A kind of solder preheating method

A soldering and preheating technology, applied in welding equipment, electric heating devices, metal processing equipment, etc., can solve the problems of easy generation of air bubbles in flux, short circuit of electronic components and explosion of solder joints, etc., to reduce the amount of spatter, reduce Short circuit, the effect of reducing the power of solder joint explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

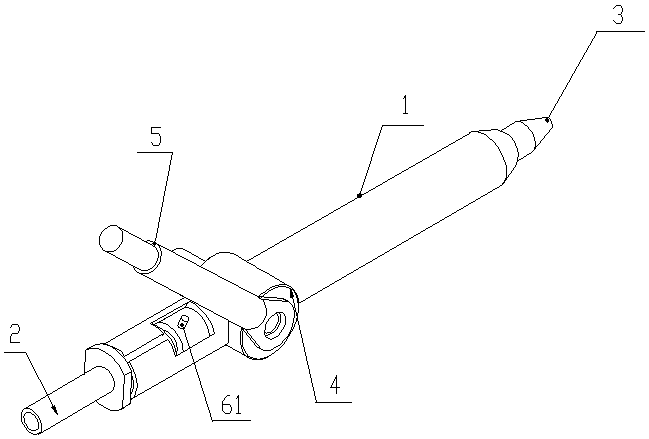

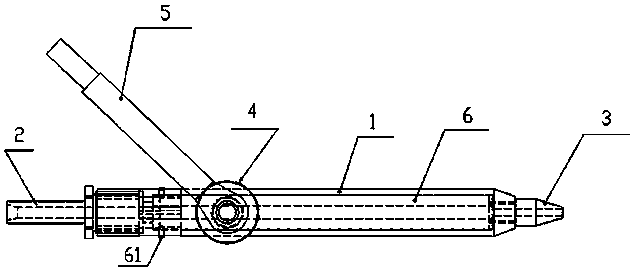

Image

Examples

Embodiment 1

[0023] Embodiment 1. The tin wire with a diameter of 0.8mm is preheated. Before the tin wire layer is preheated, the sealing damage treatment is first performed. The tin wire does not set the preheating temperature. The temperature set when the tin wire is soldered with a high-temperature soldering iron is At 380°C, the amount of tin beads produced is less than 60%.

Embodiment 2

[0024] Embodiment 2. The tin wire with a diameter of 0.8 mm is preheated. The sealing damage treatment is not performed before the tin wire layer is preheated. The tin wire preheating time is set to 2 minutes, and the tin wire preheating temperature is set to 65 ℃, the temperature of the preheated soft tin wire for high-temperature soldering iron soldering is 380 ℃, and the amount of tin beads produced is less than 15%.

Embodiment 3

[0025] Embodiment 3. Preheating the tin wire with a diameter of 0.8 mm. Before the tin wire layer is preheated, the sealing damage treatment is first performed. The tin wire preheating time is set to 2 minutes, and the tin wire preheating temperature is set to 65 ℃, the temperature of the preheated soft tin wire for high-temperature soldering iron soldering is 380 ℃, and the amount of tin beads produced is less than 5%. It can be seen that before the tin wire is preheated, the sealing damage treatment is first performed on the tin wire layer. The optimal time for preheating the tin wire is 2 minutes, and the optimal temperature for preheating the tin wire is 65°C. When the optimum temperature of the final soft tin wire for high-temperature soldering iron soldering is selected as 380°C, under this condition, it not only greatly reduces the amount of solder balls produced, but also alleviates the rapid expansion of the flux and weakens the soldering process. The medium flux is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com