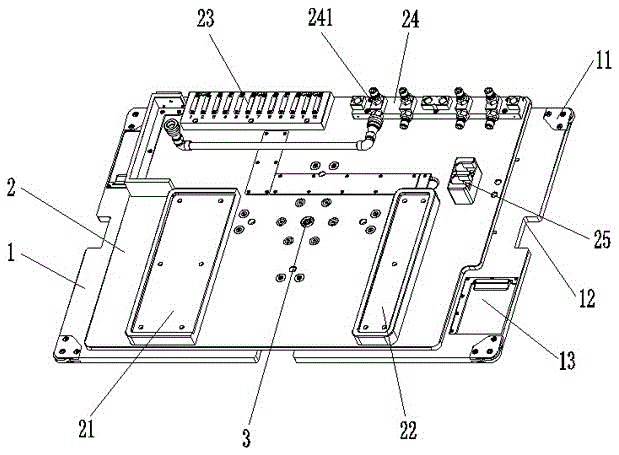

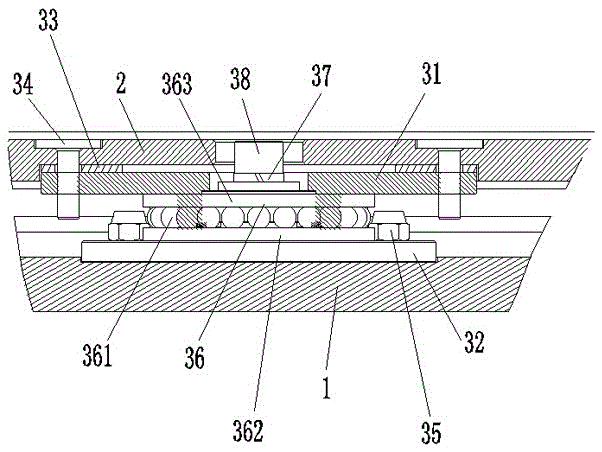

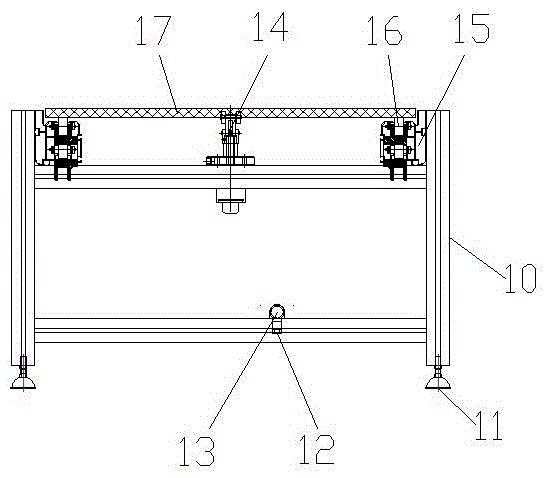

The invention relates to an intelligent tooling plate for assembling an air conditioner. The intelligent tooling plate comprises a bottom plate assembly, a rotating plate assembly, a rotary table assembly, guide pulleys, dog catch spacing openings, file folder grooves, one or more first die sets, one or more second die sets, connecting line assemblies, a connector mounting plate, coolant connectors, an electric connection terminal, an upper mounting plate, a fillister head screw, an elastic washer, a rotary table, a rotary table lower mounting plate, upper mounting plate screws, lower mounting plate screws and a rotating plate mat. The rotary table disclosed by the invention has the functions of automatic positioning and being capable of elastically adjusting rising or falling, so that more than two die sets can perform synchronous assembly or synchronous test simultaneously and accurately on air conditioner assemblies with a plurality of different faces placed on the rotary table, the problem that the operation of the next station of a conventional air conditioner mounting assembly line can be started only after the completion of the operation of the previous station so that time is wasted is solved, the disadvantages of being high in cost, large in volume, difficult to maintain and low in assembling efficiency in the conventional air conditioner mounting assembly line are avoided, and the intelligent tooling plate disclosed by the invention is high in intelligent degrees and low in cost.

Owner:GUANGDONG HUI LIXING SEIKO TECH

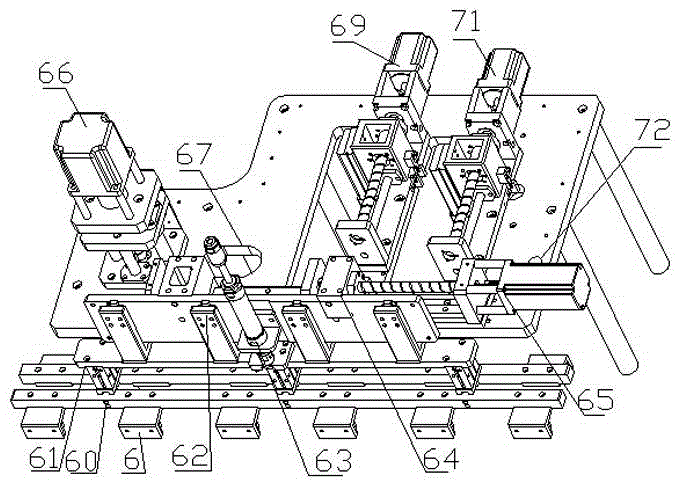

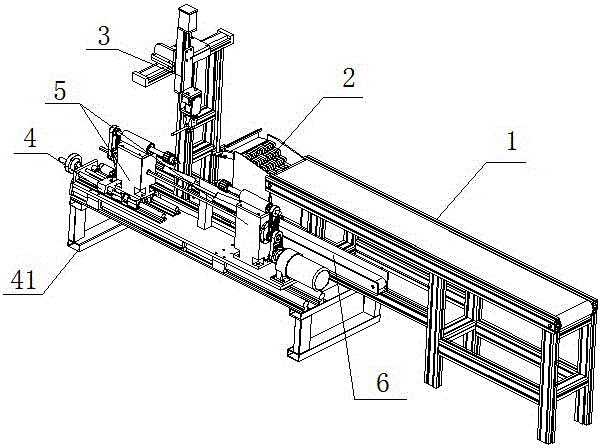

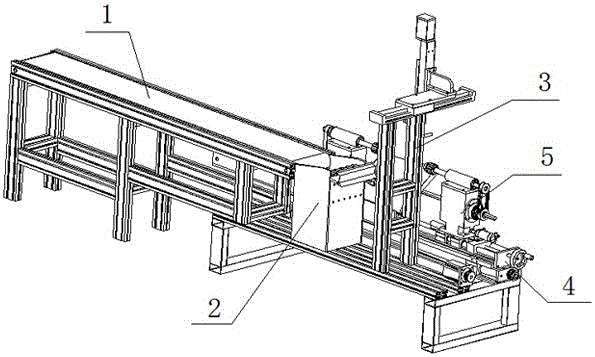

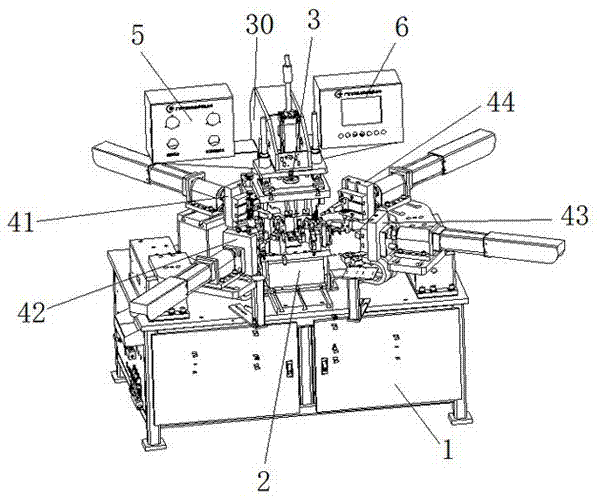

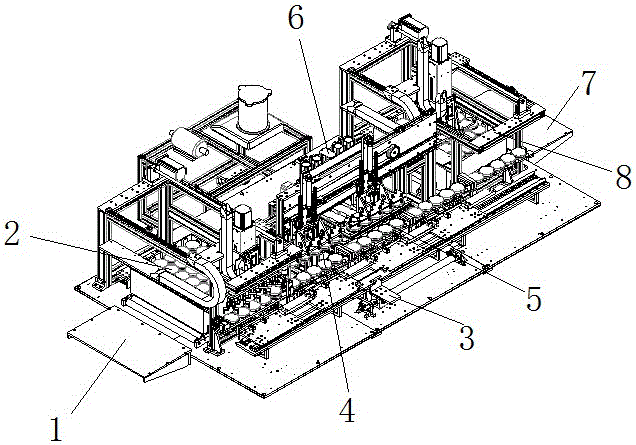

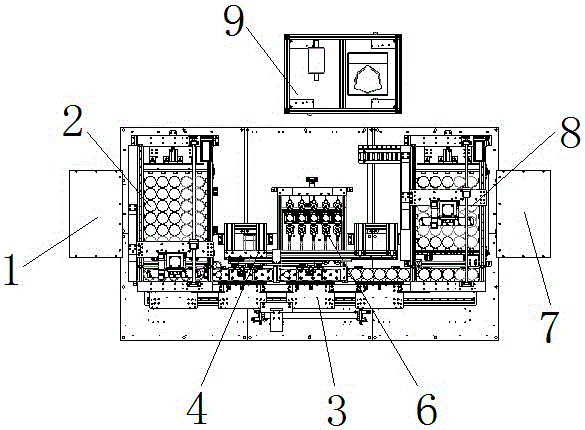

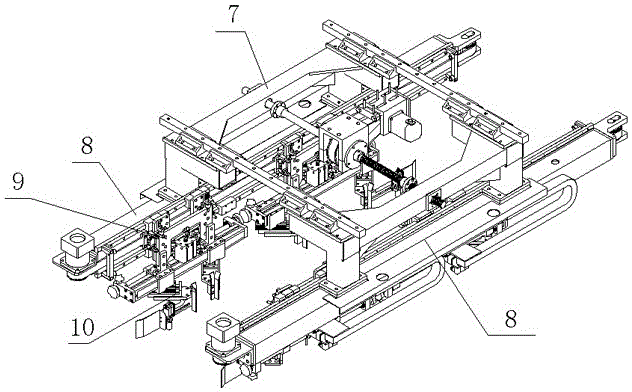

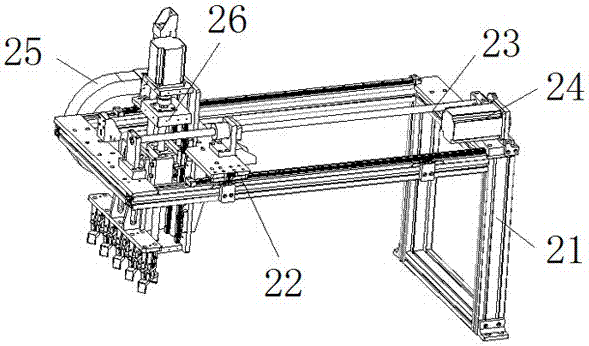

Linear automatic fan assembling machine

ActiveCN104879326ARealize automatic assemblyImprove the degree of intelligent operationPump componentsPumpsIndustrial AccidentAgricultural engineering

The invention discloses a linear automatic fan assembling machine which comprises a rack, a fan frame feeding assembly line, a fan blade feeding assembly line, a finished product discharging assembly line, a fan frame jig mechanism, a left mounting mechanism and a right mounting mechanism. The fan frame feeding assembly line is transversely connected with the left side of the rack, the fan blade feeding assembly line is transversely connected with the left side of the rack, the finished product discharging assembly line is longitudinally arranged on the right side of the rack and below the fan blade feeding assembly line, the fan frame jig mechanism is arranged at the top of the rack, and the left mounting mechanism and the right mounting mechanism are arranged on the fan frame jig mechanism. A linear layout structure is adopted, full-automatic feeding is achieved, a fan is assembled fully automatically, the intelligent operation degree is high, a plurality of stations can be arranged to carry out assembly line operation at the same time, the occupied area is saved, space is saved, cost is lowered, work efficiency is greatly improved, safety and reliability are achieved, the danger of industrial accidents easily caused by a manual feeding operation mode is avoided, and the linear automatic fan assembling machine is simpler in structure, scientific and reasonable and convenient to widely use and popularize.

Owner:东莞市诺辉自动化机械有限公司

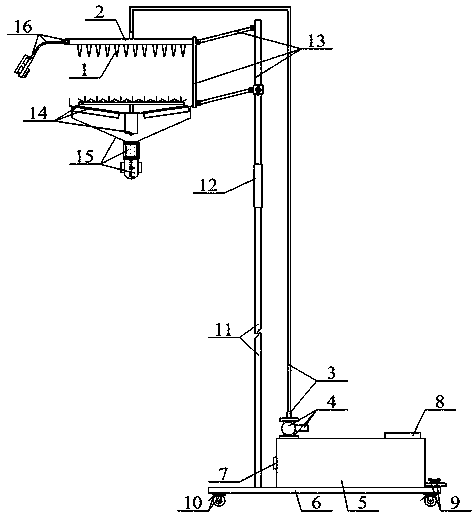

Intelligent cleaning device for optical energy street lamp

InactiveCN110216096AConvenience guaranteedAdd cleaning functionCleaning using toolsCleaning using liquidsEngineeringControl switch

The invention provides an intelligent cleaning device for an optical energy street lamp. The intelligent cleaning device for the optical energy street lamp comprises a liquid spraying nozzle, a liquidspraying row, a metal soft guide pipe, a liquid absorbing pump, a cleaning box, a moving base, a control switch, a liquid injection cover, a discharging pipe with a valve, a moving wheel, a telescopic rod, a connecting sleeve pipe and an auxiliary angle adjusting frame. The intelligent cleaning device for the optical energy street lamp is provided with a mounting lining base I, a connecting lining base, a mounting lining base II, an adjusting pipe, a supporting upright column, a wing-shaped screw, a movable rod I and a movable rod II, so that the inclination angle of the device can be adjusted according to the mounting inclination angle of the street lamp; during adjustment, the wing-shaped screw is loosened and the position of the adjusting pipe on the outer wall of the supporting upright column can be adjusted in a sliding way, the movable rod I can act in the mounting lining base II and the mounting lining base I arranged on the upper part, and the movable rod II can act in the mounting lining base II and the mounting lining base I arranged on the lower part, so that the position of the connecting lining base can be changed conveniently, the inclination angel of the liquid spraying row can be changed, the convenience of spraying liquid cleaning is guaranteed and the use requirement is met.

Owner:河南睿光新能源科技有限公司

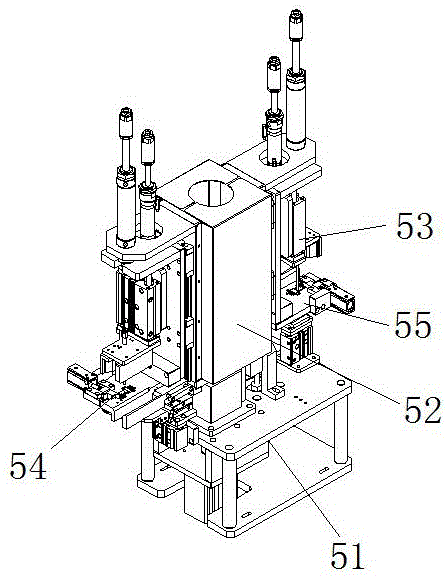

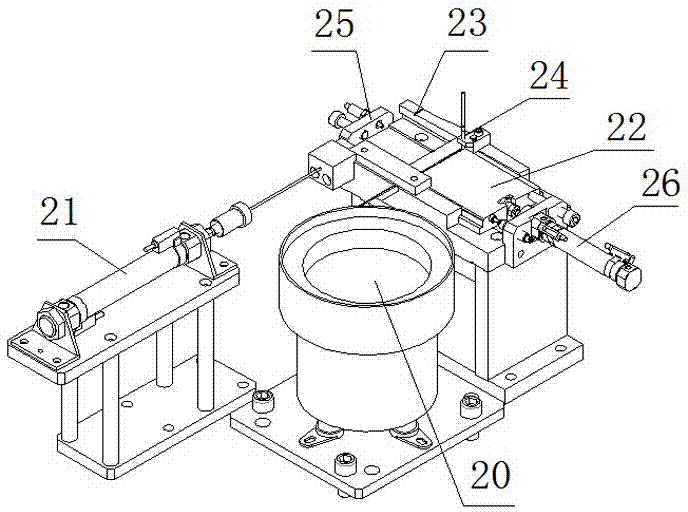

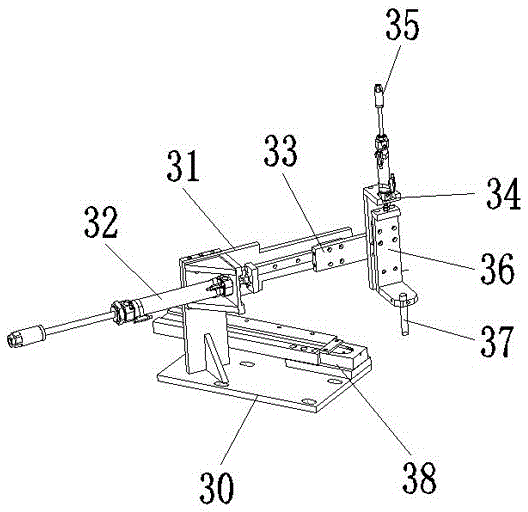

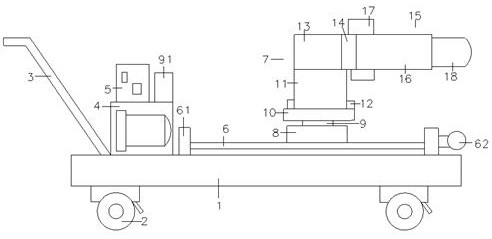

Intelligent full-automatic high-frequency quenching machine

ActiveCN105063300AImprove the degree of intelligent operationUniform hardness after quenchingIncreasing energy efficiencyQuenching devicesOptical axisOperation mode

The invention relates to an intelligent full-automatic high-frequency quenching machine. The machine comprises an automatic feeding conveyer belt, a material distributing positioning mechanism, a material conveying mechanical arm, a space adjusting positioning mechanism, a rotating center mechanism and a finished product discharging conveyer belt. The machine is novel machining equipment which is suitable for an unthreaded shaft and a stepped shaft and capable of achieving high-frequency quenching in a full-automatic mode at the same time, and thus workpieces can be rotated, heated, moved and sprayed at the same time. After quenching is completed, the workpieces fall into the finished product discharging conveyer belt to be recycled automatically. The quenching machining hardness is even, and a hardness layer and a transition area can both be adjusted in a full-automatic mode according to production needs. A computer intelligent operation mode is adopted, no manual participation is needed in the whole process and positioning is accurate. The rotating speed of a left ejection center and the rotating speed of a right ejection center can reach 800 turns per minute. The diameter range of metal parts applicable to being machined is 5-80 mm, and the yield can reach 600 pieces per hour. The high-frequency quenching quality and speed are high, and the degree of automation is high as well.

Owner:东莞市建诚高频淬火科技有限公司

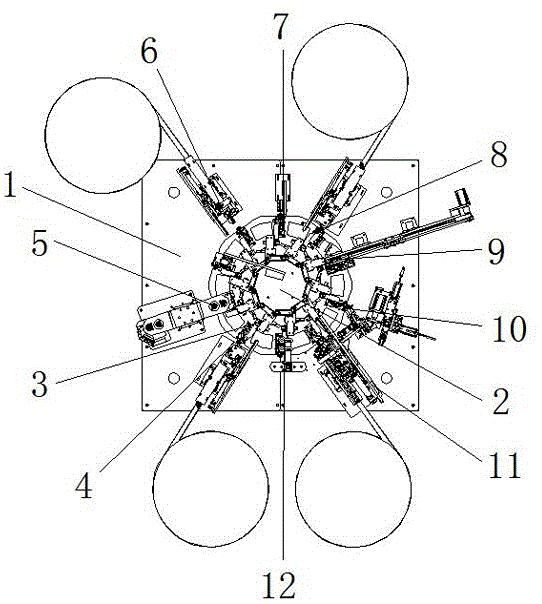

Full-automatic assembly machine for toy gamepads

InactiveCN105921999AImprove the degree of intelligent operationImprove efficiencyAssembly machinesMetal working apparatusAgricultural engineeringAutomation

The invention discloses a full-automatic assembly machine for toy gamepads. The full-automatic assembly machine comprises a machine table, a rotating plate allowing positions to be changed is installed in the center of the machine table, an installing die holder mechanism for assembling the toy gamepads is arranged on the circumference of the rotating plate, and an upper cover assembling mechanism, a resistor disc assembling mechanism, an accelerator rod assembling mechanism, a spring assembling mechanism, a lower cover assembling mechanism, a product discharging mechanism, a button assembling mechanism, an outer cover assembling mechanism and an upper cover screw driving mechanism are sequentially arranged around the periphery of the rotating plate. According to the full-automatic assembly machine, by arranging the upper cover assembling mechanism, the resistor disc assembling mechanism, the accelerator rod assembling mechanism, the spring assembling mechanism, the lower cover assembling mechanism, the product discharging mechanism, the button assembling mechanism, the outer cover assembling mechanism and the upper cover screw driving mechanism, full-automatic assembly operation of upper covers, resistor discs, accelerator rods, springs, lower covers, buttons and outer covers of the toy gamepads can be realized, the automation degree and the intelligent operation degree are high, the efficiency is high, the assembling effect is good, the cost is low, use is convenient and fast, and the capacity is high.

Owner:东莞市火速自动化科技有限公司

Full-automatic intelligent double-way box holding mechanism

ActiveCN105291484AShorten the timeShorten the production cycleBoxes/cartons making machineryContainer making machineryPaperboardEngineering

The invention provides a full-automatic intelligent double-way box holding mechanism which comprises a base, a machine frame, a fold-in forming mechanism, a box pressing mechanism, a rear section conveyor belt and a double-way box holding mechanism. The rear section conveyor belt is arranged in the center of the machine frame and used for feeding a paperboard box and face paper. A left and right box holding manner is adopted in the double-way box holding mechanism for asynchronous feeding operation performed station to station and a left station and a right station are arranged for asynchronous paper box forming and processing treatment. Due to the adoption of a double-station asynchronous paper box forming manner, the time spent in waiting the paper box to be formed and processed in the box holding and feeding process is shortened, after the paper box is processed, a manner that formed paper box discharging and box holding and feeding are performed synchronously is adopted in the double-way box holding mechanism, and the time spent in waiting the finished paper box to be discharged in the box holding and feeding process is shortened as well; and the mechanism is suitable for conducting box holding and forming treatment on paper boxes of various different specifications synchronously, a production period is shortened greatly, production efficiency is improved by over one time, the capacity is improved by over one time, efficiency is high, the effect is good, cost is low, and the intelligent operation degree is high.

Owner:广东力顺源智能自动化有限公司

Fuel filler cap welder

ActiveCN105436731AHigh precisionSmall heat rangeWelding/cutting auxillary devicesAuxillary welding devicesScaling dimensionSoldering gun

The invention discloses a fuel filler cap welder which comprises a machine table, a first welding set, a second welding set, a third welding set, a fourth welding set, an upper mould bracket, an upper mould set, an operation box and a display screen. According to the fuel filler cap welder, a fuel filler cap can be positioned by virtue of an upper mould, so that the fuel filler cap welder can be suitable for positioning fuel filler caps with different scale dimensions; a fuel cap bracket is subjected to positioning and fine turning by fixing a conductive electrode base by virtue of four fuel cap brackets , so that the fuel filler cap welder can be suitable for positioning the fuel cap brackets with different scale dimensions, and also can be suitable for positioning fuel cap rotary plates with different scale dimensions, and therefore, precise mould closing of the upper mould set and a lower mould set is realized; a plurality of welding guns can be used for simultaneously welding a fuel cap, so that the efficiency is high; a fuel filler cap welding workpiece is small in heating range, so that the fuel filler cap is small in deformation and even is not deformed, and therefore, a workpiece welding position is high in precision, a welding spot is free of an insufficient welding phenomenon, a welding spot is firm, a yield is high, a rate of defective products is lower than 1 / 10000, the cost is low, and the intelligent degree is high.

Owner:HERON INTELLIGENT EQUIP CO LTD

Automatic diverging and filling machine for plant nutrition cultivation solution

InactiveCN105667850AControl filling volumeConsistent filling volumeLiquid materialAutomatic controlPlant nutrition

The invention relates to an automatic diverging and filling machine for a plant nutrition cultivation solution. The automatic diverging and filling machine comprises a solution storage tank feeding rack, a solution storage tank feeding mechanism, a solution storage tank delivery mechanism, a solution storage tank cover delivery mechanism, a solution storage tank cover exchange temporary storage rack, a cultivation solution diverging mechanism, a solution storage tank discharging rack, a solution storage tank discharging mechanism and a cultivation solution conveying mechanism, wherein the solution storage tank cover exchange temporary storage rack is arranged at the back of the solution storage tank delivery mechanism. The automatic diverging and filling machine integrates automatic delivery of the solution storage tank, automatic positioning, automatic lifting height adjustment, automatic cap removal of the solution storage tank, automatic removed cap temporarystorageof the solution storage tank, automatic filling of the solution storage tank, automatic control on solution storage amount, automatic capping of the solution storage tank after filling, and automatic discharging, and can control the filling amount of the cultivation solution with high precision, so that the filling amount of the cultivation solution of each bottle of the solution storage tank is consistent, deviation of the filling amount is small, intelligent operation degree is high, efficiency is high, effect is good and cost is low.

Owner:DONGGUAN MING HUA AUTOMATION EQUIP

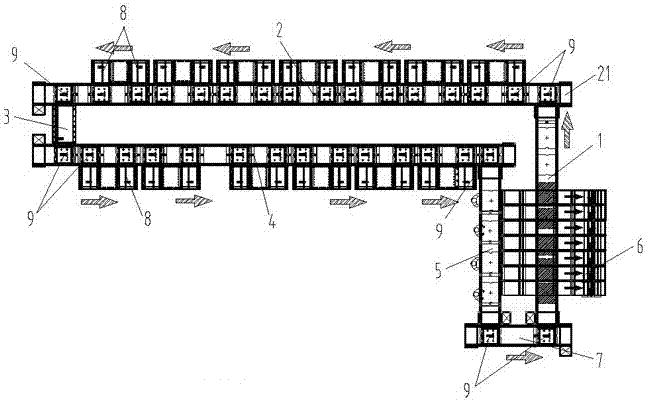

Environment-friendly overhaul line for waste recycled objects

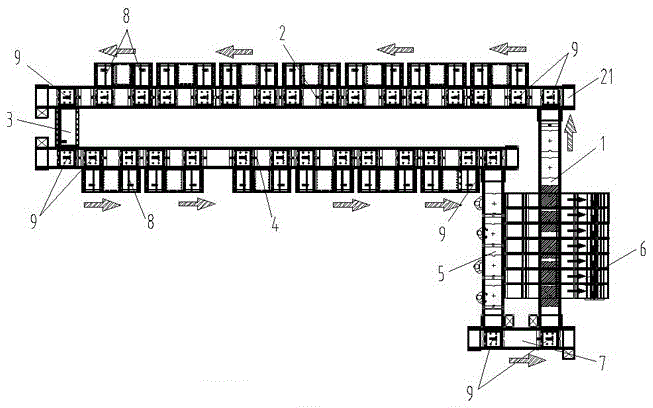

ActiveCN105480693AEasy to scale managementImprove work efficiencyConveyor partsTransition lineTransmission line

An environment-friendly overhaul line for waste recycled objects comprises a tool plate feeding conveying line, a first overhaul transmission line, an overhaul transition line, a second overhaul transmission line, a pick-up and distribution conveying line, a classification conveying line and a tool plate recycling transition line. By means of the environment-friendly overhaul line, the multiple overhaul transmission lines and multiple overhaul mechanisms can be arranged according to production requirements and can be used for overhauling different procedures of tool plates in a full-automatic manner; and each overhaul transmission line and the tool plate recycling transition line are each provided with multiple ejecting and horizontally-moving mechanisms so that various different transmission lines can be conveniently connected, overhaul and recycling of multiple different procedures can be conducted on tool plates, and the tool plates can be conveniently conveyed. The overhaul efficiency is high, full-automatic waste object conveying, full-automatic tool plate overhaul, full-automatic and cyclic tool plate recycling and full-automatic waste object classified recycling are integrated, full-automatic operation is achieved in the whole process, manual intervention is little, the work efficiency is high, the labor cost is low, the intelligent operation degree is high, and large-scale management is facilitated.

Owner:GUANGDONG HUI LIXING SEIKO TECH

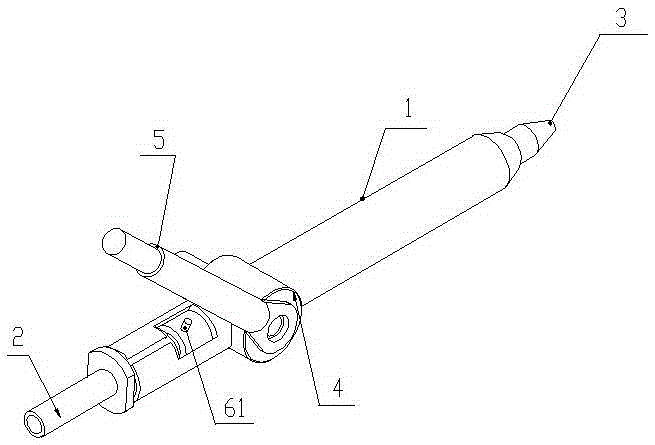

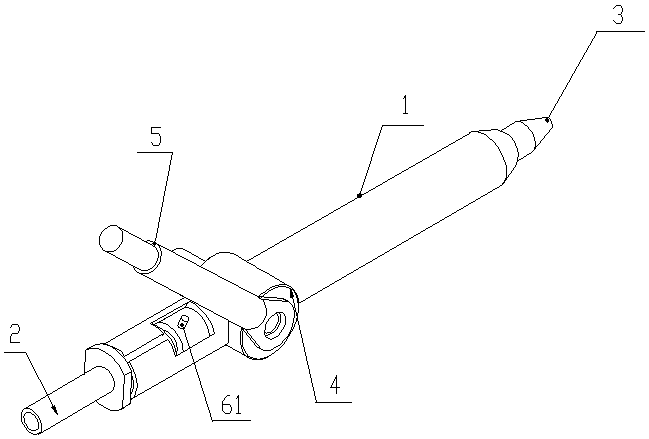

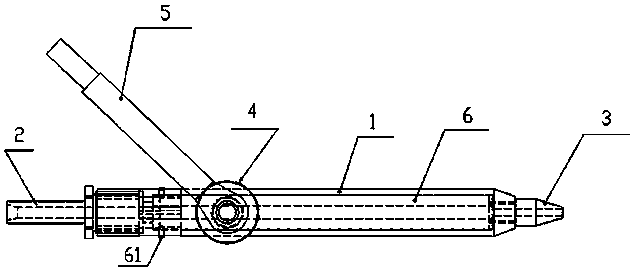

Automobile solenoid valve coil winding process

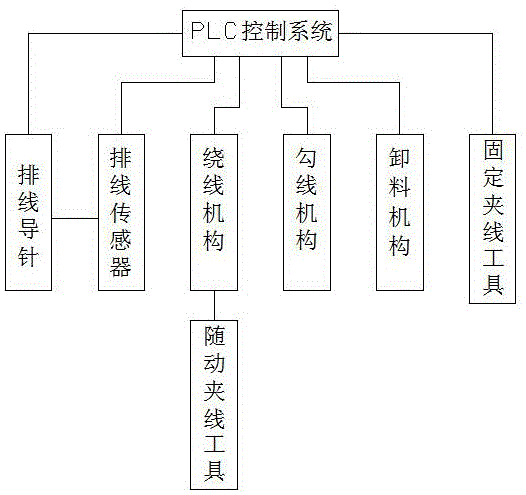

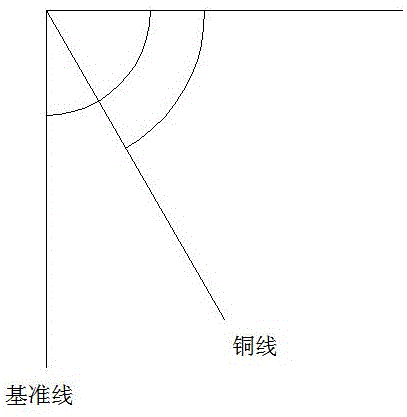

ActiveCN105914033ASolve the phenomenon of fragileRealize fully automatic windingCoils manufactureControl systemSolenoid valve

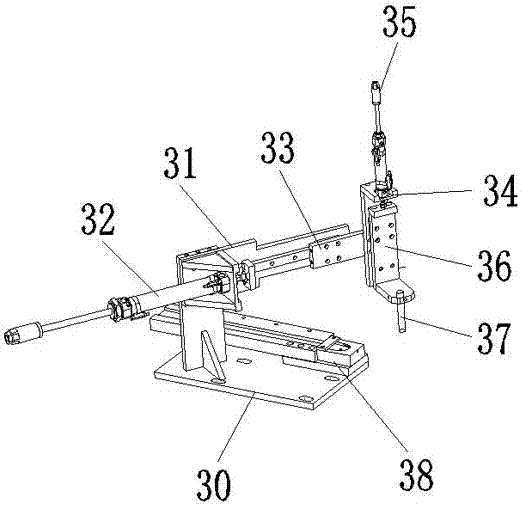

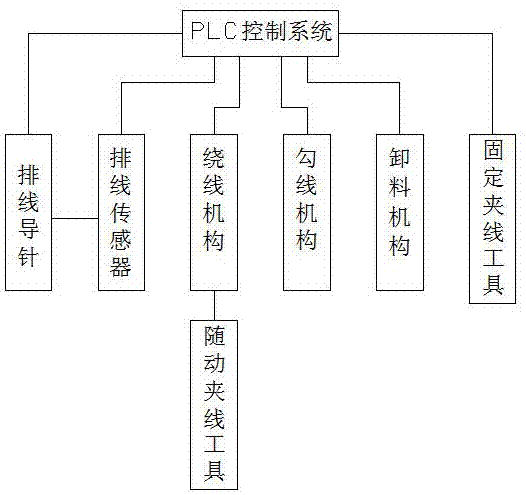

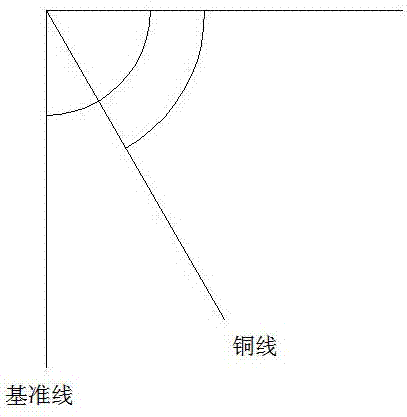

The invention provides an automobile solenoid valve coil winding process. According to the process, a PLC control system and a winding displacement guide pin, a winding displacement sensor, a winding mechanism, a wire hooking mechanism, a striping mechanism and a fixed wire clamping tool which are connected with the PLC control system and a follow-up wire clamping tool connected with the winding mechanism are included. The winding displacement guide pin, the winding displacement sensor, the winding mechanism, the wire hooking mechanism, the fixed wire clamping tool and the striping mechanism are arranged and in control connection with the PLC control system, and the follow-up wire clamping tool and the striping mechanism achieve winding of an automobile solenoid valve coil; the winding mechanism drives a solenoid valve coil framework to conduct winding, the winding displacement guide pin swings leftwards and rightwards to conduct winding displacement, the winding displacement sensor is actually fed back to the PLC control system according to the swing angle alpha of the winding displacement guide pin, and the PLC control system calculates out the winding displacement speed according to the winding displacement calculation formula, so that winding displacement is conducted by dynamically controlling the winding displacement speed of the winding displacement guide pin; the wire hooking mechanism guides a copper wire and conducts pin winding on a left pin from low to high, and fully automatic winding is achieved.

Owner:苏州创易技研股份有限公司

Ceramic grinding hole expanding machine

The invention provides a ceramic grinding hole expanding machine. The machine comprises a stand, a ceramic feeding mechanism, a jig turning plate mechanism, a first drilling mechanism, a second drilling mechanism, a first hole expanding mechanism, a second hole expanding mechanism, a third hole expanding mechanism, a ceramic jig mechanism, a ceramic blanking mechanism, a ceramic recovering mechanism, a ceramic blowing-off mechanism, a control system, a cooling barrel and a jig separating power mechanism. The machine is applicable to drilling, hole expanding, accurate positioning and processing of fine ceramic, so as to achieve consistent aperture and straight through holes; the minimum diameter of an expandable inner hole is 0.6mm, and the maximum diameter is up to 10mm; the length of the expandable inner hole is 4 to 30mm; in addition, accurate positioning and full automatic and accurate feeding can be achieved; qualified products and unqualified products can be fully automatically sieved and can accurately blanked and individually recovered; therefore, the intelligence operation degree is high, the working efficiency is high, the processing time is saved, the yield of products is high, the effect is good, the cost is small, the use is simple, convenient and fast, and the demand of fine industry development can be met.

Owner:DONGGUAN JINGKE AUTOMATION TECH

Soldering tin preheating principle and application

The invention discloses a soldering tin preheating principle and application. According to the invention, a bonding wire comprises a solder layer and scaling powder arranged in the solder layer, the soldering tin preheating principle is applied to carry out preheating treatment on solder before soldering iron is used for welding tin at a high temperature, and enables the solder to become the soft state after preheating from the solid state before preheating; after the solder layer and the scaling powder arranged in the solder layer are preheated, the solder layer is enabled to become soft from the solid state, and during the high-temperature welding process, the soft solder layer relieves the sharp expansive force of the scaling powder, weakens the power of welding spot explosion caused by instantaneous, rapid and sharp heated expansion of the scaling powder during the welding process, and reduces the phenomenon that welding spot explosion generates tin balls, and the tin balls splash to the surfaces of electronic elements to cause a short circuit. The preheating time, the temperature, the supply current and the power-on or power-off states can be intelligently controlled according to the production demands, the intelligent operation degree is high, the tin ball splashing quantity during welding spot explosion can be controlled and greatly reduced, the operation is very safe, the yield of the electronic elements is high, the quality effect is excellent, and the production cost is lowered.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

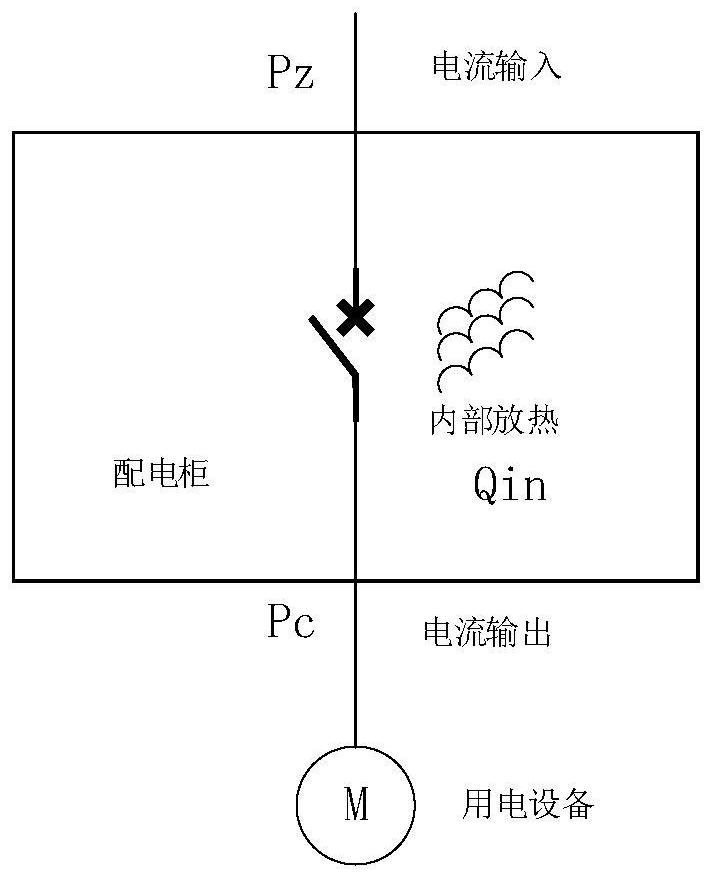

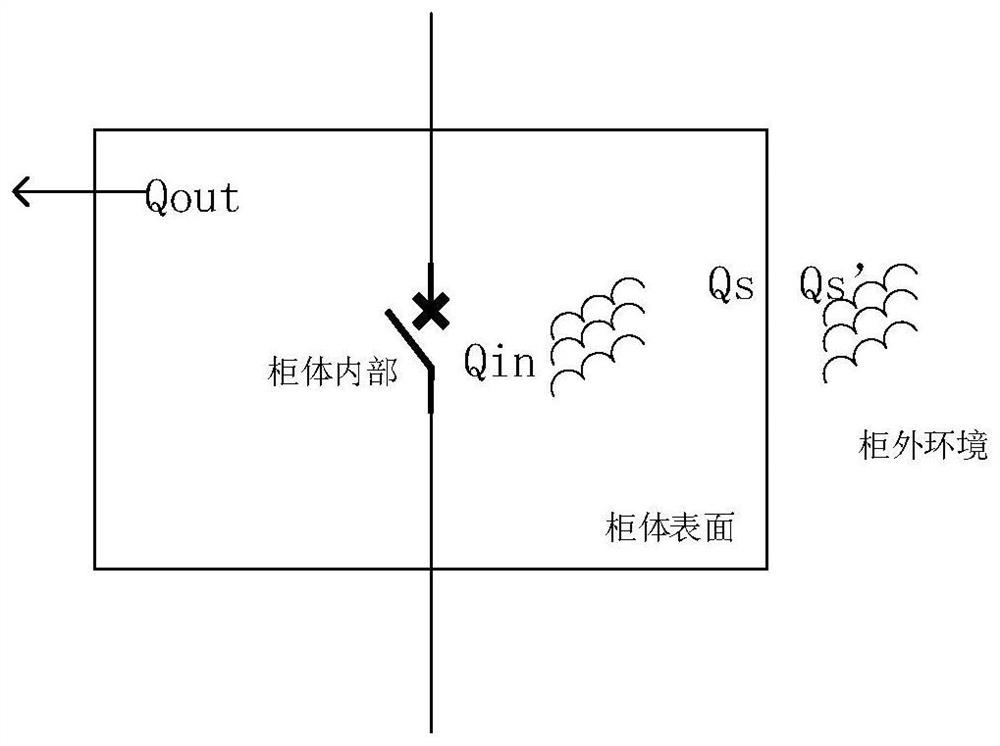

Fault analysis method for surface temperature inspection of power distribution cabinet

ActiveCN114692433AImprove the degree of intelligent operationLow implementation costCircuit arrangementsDesign optimisation/simulationComputational physicsFault analysis

The invention relates to a fault analysis method for surface temperature inspection of a power distribution cabinet. The method comprises the following steps: selecting characteristic parameters for establishing a prediction model; regular and cyclic inspection and recording are carried out on each power distribution unit, and a multivariate quadratic linear regression model is established for the predicted temperature T (x) of the surface of the cabinet body at the Xth time; the maximum load rate dMAX and the sample absolute average error TMAD of the sample are calculated as judgment threshold values during temperature prediction; performing surface temperature detection on a power distribution unit of the power distribution cabinet, and recording temperature data; the data are substituted into the linear regression equation, the surface temperature predicted value T predicted value and the error delta between the actual value T actual value and the predicted value T predicted value are calculated, and delta = T actual value-T predicted value; judging the size of delta and the size of TMAD, if delta gt; and the TMAD analyzes the environment temperature of the distribution room, if the environment temperature is larger than a, temperature abnormity alarm reminding is carried out, if the environment temperature is smaller than a, the operation load rate dK of the last two times of sampling is calculated, and if dK is smaller than or equal to dMAX, abnormity alarm is carried out on electrical elements of the distribution unit.

Owner:中原环保股份有限公司

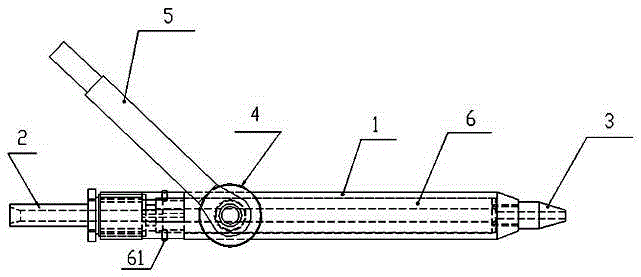

Threading and glue dispensing machine

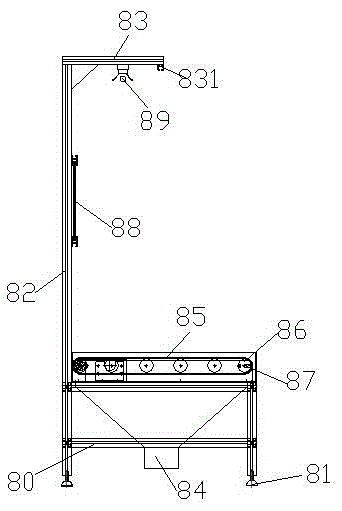

InactiveCN105457849AImprove the degree of intelligent operationImprove yieldLiquid surface applicatorsSevering textilesControl systemHooking

The invention discloses a threading and glue dispensing machine. The threading and glue dispensing machine comprises a feeding and conveying rail, a moving mechanism, an upper and lower carrier circulating mechanism, a thread pulling and clamping mechanism, a thread cutting mechanism, a thread hooking and retreating mechanism, a 90 degree rotating mechanism, a glue dispensing mechanism, a finished product discharging mechanism and a control system. According to the invention, the feeding and conveying rail feeds labels, the moving mechanism sucks the labels from the feeding and conveying rail, carriers of the upper and lower carrier circulating mechanism locate the labels accurately, the thread pulling and clamping mechanism feeds threads and stretch the threads tight, the thread cutting mechanism cuts the threads, the thread hooking and retreating mechanism hooks and retreats the threads, the 90 degree rotating mechanism turns the threaded labels by 90 degrees, the glue dispensing mechanism dispenses glue on the labels turned by 90 degrees, the finished product discharging mechanism clamps the threaded labels and discharges finished products, full-automatic conveying and feeding, moving and locating of the labels and feeding, hooking, stretching, cutting, glue dispensing, discharging and recycling of the threads are integrated, the glue dispensing amount is stable, the efficiency is high, and the cost is low.

Owner:YELLOWKNIFE DATA CABLE CO LTD

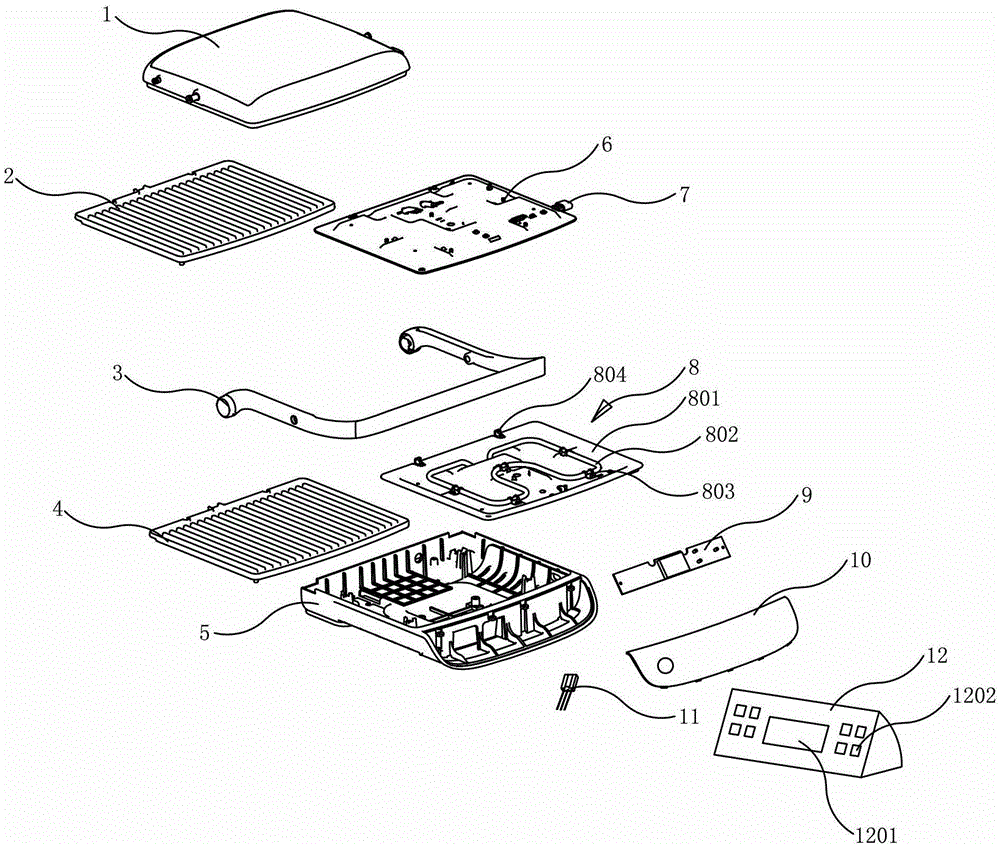

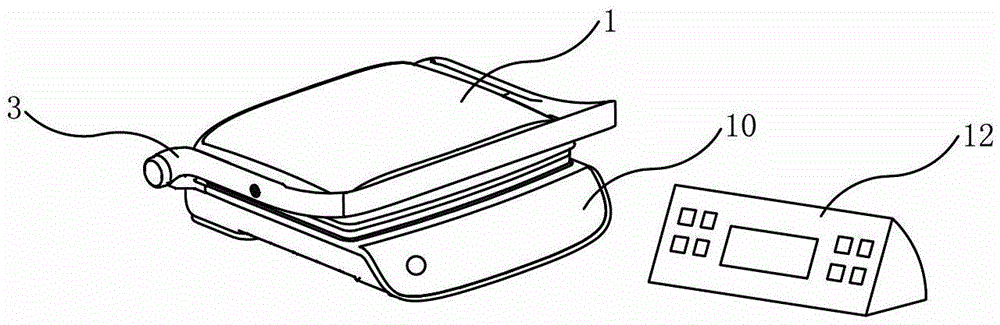

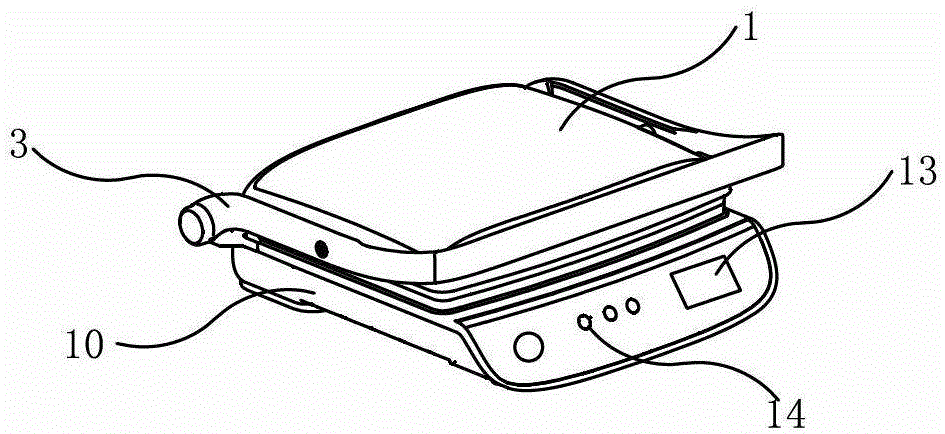

Remote control grill and method of operation thereof

ActiveCN103082881BReasonable structural designImprove the degree of intelligent operationRoasters/grillsFrying pansCooking & bakingRemote control

The invention relates to a remote control type baking device and an operating method thereof. The remote control type baking device is designed for solving the problem that an existing similar product is poor in structural design. An upper heating element is arranged at the bottom of an upper shell of the baking device, the upper heating element is connected with an upper baking tray, a lower heating element is arranged on the top of a lower shell, the lower heating element is connected with the lower heating element, and a locking knob is arranged on the lower shell. A rocking bar is of a U shape, one opening end of the rocking bar is hinged with one end of the lower shell, and the inner diameter of the middle section of the rocking bar is hinged with the middle section of the upper shell. The remote control type baking device is characterized in that an infrared receiver is arranged on a printed circuit board (PCB) control panel. The remote control type baking device further comprises a remote control, the remote control is provided with a display screen and buttons, and the remote control is of a triangular prism shape. The remote control is a programmable control box, a programmable chip is arranged in the remote control, and the remote control is provided with a data input port. The remote control type baking device is reasonable in structural design, high in intelligent operation degree, simple and convenient to use, good in safety, and suitable for being used as a home baking device and improvement of a similar product.

Owner:NINGBO BIYI ELECTRIC APPLIANCE

An air conditioner assembly intelligent tooling board

ActiveCN105479415BAvoid Composition CostsLow costAssembly machinesWork benchesElectricityAssembly line

The invention relates to an intelligent tooling plate for assembling an air conditioner. The intelligent tooling plate comprises a bottom plate assembly, a rotating plate assembly, a rotary table assembly, guide pulleys, dog catch spacing openings, file folder grooves, one or more first die sets, one or more second die sets, connecting line assemblies, a connector mounting plate, coolant connectors, an electric connection terminal, an upper mounting plate, a fillister head screw, an elastic washer, a rotary table, a rotary table lower mounting plate, upper mounting plate screws, lower mounting plate screws and a rotating plate mat. The rotary table disclosed by the invention has the functions of automatic positioning and being capable of elastically adjusting rising or falling, so that more than two die sets can perform synchronous assembly or synchronous test simultaneously and accurately on air conditioner assemblies with a plurality of different faces placed on the rotary table, the problem that the operation of the next station of a conventional air conditioner mounting assembly line can be started only after the completion of the operation of the previous station so that time is wasted is solved, the disadvantages of being high in cost, large in volume, difficult to maintain and low in assembling efficiency in the conventional air conditioner mounting assembly line are avoided, and the intelligent tooling plate disclosed by the invention is high in intelligent degrees and low in cost.

Owner:GUANGDONG HUI LIXING SEIKO TECH

A threading glue machine

InactiveCN105457849BImprove the degree of intelligent operationImprove yieldLiquid surface applicatorsSevering textilesControl systemHooking

The invention discloses a threading and glue dispensing machine. The threading and glue dispensing machine comprises a feeding and conveying rail, a moving mechanism, an upper and lower carrier circulating mechanism, a thread pulling and clamping mechanism, a thread cutting mechanism, a thread hooking and retreating mechanism, a 90 degree rotating mechanism, a glue dispensing mechanism, a finished product discharging mechanism and a control system. According to the invention, the feeding and conveying rail feeds labels, the moving mechanism sucks the labels from the feeding and conveying rail, carriers of the upper and lower carrier circulating mechanism locate the labels accurately, the thread pulling and clamping mechanism feeds threads and stretch the threads tight, the thread cutting mechanism cuts the threads, the thread hooking and retreating mechanism hooks and retreats the threads, the 90 degree rotating mechanism turns the threaded labels by 90 degrees, the glue dispensing mechanism dispenses glue on the labels turned by 90 degrees, the finished product discharging mechanism clamps the threaded labels and discharges finished products, full-automatic conveying and feeding, moving and locating of the labels and feeding, hooking, stretching, cutting, glue dispensing, discharging and recycling of the threads are integrated, the glue dispensing amount is stable, the efficiency is high, and the cost is low.

Owner:YELLOWKNIFE DATA CABLE CO LTD

Coil winding process for automobile solenoid valve

ActiveCN105914033BSolve the phenomenon of fragileRealize fully automatic windingCoils manufactureBobbinSolenoid valve

A coil winding process for an automobile solenoid valve of the present invention, comprising a PLC control system, and a wire guide pin, a wire sensor, a winding mechanism, a hooking mechanism, an unloading mechanism and a fixed clamping wire respectively connected to the PLC control system tool, and a follow-up clamping tool connected with the winding mechanism. The present invention connects and controls with the PLC control system respectively by being provided with a wire arranging guide pin, a wire arranging sensor, a winding mechanism, a hooking mechanism, a fixed clamping tool and an unloading mechanism, and the follow-up clamping tool and the unloading mechanism realize the automatic control of the vehicle. The coil of the solenoid valve is wound; the winding mechanism drives the coil frame of the solenoid valve to wind the coil, and the wire guide pin swings left and right to arrange the wires, and the wire guide sensor swings according to the angle α of the wire guide pin 实 Feedback to the PLC control system, the PLC control system calculates the speed of the wire according to the calculation formula of the wire, so as to realize the dynamic control of the wire speed of the wire guide needle to carry out the wire; the hooking mechanism guides the copper wire to the left pin by Foot binding from low to high, which realizes fully automatic winding.

Owner:苏州创易技研股份有限公司

A closed-loop intelligent fine-tuning alignment automatic winding machine

ActiveCN105810430BNot easy to disconnectPrevent disconnectionCoils manufactureCable transmissionWinding machine

A closed-loop intelligent fine-tuning full-automatic winding machine of the present invention includes a machine table, a wire arranging transmission mechanism, an independent wire arranging mechanism, a winding mechanism, a finished product unloading mechanism, a wire clamping mechanism, a skeleton feeding mechanism, and a finished product unloading mechanism. magazine, operating system touch screen and tension mechanism. In the present invention, the coil skeleton is automatically loaded by the skeleton feeding mechanism. The wire mechanism is equipped with an intelligent cable sensor to intelligently feedback the wire speed to adjust the wire angle of the wire guide pin to adapt to the instant winding speed. It avoids the situation of wire breakage in wire hook welding. It fully automatically completes the winding of precision coils without disorder, and automatically completes the winding, hooking and arranging of wires from the top to the bottom. High degree and low cost.

Owner:苏州创易技研股份有限公司

A kind of solder preheating method

ActiveCN105397231BReduce powerRelieves sudden swellingHeating appliancesSoft stateElectronic component

The invention discloses a soldering tin preheating principle and application. According to the invention, a bonding wire comprises a solder layer and scaling powder arranged in the solder layer, the soldering tin preheating principle is applied to carry out preheating treatment on solder before soldering iron is used for welding tin at a high temperature, and enables the solder to become the soft state after preheating from the solid state before preheating; after the solder layer and the scaling powder arranged in the solder layer are preheated, the solder layer is enabled to become soft from the solid state, and during the high-temperature welding process, the soft solder layer relieves the sharp expansive force of the scaling powder, weakens the power of welding spot explosion caused by instantaneous, rapid and sharp heated expansion of the scaling powder during the welding process, and reduces the phenomenon that welding spot explosion generates tin balls, and the tin balls splash to the surfaces of electronic elements to cause a short circuit. The preheating time, the temperature, the supply current and the power-on or power-off states can be intelligently controlled according to the production demands, the intelligent operation degree is high, the tin ball splashing quantity during welding spot explosion can be controlled and greatly reduced, the operation is very safe, the yield of the electronic elements is high, the quality effect is excellent, and the production cost is lowered.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

A ceramic grinding hole reaming machine

Owner:DONGGUAN JINGKE AUTOMATION TECH

A fully automatic intelligent two-way box holding mechanism

ActiveCN105291484BShorten the timeShorten the production cycleBox making operationsPaper-makingPaperboardEngineering

The invention provides a full-automatic intelligent double-way box holding mechanism which comprises a base, a machine frame, a fold-in forming mechanism, a box pressing mechanism, a rear section conveyor belt and a double-way box holding mechanism. The rear section conveyor belt is arranged in the center of the machine frame and used for feeding a paperboard box and face paper. A left and right box holding manner is adopted in the double-way box holding mechanism for asynchronous feeding operation performed station to station and a left station and a right station are arranged for asynchronous paper box forming and processing treatment. Due to the adoption of a double-station asynchronous paper box forming manner, the time spent in waiting the paper box to be formed and processed in the box holding and feeding process is shortened, after the paper box is processed, a manner that formed paper box discharging and box holding and feeding are performed synchronously is adopted in the double-way box holding mechanism, and the time spent in waiting the finished paper box to be discharged in the box holding and feeding process is shortened as well; and the mechanism is suitable for conducting box holding and forming treatment on paper boxes of various different specifications synchronously, a production period is shortened greatly, production efficiency is improved by over one time, the capacity is improved by over one time, efficiency is high, the effect is good, cost is low, and the intelligent operation degree is high.

Owner:广东力顺源智能自动化有限公司

A linear fan automatic assembly machine

ActiveCN104879326BRealize automatic assemblyImprove the degree of intelligent operationPump componentsPumpsAgricultural engineeringFully automatic

A linear fan automatic assembly machine of the present invention comprises a frame, and a fan frame feeding line horizontally connected and arranged on the left side of the frame, and a fan blade feeding line horizontally connected and arranged on the left side of the frame, and a fan blade feeding line arranged vertically on the left side of the frame On the right side of the frame, the finished product unloading line under the fan blade feeding line, and the fan frame fixture mechanism set on the top of the frame, and the left mounting mechanism and right mounting mechanism set above the fan frame fixture mechanism. The present invention adopts a linear layout structure, so that it realizes fully automatic feeding, fully automatic assembly of fans, and a high degree of intelligent operation. It can also arrange multiple stations at the same time for assembly line operations, saving floor space and space. The cost is reduced, the work efficiency is greatly improved, and it is safe and reliable, avoiding the danger of work-related accidents easily caused by the operation mode of manual feeding, and the structure is simpler, scientific and reasonable, and is convenient for widespread promotion and use.

Owner:东莞市诺辉自动化机械有限公司

A special slotting machine for building decoration

ActiveCN109290902BImprove the degree of intelligent operationImprove work efficiencyGrinding feed controlWorking accessoriesFrequency conversionElectric machine

The invention relates to a special slotting machine for building decoration, which comprises a base, a fixed pulley is arranged on the bottom of the base, a push handle is welded on the base, the distance between the push handle and the base is 45‑60°, the push handle is connected with a variable frequency motor, and the variable frequency motor is equipped with The controller and the motor are connected to the slide rail, the two ends of the slide rail are provided with limit blocks, the limit block is provided with a blower, and the slide rail is provided with a slotting device. The invention has high intelligent operation degree, compact overall structure, good fixing effect, strong stability, zero error and high working efficiency.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

An environmentally friendly dismantling and inspection line for waste and recycled items

ActiveCN105480693BSmooth connectionEasy to scale managementConveyor partsEngineeringTransmission line

Owner:GUANGDONG HUI LIXING SEIKO TECH

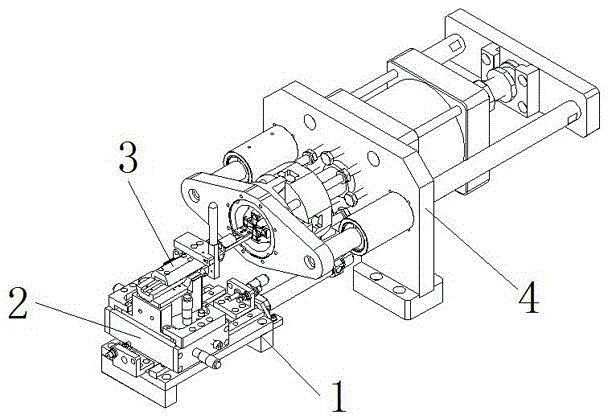

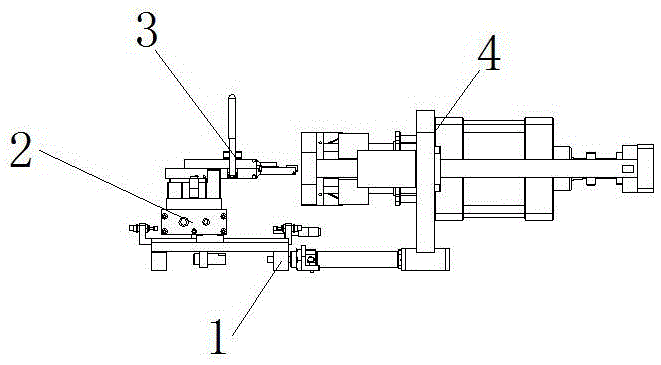

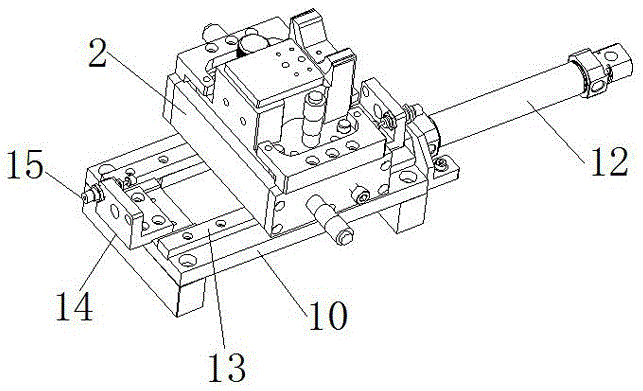

Automatic riveting machine for Tape-c data line shells

InactiveCN105642767AIncrease production capacityImprove work efficiencyMetal-working feeding devicesPositioning devicesData linesElectrical and Electronics engineering

The invention discloses an automatic riveting machine for Tape-c data line shells. The automatic riveting machine comprises a hoop-rivet shifting mechanism, a hoop-rivet positioning mechanism, a hoop-rivet fixing fixture and a hoop-rivet mechanism. The hoop-rivet positioning mechanism is slidably arranged on the upper surface of the hoop-rivet shifting mechanism. The hoop-rivet fixing fixture is installed at the top of the hoop-rivet positioning mechanism. The hoop-rivet mechanism is installed on the right side of the hoop-rivet fixing fixture. According to the automatic riveting machine for the Tape-c data line shells, by arranging the hoop-rivet shifting mechanism, the hoop-rivet positioning mechanism, the hoop-rivet fixing fixture and the hoop-rivet mechanism, shifting of the hoop-rivet fixing fixture is achieved through the hoop-rivet shifting mechanism, shifting of the hoop-rivet fixing fixture is positioned precisely through the hoop-rivet positioning mechanism, and the Tape-c data line shells in the hoop-rivet fixing fixture is riveted automatically through the hoop-rivet mechanism; the output of the riveted Tape-c data line shells through the full automatic riveting machine reaches 16 per minute or more, the productivity is high, and the riveting effect is good; the cost is low, the working efficiency, the rate of the finished products and the degree of intelligent operation are high, using is convenient and quick, and the structure is simple.

Owner:DONGGUAN MING HUA AUTOMATION EQUIP

A robot for automatic implantation of insulating sleeves and wrapping of wires

ActiveCN105761930BFully automatedImprove the degree of intelligent operationCoils manufactureEngineeringHooking

The invention relates to a robot with functions of automatic inserting of an insulating sleeve, wire winding and glue coating. The robot comprises a machine frame, an automatic framework feeding mechanism, a framework wire winding and glue coating mechanism, a tension force mechanism and a mechanical state alarm lamp, wherein the automatic framework feeding mechanism is mounted on the right side of the machine frame and used for transporting frameworks, the framework wire winding and glue coating mechanism is mounted in the machine frame and used for performing pipe casing, wire displacement and glue coating on the frameworks, and the pulling force mechanism and the mechanical state alarm lamp are mounted on the machine frame. According to the robot disclosed by the invention, the automatic framework feeding mechanism and the framework wire winding and glue coating mechanism are arranged, the automatic framework feeding mechanism is used for fully and automatically conveying the framework, and the framework wire winding and glue coating mechanism is provided with a wire winding main shaft mechanism, framework feeding mechanisms, a right-angle wire pressing mechanism, a pipe conveying mechanism, a wire displacement positioning mechanism, a wire conveying and pipe penetrating mechanism, a glue coating mechanism and a finished product discharging mechanism, full automation completion of a series of operations of feeding the frameworks, conveying casing pipes, threading the casing pipes, thread hooking on the frameworks, wire displacement of the frameworks, coating glue of the frameworks, discharging finished products and full automation wire displacement and positioning are realized, the intelligent operation degree is high, the efficiency is high, the effects are good, and the cost is low.

Owner:苏州创易技研股份有限公司

A plant nutrient cultivation liquid automatic diversion canning machine

InactiveCN105667850BControl filling volumeConsistent filling volumeLiquid materialAutomatic controlPlant nutrition

Owner:DONGGUAN MING HUA AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com