Automatic cleaning method of intelligent household food processor

A food processing machine and automatic cleaning technology, which can be used in home appliances, applications, kitchen utensils, etc., can solve the problems of installation, difficulty of food processing machines, and cleaning difficulties for customers, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

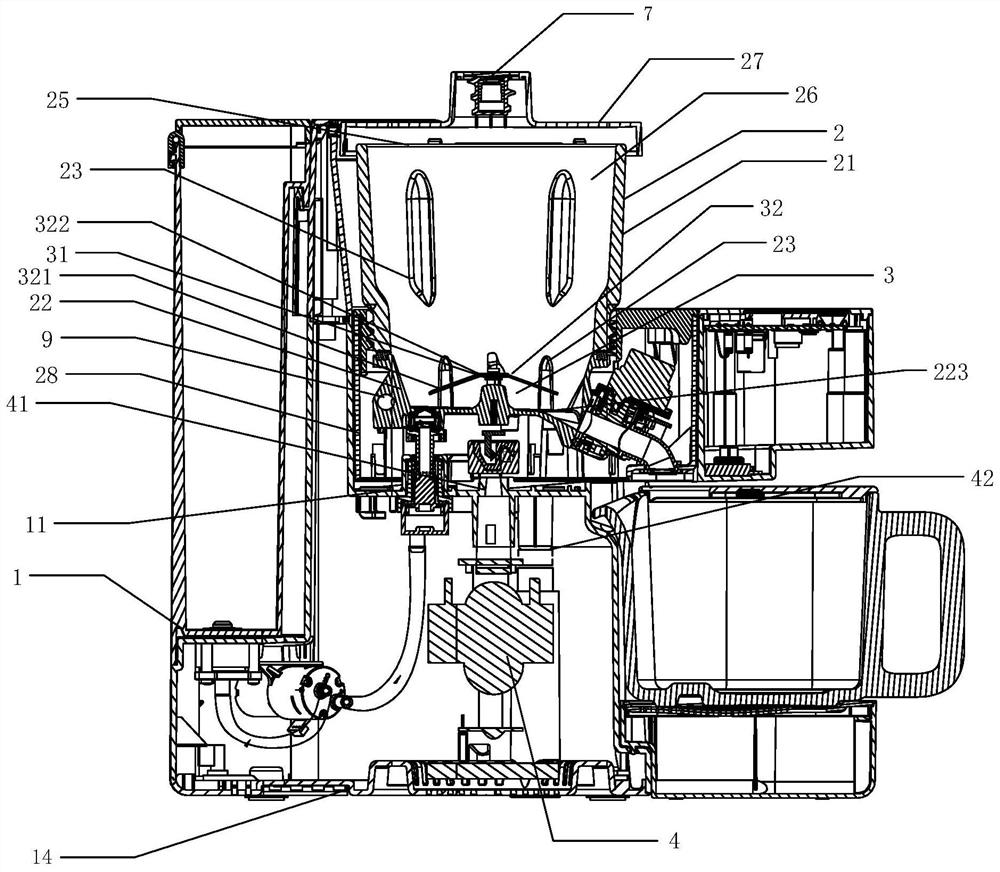

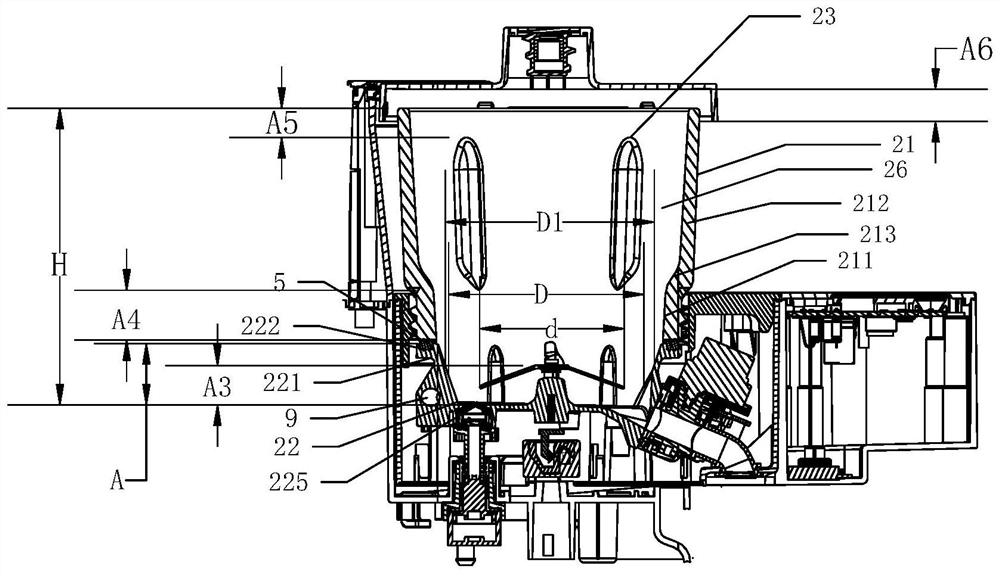

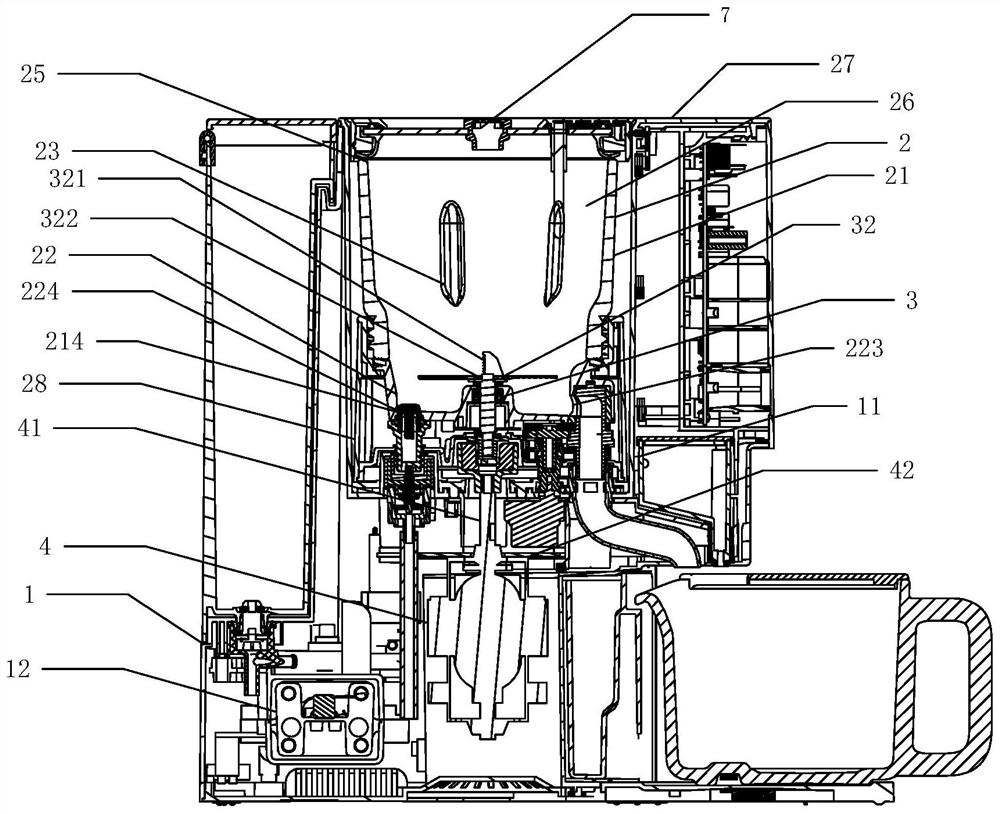

[0046] like Figures 1 to 5 As shown, the present invention provides an automatic cleaning method for a household food processor. The food processor includes a body 1, a motor 4, a cutter assembly 3, a stirring cup 2 and a cup that is closed on the opening 25 of the stirring cup 2. Cover 27, the stirring cup 2 includes a glass body 21 with openings both up and down, and a metal plate 22, the glass body 21 and the metal plate 22 are sealed and connected as one, and the cutter assembly 3 includes a cutter shaft 31 and a blade set on the cutter shaft 31 The smashing knife 32 at the top, the knife shaft 31 extends upwards into the stirring cup 2 through the opening in the center of the metal plate 22, the motor 4 drives the smashing knife 32 to rotate, and the cup cover 27, the glass body 21 and the metal plate 22 are enclosed to form a stirring Cup cavity 26, the capacity of the stirring cup cavity 26 is V, the cavity height of the stirring cup is H, the average depth of the meta...

Embodiment 2

[0094] The difference between this embodiment and the first embodiment is that the heating method of the food processor is different from that of the first embodiment, and naturally the cleaning method of the food processor is also slightly different.

[0095] The body of the food processing machine is provided with a water tank 10, a steam generator 13 is arranged in the body 1, and a steam inlet 224 is arranged at the bottom of the metal plate 22, the water in the water tank 10 is supplied to the steam generator 13, and the steam generator 13 is passed through the steam The steam generated by the generator 13 is delivered to the steam valve 12 through the pipeline, and the steam valve 12 controls the steam to pass into the stirring cup 2 from the steam inlet.

[0096] Of course, understandable, such as Figure 5 As shown, the body 1 of the food processor includes a base 11, and the stirring cup 2 also includes a cup support 24, which connects the glass body 21 and the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com