Manual electric double control baffle type one-way overspeed closing valve

An overspeed closing and baffle-type technology, which is applied to control valves, valve details, valve devices, etc., can solve the problems of difficult adjustment of the closing flow rate threshold, false alarms, and easy springing of the valve plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

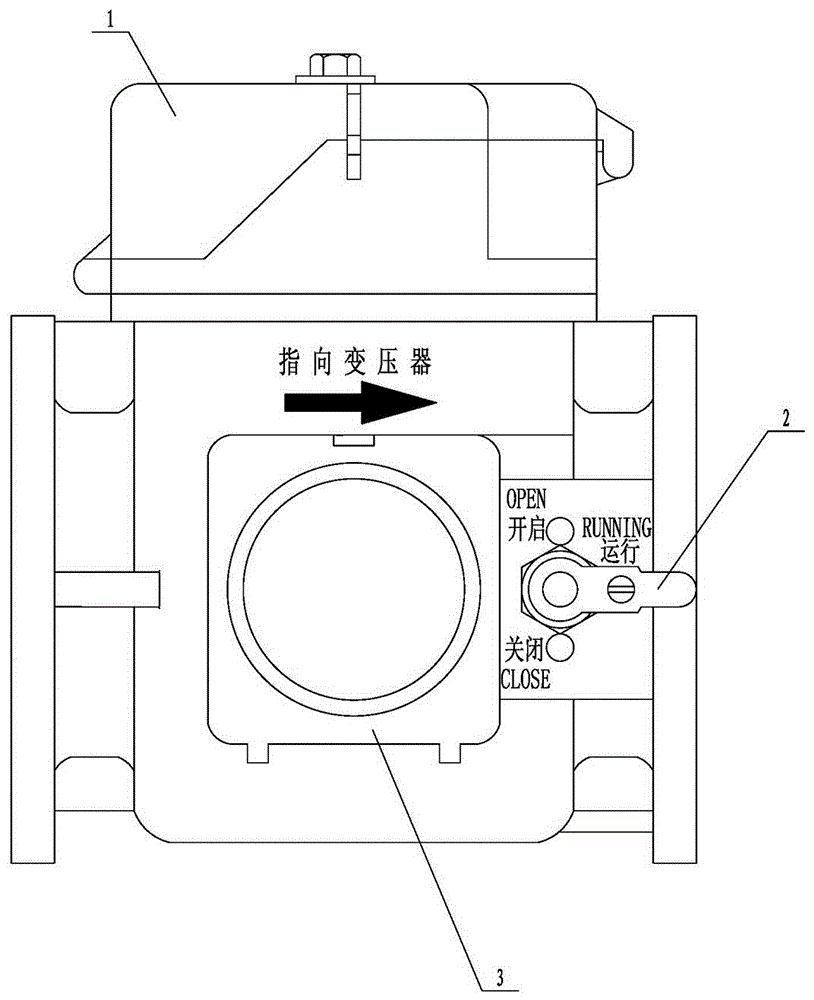

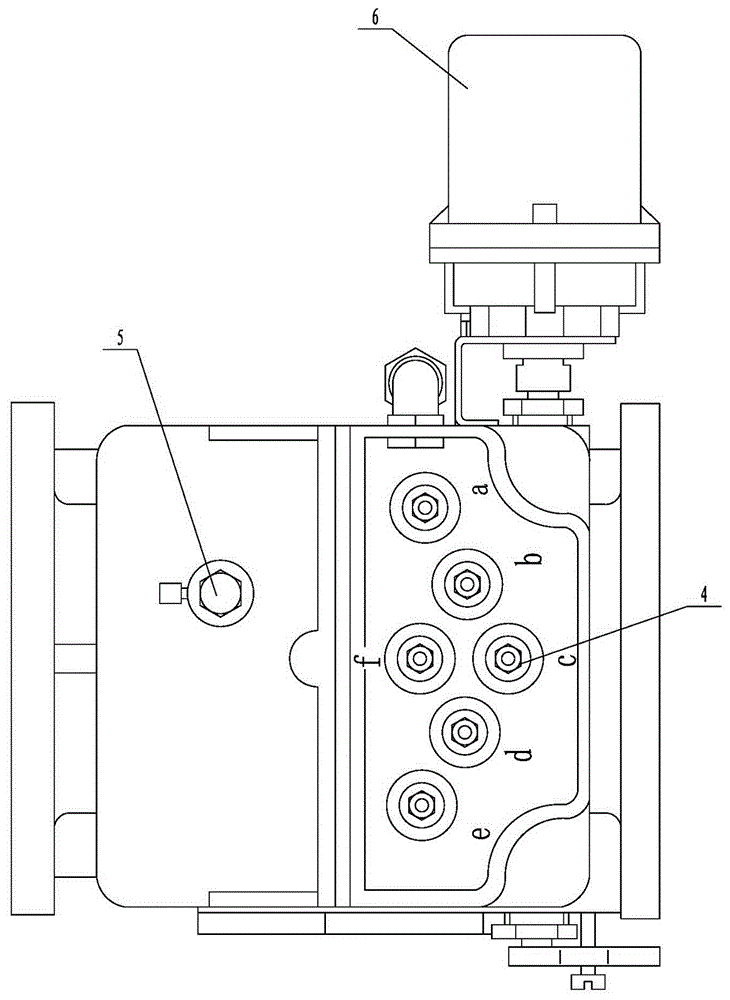

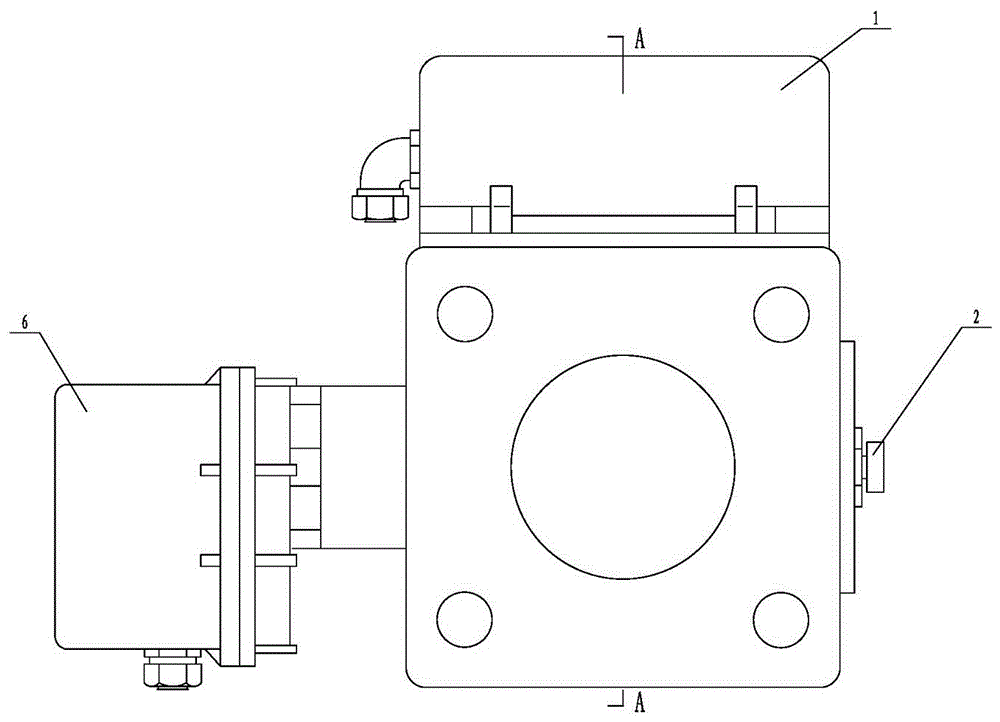

[0035] The following combination Figure 1~Figure 9 , the content of the present invention will be described in detail through specific embodiments. The manual electric double-control baffle type one-way overspeed shut-off valve includes a housing, a machine cover 1 arranged on the top of the housing, and an electric controller 6 arranged on one side of the housing, and an oil inlet 8 is provided on the opposite side of the housing. and the oil outlet 12, the other side is provided with a window 3, a cavity is provided between the oil inlet and the oil outlet, a base plate 17 is provided at the bottom of the cavity, a stand is provided on the base plate, and a valve plate is provided on the oil outlet Assemblies and manual control components and electric control components for controlling the valve plate assembly, the valve plate assembly includes the active plate 15 hinged on the bottom plate, the reed switch limited in the cavity, and the magnetic steel I set on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com