A reinforcement and repair method for beam-column mortise and tenon joints of wooden structures

A repair method and technology for wood structures, which are applied in the field of reinforcement and repair of beam-column-mortise joints of wood structures, can solve the problems of insignificant improvement of joint shear bearing capacity, reduction of joint seismic performance, and reduction of structural ductility coefficient, etc., so as to overcome the stiffness of tenon-mortise joints. The effect of lowering, improving node ductility, and improving energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

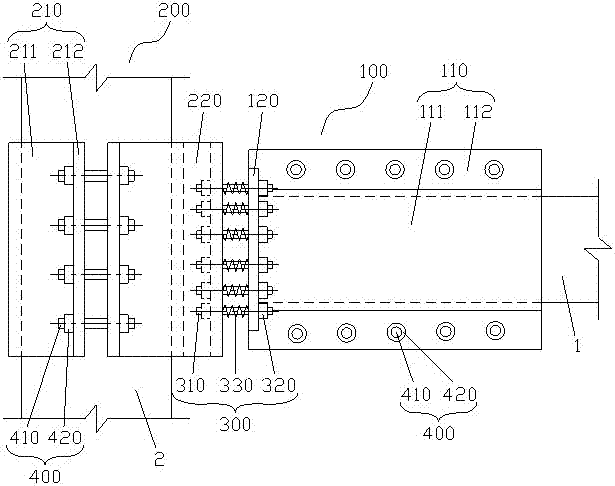

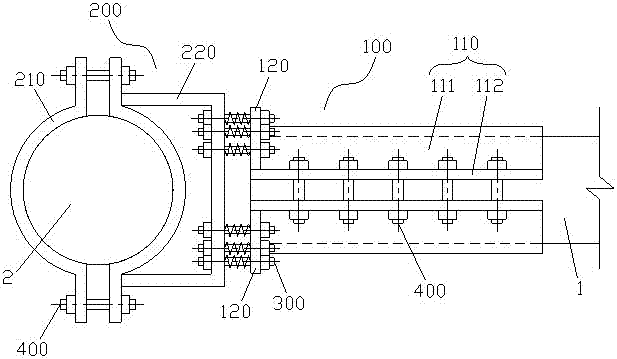

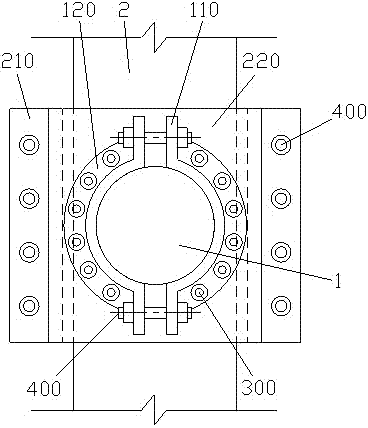

[0028] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

[0029] like Figures 1~5 As shown in the figure, a method for reinforcing and repairing a beam-column tenon-mortise joint of a wood structure includes the following steps:

[0030] (1) Determine the area to be reinforced according to the size and stress of the beam-column mortise-and-mortise joint of the wood structure. Specifically, the area to be reinforced is determined according to the actual beam-column size and external load distribution. For example, the length of the beam-column to be reinforced is the beam-column diameter. (circle) or 1~3 times the side length (square).

[0031] (2) Design a horizontal hoop 100 adapted to the tenon end of the wooden beam 1 and a vertical hoop 200 adapted to the mortise section of the wooden colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com