Thin film transistor array substrate and its preparation method, touch display panel

A thin-film transistor and touch display panel technology, which is applied in the field of touch technology and display, can solve problems such as poor group accuracy and actual thickness deviation of the touch display panel, and achieve the effect of reducing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

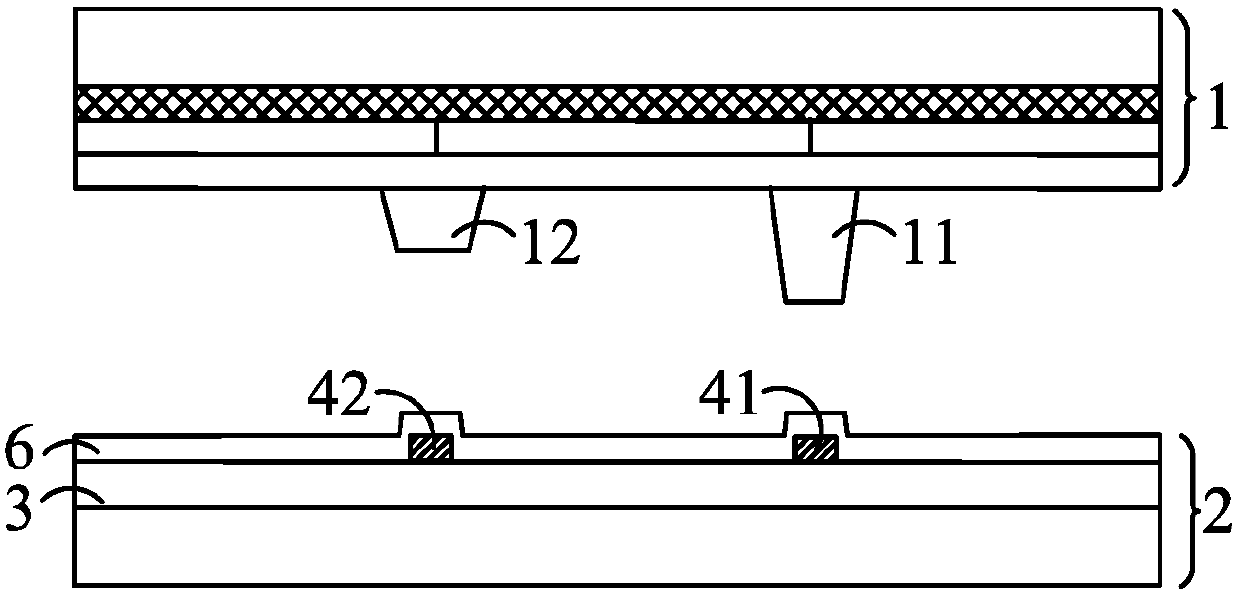

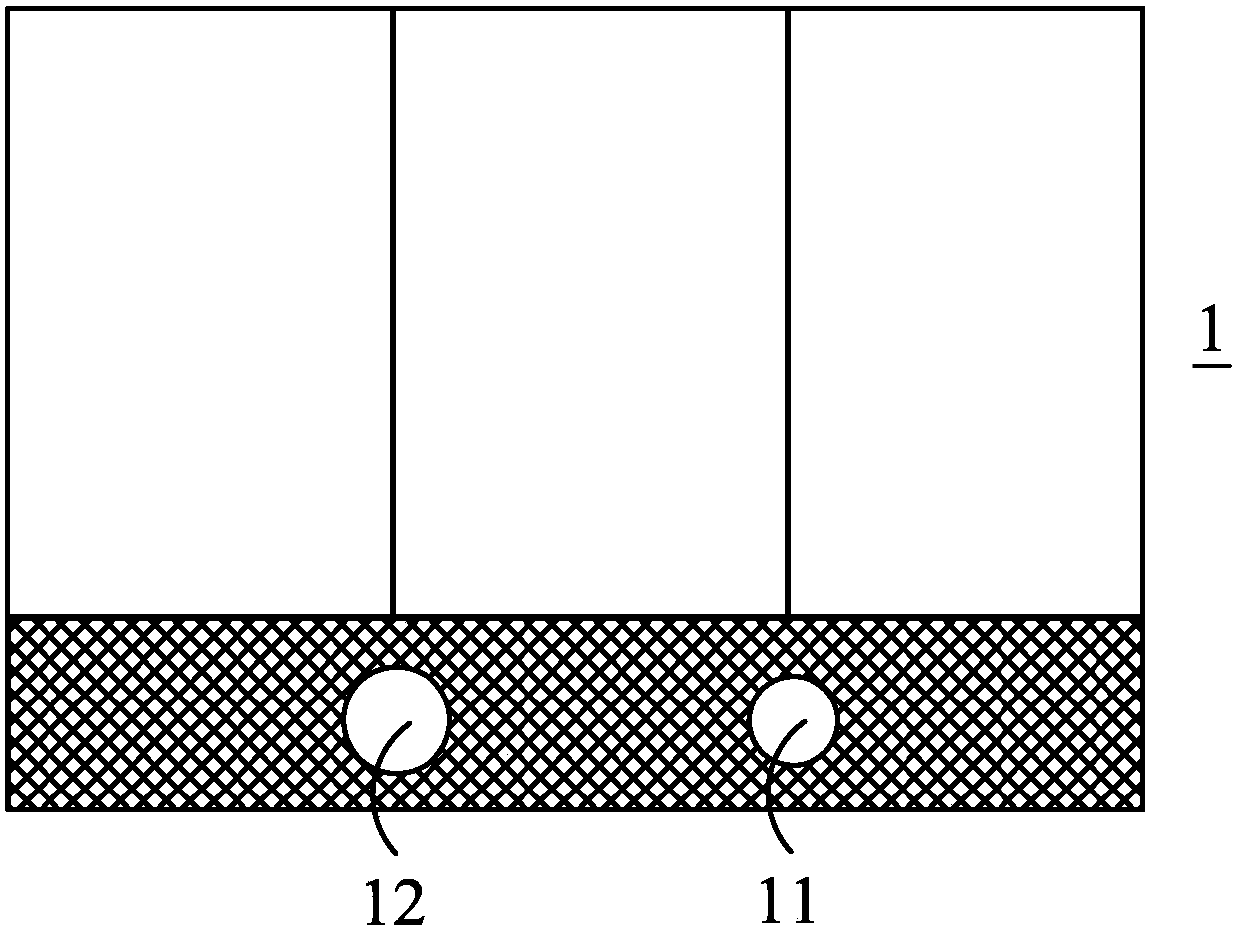

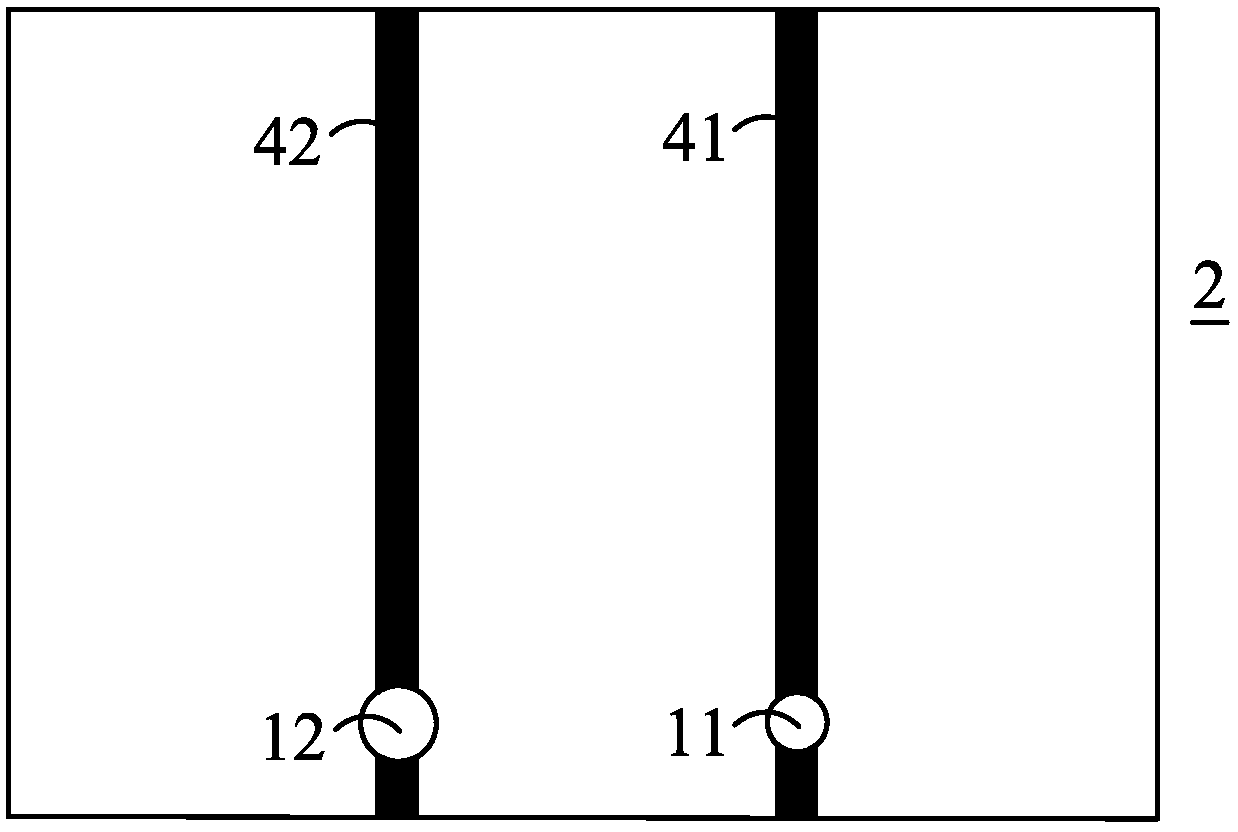

[0038] This embodiment provides a touch display panel, as shown in 6, comprising a color filter substrate 1 and a thin film transistor array substrate 2 arranged oppositely, and a liquid crystal layer ( not shown).

[0039] Wherein, the lower surface of the color filter substrate 1 extends toward the direction of the thin film transistor array substrate (ie Figure 6 Extending downward in the center) is provided with a first columnar spacer 11 and a second columnar spacer 12, and the first columnar spacer is higher than the second columnar spacer, both of which are cross-sectional areas from top to bottom gradually Decreasing cylinder. A planarization layer 3 is provided on the upper surface of the thin film transistor array substrate 2 , and the planarization layer 3 is recessed toward the inside to form grooves 31 arranged at intervals. The first touch electrode lead 41 and the second touch electrode lead 42 are accommodated in the groove 31 respectively, and the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com