Large-scale soil interface shear test model and test method

A technology of shear test and interface, applied in the field of geotechnical engineering, achieves the effects of low cost, direct and simple design, and abundant sources

Active Publication Date: 2016-04-20

CHINA UNIV OF MINING & TECH

View PDF11 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Purpose of the invention: In order to overcome the deficiencies in the prior art, the present invention provides a large-scale soil interface effect shear model test method, which can

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

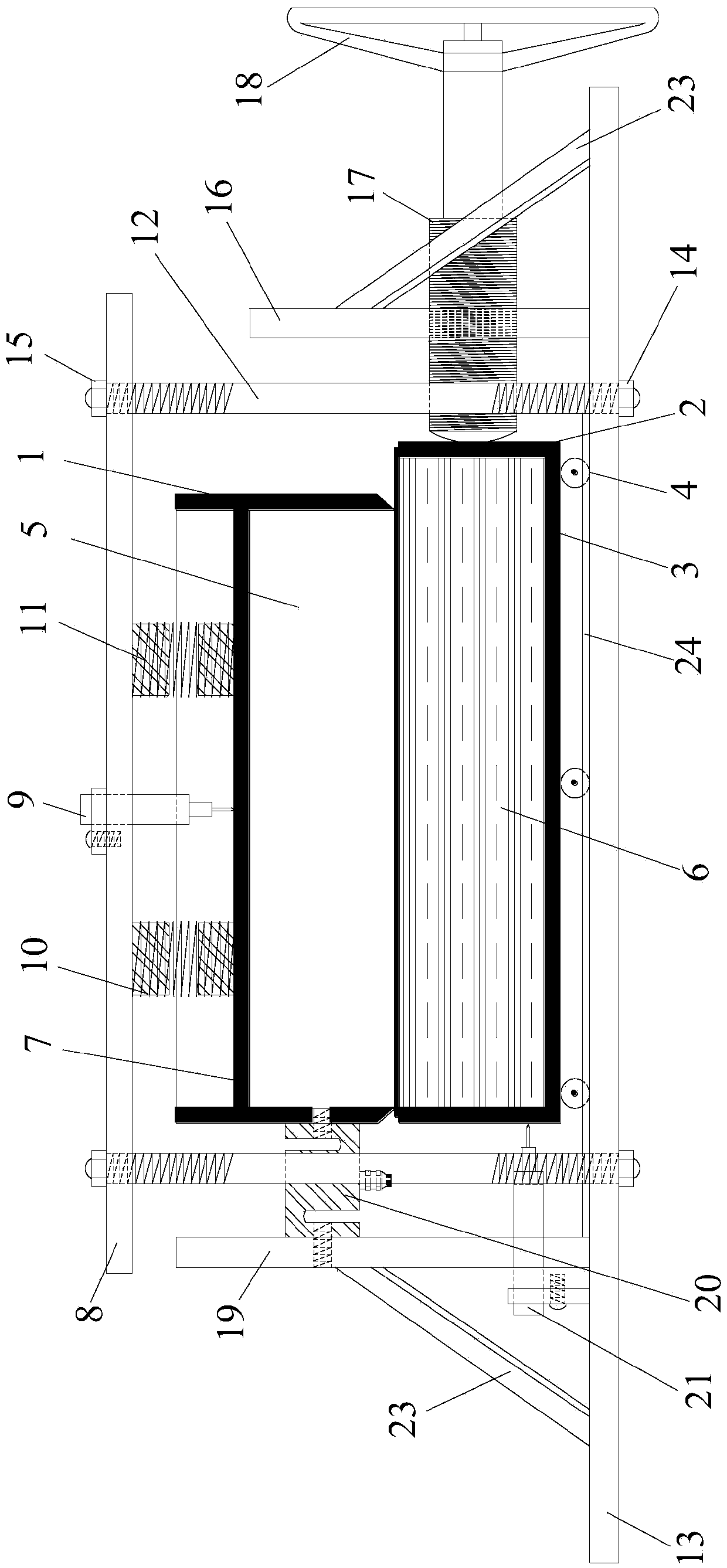

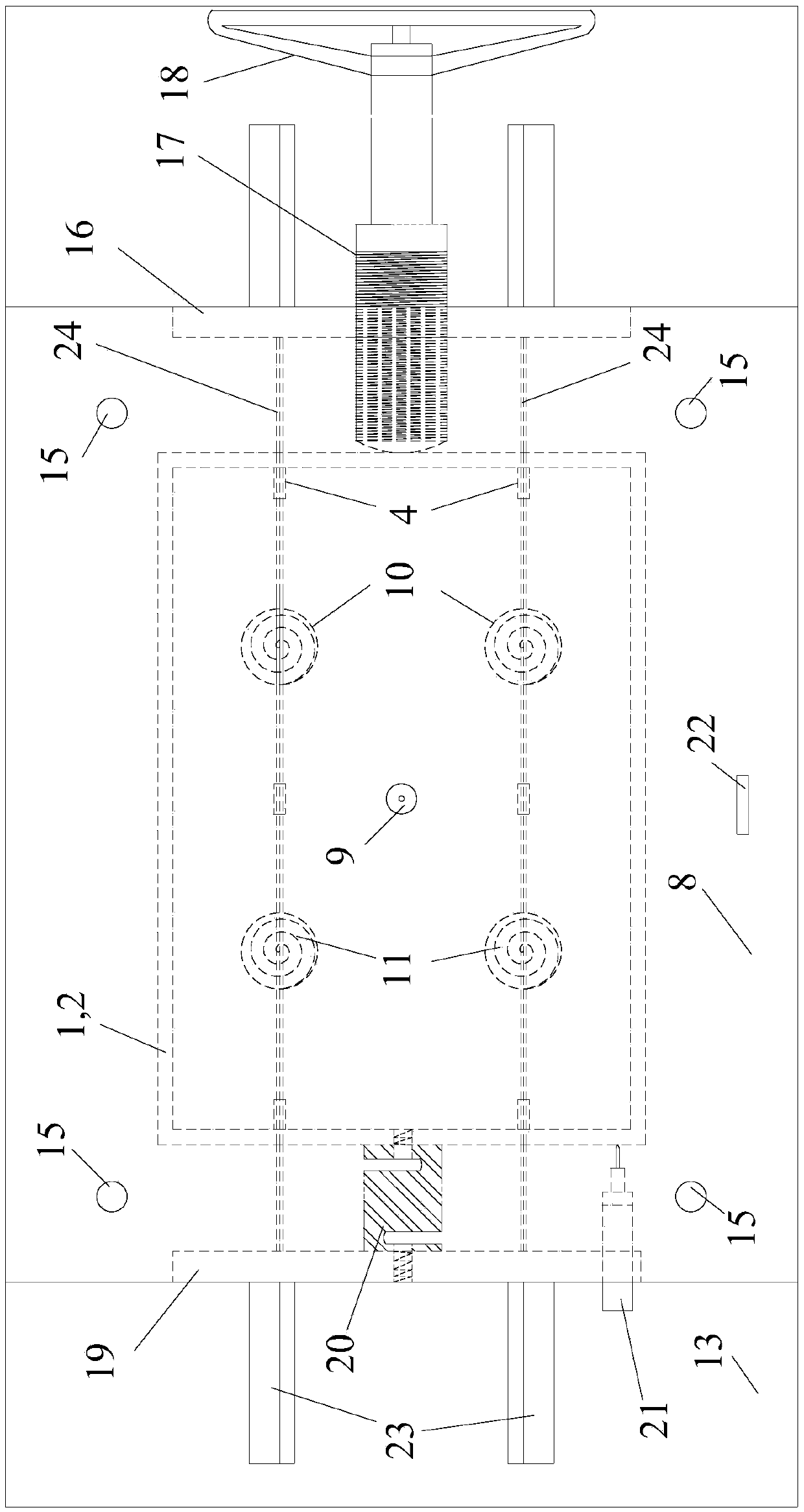

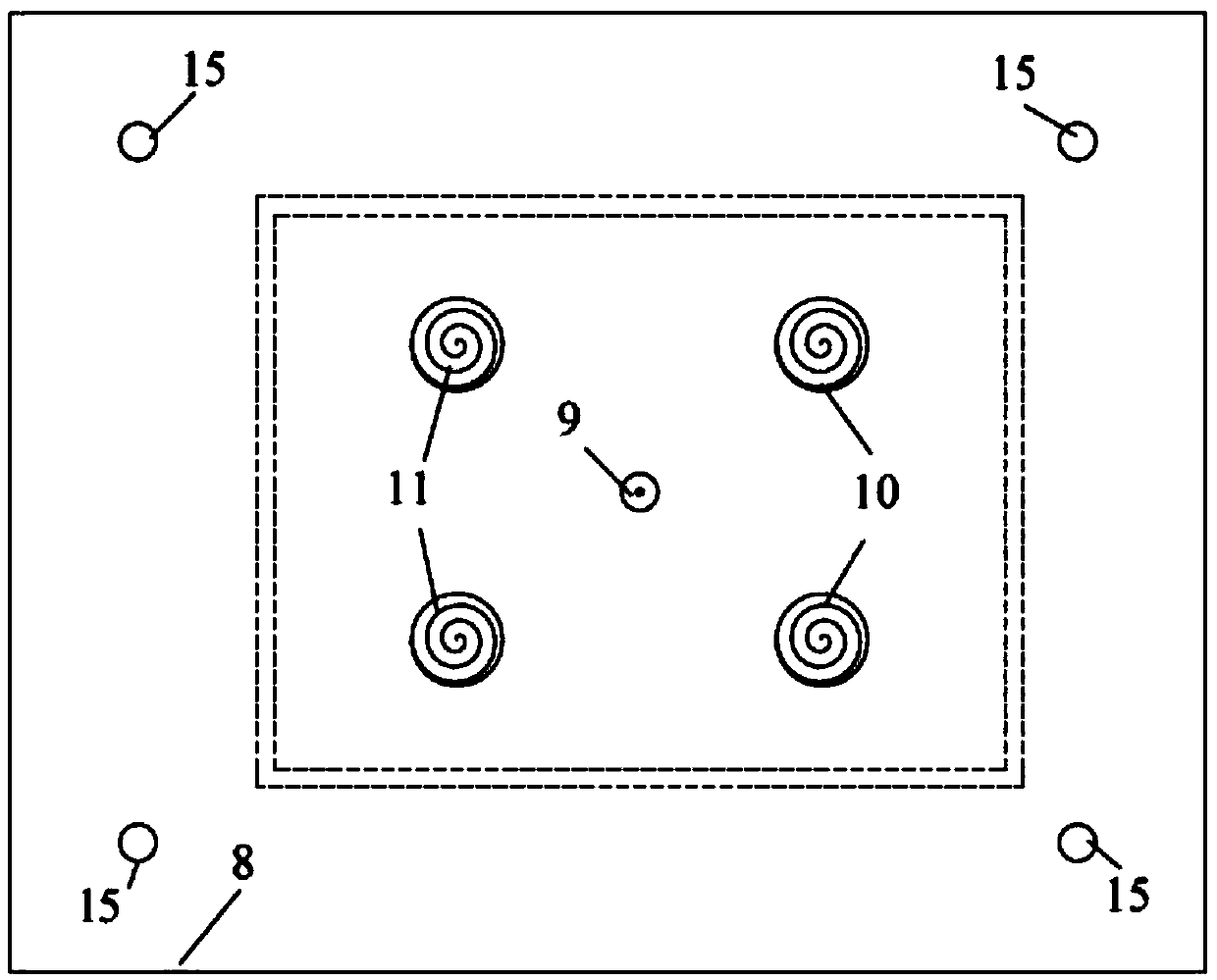

The invention discloses a large-scale soil interface shear test model and a test method. The test model consists of a model box, test materials, pressurization equipment, shearing equipment and measuring equipment. The model box comprises an upper box and a lower box, the test materials include sandy soil and clay, the pressurization equipment includes a pressure plate, an upper pressure plate, a pressure spring fixed column, a pressure spring, a double-end stud and a bottom plate, the shearing equipment consists of a left baffle plate, a fine thread screw and a handle, and the measuring equipment comprises a right baffle plate, a pressure sensor, a vertical displacement sensor, a horizontal displacement sensor and a camera. The test method comprises the steps of: determining the test materials, consolidating lower box soil, performing soil interface treatment, and carrying out shearing model test. The large-scale soil interface shear test model and the test method provided by the invention can be used for studying interface shear strength change rule and soil shear deformation rule generated due to interfacial effect among different soil layers. Different from other large-scale direct shear equipment with high cost and complex procedures, the test model provided by the invention has the advantages of direct and simple design, rich source materials, and low cost.

Description

technical field [0001] The invention belongs to the technical field of geotechnical engineering, and in particular relates to a large-scale shear test model and a test method considering soil interface effects. Background technique [0002] As a cohesive or non-cohesive heterogeneous granular material with pores, its shear strength characteristics are also one of the basic contents reflecting its pore law. The shear failure of soil is an important characteristic of soil strength failure. The problem of shear strength of soil is the problem of strength of soil. The shear strength is an important mechanical index of the soil within the scope of the project. The foundation bearing capacity of buildings and structures, the earth pressure of underground structures, retaining walls, and the stability of artificial and natural slopes are all affected by the shear strength of the soil. influence and control. Most of the soil within the scope of the project is layered heterogeneous...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24G01N3/06G01N1/28

CPCG01N1/286G01N3/068G01N3/24G01N2203/0025G01N2203/0075G01N2203/0641

Inventor 崔振东赵羚子张忠良张成林杨家强樊思成华珊珊李丁何鹏鹏袁强赵鹏袁丽

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com