Method and quilting machine for joining two textile planar formations

A technology for forming objects and quilting machines, applied in the field of quilting machines, can solve the problems of long downtime maintenance or repair of quilting machines, large mechanical load of mechanical parts, etc., to reduce mechanical load, reduce downtime, and reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

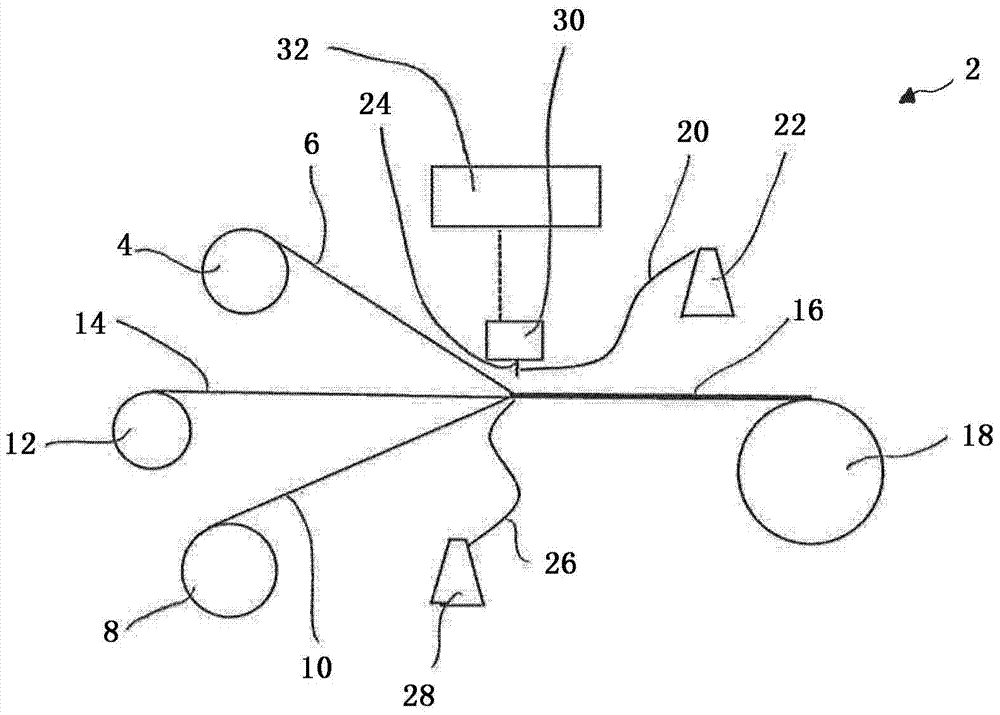

[0029] figure 1 The quilting machine 2 is schematically and simplified shown in side view in FIG. The quilting machine 2 has a first unwinding roller 4 on which a first woven flat product 6 is uncoiled. In this case, the woven first sheet-like formation is the top material. Furthermore, the quilting machine 2 has a second unwinding roller 8 , on which the woven second sheet-like product 10 is uncoiled. The second planar formation of the textile is the lower material. Furthermore, the quilting machine 2 also comprises a third unwinding roller 12 on which the cushioning material 14 is uncoiled. The upper material 6 , the lower material 10 and the cushion material 14 are joined into a cover 16 which is wound onto a winding roll 18 . In this case, the upper material 6 , the lower material 10 and the cushion material 14 are unrolled by winding rollers 4 , 8 , 12 and rolled up as a cover 16 onto a winding roller 18 . The winding rollers 18 are torque- and speed-controlled so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com