Clamping structure for replacing FCT test equipment sky board

A technology of clamping structure and testing equipment, applied in the parts, measuring devices, measuring electrical variables of electrical measuring instruments, etc., can solve the problems of error-prone, slow top plate speed, etc., to improve efficiency, reduce unreliable fixing, The effect of avoiding product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

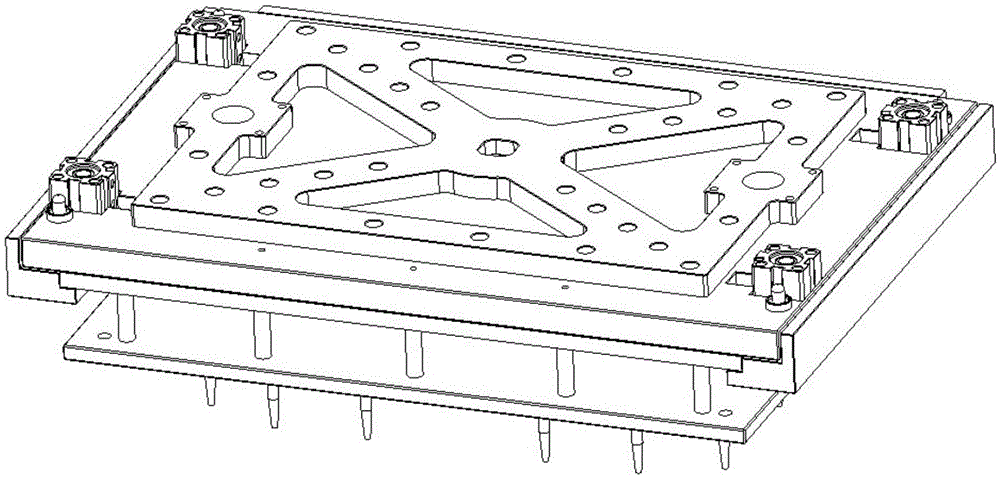

[0038] like figure 1 , Figure 11 to Figure 13 As shown, the clamping structure for replacing the top plate of the FCT test equipment provided by the embodiment of the present invention generally includes a top plate assembly and a clamping assembly.

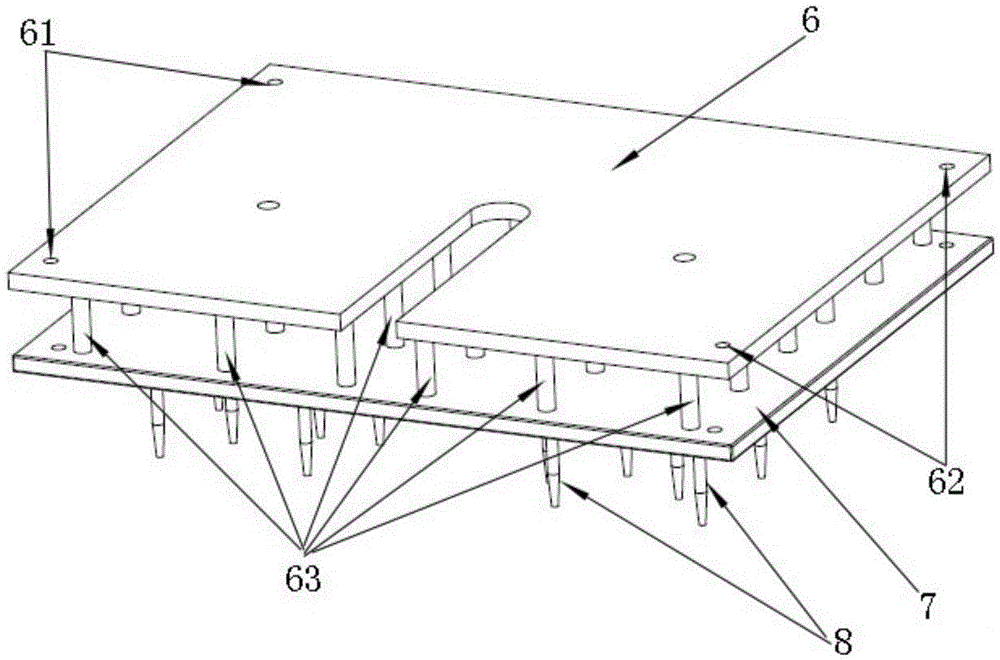

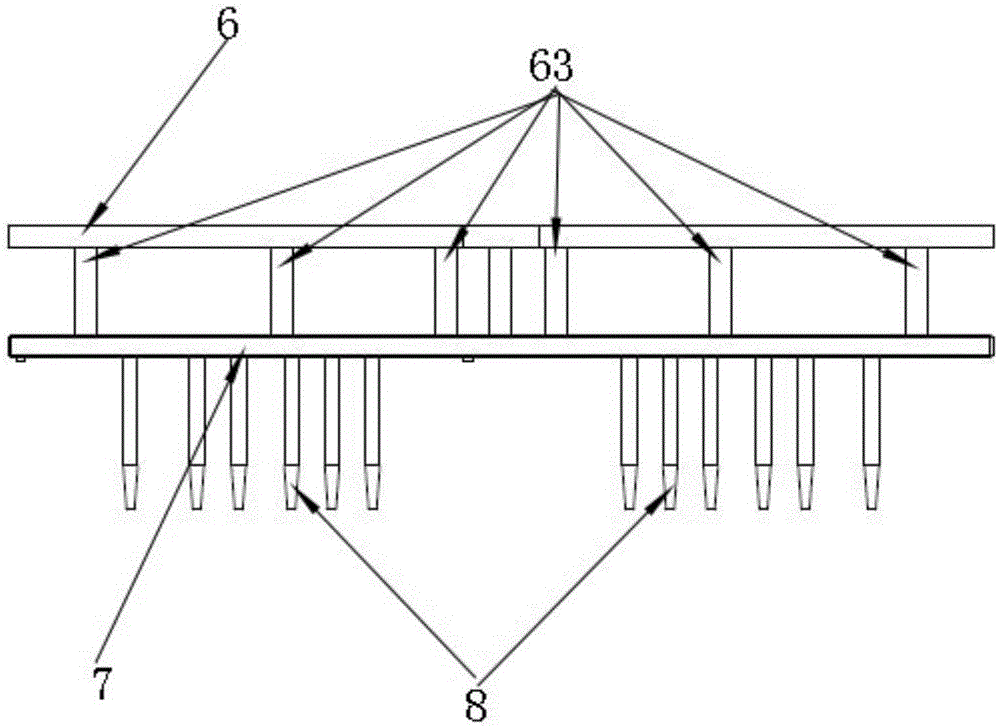

[0039] Top plate components such as Figure 2 to Figure 5 Shown in, including top plate 7, clamping plate 6. The top plate assembly is composed of a top plate and a clamping plate. The top plate 7 is mainly used for fixing the pressure bar 8, and the clamping plate 6 plays a role of positioning and fixing. It is provided with four positioning holes 61, 62, which are connected with the clamping assembly. The positioning column 4 cooperates to realize the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com