Full-automatic winding all-in-one machine of cylindrical nickel hydride battery

A cylindrical battery, fully automatic technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low winding automation and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

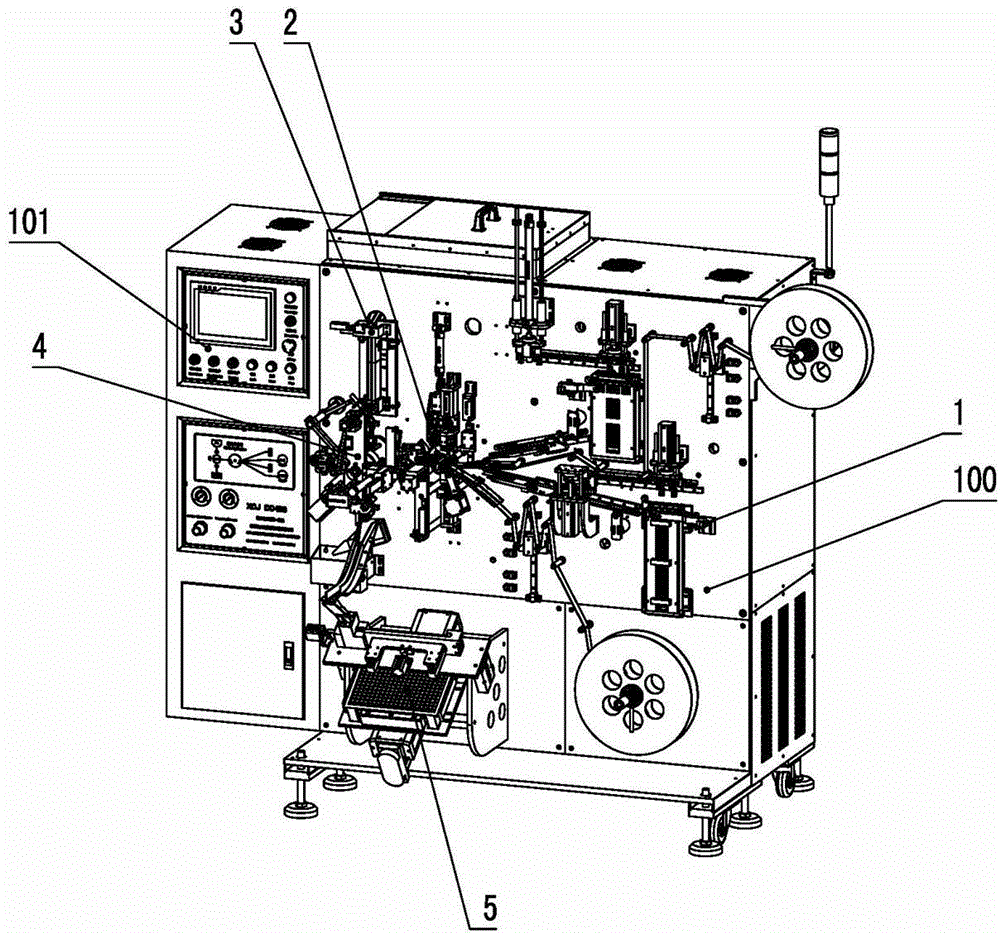

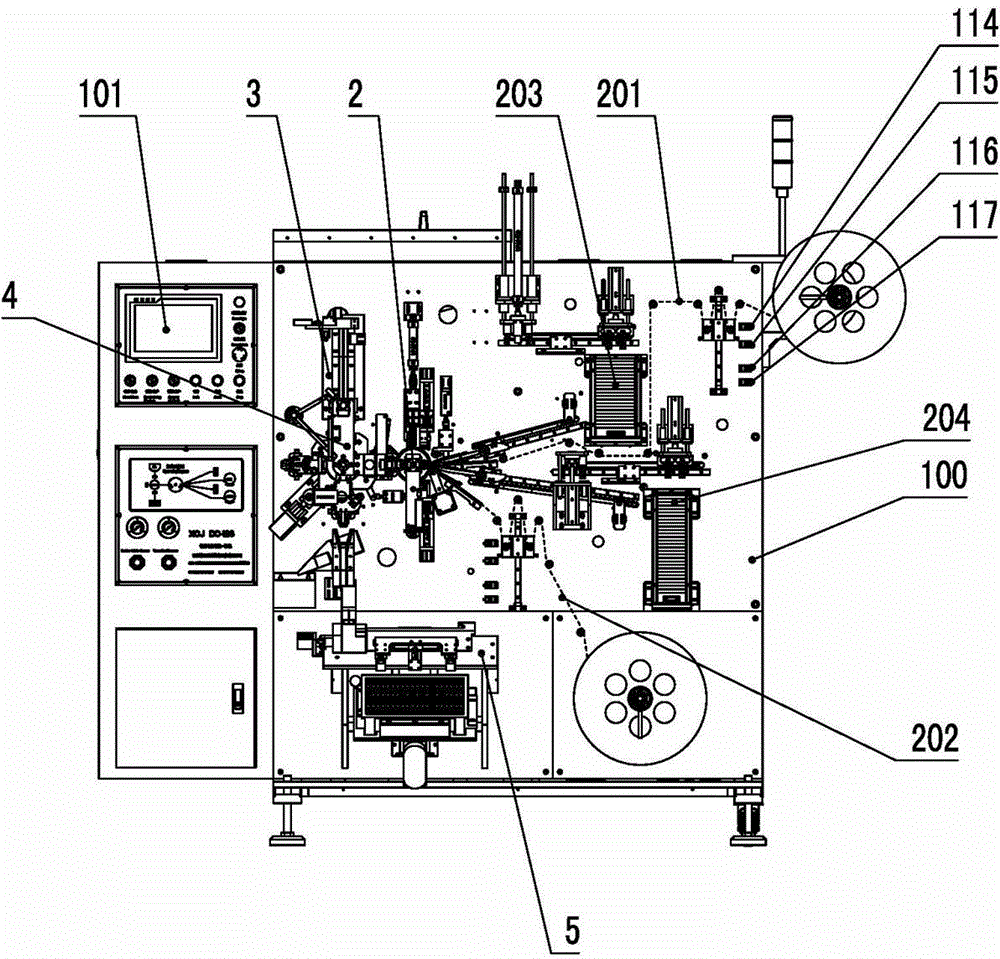

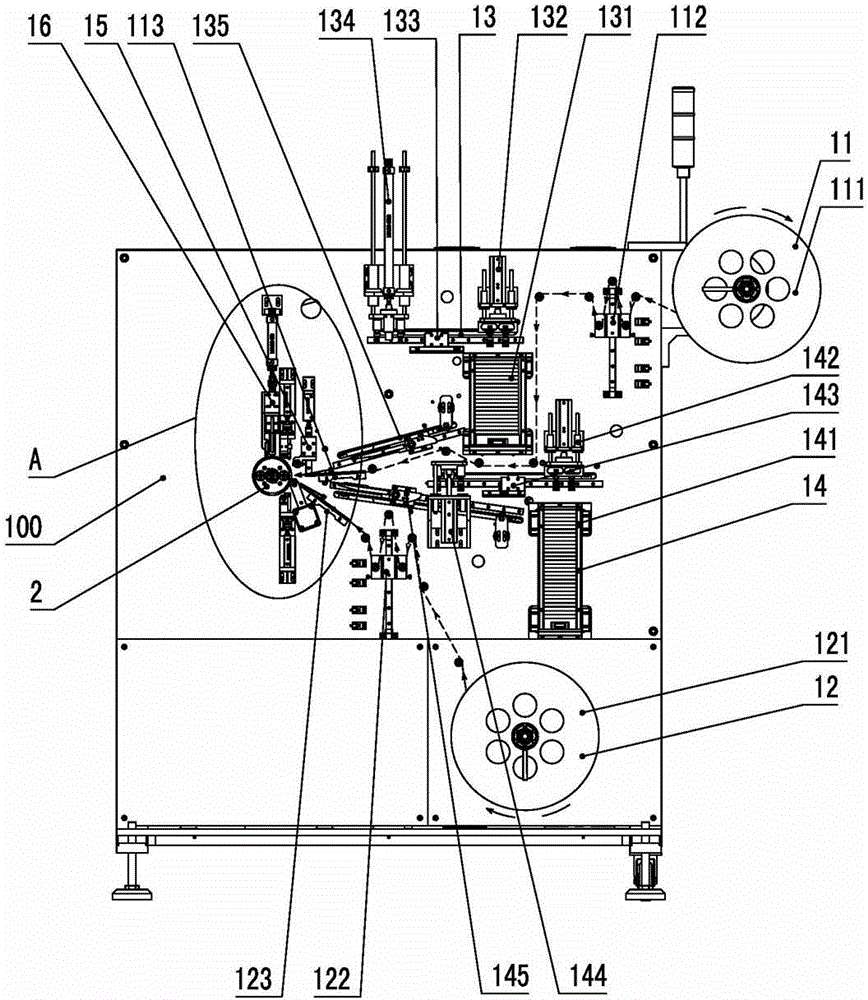

[0086] Figure 1 to Figure 27 The reference numerals in the figure are: machine base 100; control box 101; feeding mechanism 1; upper layer cell diaphragm paper transmission mechanism 11; Block 1122; upper layer tension adjustment counterweight block 1123; upper layer guide rail 113; upper layer paper shortage proximity switch 114; upper layer paper placement proximity switch 115; upper layer stop paper release switch 116; upper layer broken paper proximity switch 117; lower layer cell diaphragm paper Transmission mechanism 12; lower paper tray 121; lower tension adjustment mechanism 122; lower guide rail 123; negative electrode foil transmission mechanism 13; negative electrode foil storage box 131; negative electrode foil retrieving mechanism 132; negative electrode foil retrieving cylinder 1321; Negative electrode foil retrieving sucker 132...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com