Solid-state brewing technique for peach fruit vinegar

A solid-state, peach-fruit technology, applied in the field of peach-fruit vinegar solid-state brewing technology, can solve the problems of the all-solid-state fermentation method vinegar brewing process, which has been reported, the vinegar flavor is weak, and the aroma is insufficient, so as to promote appetite, reduce steaming links, and promote effects of metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 A solid-state brewing process of peach fruit vinegar includes the following steps:

[0024] (1) Raw material processing: Take the sterilized peach thick pulp and peach residue for later use (it can be taken directly from the peach pulp processing production line, the peach concentrated pulp and peach residue can be used directly without further sterilization and reduce the steaming process), take The bran and rice husk are autoclaved (121°C, 20 minutes) and cooled for later use;

[0025] (2) The bran prepared by bran koji is autoclaved and cooled and then connected to the AS3.324 strain. After about 72 hours of cultivation at 30℃, the starch in the bran is decomposed until the saccharification power is ≥800 units. At the time, the bran koji is broken and ready for use;

[0026] (3) Yeast liquid preparation: Prepare 10% yeast liquid with dry yeast for wine, and store it at 20°C for later use;

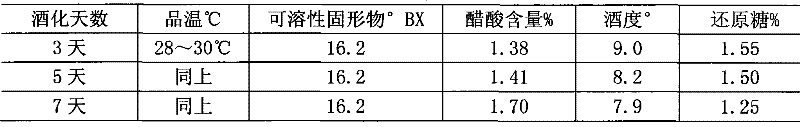

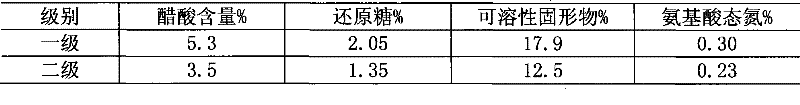

[0027] (4) Solid-state saccharification and alcohol fermentation. Mix 100k...

Embodiment 2

[0038] Example 2 A solid-state brewing process of peach fruit vinegar is as follows:

[0039] (1) Raw material processing: Peach concentrate (30~32°BX) and peach pulp (taken from the peach pulp processing line) produced with Okubo peach as the main raw material, take the bran and bran for autoclaving and cooling Backup

[0040] (2) Preparation of bran koji: After the bran is autoclaved, it is cooled and then connected to Aspergillus niger, and cultivated at 32°C until the saccharification power is ≥800 units, and it is ready for use after being broken;

[0041] (3) Yeast liquid preparation Same as above;

[0042] (4) Solid-state saccharification and alcohol fermentation. Mix 100kg of peach pulp, 220kg of pomace, 15kg of bran, 55kg of bran, 10kg of barley koji, 15kg of bran koji, and 15kg of 10wt% yeast solution, and then ferment for 9 days. The suitable fermentation temperature is about 30℃.

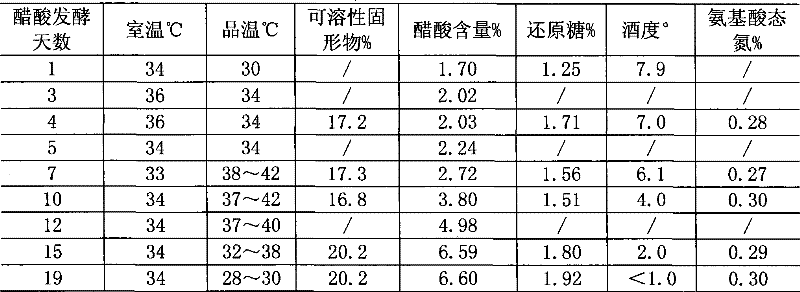

[0043] (5) Preparation of Acetic Acid Bacteria Liquid Inoculate the rejuvenated acetic acid ...

Embodiment 3

[0048] Example 3 A solid-state brewing process of peach fruit vinegar, which is basically the same as Example 1, except that: in step (4), 100 kg of Okubo peach pulp, 180 kg of peach residue, 20 kg of bran, 50 kg of bran, and barley wine 15 kg of koji, 15 kg of bran koji, and 8 kg of 10wt% yeast solution are mixed uniformly and then fermented for 10 days in a closed fermentation, the fermentation temperature is controlled at 30±1°C; no aging step is included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com