Slab track bed built-in regulator

The technology of a slab track bed and adjuster is applied in the directions of roads, tracks, ballast layers, etc., which can solve the problems of less tools and difficulty in adjusting the track bed slab, and achieve the effects of improving efficiency, reducing disassembly costs, and having a compact and precise structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

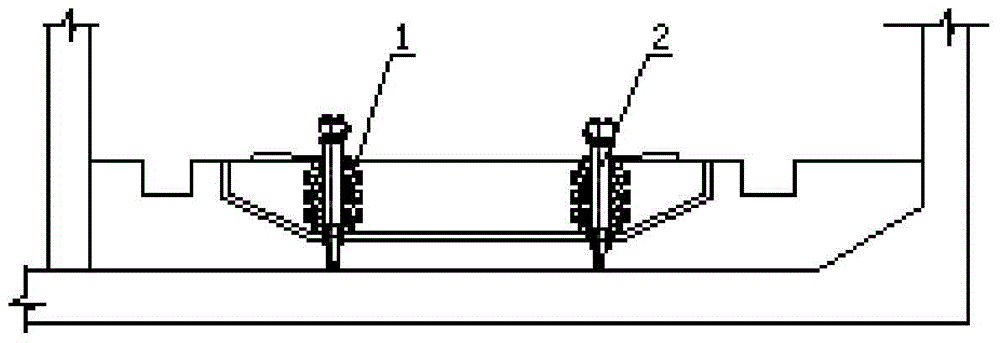

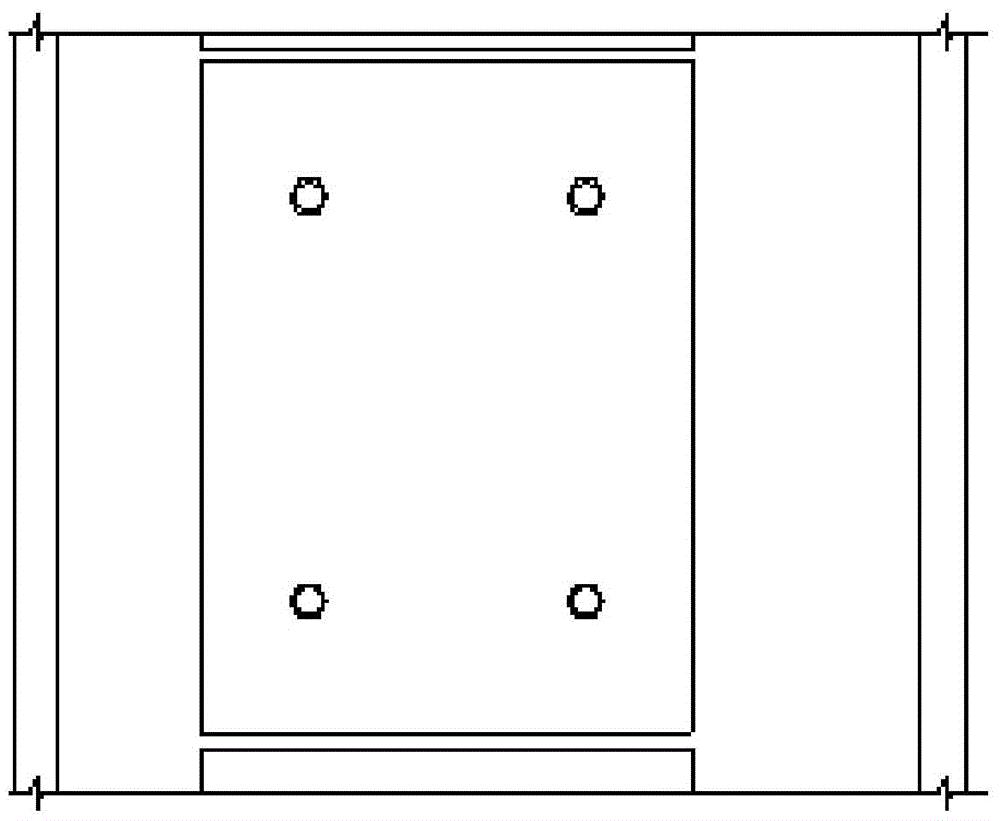

[0026] see figure 1 with figure 2 , shows the built-in regulator of the slab track bed of the present invention.

[0027] The slab track bed built-in regulator includes a slab track bed built-in fixer 1 and a built-in adjustment mechanism 2, the built-in fixer 1 is embedded in the slab track bed, see figure 2 , which can be four symmetrically arranged and distributed in the four positioning holes of the slab-type track bed. The built-in adjustment mechanism 2 is installed in the arranged built-in fixer 1 to form a supporting position for the entire track bed, so that Precisely adjust the position and height of the bed plate.

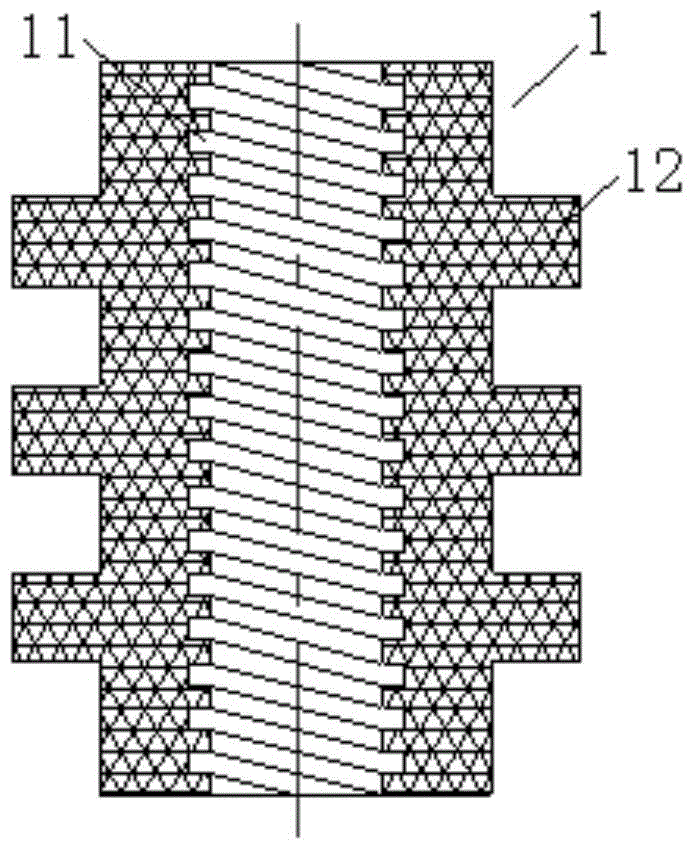

[0028] Wherein, the built-in fixer 1 can be made of MC nylon to improve connection strength and effect, see image 3 , the built-in fixer 1 is a cylindrical structure, the inner edge of which is provided with a coarse tooth internal thread 11, and the outer edge is provided with a plurality of annular bosses arranged at intervals. During fixing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com