PCB manufacturing method

A manufacturing method and technology of inner layer core board, applied in the direction of printed circuit manufacturing, printed circuit connected with non-printed electrical components, electrical components, etc. Problems such as signal loss, to improve the quality and speed of signal transmission, and to expand the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

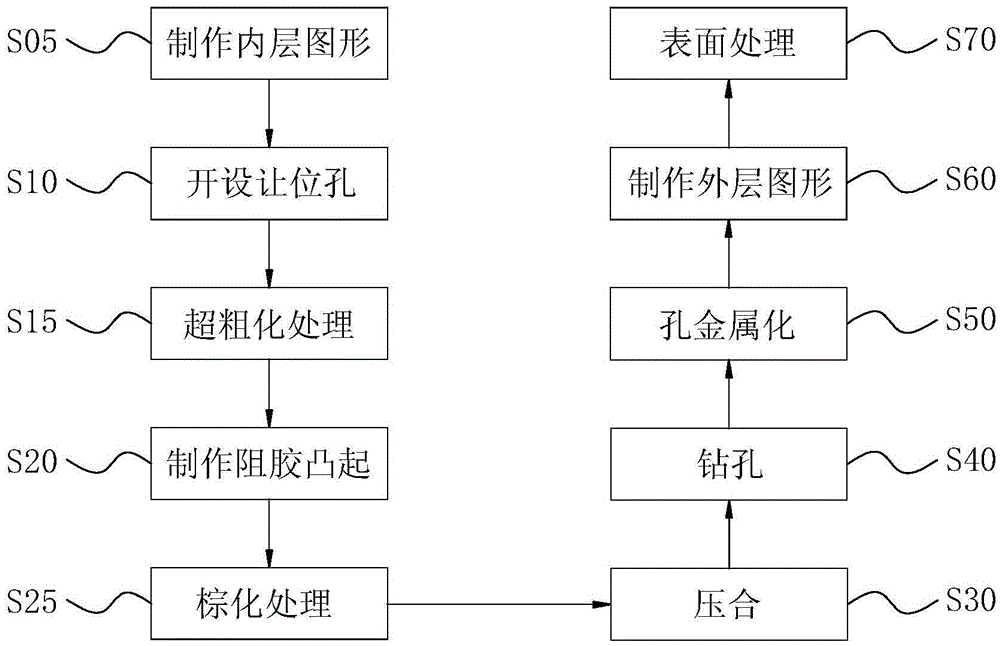

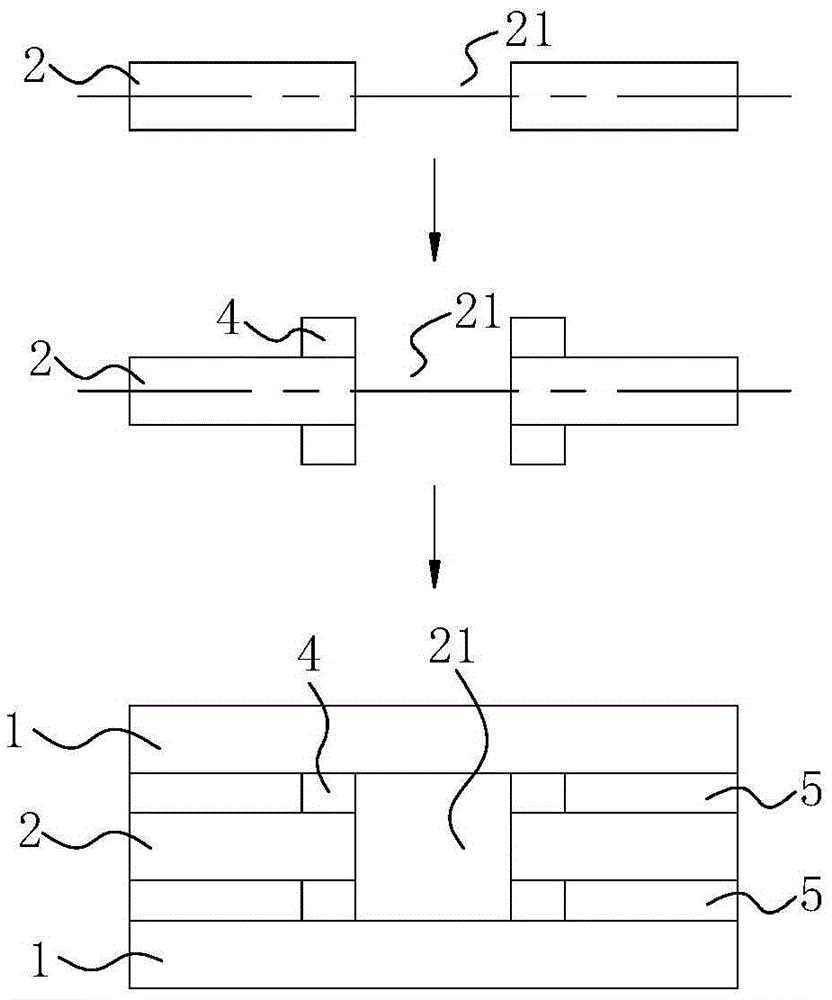

[0068] Such as figure 1 and figure 2 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0069] S05, making the inner layer graphics on the inner layer core board;

[0070] S10. Provide the inner core board 2 that needs to be drilled, and set up a relief hole 21 on the inner core board 2 that needs to be drilled;

[0071] S15, performing super-roughening treatment on the inner core board;

[0072] S20, on the end surface of the inner layer core board 2 to be opened and on the edge of the relief hole 21, make a glue-resisting protrusion 4;

[0073] S25, browning the inner core board;

[0074] S30, providing a non-perforated core board and a prepreg 5, and pressing the non-perforated core board, the prepreg 5 and the inner core board 2 to be perforated to form a laminated board with a closed cavity;

[0075] S40, drilling the plywood, and performing post-drilling treatment;

[0076] S50, performing electroless copper deposition and electroplating...

Embodiment 2

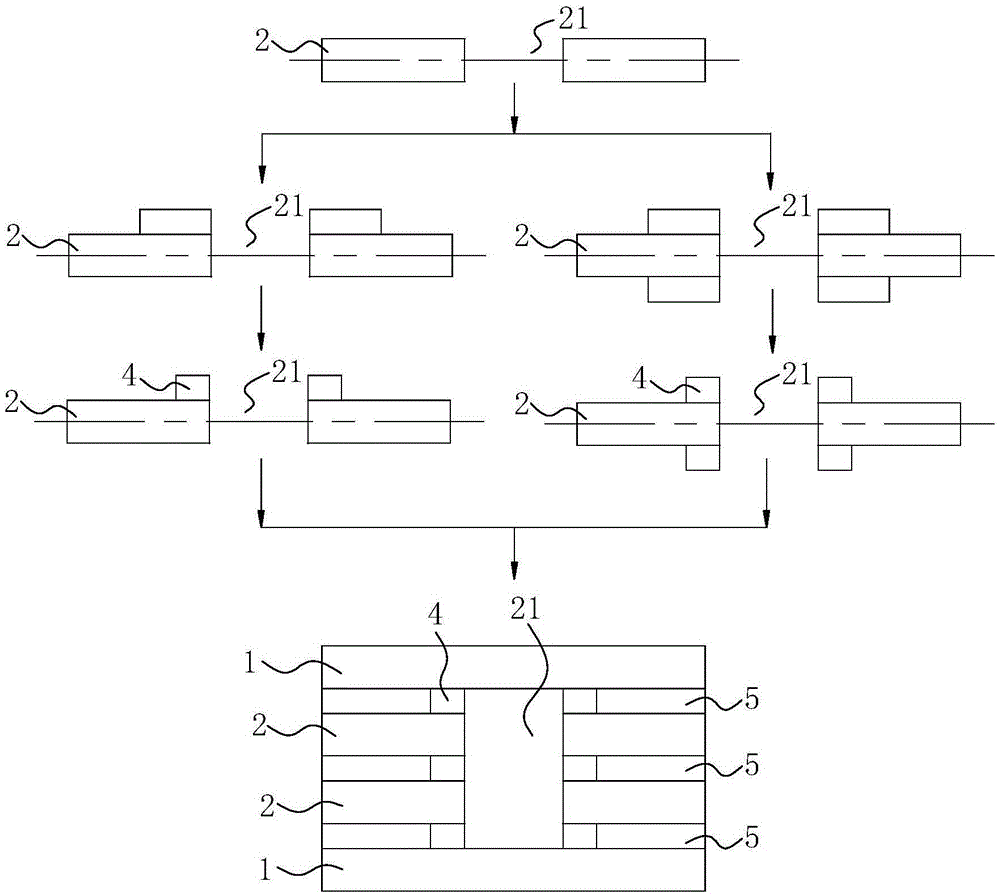

[0093] Such as figure 1 and image 3 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0094] S05, making the inner layer graphics on the inner layer core board;

[0095] S10. Provide the inner core board 2 that needs to be drilled, and set up a relief hole 21 on the inner core board 2 that needs to be drilled;

[0096] S15, performing super-roughening treatment on the inner core board;

[0097] S20, on the end surface of the inner layer core board 2 to be opened and on the edge of the relief hole 21, make a glue-resisting protrusion 4;

[0098] S25, browning the inner core board;

[0099] S30, providing a non-perforated core board and a prepreg 5, and pressing the non-perforated core board, the prepreg 5 and the inner core board 2 to be perforated to form a laminated board with a closed cavity;

[0100] S40, drilling the plywood, and performing post-drilling treatment;

[0101] S50, performing electroless copper deposition and electroplating ...

Embodiment 3

[0120] Such as figure 1 and Figure 4 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0121] S05, making the inner layer graphics on the inner layer core board;

[0122] S10. Provide the inner core board 2 that needs to be drilled, and set up a relief hole 21 on the inner core board 2 that needs to be drilled;

[0123] S15, performing super-roughening treatment on the inner core board;

[0124] S20, on the end surface of the inner layer core board 2 to be opened and on the edge of the relief hole 21, make a glue-resisting protrusion 4;

[0125] S25, browning the inner core board;

[0126] S30, providing a non-perforated core board and a prepreg 5, and pressing the non-perforated core board, the prepreg 5 and the inner core board 2 to be perforated to form a laminated board with a closed cavity;

[0127] S40, drilling the plywood, and performing post-drilling treatment;

[0128] S50, performing electroless copper deposition and electroplating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com