Intelligent full-automatic high-frequency quenching machine

A high-frequency quenching and fully automatic technology, applied in the direction of quenching devices, improving energy efficiency, process efficiency, etc., can solve problems such as difficult to guarantee hardened layer, poor effect, and inability to control the continuity of metal workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

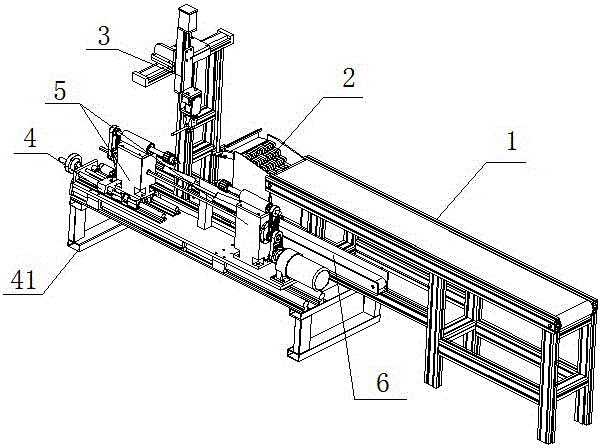

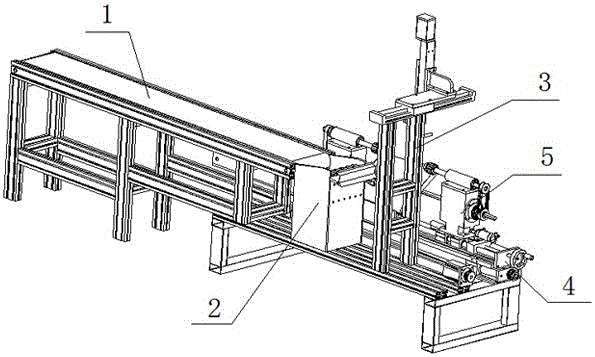

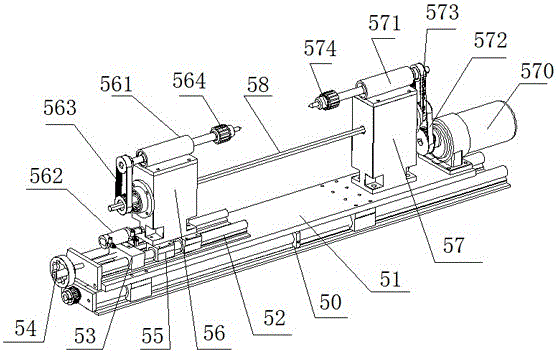

[0013] In this example, refer to Figure 1 to Figure 4 As shown, an intelligent full-automatic high-frequency quenching machine of the present invention includes a feeding conveyor belt 1, and a material distribution positioning mechanism 2 arranged at the end of the feeding conveyor belt 1, and is arranged on the left side of the material distribution positioning mechanism 2 The feeding manipulator 3, and the distance adjustment and positioning mechanism 4 arranged in front of the feeding manipulator 3, and the tripod 41 arranged under the two ends of the distance adjustment and positioning mechanism 4, and the rotating top mechanism 5 arranged on the distance adjustment and positioning mechanism 4, And the finished product unloading conveyer belt 6 that is arranged on the back of the rotary top mechanism 5; the rotary top mechanism 5 includes the rotary top overall displacement mechanism 50, and the rotary top bottom plate 51 that is arranged on the rotary top overall displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com