Robot for power transmission line inspection

A technology for inspection robots and power transmission lines, applied in the field of power transmission, can solve problems such as inability to complete inspection work, be easily affected by weather conditions, and high cost of helicopters, so as to ensure safety and stability, improve climbing ability, and strong obstacle-crossing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

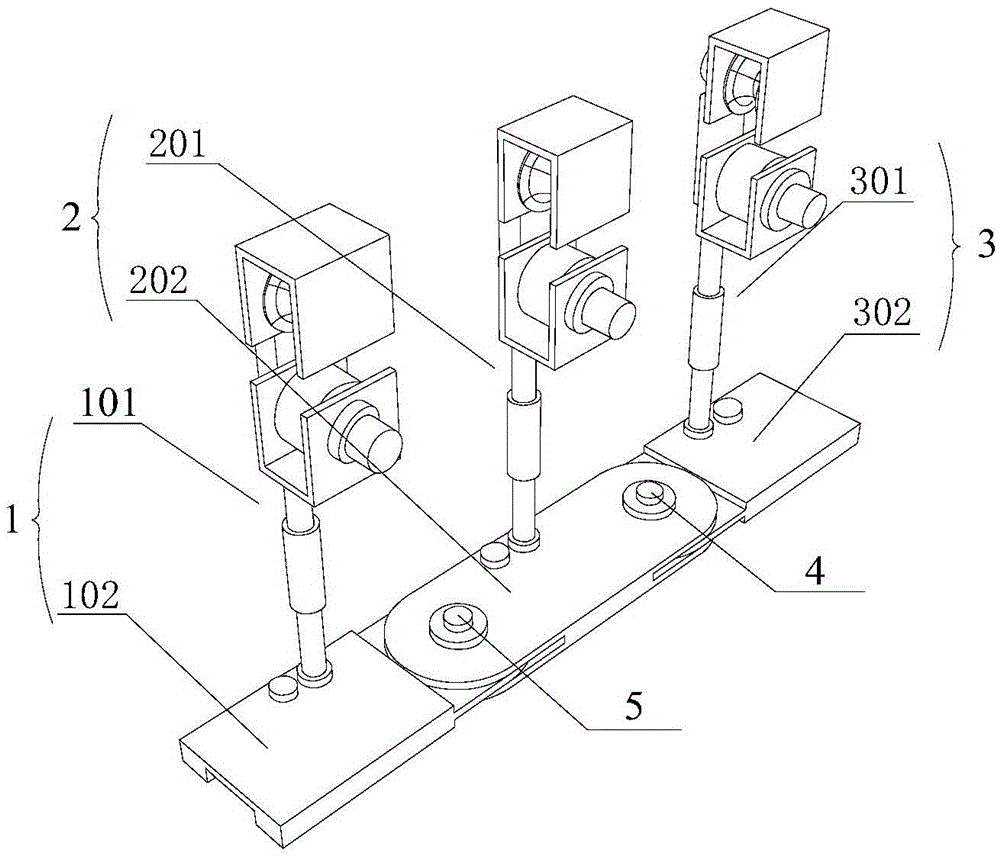

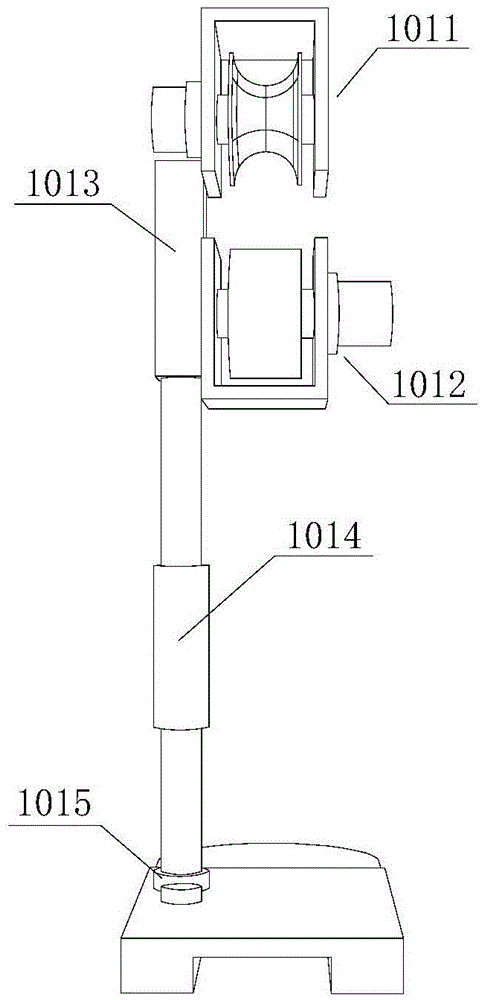

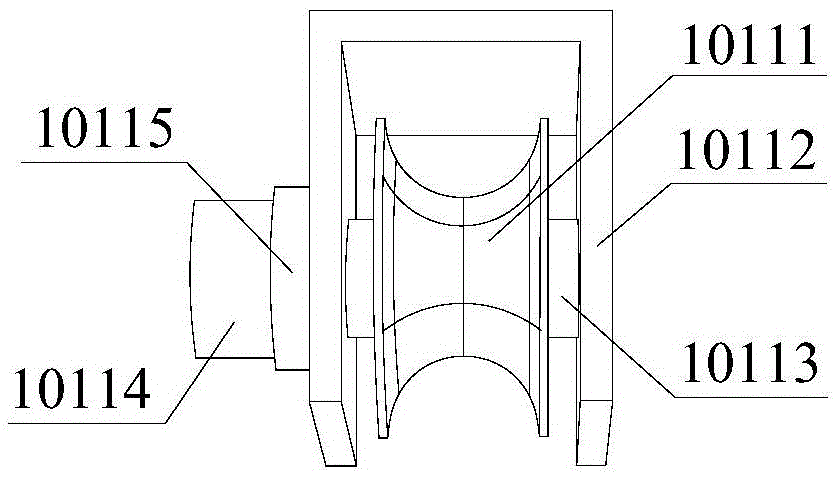

[0056] Such as figure 1 A transmission line inspection robot shown includes a front body 1, a middle body 2, a rear body 3, a rear steering mechanism 4, and a front steering mechanism 5; the front body 1 includes a front arm 101, a front body 102, and the The middle body 2 includes a middle arm 201 and a middle body 202, and the rear body 3 includes a rear arm 301 and a rear body 302; the front body 102 is connected to the middle body 202 through a front steering mechanism 5; the middle body 202 is connected to the rear body 302 is connected through the rear steering mechanism 4; the front arm 101, the middle arm 201, and the rear arm 301 have the same mechanical structure, and only the front arm 101 will be described in detail below, and the specific structures o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com