A linear fan automatic assembly machine

An automatic assembly machine, linear technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of increased floor space, increased floor space, and high manufacturing costs of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

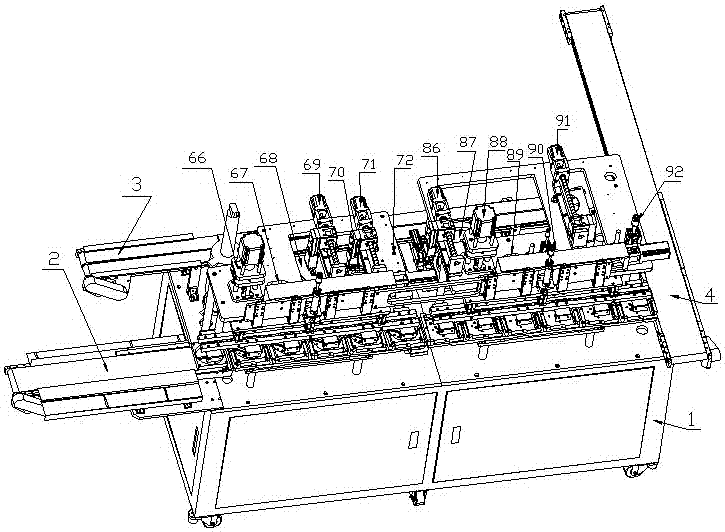

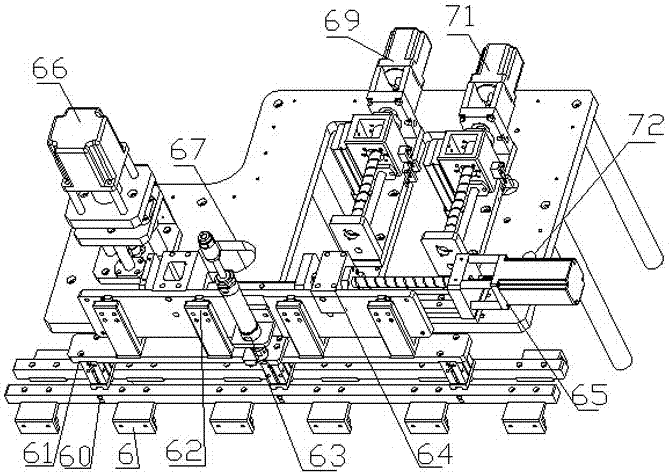

[0015] In this example, if Figure 1 to Figure 4 As shown, a linear fan automatic assembly machine of the present invention includes a frame 1, a fan frame feeding line 2 that is horizontally connected and arranged on the left side of the frame 1, and a fan blade that is horizontally connected and arranged on the left side of the frame 1 The feeding line 3, and the finished product unloading line 4 arranged longitudinally on the right side of the frame 1 and below the fan blade feeding line 3, and the fan frame fixture mechanism arranged on the top of the frame 1, and the fan frame fixture mechanism The left mounting mechanism and the right mounting mechanism above.

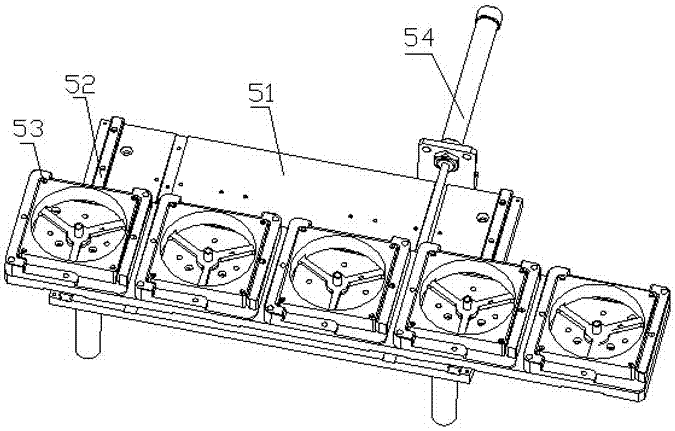

[0016] Wherein, the fan frame fixture mechanism is provided with a fan frame fixture platform 51, and a fan frame fixture front and rear sliding mechanism 52 longitudinally arranged at both ends of the fan frame fixture platform 51, and a front and rear sliding mechanism 52 slidingly arranged on the fan frame fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com