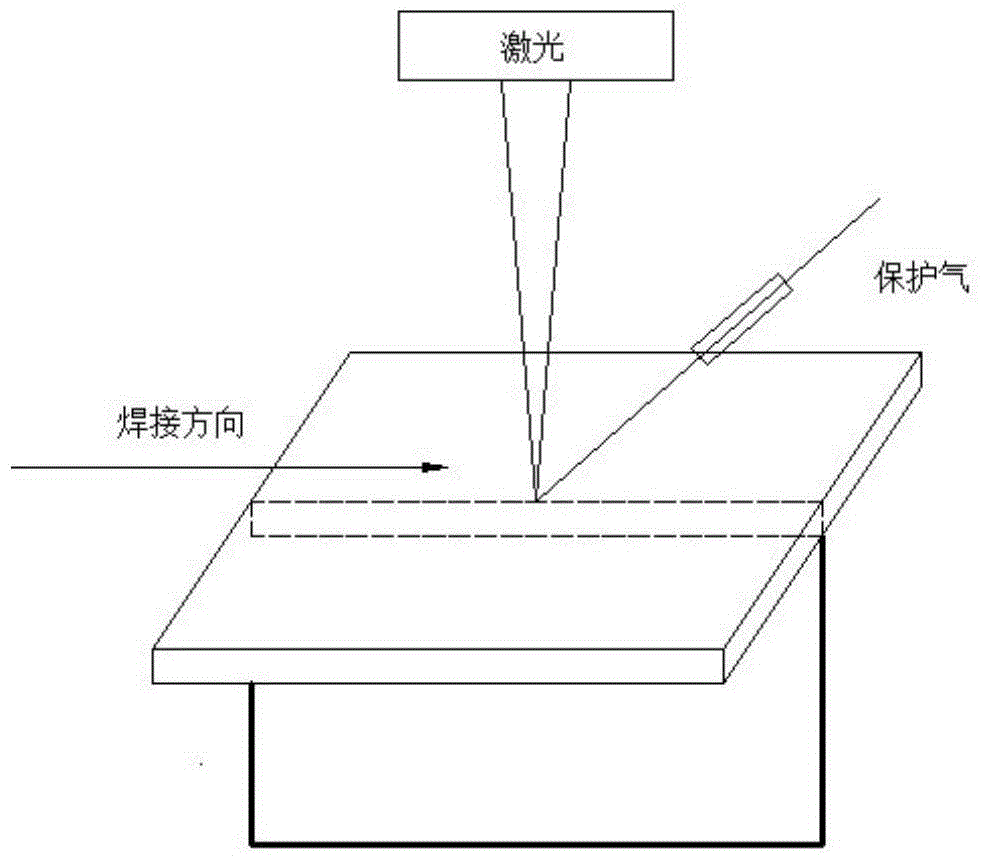

A fixture for laser penetration welding of T-joints and its welding method

A welding method and penetration welding technology, which can be used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficulties, and achieve the effects of low cost, good welding seam formation, and improved welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

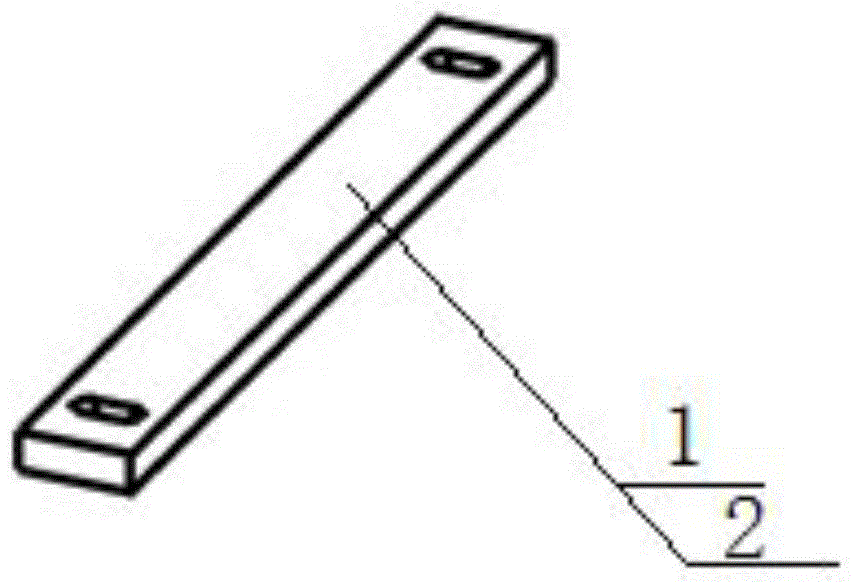

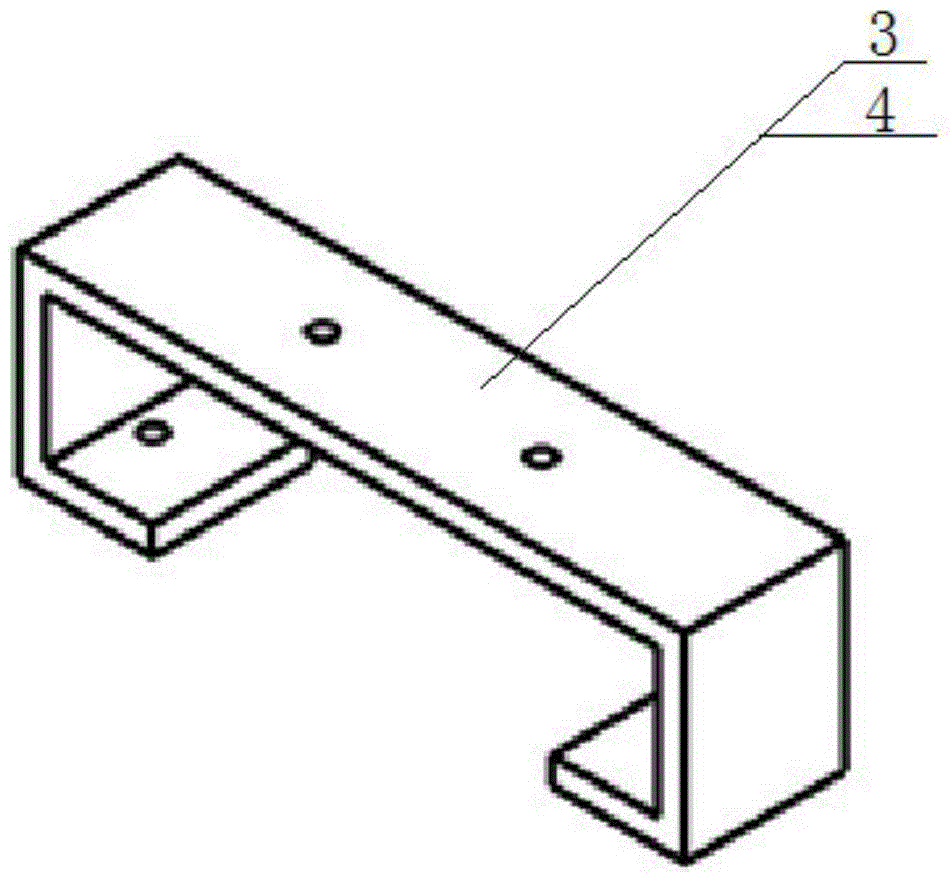

[0033] as attached Figure 2-8 As shown, a fixture for laser penetration welding of T-joints, including: a first pressure plate 1 and a second pressure plate 2 in the shape of a bar with the same size and length, and a first bracket 3 and a second bracket 4 with a door frame shape in section , a rectangular plate base 5, washers 6 and bolts 7, the two ends of the first press plate 1 and the second press plate 2 are respectively provided with an oval hole with a long diameter perpendicular to the long side of the press plate, the first press plate 1 and the second press plate 2 are mutually Parallel, isolated, and fixed on both sides of the center line of the base 5 by the washer 6 and the bolt 7 respectively, the first bracket 3 and the second bracket 4 are respectively arranged on the sides of the first pressure plate 1 and the second pressure plate 2 The outer side is fixed on the base 5 by washers 6 and bolts 7 . The upper frames of the first bracket 3 and the second brack...

Embodiment 2

[0041] As the preferred technical solution of the present invention, according to the laser penetration welding welding parameter debugging of T-shaped joints of steel plates, the parameters are welded according to the following process parameters, the laser output power is 4500W, and the welding speed is 1.8m / min , the protective gas flow rate is 25l / min, and the defocus is -5mm. The T-shaped joint welded with the process parameters of this embodiment has better weld penetration and more beautiful shape. All the other structures and advantages are identical to Embodiment 1.

Embodiment 3

[0043] As the preferred technical solution of the present invention, according to the laser penetration welding welding parameter debugging of the T-shaped joint of the steel plate, the described parameters are welded according to the following process parameters, the laser output power is 4500W, and the welding speed is 2.1m / min , protective gas flow rate 25l / min, defocusing amount 0mm. Using the process parameters of this embodiment to weld the T-joint, the speed is fast, the time of the weld seam in the high temperature zone is shortened, and the solidification and forming are faster, so it is not easy to be oxidized. All the other structures and advantages are identical to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com