Deep-water high-flow-speed fixed-point accurate throwing and filling device and construction method

A construction method and high flow rate technology, applied in infrastructure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

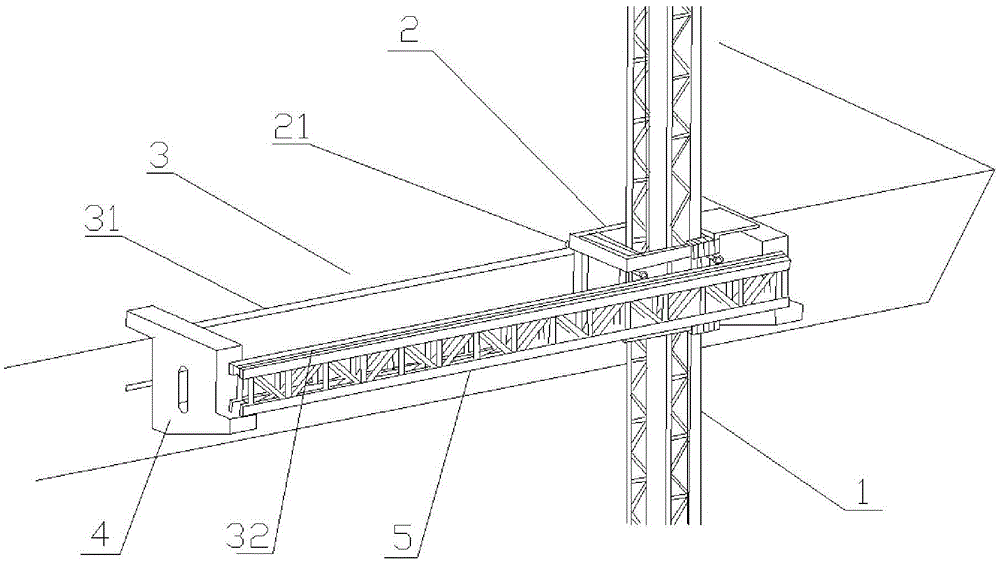

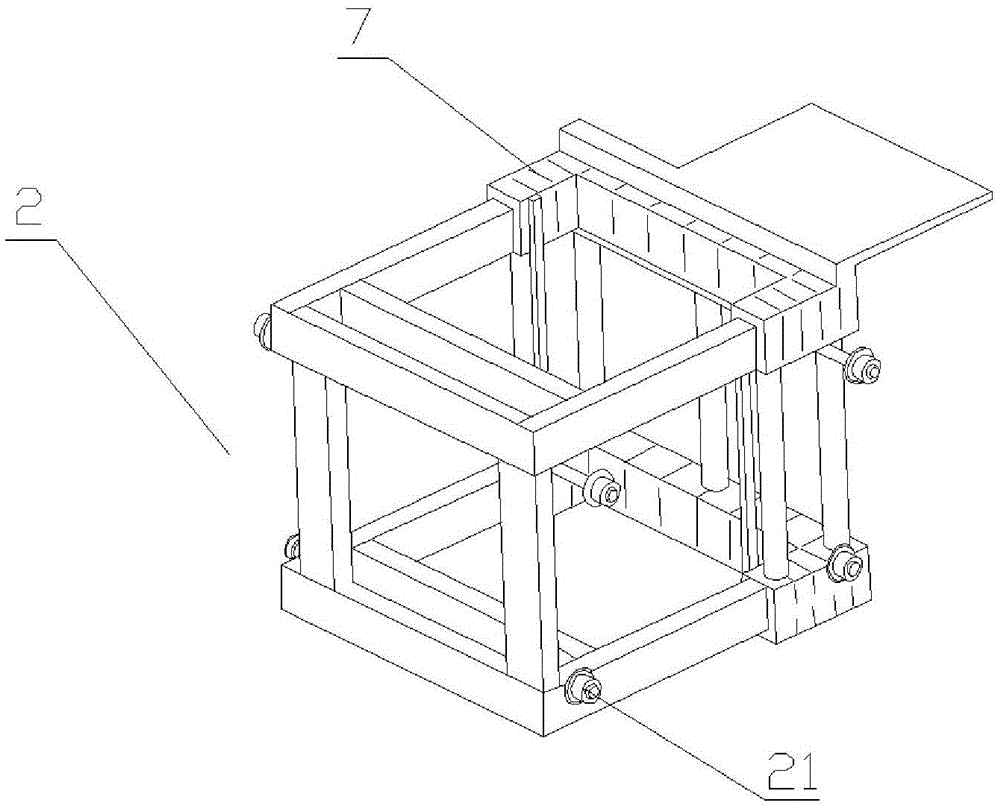

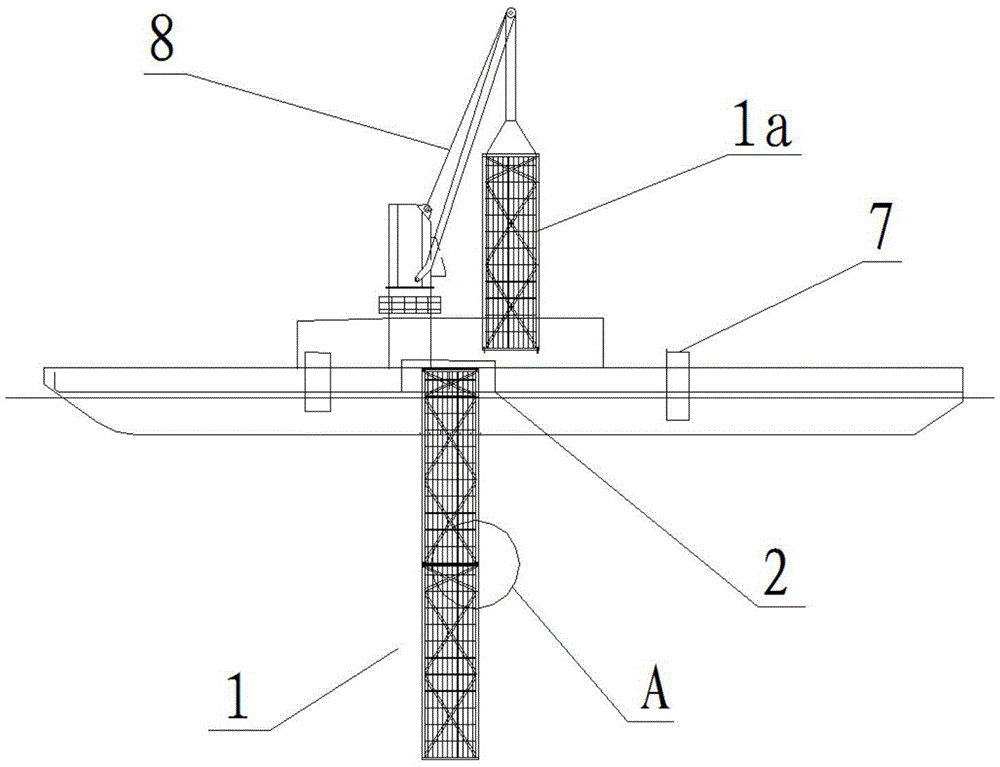

[0026] like Figure 1 to Figure 4 As shown in the figure, the deep-water high-velocity fixed-point precise throwing device of the present invention includes a chute 1 for constraining riprap, a trolley 2 for installing the chute 1, and a trolley track 3 installed on the side of the ship. The trolley 2 can move along the The trolley rail 3 moves. The trolley track includes a ship side track 31 and a cantilever track 32 arranged on the side of the ship, a cantilever beam 4 is set on the side of the ship, a track beam 5 is set on the cantilever beam 4, and a cantilever track 32 is set on the track beam 5. Free and stable walking on the side of the boat.

[0027] Using chute 1, the riprap can be precisely constrained to the set position to prevent the riprap from being washed away by the flowing water. Constrain the chute 1 on the trolley 2, and the trolley 2 is provided with a small wheel 21, which can walk along the track 3. When the stone throwing is completed at one position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com