Coil winding process for automobile solenoid valve

A solenoid valve coil and winding process technology, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as low efficiency, increased winding speed, and increased defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

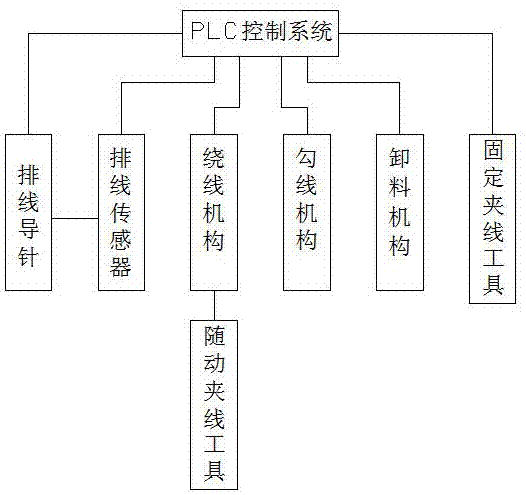

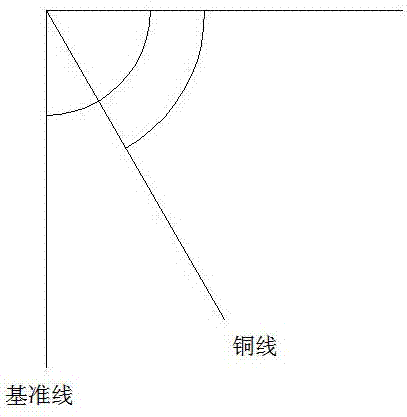

[0017] In this example, refer to Figure 1 to Figure 2 As shown, a kind of automobile electromagnetic valve coil winding process of the present invention, comprises PLC control system, and the cable guide needle that is connected with PLC control system respectively, cable sensor, winding mechanism, hooking mechanism, unloading mechanism and A fixed thread clamping tool, and a follow-up thread clamping tool connected with the winding mechanism, and the thread arranging guide pin is connected with the cable arranging sensor. The object of the automobile solenoid valve coil winding is the solenoid valve coil skeleton. The solenoid valve coil skeleton is composed of a coil and two pins. The two pins include the left pin and the right pin. The left pin and the right pin are respectively located on Both ends of the bobbin.

[0018] In one embodiment, the coil winding process steps of the automobile solenoid valve are as follows: step 1, the fixed clamping tool moves forward and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com