Zero clearance oil seal assembly

An oil seal and sealing part technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of reduced turbine efficiency, frictional heat, long contact time, etc., to improve turbine efficiency and prevent static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

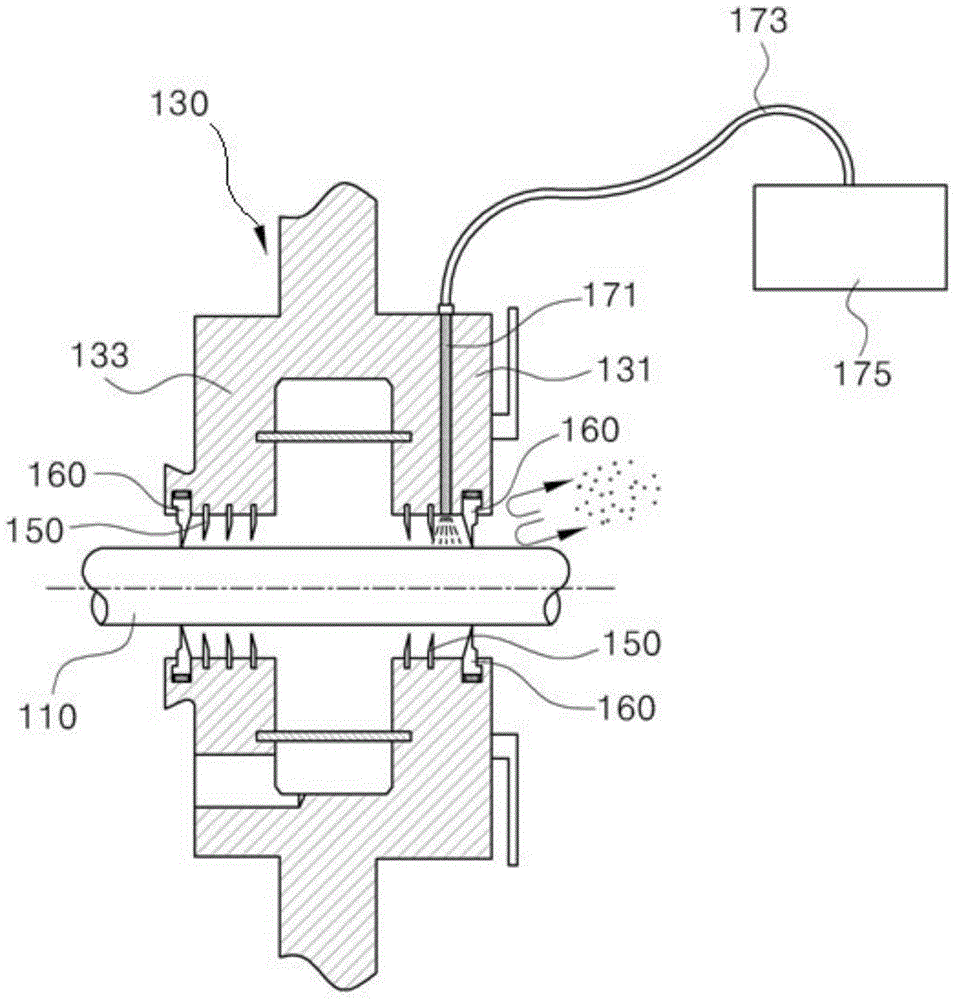

[0034] image 3 is a schematic diagram showing the structure of the oil seal device according to the present invention, Figure 4 It is an enlarged view of important parts illustrating the installation structure of the movable type seal part according to the present invention, Figure 5 It is a sectional view of important parts illustrating the installation structure of the elastic member according to the present invention.

[0035] As shown in the drawings, the present invention relates to an oil seal device that generally includes a ring support 130 , a plurality of seal portions 150 , and a movable seal portion 160 .

[0036] At this time, the ring support body 130 is set to wrap the outer diameter of the rotating shaft 110 . refer to image 3 , the ring support body 130 is formed with a front support part 131 and a rear...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap