Dimension optimization method for key components of two-phase flow annular space lumped sensing system

A technology of annular space and sensing system, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of failure to meet the accuracy requirements of output profile testing, limited water content resolution, etc., to reduce the slippage effect and improve Measuring accuracy, effect of good geometric dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

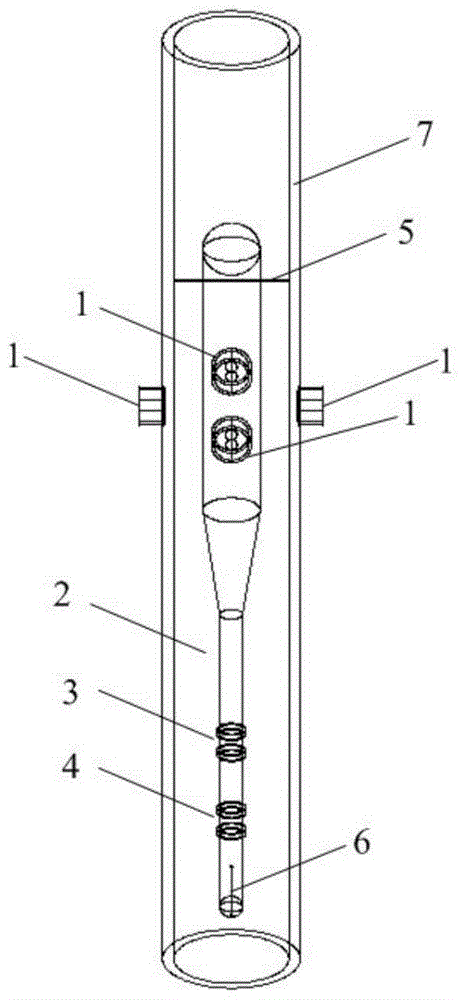

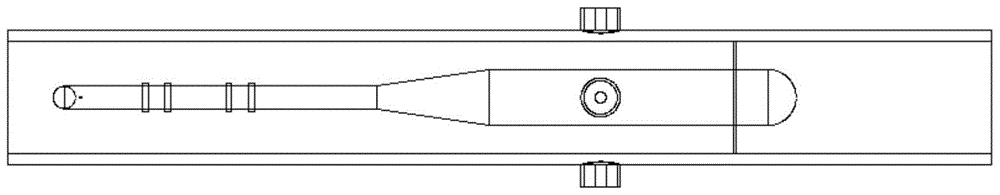

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The invention includes

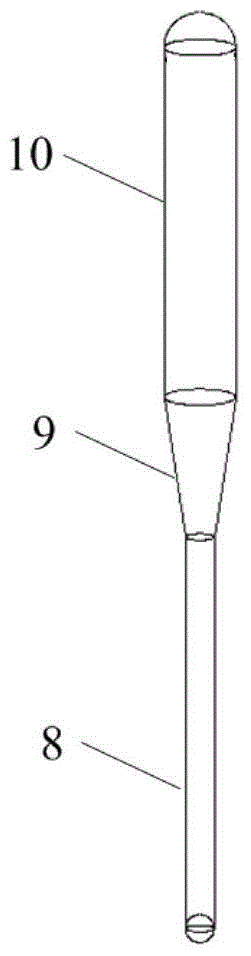

[0043] (1) The two-phase flow annular space lumped sensing system is composed of variable-diameter insulating inserts, distributed circular conductance array probes, and related speed-measuring electrodes embedded on the inserts, such as figure 1 shown. The insulating insert is divided into three parts, namely the thin diameter section, the transition section and the thick diameter section, such as image 3 shown. Each local probe consists of an external cylindrical excitation electrode, an internal cylindrical measuring electrode and an intermediate insulating medium, such as Figure 4As shown, where E represents the excitation electrode, which is connected to the 20kHz sinusoidal voltage excitation signal, and M represents the measurement electrode, which is connected to the signal conditioning circuit. Conductive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com