Labor-saving platen assembly structure capable of increasing lever ratio

A labor-saving and leverage-ratio technology, which is applied to friction clutches, clutches, mechanical drive clutches, etc., can solve problems such as large clutch separation force, and achieve reliable performance, compact and simple structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

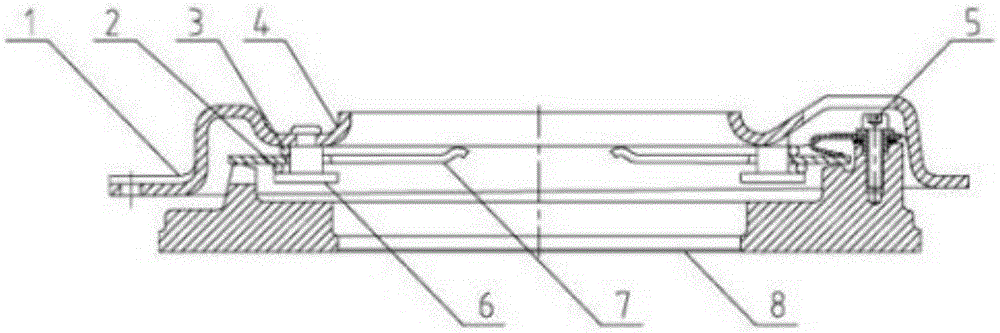

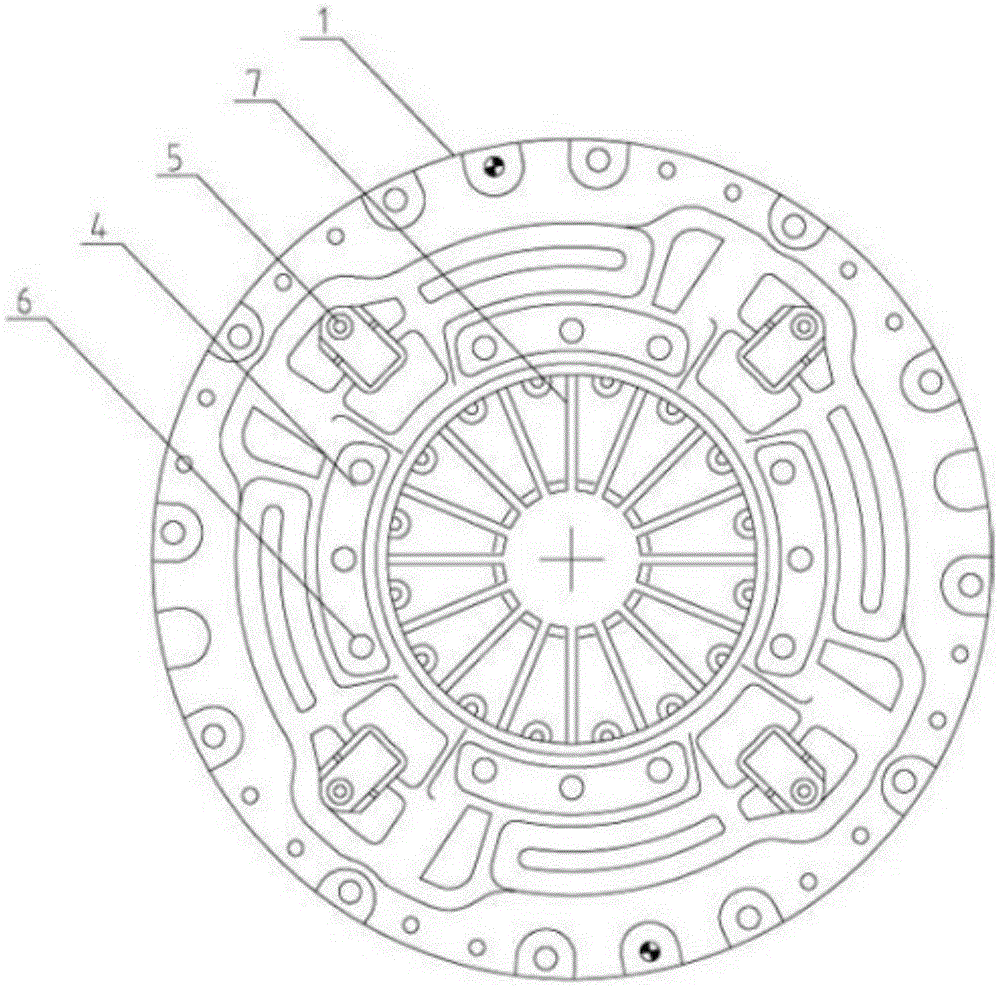

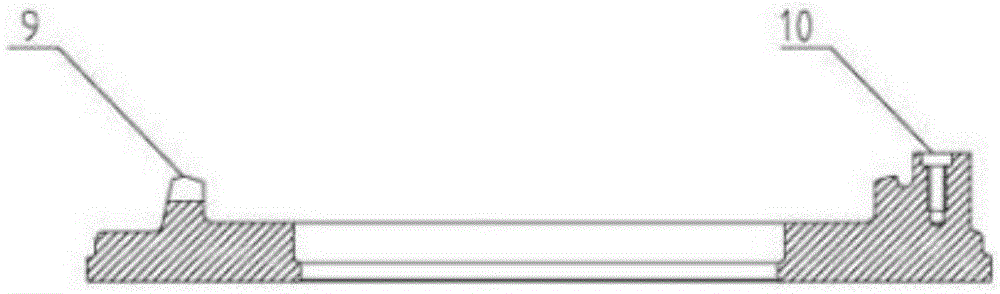

[0016] Examples, see figure 1 , a labor-saving pressure plate assembly structure with increased leverage ratio, which has a pressure plate 8 with an annular boss 9 on the pressure plate 8, see image 3 , Figure 4 , the outer side of the ring boss 9 of the pressure plate 8 is provided with a connecting hole 10. At the connecting hole 10 of the ring boss 9 of the pressure plate 8, a cover plate 1 is installed with a connector 5, see figure 1 , figure 2 The cover plate 1 is provided with a mounting groove 4. A diaphragm spring 7 is installed between the cover plate 1 and the annular boss 9 of the pressure plate 8. There are several strip-shaped mounting holes 11 on the diaphragm spring 7. For details, see Figure 6 , each strip-shaped mounting hole 11 in the diaphragm spring 7 is equipped with a rivet 6. The lower end of the rivet 6 is provided with a pillow block 13, see Figure 7 The diaphragm spring 7 is composed of several rivets 6 in the strip-shaped mounting holes 11 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap