A warehouse automatic circulation system

A warehousing and automatic technology, applied in the direction of mechanical conveyors, storage devices, transportation and packaging, etc., can solve the problems of robot utilization rate reduction, energy consumption and logistics cost increase, achieve high manufacturing costs, improve operating efficiency, and simplify queuing The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

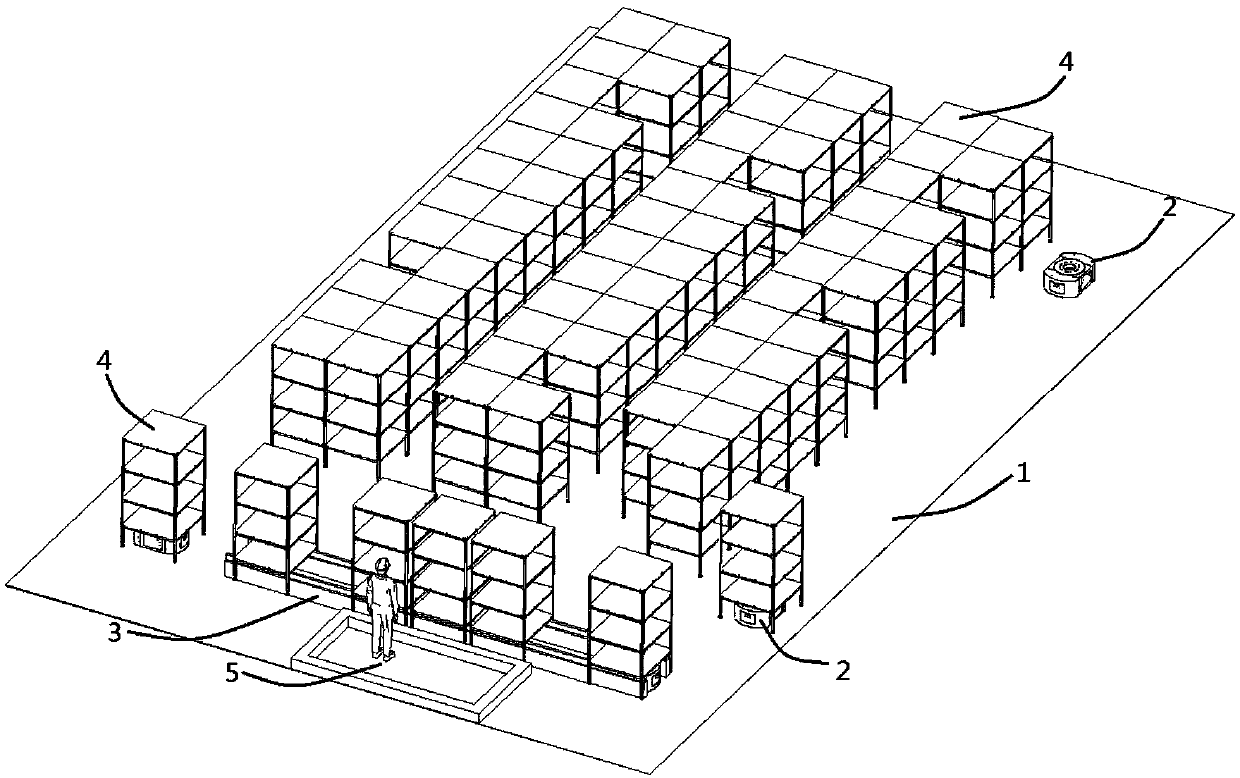

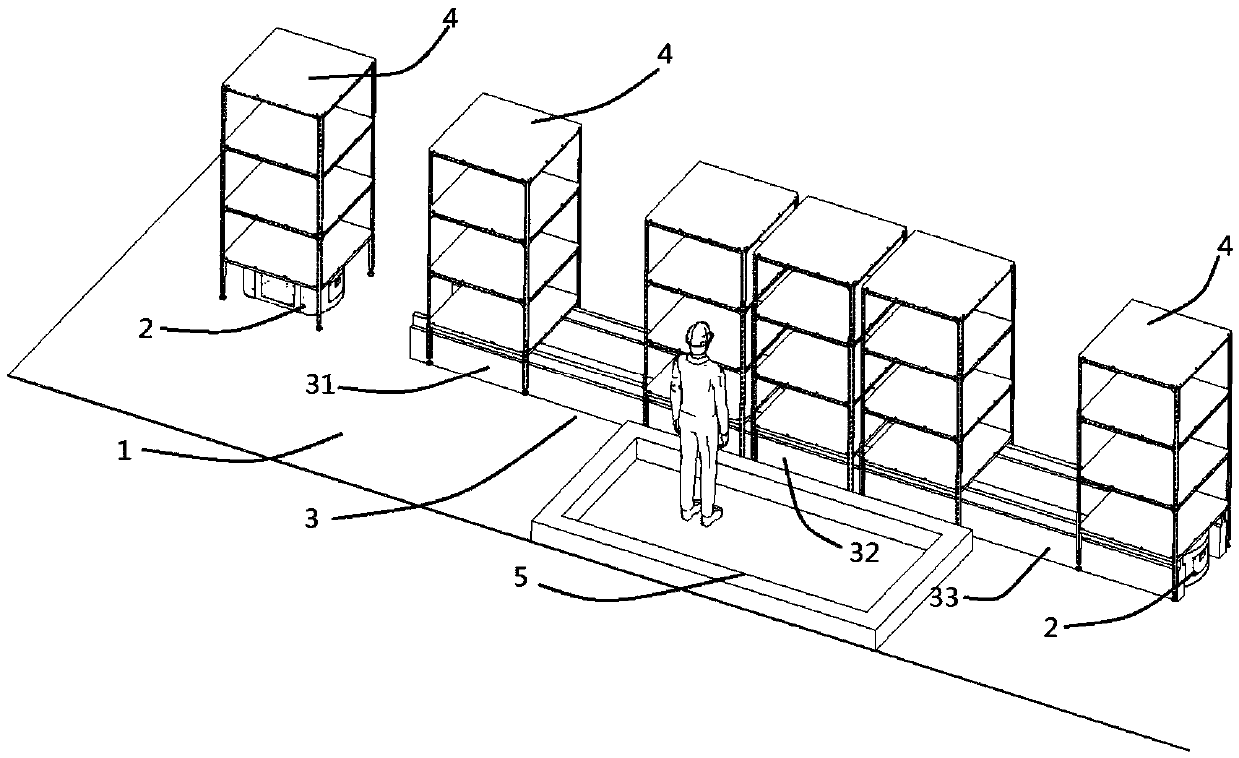

[0030] Such as figure 1 As shown, the present invention discloses a warehouse automatic circulation system, including several shelf units 4, at least one drive unit 2 and a transmission mechanism 3;

[0031] 1. Shelf unit 4

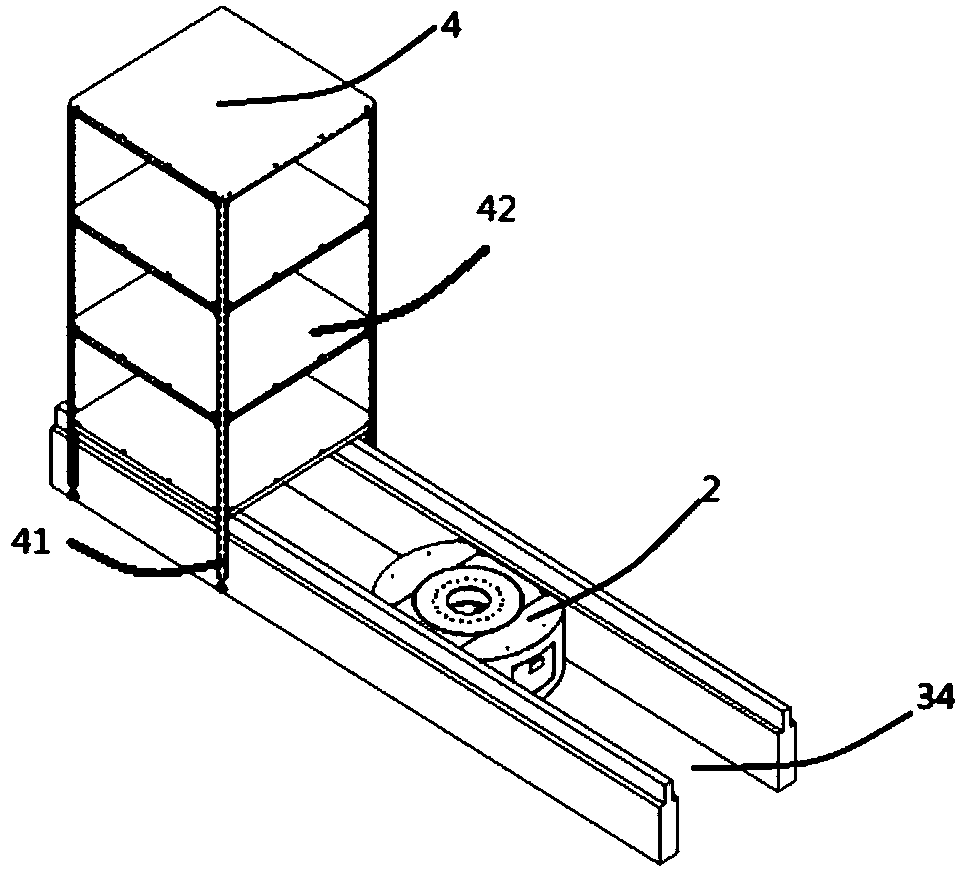

[0032] The shelf unit 4 is used to store objects to be transported, and one or more types of objects stored in the same shelf unit 4 can be picked by the picking system. Such as figure 1 , Figure 5 As shown, the shelf unit 4 is arranged on the working plane 1 according to the requirements, and the realization form of the shelf unit 4 can be various. For example, it is equipped with rollers and can move in the working plane 1. For example, the shelf unit 4 cannot be moved without rollers. The shelf unit 4 of the embodiment of the invention is as Figure 5 As shown, it includes the shelf legs 41 and the storage space 42. The shelf legs 41 support the storage space 42, so that the bottom of the storage space 42 is at a certain distance from the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com