Device for winding 8-shaped coils

A winding and coil technology, which is applied in the field of figure-8 coil winding devices, can solve the problems of low efficiency, high manufacturing difficulty and low efficiency, and achieves the effects of convenient use, improved productivity, and elimination of complicated manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

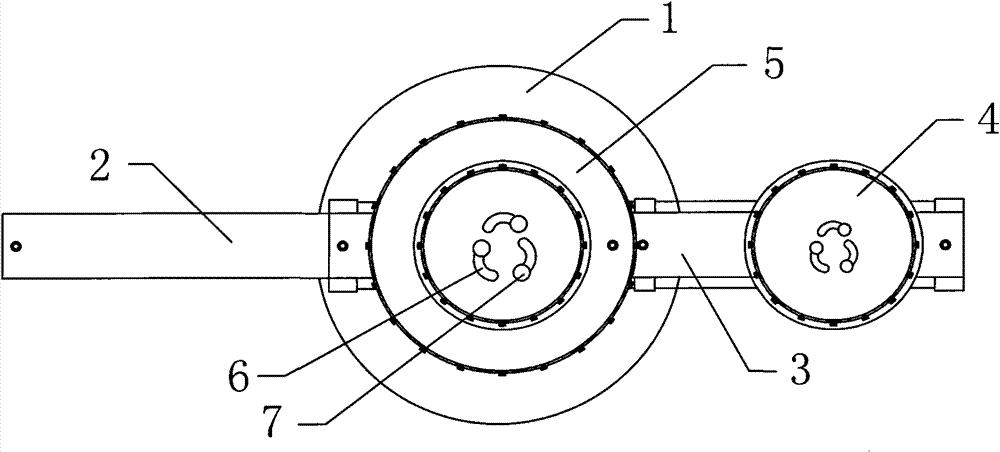

[0018] Such as figure 1 The 8-shaped coil winding device shown includes a device body, and the driving end of the device body is provided with a driving faceplate 1. The special feature is that a fixed template 2 is installed on the drive faceplate 1, and a 2. The movable cover is provided with a sliding template 3. At the same time, a small coil winding component 4 and a large coil winding component 5 are provided on the sliding template 3 . Thus, by moving the sliding template 3, the small coil winding part 4 or the large coil winding part 5 can be moved to the center of the machine tool of the device body to realize corresponding coil winding.

[0019] In view of a preferred embodiment of the present invention, in order to facilitate the smooth operation of the driving faceplate 1 to drive the fixed template 2, and to stabilize the entire operation process, an auxiliary fixing flange is provided at the contact end of the driving faceplate 1 and the fixed template 2 . At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com