Annular space double-sensor conducting probe for flow parameter measurement of two-phase flow

A technology of annular space and flow parameters, applied in the direction of volume/mass flow generated by electromagnetic effect, which can solve the problem of low spatial resolution and achieve the effect of high-resolution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

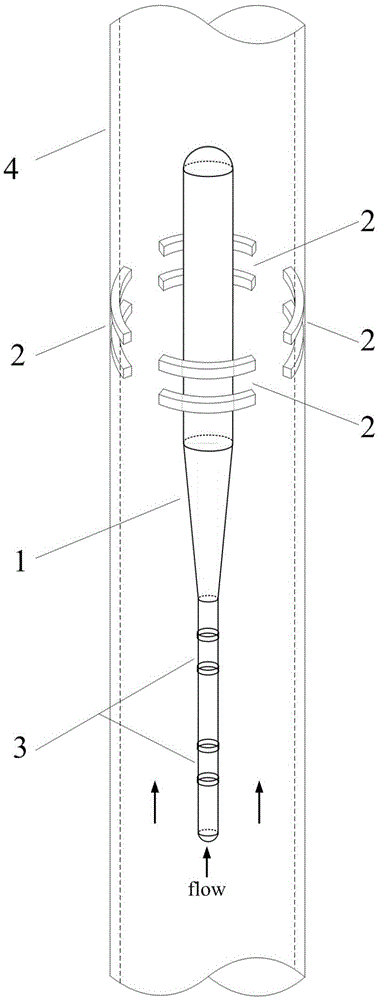

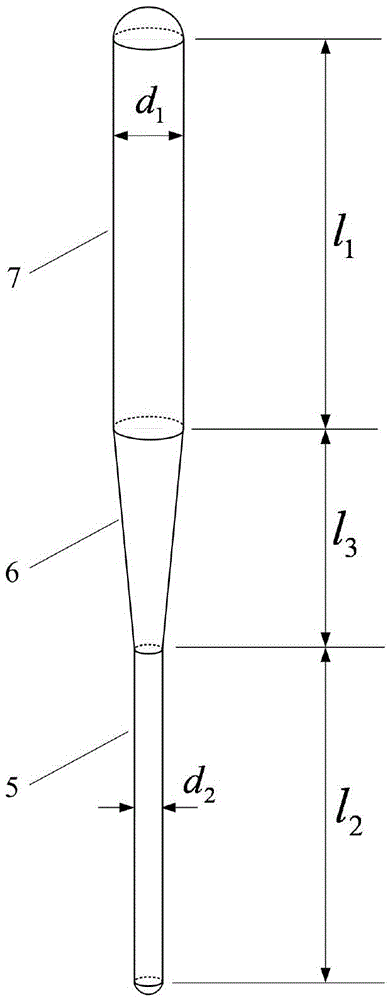

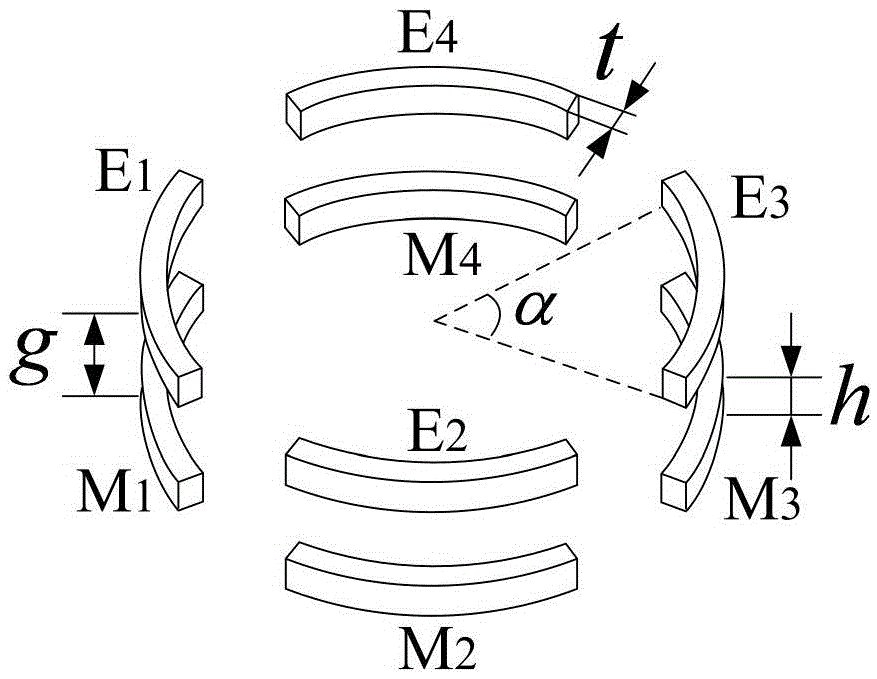

[0029] The annular space dual-sensing conductance probe of the present invention is designed based on the principle of electrical sensitivity. Aiming at the non-uniform distribution and random motion characteristics of the two-phase flow in the vertical pipe, the fluid is forced to flow in the annular space by placing an insulating insert with a variable diameter in the center of the pipe. flow. It aims to use the distributed high-resolution characteristics of the fluid in the annular space to realize the measurement of the phase separation holdup (ratio of the phase separation volume to the total fluid volume) of the two-phase flow by using the annular space separation rate sensor; at the same time, use the annular space correlation velocity sensor Realize two-phase flow related velocity measurement; finally, based on the phase separation ratio and related velocity measurement results, establish the total flow measurement model and drift velocity model to realize the two-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com