Rotor shaft end locking device and method

A technology for locking devices and rotor shafts, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems affecting the performance of servo motors, affecting the quality of rotor shafts, and damage to the surface of rotor shafts, so as to ensure performance, protect surface quality, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

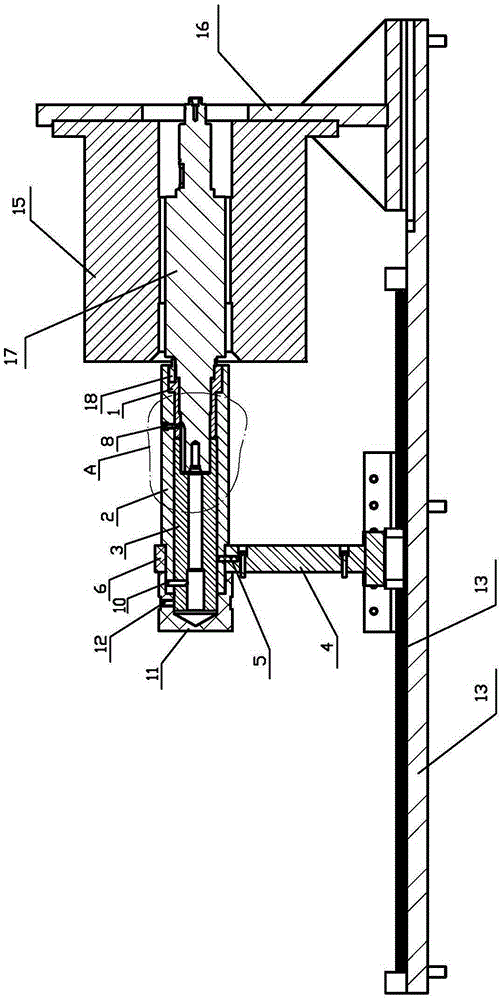

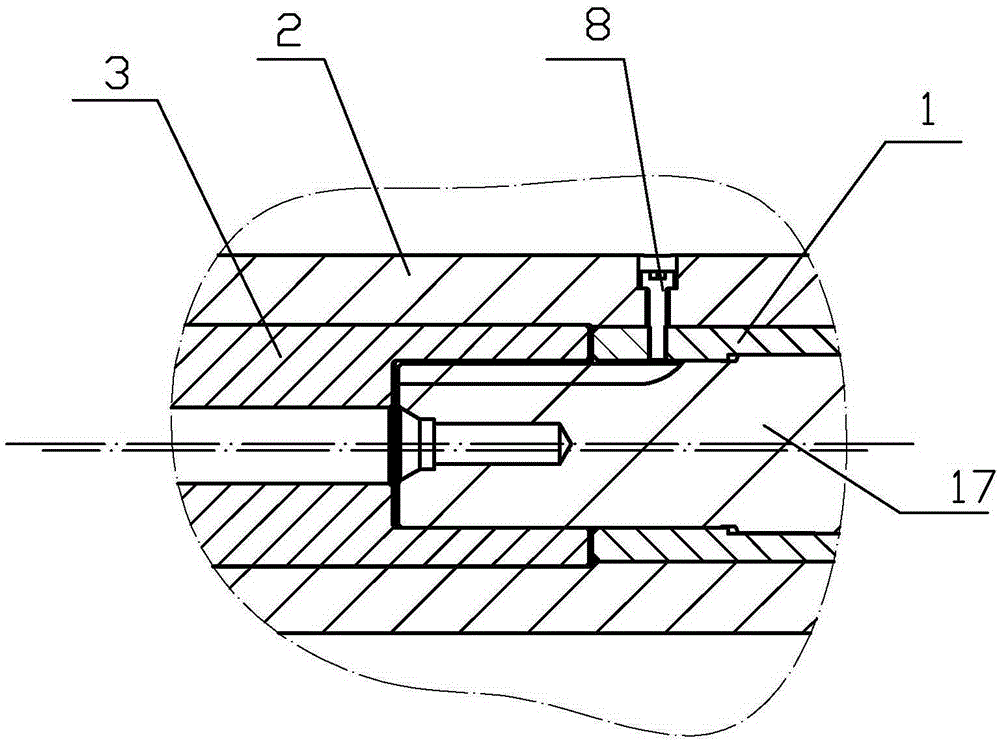

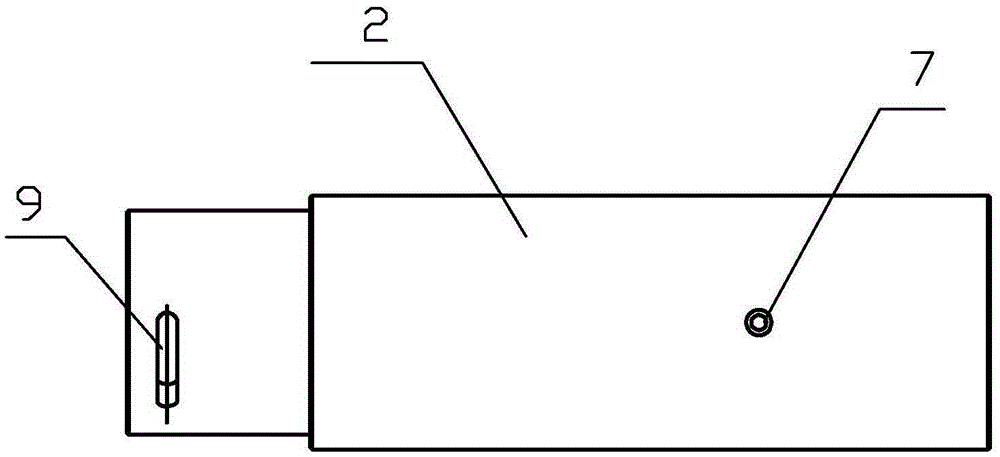

[0025] Embodiment: The rotor shaft end locking device of this embodiment, such as figure 1 As shown, it includes support base 4, positioning sleeve 1, fixed sleeve 2 and locking sleeve 3, the front end of fixed sleeve 2 is fixed on a support base 4, and there is a vertical upward positioning pin on the support base 4 5. The positioning pin 5 is inserted into the front part of the fixed bushing 2, and the fixed gland 6 is installed on the opposite side of the front part of the fixed bushing 2 and the positioning pin 5. The locking bushing 3 and the positioning bushing 1 are installed in the shaft hole of the fixed bushing 2, the locking bushing 3 is in front, the positioning bushing 1 is behind, and the front end of the locking bushing 3 protrudes from the fixed bushing The front end of 2, the rear end of the axle hole of locking axle sleeve 3 is a shoulder hole, and the shoulder hole and positioning axle sleeve 1 are close to each other. Such as figure 2 As shown, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com