Cable connector moisture-roof cover

A technology of cable joints and moisture-proof covers, applied in the direction of cable joints, etc., can solve the problems of inconvenient use of cables, breakdown of cable insulation, and easy occurrence of water branches, etc., and achieve the effects of compact structure, extended service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

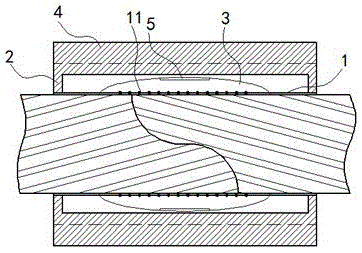

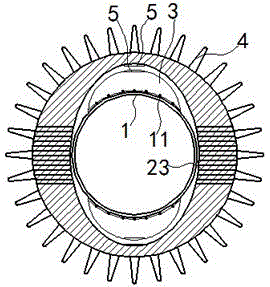

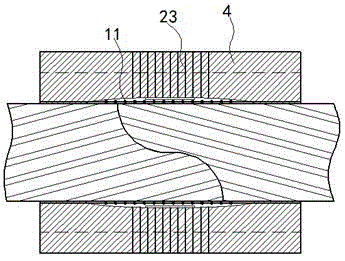

[0015] exist Figure 1 to Figure 4 In the shown embodiment, the moisture-proof cover for the cable joint includes a cable pipe 1 and a drive pipe 2; The air hole 11 is covered with an arc-shaped air chamber 3 made of elastic material on the outside of each of the one-way air suction holes 11, and is filled with a small amount of solid desiccant in the arc-shaped air chamber 3; The arc surface of the arc-shaped air chamber 3 is also provided with a one-way exhaust hole, which is not shown in the figure because the size of the one-way exhaust hole is small; the drive tube 2 is coaxially sleeved on the line Outside the tube 1, the driving tube 2 can rotate freely relative to the wire tube 1; the inner peripheral wall 21 of the driving tube 2 is in the shape of an oval cylinder, and the outer peripheral wall 22 of the driving tube 2 is in the shape of a cylinder; Guide vanes 4 are equidistantly distributed on the peripheral wall 22 of the drive tube 2; an air guide hole 23 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com