Method for comprehensively recovering excrement in agricultural areas and toilet

A technology for recycling and treating feces, which is applied in toilet black water treatment, dehydration/drying/concentrated sludge treatment, household appliances, etc. It can solve the problems of feces being washed away, increase the surface area, reduce the amount of emission, and the process is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

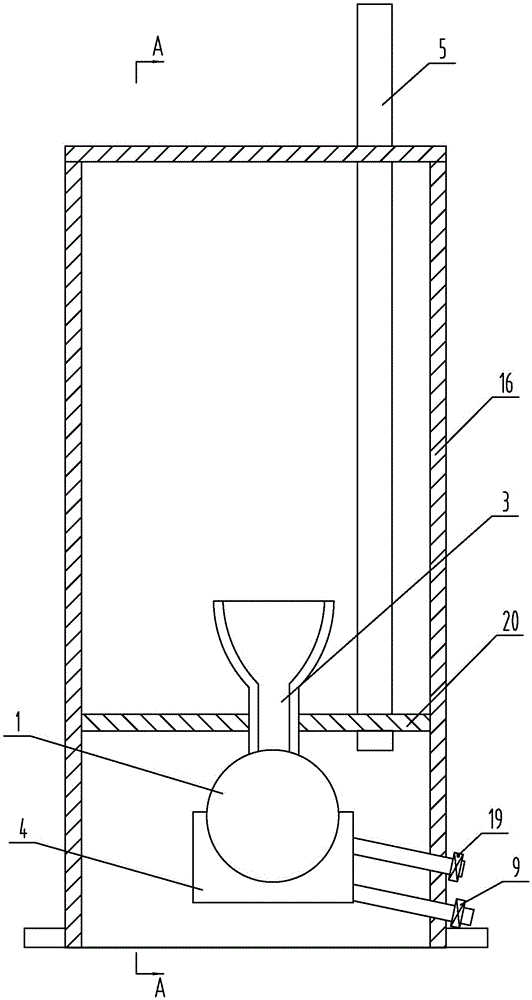

[0046] Such as Figure 4 As shown, in the present embodiment, a floor 20 is set in the space enclosed by the outer cover, and the floor 20 divides the space into upper and lower parts; The lower part of the bottom passes through the floor 20 and communicates with the front end of the septic tank 1; on the bottom wall of the septic tank 1, a urine leakage hole 21 is opened, and the urine leakage hole 21 is connected to the urine collection tank 4, and the urine collection tank 4 is connected to the urine collection pipe. A second switch 19 is arranged on the urine pipe; an extrusion hole 7 is provided on the rear end wall of the septic tank 1, and the extrusion hole 7 is connected to the dry septic tank 8, and the dry septic tank 8 is connected to the defecation pipe, and the defecation pipe is provided with the first The switch 9, the first switch 9 and the second switch 19 are all located outside the housing.

[0047] An auger 2 is installed in the cesspool 1, and the auger ...

Embodiment 2

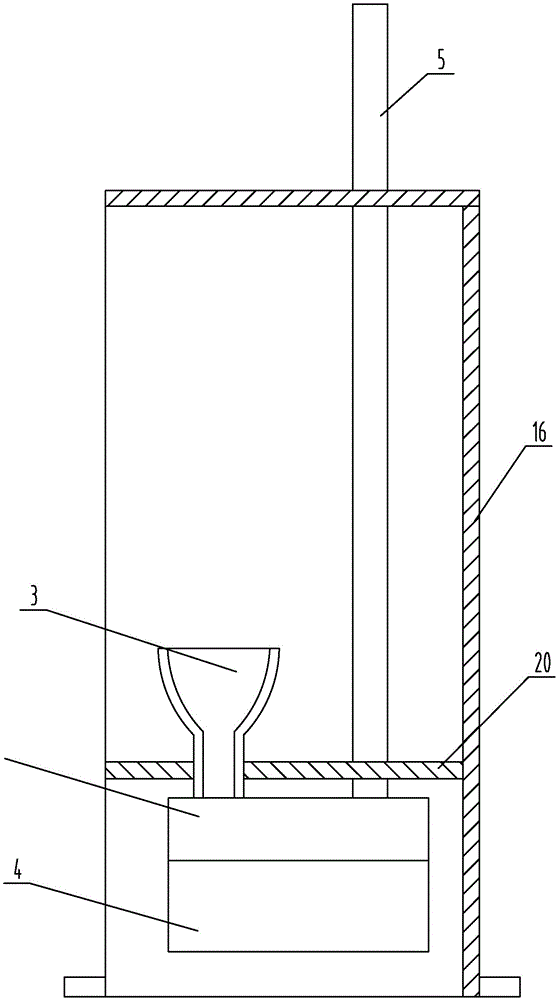

[0054] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, in this embodiment, the one-way gear 12 in the first embodiment is installed on the septic tank 1, and a bearing is installed at the connection between the septic tank 1 and the urine collection tank 4, and the bearing is installed on the front end wall of the septic tank 1, The shaft center of the bearing is arranged near the center of the septic tank 1 rotating shaft, and the bottom of the closet 3 communicates with the septic tank 1 through the inner hole of the bearing. The manpower drive device drives the cesspool 1 to rotate. This way, under the action of the centrifugal force generated by the rotation of the cesspool 1, the urine is thrown to the side wall of the cesspool 1 and discharged from the urine leakage hole 21, which can accelerate Separation of urine, enhancing the drying effect of feces. At the same time, rely on the relative movement between the auger 2 and the cessp...

Embodiment 3

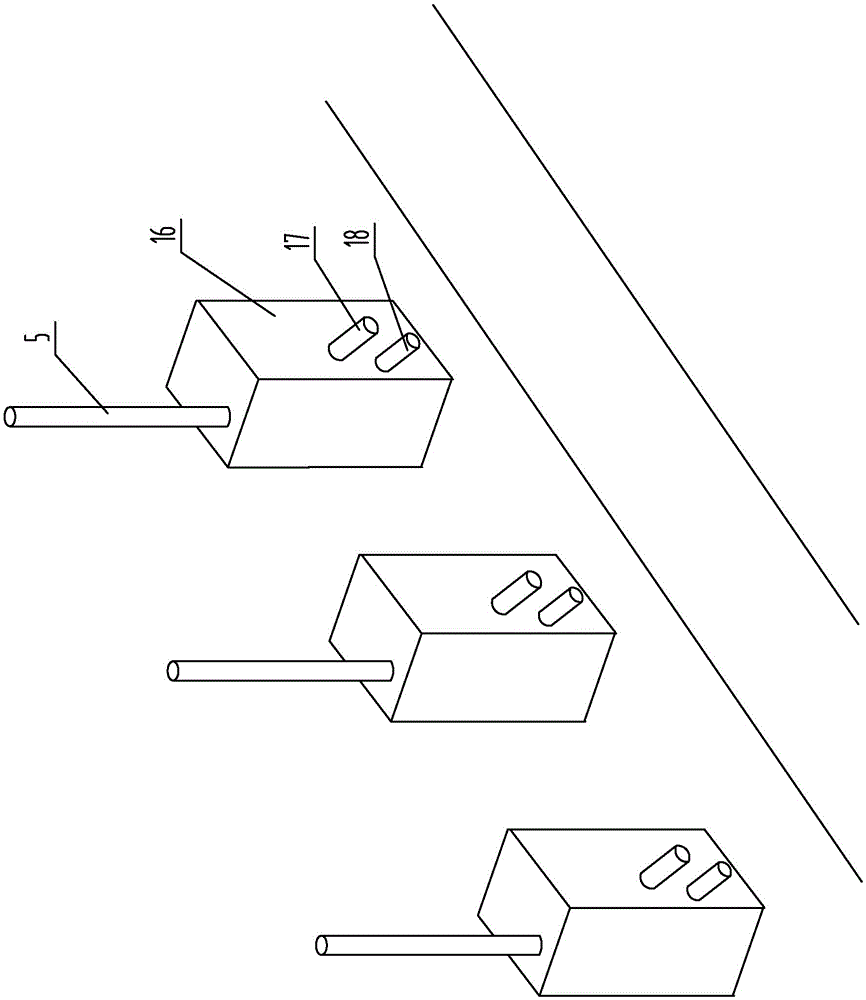

[0056] The difference between this embodiment and Embodiment 2 is that: Image 6 with Figure 7 As shown, the septic tank 1 and the auger 2 can rotate and they do not rotate at the same time, that is, when the septic tank 1 rotates, the auger 2 does not rotate; when the auger 2 rotates, the septic tank 1 does not rotate. In this way, the rotation of the cesspool 1 can be used to centrifugally throw out the urine, so as to speed up the drying speed of the ight soil. The specific measures are as follows:

[0057] The first gear 27 is installed on the cesspool 1, and the second gear 26 is installed on the rotating shaft of the auger 2. The first gear 27 and the second gear 26 are equal in diameter and coaxially arranged. On the first gear 27 and the second gear 26 The inner ring gear 25 is set on the outside of the inner ring gear, and the inner ring gear 25 is only meshed with the first gear 27 or the second gear 26 at the same time. The inner ring gear 25 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com