Obtaining sap of fresh plants and their cosmetic and therapeutic uses by thermothermal treatment

A deformation heat treatment, plant technology, applied in cosmetics, cosmetic preparations, medical raw materials derived from angiosperms, etc., can solve the problem of not mentioning deformation heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

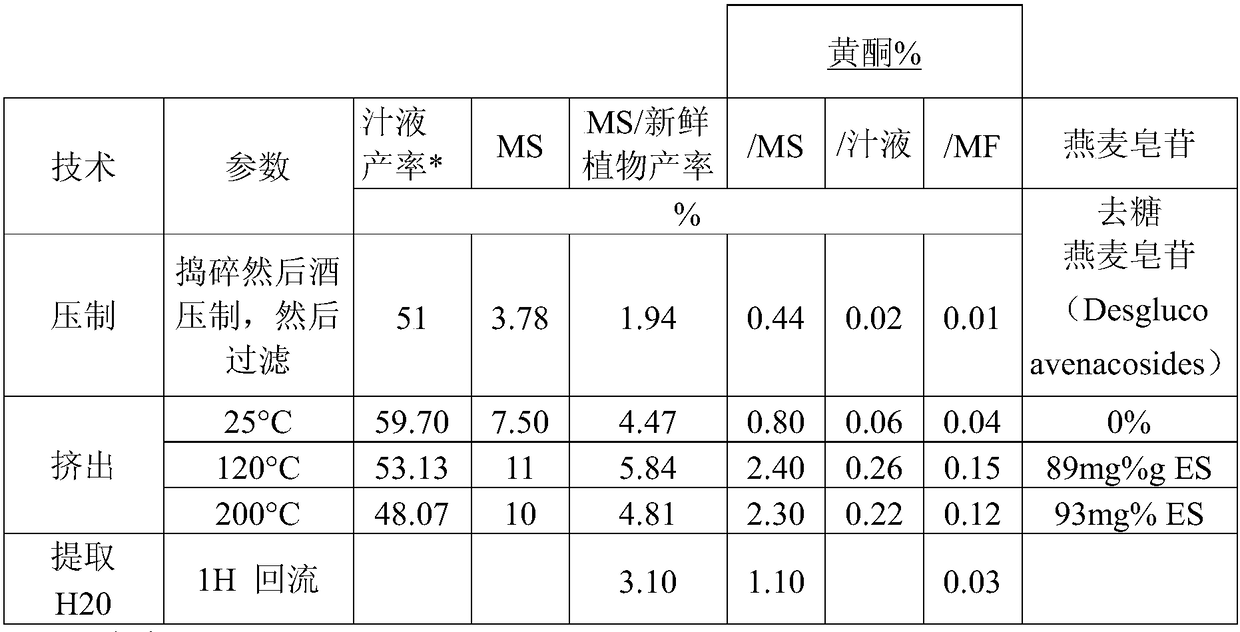

[0087] After a growth period of 2 months (oat seedlings), 12.75 kg of unfrozen (24 h at 2° C.) fresh above-ground parts of oats (Avena sativa L.) harvested by harvester were fed into The first barrel of a five-barrel twin-screw extruder with rotating, co-rotating osmotic screws—CLEXTRAL BC45. The temperature applied to different barrels is 30°C / 120°C / 120°C / 120°C / 60°C.

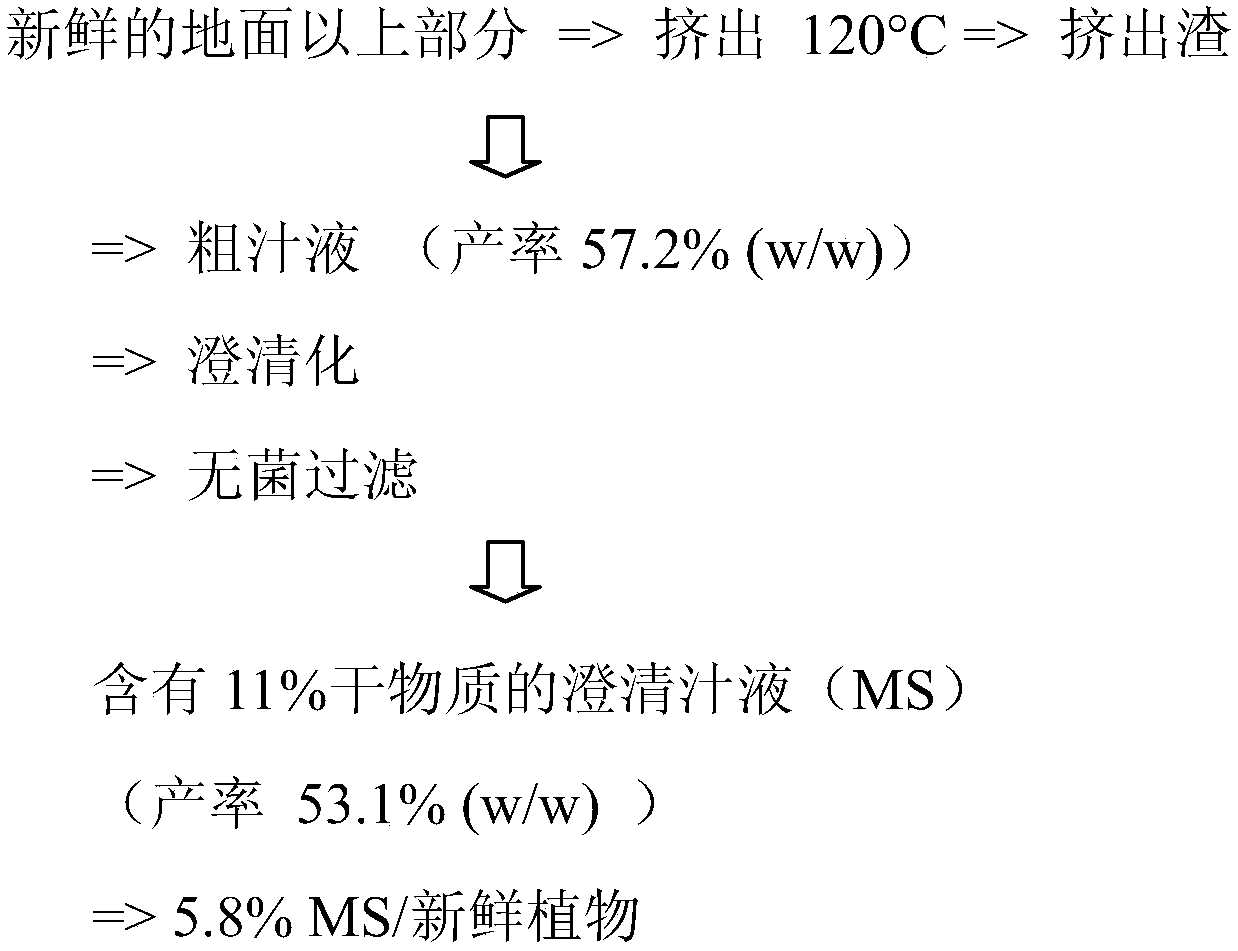

[0088] The protocol of the method is as follows (total duration of extrusion steps = 20 min; treatment rate: 38 kg plants / hour and 22 kg juice / hour)

[0089]

[0090] After extrusion, 57.2% juice w / w relative to the starting material was obtained. Then, clarification and filtration steps were carried out to obtain clarified juice with a final juice yield of 53.1% containing 11% dry matter, ie a yield of extracted dry matter of 5.8% (w / w).

[0091] The juice yield by pressing (mash-press-filter) the same raw material was 50% with 4.5% dry matter, ie a yield of 2.25% (w / w).

[0092] Thus, the extrusion tech...

Embodiment 2

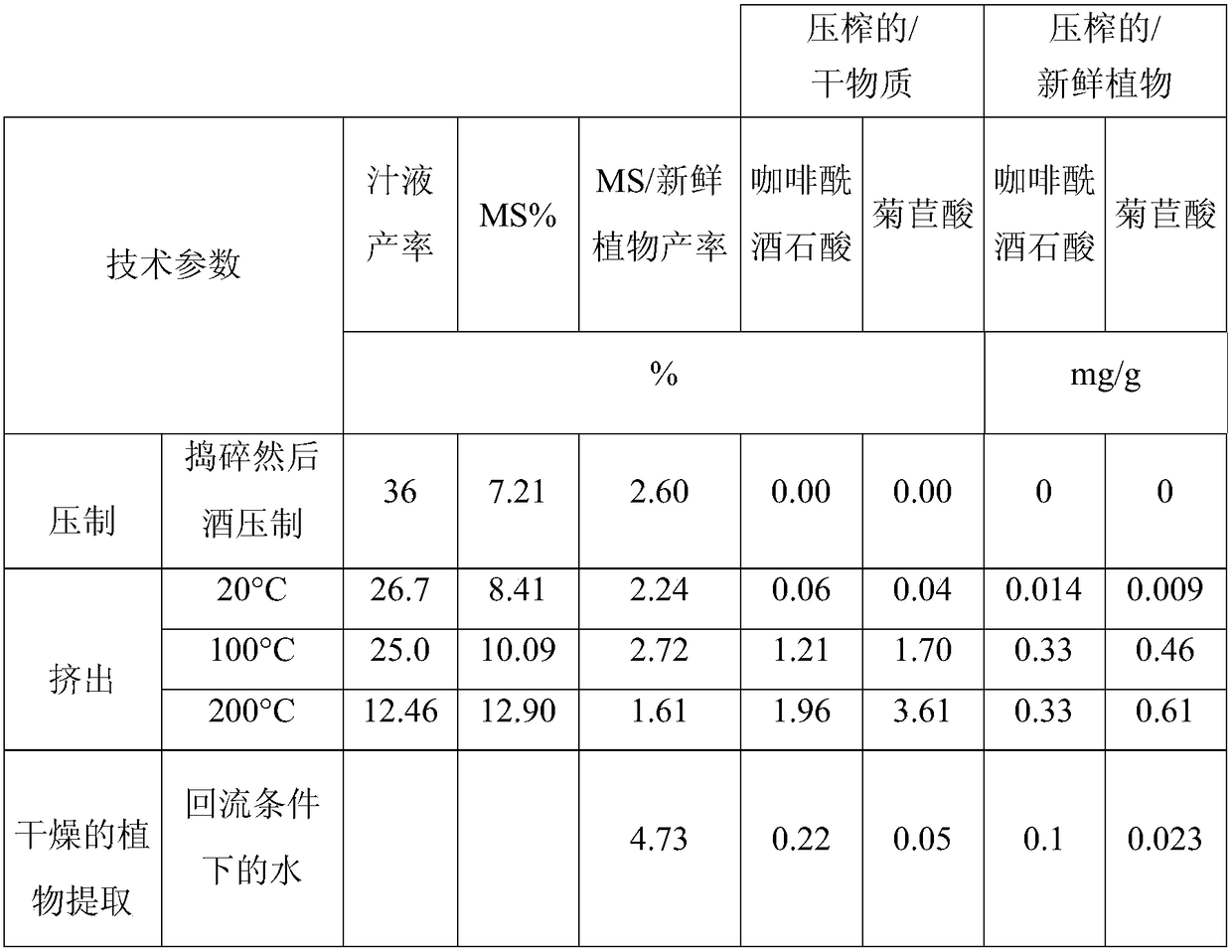

[0098] 3.14 kg of unfrozen (18 h at 2 °C) corolla of fresh Echinacea purpurea (Echinacea purpurea (L.) Moench) were fed into a five-barrel twin-screw extruder with co-rotating, co-rotating osmotic screws. Exit machine—the first barrel of CLEXTRAL BC45. The temperature applied to different barrels is 100°C / 100°C / 100°C / 100°C / 60°C. The process and mass balance are given in the table below (total time of extrusion step: 25 minutes; treatment rate: 7 kg plant / hour and 3 kg juice / hour):

[0099] Material Balance

process

dry matter

100

fresh plants

48.1

extrude

16.20%

26.9

clarification

10.81%

25

filter

10.09%

[0100] Thus, after extrusion we obtained 48.1% juice w / w relative to the starting material. Clarification and filtration steps were then performed to obtain clarified juice with a final juice yield of 25% containing 10.09% dry matter, ie a yield of 2.5% (w / w) dry matter.

[0101] The caffeic acid co...

Embodiment 3

[0111] 5.11 kg of unfrozen (20 h at 2° C.) fresh, above-ground parts of lemon balm (Melissa oficinalis L.) were fed into a five-barrel twin-screw with co-rotating and co-rotating osmotic screws Extruder - first barrel of CLEXTRAL BC45. The temperature applied to different barrels is 120°C / 120°C / 120°C / 120°C / 60°C. The process and mass balance are given in the table below (total duration of the extrusion step: 7 minutes; treatment rate: 46 kg plant / hour and 29 kg juice / hour):

[0112]

[0113] Under these conditions, extrusion allowed to obtain a juice with a yield close to 50% and with a dry matter content of 6.5%. In particular, this substance contains rosmarinic acid, which is usually extracted by a hydroalcoholic mixture, such as 70% ethanol). The content of rosmarinic acid in the dry matter extracted by extrusion without any organic solvent was 2.4% (w / w), ie comparable to 70% ethanol extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com