Valve sealing structure

A valve sealing and sealing structure technology, applied in shaft sealing, valve details, valve devices, etc., can solve problems such as unfavorable long-term development, poor sealing effect, water leakage, etc., to achieve long service life, improved sealing degree, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

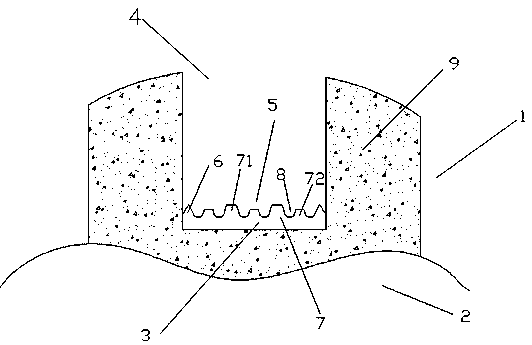

[0011] Such as figure 1 The valve sealing structure described above includes a valve body 1 and a valve stem 2, a sealing structure 3 is provided between the valve body 1 and the valve stem 2, and the sealing structure 3 includes a concave groove arranged on the valve body. Groove 4, inside the groove 4 is a wave-shaped structure 5, the wave-shaped structure 5 is composed of raised triangular waves 6 and trapezoidal waves 7, and the triangular waves 6 are located on both sides of the inside of the groove 4, so The trapezoidal waves 7 are arranged between the triangular waves 6, and are distributed at intervals by small trapezoidal waves 71 and large trapezoidal waves 72, and arc-shaped grooves 8 are arranged between the small trapezoidal waves 71 and the large trapezoidal waves 72. A frosted layer 9 is provided on the outer wall of the arc-shaped groove 8 .

[0012] The above descriptions are preferred embodiments of the present invention, and should not be used to limit the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com