A Side Rail Type Single Girder Bridge Crane

A bridge crane and side rail technology, which is applied in the direction of traveling bridge cranes, cranes, track systems, etc., can solve problems such as lifting height restrictions, and achieve the effect of increasing the lifting height and stable operation of the trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

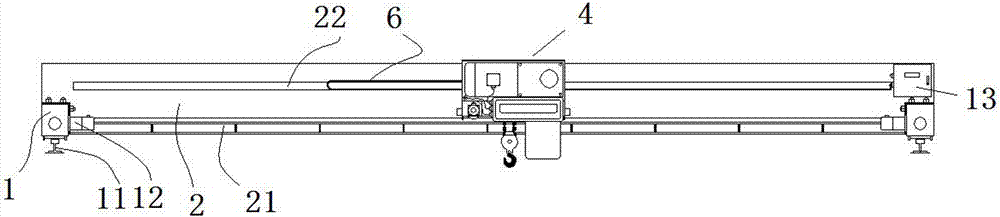

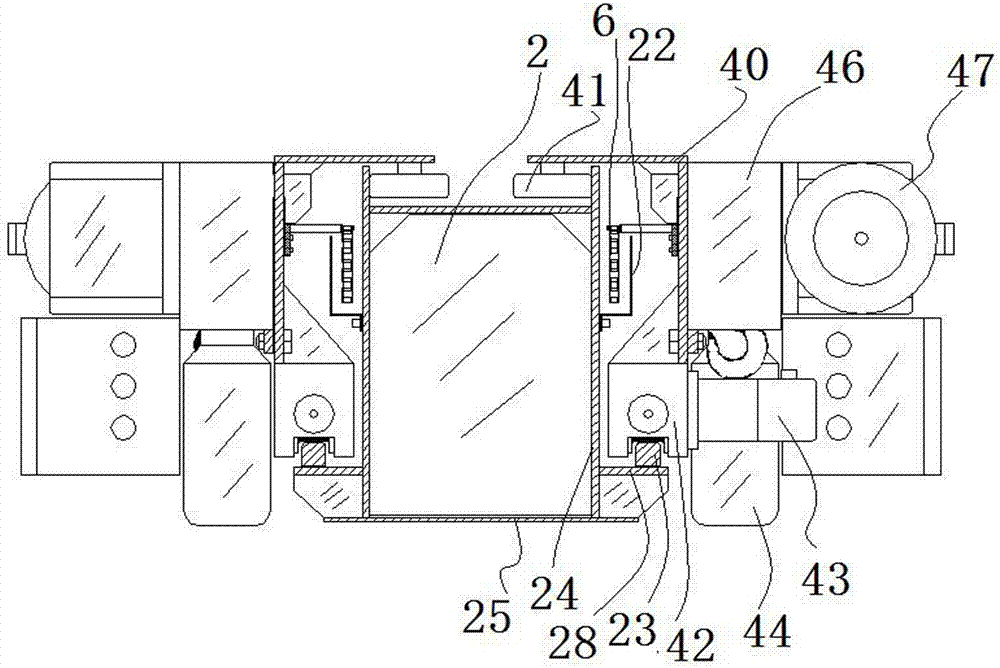

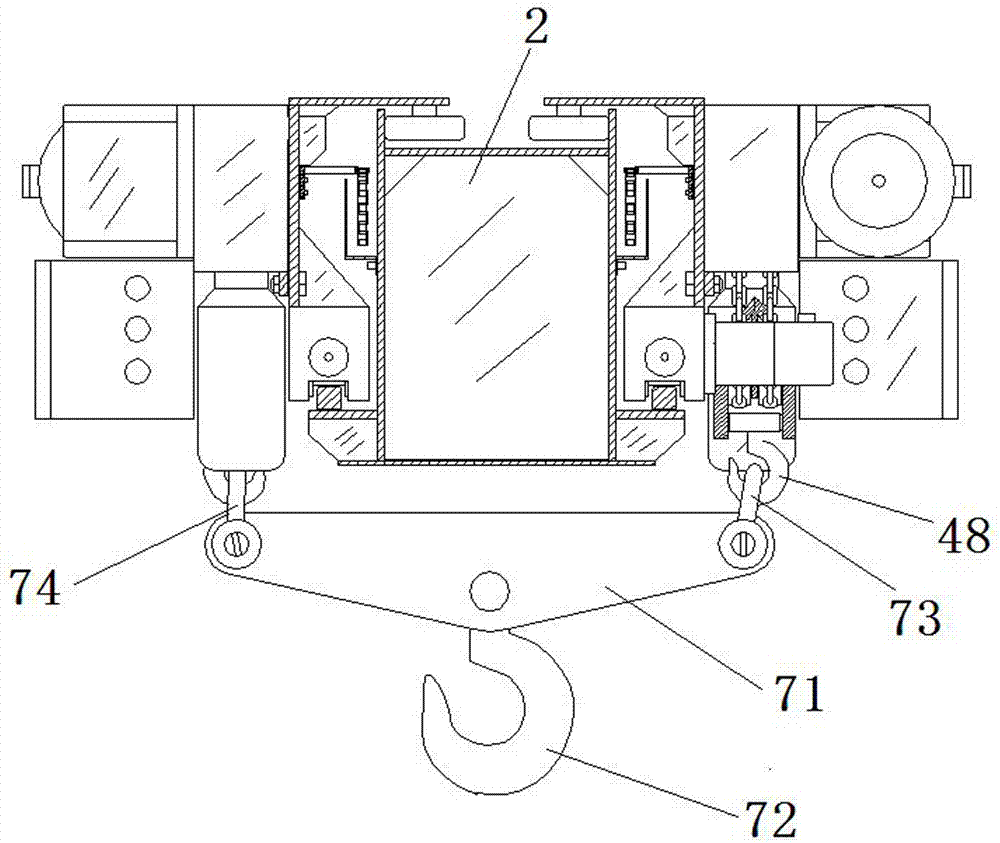

[0032] Embodiment 1 of the side rail type single girder bridge crane of the present invention: as Figure 1-4 As shown in 7-16, the side rail single-girder bridge crane includes a main beam 2 extending in the front-to-back direction, and a trolley 4 assembled on the main beam 2 for guiding movement. The front and rear ends of main beam 2 are provided with running end beams 1, and running end beams 1 run on corresponding cart tracks 11 arranged in the factory building, and running end beams are driven by left and right running motors 12. An end beam electrical box 13 is arranged on the running end beam. The main girder 2 is a box-shaped structure, including a lower cover 25, a first web 27, a second web 24 and an upper cover 26 arranged on the lower cover 25, the first web 27, the second web 24 They are arranged in parallel and located between the upper cover plate 26 and the lower cover plate 25 . Internal ribs are provided inside the main beam 2 . The lower cover plate 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com