High altitude test system and method for aircraft engine oil system

An aero-engine and lubricating oil system technology, applied in the field of aero-engines, can solve the problems of not fully representing the reliability and life of work, affecting the development progress and development cost of the engine, and unable to truly reflect the working performance of the lubricating oil pump group, so as to reduce the test Hours and costs, high accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

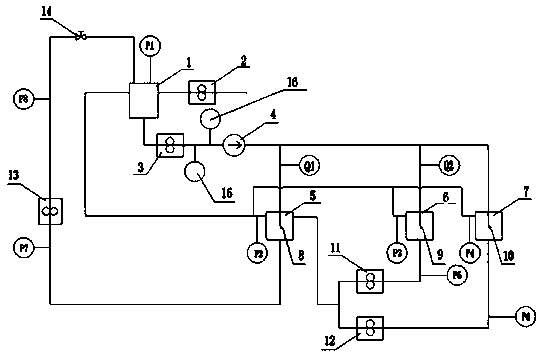

[0029] Such as figure 1 As shown, this embodiment provides an aeroengine lubricating oil system high-altitude test system. The test system simulates a certain engine lubricating oil system. The engine includes three bearing cavities connected in parallel with each other, and two of the three bearing cavities A bearing cavity oil return pump is connected in series on the oil circuit. The oil in the two bearing cavity oil return pumps is collected and drawn back to the main oil return pump of the engine lubricating oil system through the bearing cavity without the series oil return pump, and the main oil return pump is connected to the oil tank. The bearing cavity is connected in parallel with the oil tank with a ventilation system.

[0030] The high altitude performance of the engine's oil system can be tested by simulating the engine's oil system through the following settings; figure 1 As shown, the test system is provided with a vacuum pump 2, an oil tank 1, a booster pump 3, a ...

Embodiment 2

[0034] This embodiment provides an aeroengine lubricating oil system altitude test method, using the aeroengine lubricating oil system altitude test system described in Example 1 to test the altitude performance of an engine described in Example 1; It includes the following steps:

[0035] S1. Simulate the lubricating oil system of the engine under test, and set the connection relationship and quantity of oil tank 1, booster pump 3, lubricating oil cavity and oil return pump;

[0036] S2. Turn on booster pump 3, oil tank and oil return pump;

[0037] S3. Adjust the equivalent nozzle A so that the lubricating oil cavity A is the same as the corresponding tested engine bearing cavity oil supply Q1; adjust the equivalent nozzle B so that the lubricating oil cavity B is the same as the corresponding tested engine bearing cavity oil supply Q2; Adjust the equivalent nozzle C so that the oil supply volume of the lubricating oil cavity C is the same as the corresponding bearing cavity of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap