Multi-tubular high-speed vehicle stabilization method

A multi-tube, automotive technology, applied in the direction of body stability, body, vehicle parts, etc., can solve problems such as unsafe, uneconomical, and poor visibility of the car, and achieve the effects of stable high-speed driving, energy saving, and increased grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

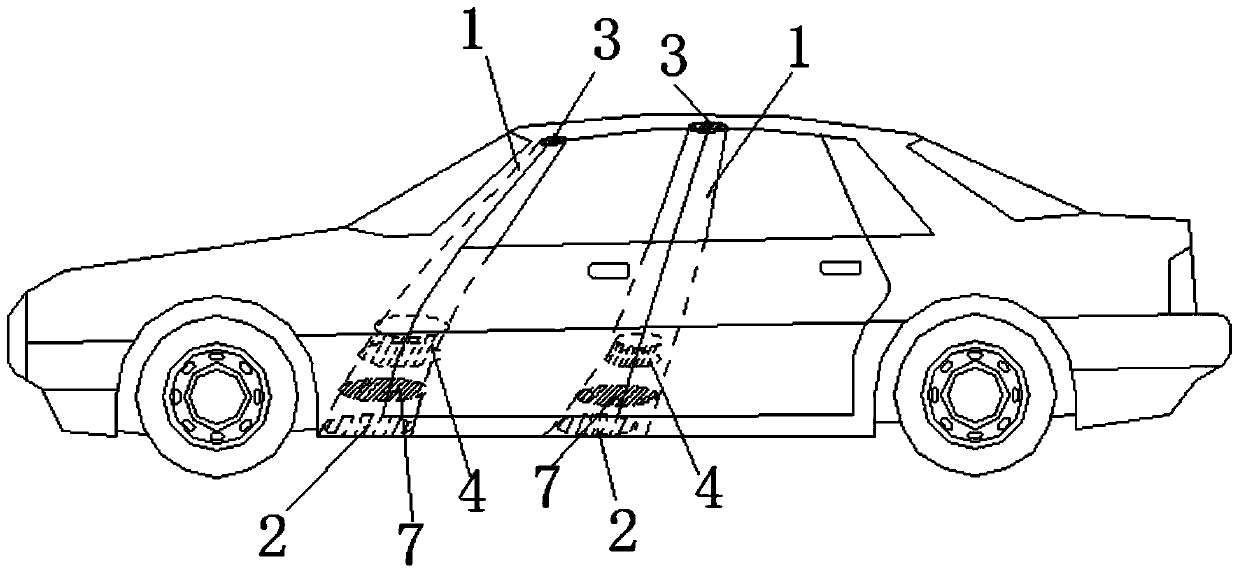

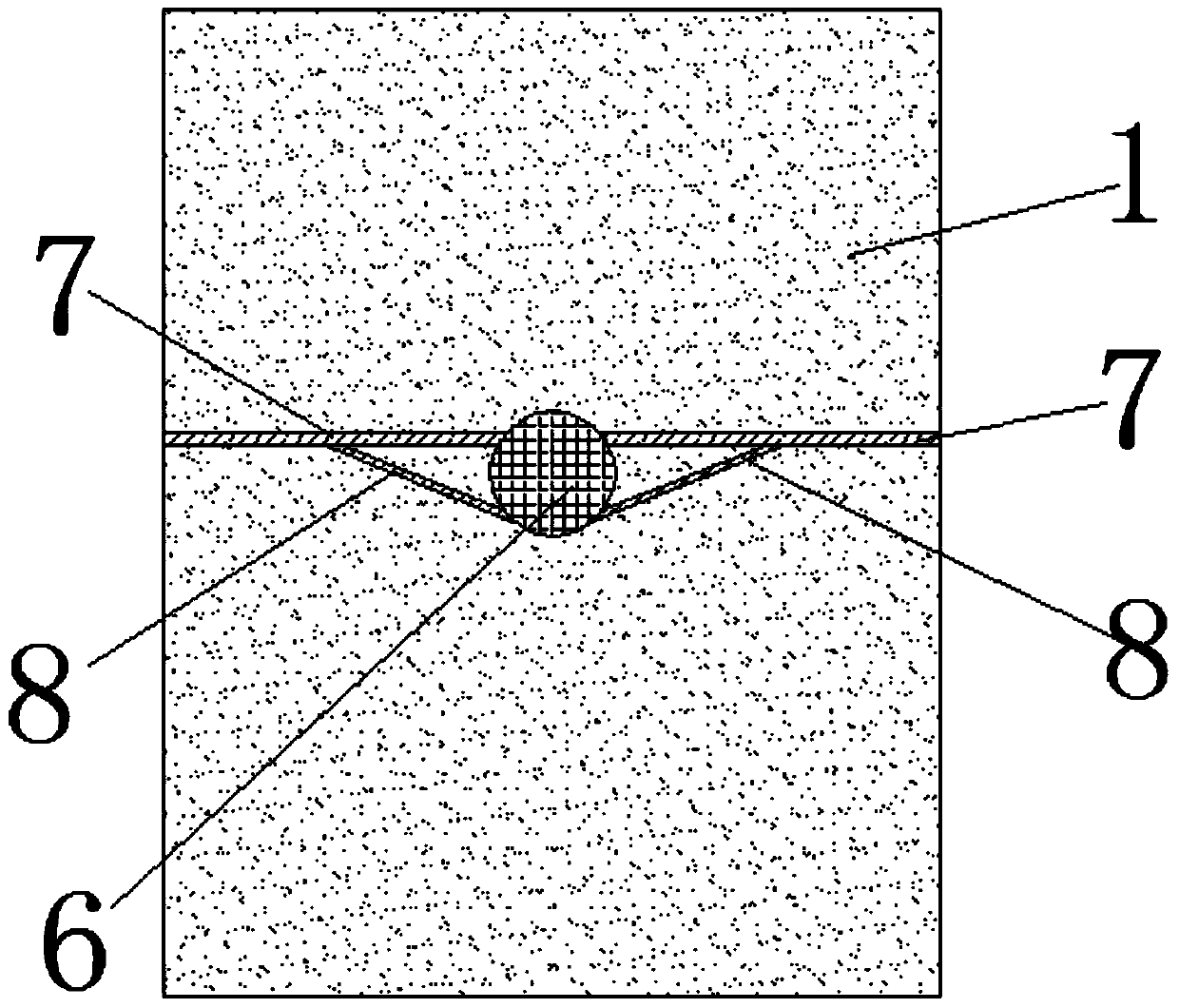

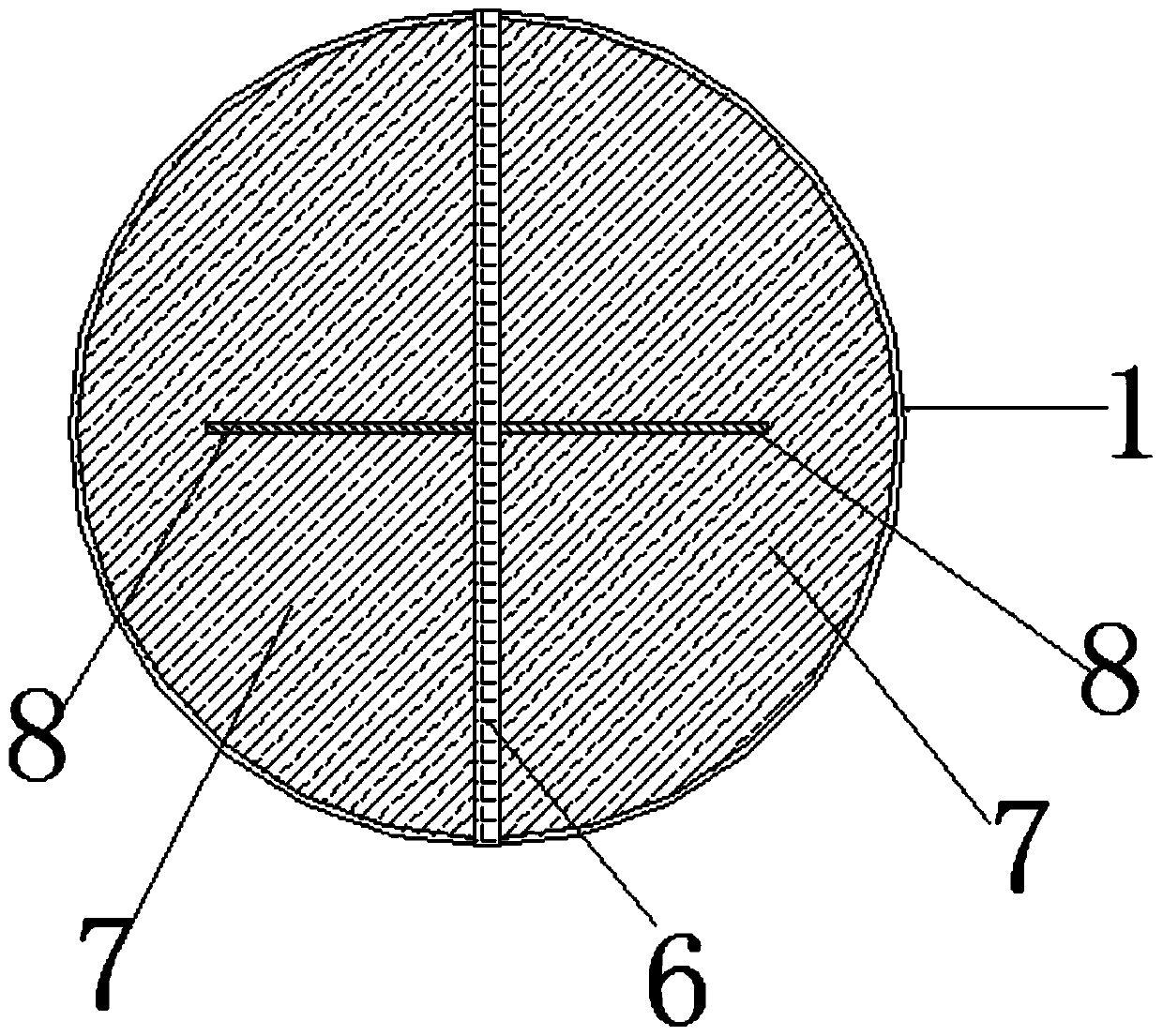

[0025] Such as figure 1 , figure 2 and image 3 As shown, a multi-pipe type high-speed automobile stabilization method includes a drainage pipe 1 and a cross bar 6, the drainage pipe 1 is installed in the A-pillar and B-pillar on both sides of the automobile, and the lower end of the drainage pipe 1 passes through the chassis of the automobile And welded with the chassis to form the air inlet 2, the upper end of the drainage pipe 1 passes through the roof of the car and is welded with the roof to form the exhaust port 3, the diameter of the air inlet 2 is greater than the diameter of the exhaust port 3; The horizontal bar 6 is horizontally fixed in the drainage tube 1, and two semicircular lightweight thin sheets 7 are installed on the horizontal bar 6, and the thin sheets 7 are connected with the horizontal bar 6, and a support rod 8 is installed un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap