Vacuum track magnetically levitated train system

A magnetic levitation train and magnetic levitation technology, applied in tunnel systems, sliding/floating railway systems, tracks, etc., can solve the problems of reduced operating efficiency, large air resistance, and non-mechanical emergency braking of the track system, so as to improve the operation The effect of efficiency and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

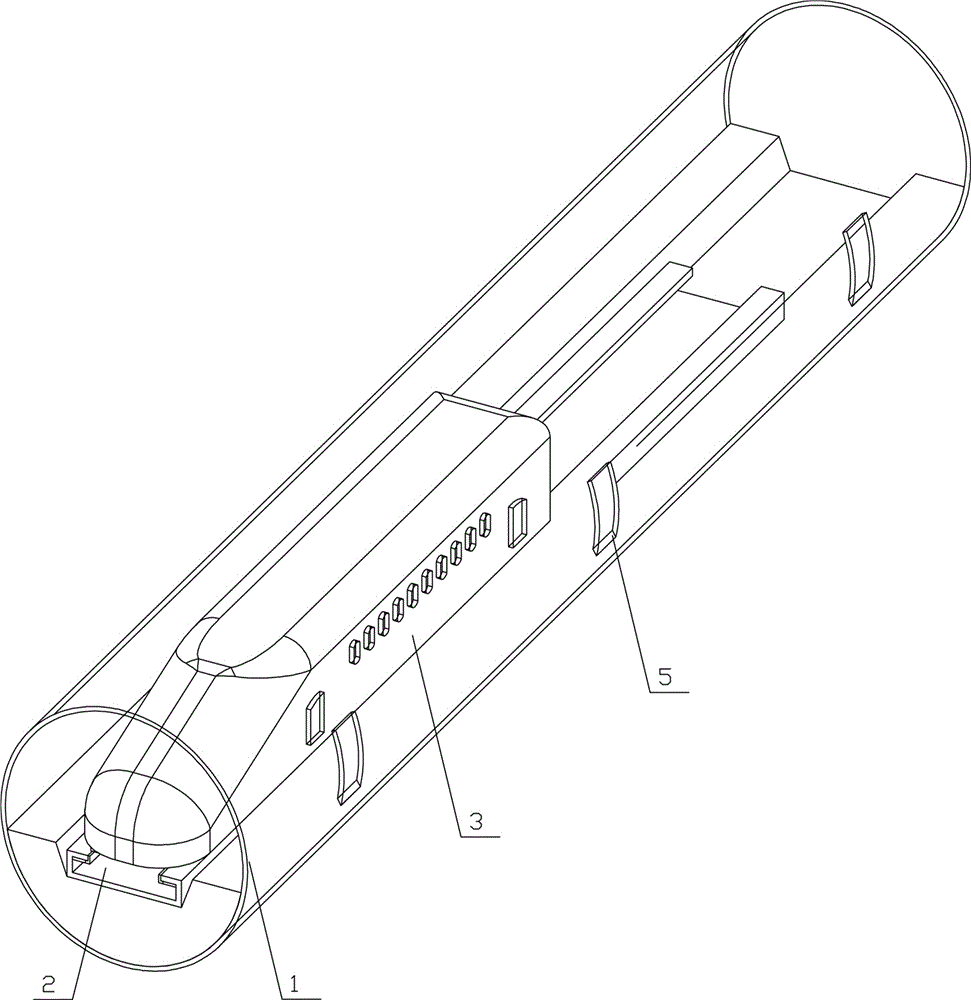

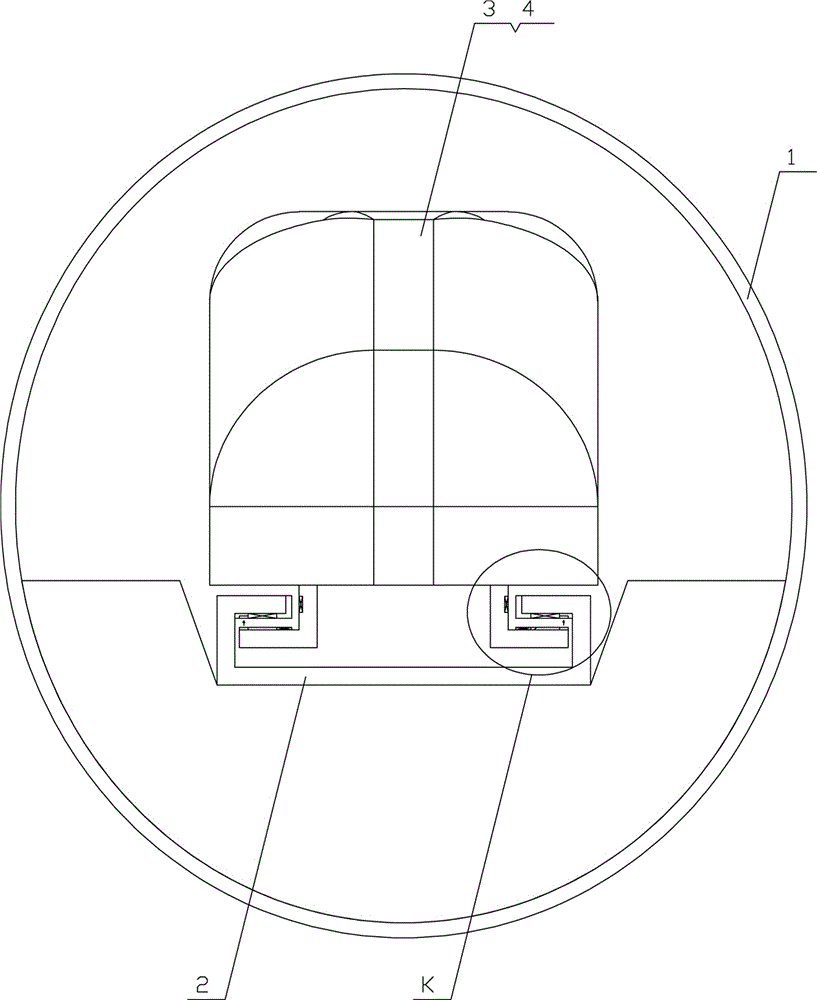

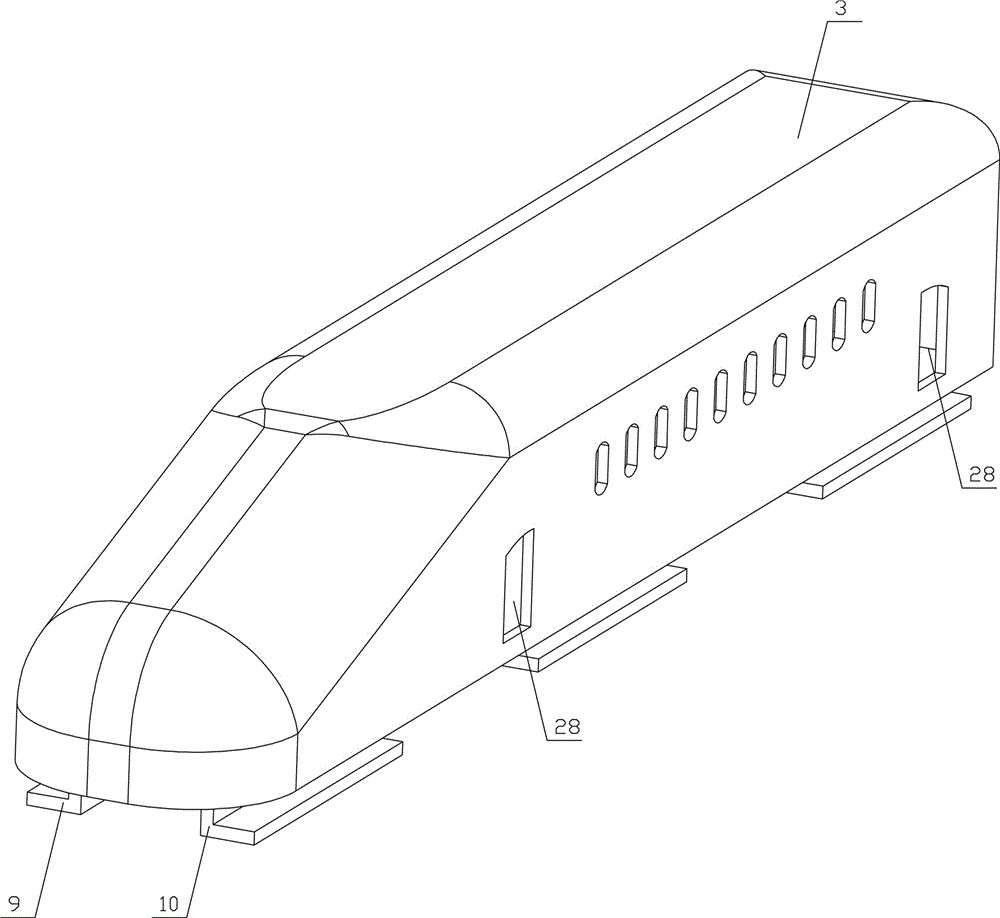

[0033] Example 1, see Figure 1-12 , the present invention includes vacuum tunnel 1, magnetic levitation track 2, magnetic levitation train, station train operation system and driving train operation system and master control train operation system, is provided with several switch doors 5 on vacuum tunnel 1, and maglev train includes locomotive 3 and several compartments 4, several sets of suspension frames are provided on the underside of the headstock 3 and the compartment 4, and an in-vehicle control system and an air circulation system are respectively separately provided in the front end 3 and the compartment 4; the magnetic levitation track 2 and the Each group of suspension frames forms an inwardly cohesive structure, wherein the magnetic levitation track 2 is an integrated inner hook structure, with left and right edges 6, 7 symmetrically arranged toward the inner side of the track, and at the ends of the left and right edges 6, 7 respectively There is an "L"-shaped ma...

Embodiment 2

[0043] Embodiment 2, the present embodiment is based on embodiment 1, in the present embodiment the headstock of the maglev train has the same structure as its respective compartments, and one or more sections for passenger boarding are provided on the maglev track 2 of each site 32 Upper compartment 401, the main train compartment 402 of the moving maglev train, one or more compartments at the end of the main train compartment 402 is the lower compartment 403, wherein the positions of each station 32 are Figure 14 , Figure 15 , Figure 16Respectively represented by a rectangular frame on one side of the maglev track 2; in the station area, three sets of train dispatching systems corresponding to the upper carriage 401, the main train carriage 402 and the lower carriage 403 are respectively arranged to form a station train operation system; There is a section of driving area outside the central station area, and a set of driving train operation systems corresponding to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com