Stamping die half-arc-shaped sheet metal parts

A technology for stamping dies and sheet metal parts, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient rapid positioning of sheet metal, easy upturning and sliding of sheet metal, and reduced stamping accuracy, and achieve a simple structure. , High practical performance, the effect of improving stamping yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

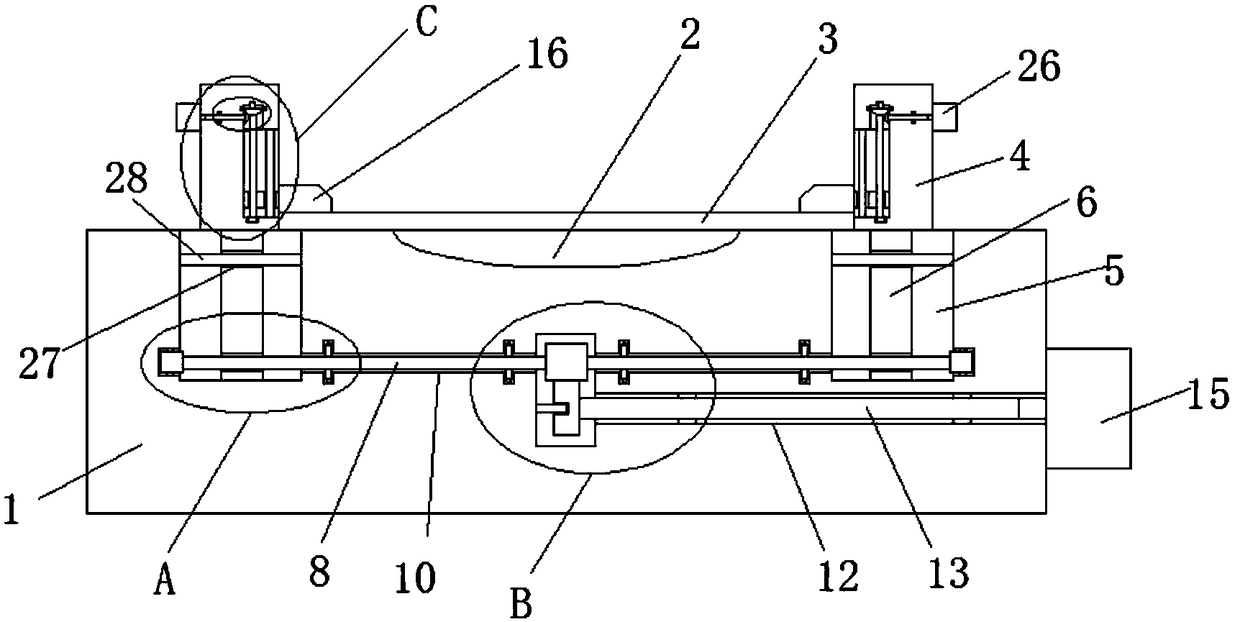

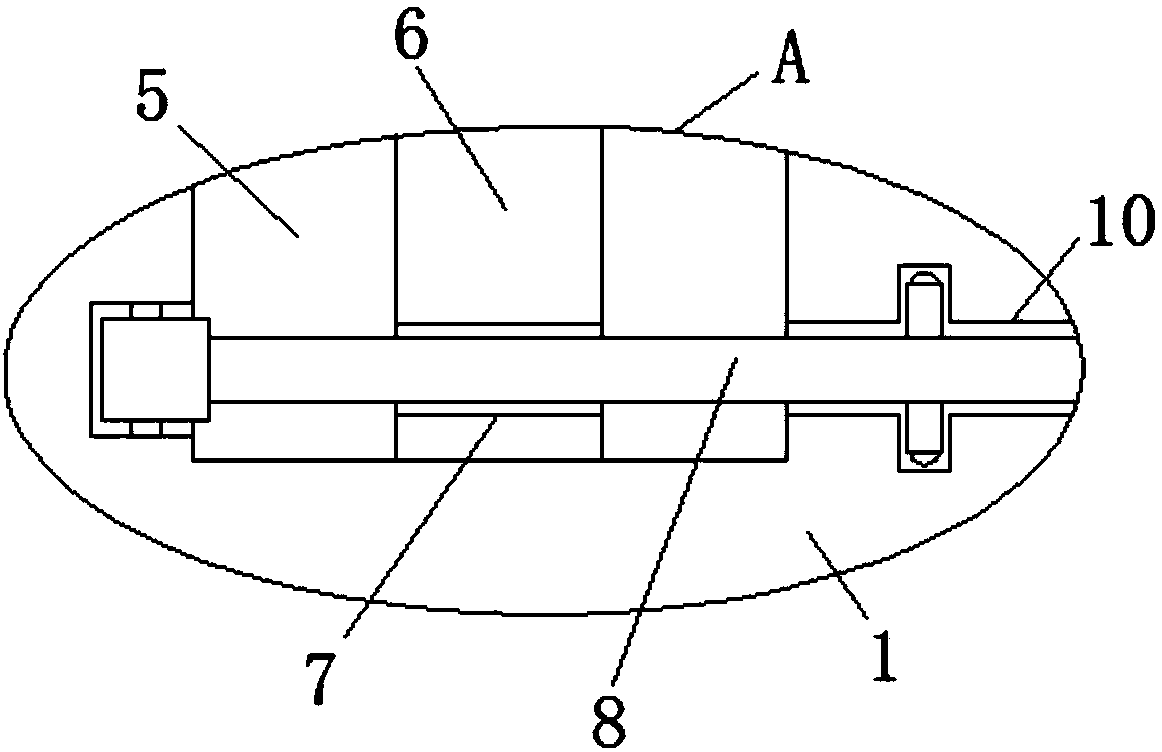

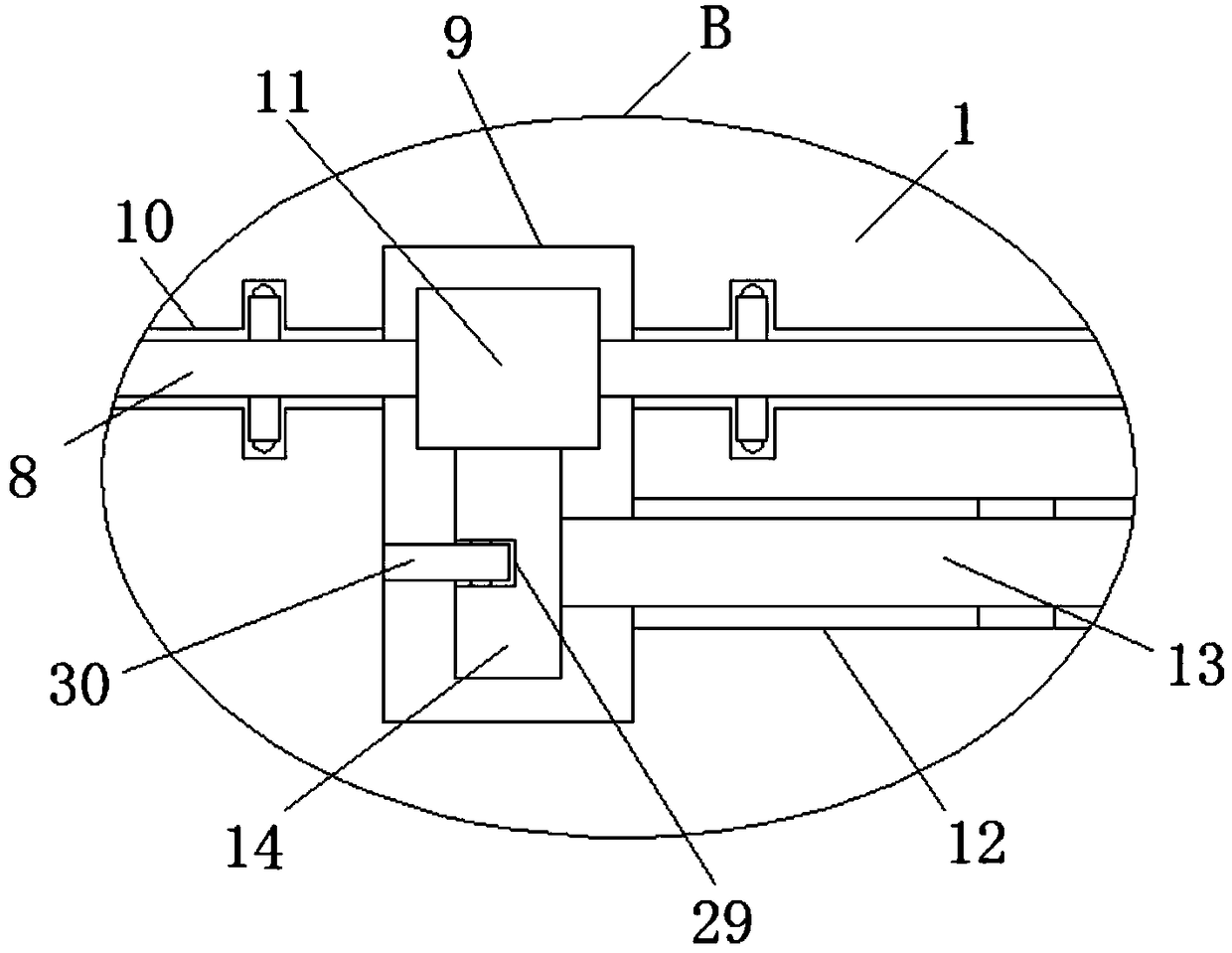

[0026] refer to Figure 1-5In this embodiment, a stamping die for half-arc sheet metal parts is proposed, which includes a female mold body 1, a semi-arc groove 2 is provided on the top of the female mold body 1, and a sheet metal mold is provided on the top of the female mold body 1. The material plate 3, the sheet metal material plate 3 covers the semi-arc groove 2, two positioning blocks 4 are slidably installed on the top of the mother mold body 1, and the sides of the two positioning blocks 4 close to each other are in contact with the sheet metal material plate 3 The top of the female mold body 1 is provided with two first grooves 5, the semi-arc groove 2 is located in the middle of the two first grooves 5, and the first slider 6 is slidably installed in the first groove 5, The top of the first slide block 6 is welded on the bottom of the corresponding positioning block 4, and the first slide block 6 is provided with a first threaded through hole 7, and the first threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com