Self-sealing eccentric half-ball valve

A self-sealing, hemispherical valve technology, applied in the direction of valve devices, cocks including cut-off devices, mechanical equipment, etc., can solve problems such as shortening and increasing valve plate life, leakage or leakage of ball valves, etc., to prolong service life and open The effect of small torque, not easy to leak or leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

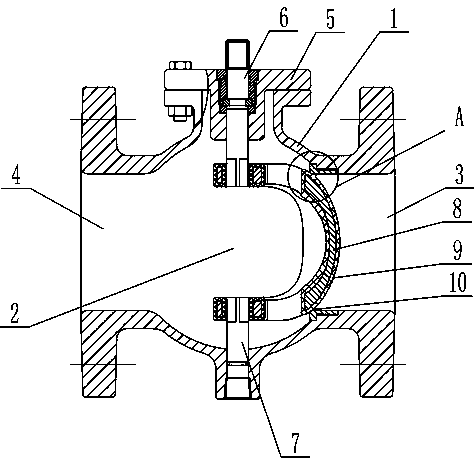

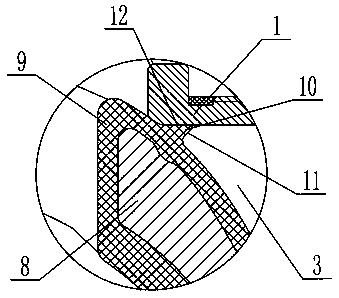

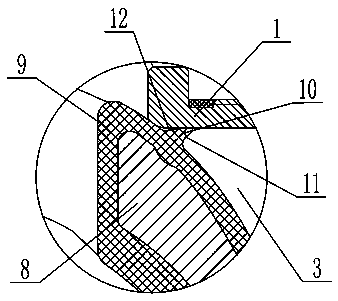

[0015] like figure 1 and figure 2 As shown, the self-sealing eccentric hemispherical valve includes a valve body 1, and a liquid inlet cavity 2 is arranged in the valve body 1. One end of the valve body 1 is provided with a water inlet hole 3 that communicates with the liquid inlet chamber 2, and the other end is provided with a liquid inlet hole 3. The water outlet hole 4 connected to the cavity 2, the valve cover 5 is connected to the top of the valve body 1, the main valve shaft 6 is connected to the valve cover 5, the auxiliary valve shaft 7 is arranged at the bottom of the valve body 1, and the liquid inlet chamber 2 is connected to the main valve The hemispherical valve plate 9 on the valve shaft 6 and the auxiliary valve shaft 7 is covered with an elastic sealing layer 10 on the surface of the hemispherical valve plate 9 . After the elastic sealing layer 9 of the sealing surface of the hemispherical valve plate 9 is in direct contact with the inner port of the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com