Intelligent typhoon resistance traffic safety lamp and control system

A technology for traffic safety and typhoon prevention, which is applied in the field of traffic lights, can solve the problems of disaster weather resistance and not much attention, and achieve the effect of strong wind disaster resistance, reliability assurance and accurate forecasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

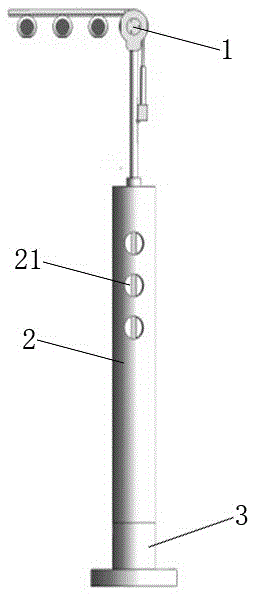

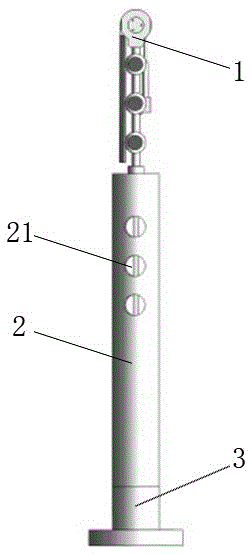

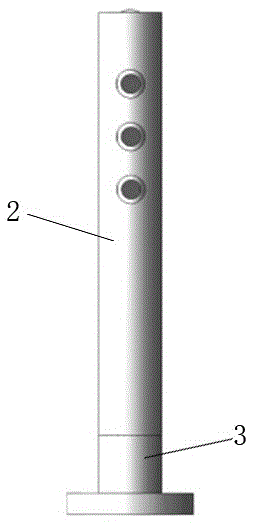

[0027] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

[0028] Such as Figures 1 to 3 As shown, a kind of intelligent anti-typhoon traffic safety lamp, wherein, comprises traffic light head 1, lamp post 2 and lamp base 3, and described lamp post 2 is arranged on the lamp base 3, and described traffic lamp head 1 is arranged on the top of lamp post 2 , the lamp post 2 is a hollow cylinder, the traffic light head 1 can be folded, and has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com