Fault analysis method for surface temperature inspection of power distribution cabinet

A fault analysis method and surface temperature technology, applied in electrical components, circuit devices, electrical digital data processing, etc., to achieve the effect of reducing maintenance costs and frequency, reducing implementation costs, and improving the degree of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

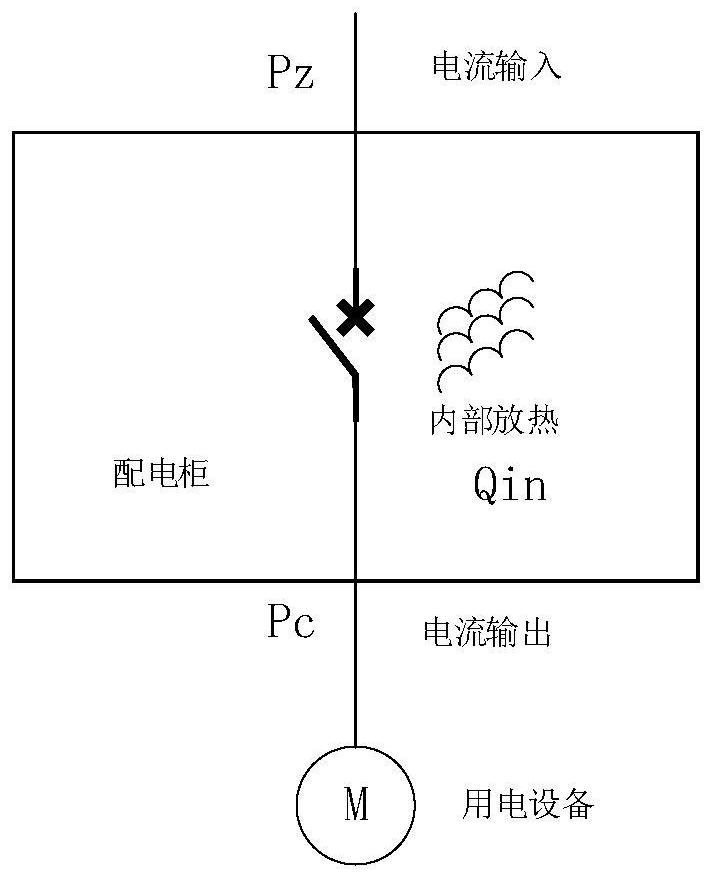

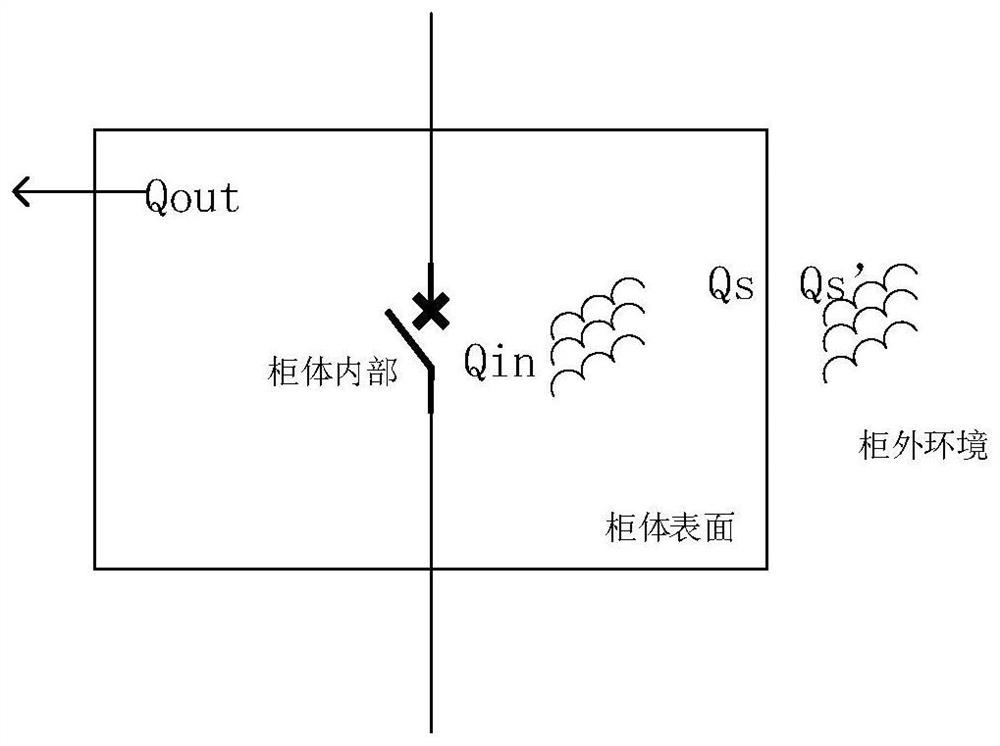

[0058] The fault analysis method for the inspection of the surface temperature of the power distribution cabinet in the embodiment of the present invention eliminates that the abnormal surface temperature of the power distribution cabinet is caused by the change of the external environment or the power supply load, but is caused by the aging or failure of the electrical components in the power distribution cabinet. , to ensure the accuracy of inspection.

[0059] When electrical components such as cables, inductors and other components in the power distribution cabinet age or fail, it is often characterized by abnormal changes in the operating heat. For example, a short circuit will cause the temperature to increase, and a short circuit will cause the temperature to decrease. As a result, the surface temperature of the power distribution cabinet will be different from normal. When the ambient temperature changes greatly, or the operating load of the power supply equipment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com