Plate unit non-destructive turnover hanger and turnover method

A spreader and supporting plate technology, which is applied in the field of plate unit turning spreader manufacturing, can solve the problems of affecting the appearance quality of the plate unit, hidden safety and quality hidden dangers, and damage to the plate unit falling, so as to avoid safety and quality risks and have a simple structure , the effect of cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

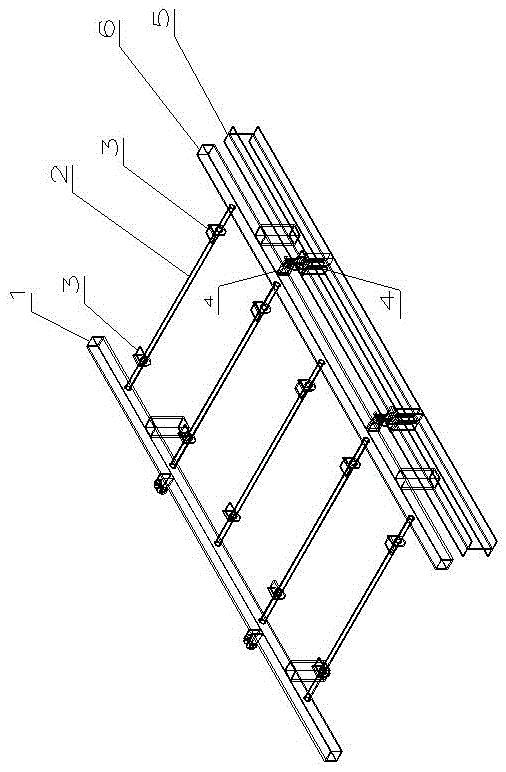

[0016] Example 1: Refer to the attached Figure 1-6 . A kind of plate unit non-destructive turning over sling. Between the lifting bracket main beam 1 and the bracket main beam 6 is formed by a plurality of bracket transverse supports 2 to form a ladder-shaped placing board unit bracket, and the ladder-shaped placing board unit bracket is in the A main beam of the bracket is hinged with the bottom beam 5 through a plurality of rotating supports 4 to form a rotating bracket of the ladder-shaped placing board unit. Each bracket cross brace 2 is covered with two L-shaped pallets 3, and the L-shaped brace 3 can move laterally on the bracket cross brace.

Embodiment 2

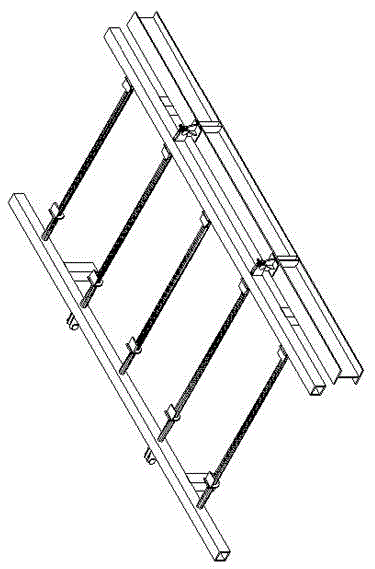

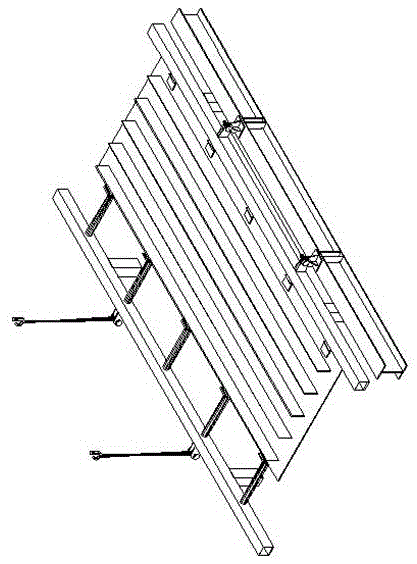

[0017] Embodiment 2: On the basis of embodiment 1, a method for turning over a plate unit non-destructive turning sling, (1) adjusting the L-shaped pallet 3 on the side of the rotating support in the rotating bracket of the ladder-type placing plate unit, Make it close to the main beam of the bracket 6, see figure 1 ; (2) Place the board unit on the rotating bracket of the ladder-shaped board unit, adjust the L-shaped pallet 3 to make it fit the board unit, see figure 2 ; (3) Lifting equipment lifts the main beam 1 of the lifting bracket in the rotating bracket of the ladder-type placing board unit, and the rotating shaft of the ladder-type placing board unit is rotated to complete the turn, see Figure 3-6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com